Abstract

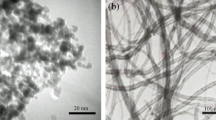

Suspensions comprised of silica nanoparticle (average diameter: 650 nm) and carbon nanofillers dispersed in polyethylene glycol were prepared and investigated. Rheological measurement demonstrated that the mixed suspensions showed a non-Newtonian flow profile, and the shear thickening effect was enhanced by the addition of carbon nanotubes (CNTs) (main range of diameter: 10–20 nm; length: 5–15 μm; purity: >97 wt%) and graphene nanoplatelets (GNs) (average diameter: >50 nm; average length: 20 μm; purity: >92 wt%). It suggested that better the aggregation effect of dispersed particles was, the more significant the shear thickening effect achieved. The results also revealed that the formation of large nanomaterials clusters could be suitable to explain the phenomena. Furthermore, the trend of shear thickening behavior of the silica suspension with CNTs was more striking than that of GNs. The physical reactions between those multi-dispersed phases had been described by the schematic illustrations in papers. Otherwise, a model was built to explain these behaviors, which could be attributed to the unique structures and inherent properties of these two different nanofillers. And the morphologies of the shear thickening fluid which were examined by transmission electron microscopy confirmed this mechanism.

Similar content being viewed by others

References

Ajayan PM, Schadler LS, Giannaris C, Rubio A (2000) Single-walled carbon nanotube-polymer composites: strength and weakness. Adv Mater 10:750–753

Barnes HA (1989) Shear-thickening (“dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J Rheol 33:329–366

Bender JW, Wanger NJ (1996) Reversible shear thickening in monodisperse and bidisperse colloidal dispersion. J Rheol 40:899–916

Boersma WH, Laven J, Stein HN (1992) Viscoelastic properties of concentrated shear-thickening dispersion. J Colloid Interface Sci 149:10–22

Bossis G, Brady JF (1989) The rheology of Brownian suspensions. J Chem Phys 91:1866–1874

Brown E, Jaeger HM (2009) Dynamic jamming point for shear thickening suspensions. Phys Rev Lett 103:086001

Chen WF, Yan LF (2010) Preparation of graphene by a low-temperature thermal reduction at atmosphere pressure. Nanoscale 2:559–563

Dong ZX, Li YH, Lin MQ, Li MY (2009) Rheological properties of polymer micro-gel dispersions. Pet Sci 6:294–298

Egres RG, Wagner NJ (2005) The rheology and microstructure of acicular precipitated calcium carbonate colloidal suspensions through the shear thickening transition. J Rheol 49:719–746

Fall A, Huang N, Bertrand F, Ovarlez G, Bonn D (2008) Shear thickening of cornstarch suspensions as a re-entrant jamming transition. Phys Rev Lett 100:018301

Fleer GJ, Lyklema J (1974) Polymer adsorption and its effect on the stability of hydrophobic colloids. II. The flocculation process as studied with the silver iodidepolyvinyl alcohol system. J Colloid Interface Sci 46:1–12

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191

Hoffman RL (1972) Discontinuous and dilatant viscosity behavior in concentrated suspensions. I. Observation of a flow instability. Trans Soc Rheol 16:155–173

Hoffman RL (1974) Discontinuous and dilatant viscosity behavior in concentrated suspensions. II. Theory and experimental tests. J Colloid Interface Sci 46:491–506

Holmes CB, Fuchs M, Cates ME (2003) Jamming transitions in a schematic model of suspension rheology. Europhys Lett 63:240–246

Hu H, Liu Y, Wang Q, Zhao J, Liang Y (2011) A study on the preparation of highly conductive graphene. Mater Lett 65:2582–2584

Hu HQ et al (2012) Enhanced dispersion of carbon nanotube in silicone rubber assisted by graphene. Polymer 53:3378–3385

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Iler RK (1971) Relation of particle size of colloidal silica to the amount of a cationic polymer required for flocculation and surface coverage. J Colloid Interface Sci 37:364–373

Jiang WQ, Sun YQ, Xu YL, Peng C, Gong XL, Zhang Z (2010) Shear-thickening behavior of polymethylmethacrylate particles suspensions in glycerine-water mixtures. Rheol Acta 49:1157–1163

