Abstract

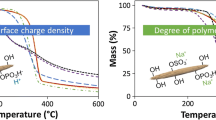

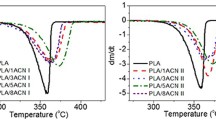

Geared towards reinforcing thermoplastics of high melting points with nanocellulose, this study evaluated the factors affecting the thermal properties of and the thermal stabilizing effect of acetylation on nanocellulose with different average degree of polymerization (DPv) from bacterial cellulose (BC). Cellulose nanocrystals with DPv values of 300 and 500 were prepared by hydrolyzing BC nanofibers with a DPv of 1100 using hydrochloric acid. The thermal stability decreased after acid hydrolysis and showed a decreasing trend with decreasing DPv. The decrease in thermal stability is attributed to the increase in the number of reducing ends (REs) with decreasing DPv. Heterogeneous acetylation to an average degree of substitution of 0.38 improved the thermal stability, and the degree of improvement increased with decreasing DPv. The dependence of the degree of improvement on the DPv is attributed to possible protection of the REs by more stable acetyl groups. The influence of protecting the REs on the degree of improvement in thermal stability was further confirmed by sodium borohydride (NaBH4) reduction. The findings suggest that the thermal stabilization caused by acetylation to nanocellulose with small DPv is a combined effect of protecting both the surface OH and the REs; while for nanocellulose with high DPv, the thermal stabilization caused by acetylation is mainly due to protection of the surface OH.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87:963–979

Agarwal UP, Reiner RS, Ralph SA (2010) Cellulose I crystallinity determination using FT–Raman spectroscopy: univariate and multivariate methods. Cellulose 17:721–733

Ashori A, Babaee M, Jonoobi M, Hamzeh Y (2014) Solvent-free acetylation of cellulose nanofibers for improving compatibility and dispersion. Carbohydr Polym 102:369–375

Ávila Ramírez JA, Suriano CJ, Cerrutti P, Foresti ML (2014) Surface esterification of cellulose nanofibers by a simple organocatalytic methodology. Carbohydr Polym 114:416–423

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Božič M, Vivod V, Kavčič S et al (2015) New findings about the lipase acetylation of nanofibrillated cellulose using acetic anhydride as acyl donor. Carbohydr Polym 125:340–351

Bradbury AGW, Sakai Y, Shafizadeh F (1979) A kinetic model for pyrolysis of cellulose. J Appl Polym Sci 23:3271–3280

Brinchi L, Cotana F, Fortunati E, Kenny JM (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr Polym 94:154–169

Calahorra ME, Cortazar M, Eguiazabal JI (1989) Thermogravimetric analysis of cellulose: effect of the molecular weight on thermal decomposition. J Appl Polym Sci 37:3305–3314

Camarero Espinosa S, Kuhnt T, Foster EJ, Weder C (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromolecules 14:1223–1230

Çetin NS, Tingaut P, Özmen N et al (2009) Acetylation of cellulose nanowhiskers with vinyl acetate under moderate conditions. Macromol Biosci 9:997–1003

Cunha AG, Zhou Q, Larsson PT, Berglund LA (2014) Topochemical acetylation of cellulose nanopaper structures for biocomposites: mechanisms for reduced water vapour sorption. Cellulose 21:2773–2787

Daruwalla EH, Nabar GM (1956) Acid hydrolysis of cellulose. J Polym Sci XX:205–208

Eichhorn SJ, Dufresne A, Aranguren M et al (2009) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Fahma F, Takemura A, Saito Y (2014) Acetylation and stepwise solvent-exchange to modify hydrophilic cellulose whiskers to polychloroprene-compatible nanofiller. Cellulose 21:2519–2527

Favier V, Canova GR, Cavaille JY et al (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351–355

Garcia E, Johnston D, Whitaker JR, Shoemaker SP (1993) Assessment of endo- 1,4-beta-d-glucanase activity by a rapid colorimetric assay using disodium 2,2′-bicinchoninate. J Food Biochem 17:135–145

Gurgel LVA, Marabezi K, Ramos LA, Curvelo AADS (2012) Characterization of depolymerized residues from extremely low acid hydrolysis (ELA) of sugarcane bagasse cellulose: effects of degree of polymerization, crystallinity and crystallite size on thermal decomposition. Ind Crops Prod 36:560–571

Habibi Y (2014) Key advances in the chemical modification of nanocelluloses. Chem Soc Rev 43:1519–1542

