Abstract

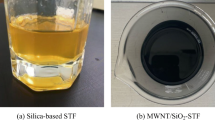

In this work, the influence of cellulose nanofibers (CNFs) on the rheological behavior of silica-based shear-thickening fluid (STF) is investigated. CNFs of 150–200 nm in diameter were extracted from cotton fibers using a supermasscolloider. CNF-reinforced STF of different concentrations (0.1–0.3 wt.%) was prepared via an ultrasonication technique. The presence of CNFs and their interaction with the silica nanoparticles in the STF were analyzed using SEM and FTIR. The addition of a minute quantity of CNF to the STF (0.3% CNF-reinforced STF) caused a marked increase in the peak viscosity, from 36.8 (unmodified STF) to 139.0 Pa s (0.2% CNF-reinforced STF), and a concomitant decrease in the critical shear rate from 33.45 to 14.8 s−1 . The presence of a large number of hydroxyl groups on the CNFs enhanced their interaction with the nanoparticles via hydrogen bonding, which induced shear thickening. The mechanism of the interaction between silica nanoparticles and CNF was also demonstrated. Oscillatory dynamic rheological analysis showed that the addition of even a small amount of CNF led to higher elastic behavior in the system at lower shear rates. In contrast, a more viscous nature was demonstrated at higher angular frequencies. As the concentration of nanofibers in the STFs increased, the crossover point between storage and loss modulus shifted to higher angular frequencies, implying stronger interaction between the constituents of the STF. The dynamic viscosity profile of all samples also exhibited shear-thickening behavior.

Similar content being viewed by others

References

Barnes HA (1999) Shear-thickening (“Dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J Rheol 33:329

Bender JW, Wagner NJ (1995) Optical measurement of the contributions of colloidal forces to the rheology of concentrated suspensions. J Colloid Interface Sci 172:171–184

Brown E, Jaeger HM (2012) The role of dilation and confining stresses in shear thickening of dense suspensions. J Rheol 56:875

Chakraborty S, Biswas S, Sa B et al (2014) In vitro and in vivo correlation of release behavior of andrographolide from silica and PEG assisted silica gel matrix. Colloids Surf A Physicochem Eng Asp 455:111–121

Dimic-Misic K, Gane PAC, Paltakari J (2013) Micro- and nanofibrillated cellulose as a rheology modifier additive in CMC-containing pigment-coating formulations. Ind Eng Chem Res 52:16066–16083

Franks GV, Zhou Z, Duin NJ, Boger DV (2000) Effect of interparticle forces on shear thickening of oxide suspensions. J Rheol 44:759

Gürgen S, Li W, Kuşhan MC (2016) The rheology of shear thickening fluids with various ceramic particle additives. Mater Des 104:312–319

Hasanzadeh M, Mottaghitalab V (2014) The role of shear-thickening fluids (STFs) in ballistic and stab-resistance improvement of flexible armor. J Mater Eng Perform 23:1182–1196

Hasanzadeh M, Mottaghitalab V (2016) Tuning of the rheological properties of concentrated silica suspensions using carbon nanotubes. Rheol Acta 55:759–766

Hasanzadeh M, Mottaghitalab V, Rezaei M (2015) Rheological and viscoelastic behavior of concentrated colloidal suspensions of silica nanoparticles: a response surface methodology approach. Adv Powder Technol 26:1570–1577

Hasanzadeh M, Mottaghitalab V, Babaei H, Rezaei M (2016) The influence of carbon nanotubes on quasi-static puncture resistance and yarn pull-out behavior of shear-thickening fluids (STFs) impregnated woven fabrics. Compos Part A Appl Sci Manuf 88:263–271

Hoffman RL (1972) Discontinuous and dilatant viscosity behavior in concentrated suspensions. I. Observation of a flow instability. J Rheol 16:155

Huang W, Wu Y, Qiu L et al (2015) Tuning rheological performance of silica concentrated shear thickening fluid by using graphene oxide. Adv Condens Matter Phys 2015:1–5

Kalman DP, Merrill RL, Wagner NJ, Wetzel ED (2009) Effect of particle hardness on the penetration behavior of fabrics intercalated with dry particles and concentrated particle—fluid suspensions. ACS Appl Mater Interfaces 1:2602–2612

Kang TJ, Kim CY, Hong KH (2012) Rheological behavior of concentrated silica suspension and its application to soft armor. J Appl Polym Sci 124:1534–1541

Laha A, Majumdar A (2016) Shear thickening fluids using silica-halloysite nanotubes to improve the impact resistance of p-aramid fabrics. Appl Clay Sci 132–133:468–474

Lee YS, Wetzel ED, Wagner NJ (2003) The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J Mater Sci 38:2825

Maranzano BJ, Wagner NJ (2001a) The effects of interparticle interactions and particle size on reversible shear thickening: hard-sphere colloidal dispersions. J Rheol 45:1205

Maranzano BJ, Wagner NJ (2001b) The effects of particle size on reversible shear thickening of concentrated colloidal dispersions. J Chem Phys 114:10514

Martoïa F, Perge C, Dumont PJJ et al (2015) Heterogeneous flow kinematics of cellulose nanofibril suspensions under shear. Soft Matter 11:4742–4755

Metzner AB (1958) Flow behavior of concentrated (Dilatant) suspensions. J Rheol 2:239

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr Polym 112:432–439

Saini S, Yücel Falco Ç, Belgacem MN, Bras J (2016) Surface cationized cellulose nanofibrils for the production of contact active antimicrobial surfaces. Carbohydr Polym 135:239–247

Salas C, Nypelö T, Rodriguez-Abreu C et al (2014) Nanocellulose properties and applications in colloids and interfaces. Curr Opin Colloid Interface Sci 19:383–396

Sha X, Yu K, Cao H, Qian K (2013) Shear thickening behavior of nanoparticle suspensions with carbon nanofillers. J Nanopart Res 15:1816-1827

Sofla MRK, Brown RJ, Tsuzuki T, Rainey TJ (2016) A comparison of cellulose nanocrystals and cellulose nanofibers extracted from bagasse using acid and ball milling methods. Adv Nat Sci Nanosci Nanotechnol 7:035004

Srivastava A, Majumdar A, Butola BS (2012) Improving the impact resistance of textile structures by using shear thickening fluids: a review. Crit Rev Solid State Mater Sci 37:115–129

Wagner NJ, Brady JF (2009) Shear thickening in colloidal dispersions. Phys Today 62:27–32

Wagner N, Wetzel ED (2009) Conformable ballistic resistant and protective composite material composed of shear thickening fluids reinforced by short fibres, US Patent US20090004413 A1

Wetzel ED (2004) The effect of rheological parameters on the ballistic properties of shear thickening fluid (STF)-Kevlar composites. In: AIP, pp 288–293

Zhang XZ, Li WH, Gong XL (2008) The rheology of shear thickening fluid (STF) and the dynamic performance of an STF-filled damper. Smart Mater Struct 17:035027

Acknowledgments

The research was financially supported by CSIR (Project No. 22/664/14/EMR-II) and DRDO (Project No. ST-13/TBR-1298).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghosh, A., Chauhan, I., Majumdar, A. et al. Influence of cellulose nanofibers on the rheological behavior of silica-based shear-thickening fluid. Cellulose 24, 4163–4171 (2017). https://doi.org/10.1007/s10570-017-1440-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1440-5