Kamibayashi M, Ogura H, Otsubo Y (2008) Shear-thickening flow of nanoparticle suspensions flocculated by polymer bridging. J Colloid Interface Sci 321:294–301

Lei GL, Liu YN, Xu CF (1994) A new calculation method for relative permeability from polymer displacement experiment. J Univ Petroleum (China) 18:100–103

Li CL, Jiang H, Wang Y, Wang YC (2011) Hyperbranched poly (methyl methacrylate)s prepared by miniemulsion polymerization and their (non)-Newtonian flow behaviors. Polymer 52:376–382

Luong ND et al (2011) Enhanced mechanical and electrical properties of polyimide film by graphene sheets via in situ polymerization. Polymer 52:5237–5242

Maranzano BJ, Wagner NJ (2001) The effects of interparticle interactions and particle size on reversible shear thickening: Hard-sphere colloidal dispersions. J Rheol 45:1205–1222

Maranzano BJ, Wanger NJ (2001) The effect of particle size on reverse shear thickening of concentrated colloidal dispersion. J Chem Phys 114:10514–10527

Novoselov KS et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Park S, Ruoff RS (2009) Chemical methods for the production of graphene. Nat Nanotechnol 4:217–227

Rafiee MA, Rafiee J, Wang Z, Song HH, Yu ZZ, Koratkar N (2009) Enhanced mechanical. Properties of nanocomposites at low graphene content. ACS Nano 3:3884–3889

Sarvestani AS, Picu CR (2004) Network model for the viscoelastic behavior of polymer nanocomposites. Polymer 45:7779–7790

Sheng K, Bai H, Sun Y, Li C, Shi G (2011) Layer-by-layer assembly of graphene/polyaniline multilayer films and their application. Polymer 52:5567–5572

Singh A, Nott PR (2003) Experimental measurements of the normal stresses in sheared Stokesian suspensions. J Fluid Mech 490:293–320

Soldano C, Mahmood A, Dujardin E (2010) Production, properties and potential of graphene. Carbon 48:2127–2150

Song P, Cao Z, Cai Y, Zhao L, Fang Z, Fu S (2011) Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polymer 52:4001–4010

Sun Y, Bao HD, Guo ZX, Yu J (2009) Modeling of the electrical percolation of mixed carbon fillers in polymer-based composites. Macromolecules 42:459–463

Tarig AH, Vijay RK, Shaik J (2010) Synthesis, processing and characterization of shear thickening fluid (STF) impregnated fabric composites. Mater Sci Eng A 527:2892–2899

Wang Fang, Li Junjun, Wang Changhcun (2012) Hydrophilic and fluorescent colloidal nanorods of MWNTs as effective targeted drug carrier. J Colloid Sci Biotechnol 1:192–200

Xu YL, Gong XL, Peng C, Sun YQ, Jiang WQ, Zhang Z (2010) Shear thickening fluids based on additives with different concentrations and molecular chain lengths. Chin J Chem Phys 23:342–346

Yang HL, Ruan JM, Zou JP, Wu QM, Zhou ZC, Zhou ZH (2009) Rheological responses of fumed silica suspensions under steady and oscillatory shear. Sci China Ser E 52:910–915

Yu KJ, Cao HJ, Qian K, Sha XF, Chen YP (2012) Shear-thickening behavior of modified silica nanoparticles in polyethylene glycol. J Nanopart Res 14:747

Zakaria S, Candy V, Samia M-C, Benjamin C, Mária O, Mohamed MC (2013) Multiwalled carbon nanotube-clicked poly(4-vinyl pyridine) as a hairy platform for the immobilization of gold nanoparticles. J Colloid Sci Biotechnol 2:53–61

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51203062), Cooperative Innovation Fund-Prospective Project of Jiangsu Province (No. BY2012064), and Science and Technology support Project of Jiangsu Province (No. BE2011014). K.J. Yu thanks the Postdoctoral Fund Project of China (No. 2012M520995).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sha, X., Yu, K., Cao, H. et al. Shear thickening behavior of nanoparticle suspensions with carbon nanofillers. J Nanopart Res 15, 1816 (2013). https://doi.org/10.1007/s11051-013-1816-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-1816-x