Hu W, Chen S, Xu Q, Wang H (2011) Solvent-free acetylation of bacterial cellulose under moderate conditions. Carbohydr Polym 83:1575–1581

Ifuku S, Nogi M, Abe K et al (2007) Surface modification of bacterial cellulose nanofibers for property enhancement of optically transparent composites: dependence on acetyl-group DS. Biomacromolecules 8:1973–1978

Jacquet N, Quiévy N, Vanderghem C et al (2011) Influence of steam explosion on the thermal stability of cellulose fibres. Polym Degrad Stab 96:1582–1588

Johnston DB, Shoemaker SP, Smith GM, Whitaker JR (1998) Kinetic measurements of cellulase activity on insoluble substrates using disodium 2,2′ bicinchoninate. J Food Biochem 22:301–319

Jonoobi M, Harun J, Shakeri A, Misra M (2009) Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 4:626–639

Kabir MM, Wang H, Lau KT, Cardona F (2013) Effects of chemical treatments on hemp fibre structure. Appl Surf Sci 276:13–23

Klemm D, Kramer F, Moritz S et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed Engl 50:5438–5466

Lee K-Y, Quero F, Blaker JJ et al (2011) Surface only modification of bacterial cellulose nanofibres with organic acids. Cellulose 18:595–605

Li J, Zhang LP, Peng F et al (2009) Microwave-assisted solvent-free acetylation of cellulose with acetic anhydride in the presence of iodine as a catalyst. Molecules 14:3551–3566

Martínez-Sanz M, Lopez-Rubio A, Lagaron JM (2011) Optimization of the nanofabrication by acid hydrolysis of bacterial cellulose nanowhiskers. Carbohydr Polym 85:228–236

Matsuoka S, Kawamoto H, Saka S (2011a) Reducing end-group of cellulose as a reactive site for thermal discoloration. Polym Degrad Stab 96:1242–1247

Matsuoka S, Kawamoto H, Saka S (2011b) Thermal glycosylation and degradation reactions occurring at the reducing ends of cellulose during low-temperature pyrolysis. Carbohydr Res 346:272–279

Matsuoka S, Kawamoto H, Saka S (2014) What is active cellulose in pyrolysis? An approach based on reactivity of cellulose reducing end. J Anal Appl Pyrolysis 106:138–146

Nakatsubo F, Yoshida N, Abe K, Yano H (2010) Chemical surface-modification of cellulose nanofibers in cellulose-compatible solvents. In: 239th ACS national meeting technical program archive

Nishino T, Kotera M, Suetsugu M et al (2011) Acetylation of plant cellulose fiber in supercritical carbon dioxide. Polymer (Guildf) 52:830–836

Nogi M, Abe K, Handa K et al (2006) Property enhancement of optically transparent bionanofiber composites by acetylation. Appl Phys Lett 89:233123

Okahisa Y, Abe K, Nogi M et al (2011) Effects of delignification in the production of plant-based cellulose nanofibers for optically transparent nanocomposites. Compos Sci Technol 71:1342–1347

Peng Y, Gardner DJ, Han Y et al (2013) Influence of drying method on the material properties of nanocellulose I: thermostability and crystallinity. Cellulose 20:2379–2392

Quiévy N, Jacquet N, Sclavons M et al (2010) Influence of homogenization and drying on the thermal stability of microfibrillated cellulose. Polym Degrad Stab 95:306–314

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers (Basel) 2:728–765

Tomé LC, Freire MG, Rebelo LPN et al (2011) Surface hydrophobization of bacterial and vegetable cellulose fibers using ionic liquids as solvent media and catalysts. Green Chem 13:2464

Uetani K, Watanabe Y, Abe K, Yano H (2014) Influence of drying method and precipitated salts on pyrolysis for nanocelluloses. Cellulose 21:1631–1639

Yano H, Sugiyama J, Nakagaito AN et al (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17:153–155

Yu H, Qin Z, Liang B et al (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93 % through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1:3938

Acknowledgments

The scholarship grant from the Ministry of Education, Culture, Sports, Science and Technology, Japan (Monbukagakusho) to Melissa B. Agustin is gratefully acknowledged. Ms. Yoko Homma is also thanked for her valuable help in the calibration and maintenance of the TG Analyzer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Agustin, M.B., Nakatsubo, F. & Yano, H. The thermal stability of nanocellulose and its acetates with different degree of polymerization. Cellulose 23, 451–464 (2016). https://doi.org/10.1007/s10570-015-0813-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0813-x