Abstract

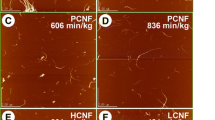

Microfibrillated celluloses (MFCs) with a high elongation potential were fabricated from periodate–chlorite oxidized cellulosic fibers (anionic charge density of 1.75 mmol/g) using high consistency milling conducted at a solids content of 7.5–15 % with a PFI mill. MFC gels were obtained after 5000 milling revolutions and after 30,000 revolutions MFCs with lateral dimension ranging from 10 to 100 nm and length up to micron-scale were obtained from all samples according to scanning electron microscopy imaging. The crystallinity in terms of crystalline indexes of MFCs was similar to untreated pulp (~65 %). Free-standing films produced from the MFC samples (milled for 30,000 revolutions) had the ultimate tensile strength and Young’s modulus of 61–115 MPa and 8–11 GPa, respectively. The films also showed very high stretchability potential in terms of strain at break values of 6.8–15.9 %. Thus, the results suggest that high consistency milling with high production capacity and decreased energy consumption can potentially be used to fabricate MFC with high mechanical performance for bulk applications.

Similar content being viewed by others

References

Ämmälä A, Liimatainen H, Burmeister C, Niinimäki J (2013) Effect of tempo and periodate–chlorite oxidized nanofibrils on ground calcium carbonate flocculation and retention in sheet forming and on the physical properties of sheets. Cellulose 20:2451–2460. doi:10.1007/s10570-013-0012-6

Besbes I, Alila S, Boufi S (2011) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr Polym 84:975–983. doi:10.1016/j.carbpol.2010.12.052

Chakraborty A, Sain M, Kortschot M (2005) Cellulose microfibrils: a novel method of preparation using high shear refining and cryocrushing. Holzforschung. doi:10.1515/HF.2005.016

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441. doi:10.1016/j.eurpolymj.2007.05.038

Henriksson M, Berglund LA, Isaksson P et al (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585. doi:10.1021/bm800038n

Ho TTT, Abe K, Zimmermann T, Yano H (2015) Nanofibrillation of pulp fibers by twin-screw extrusion. Cellulose 22:421–433. doi:10.1007/s10570-014-0518-6

Hsieh Y-C, Yano H, Nogi M, Eichhorn SJ (2008) An estimation of the Young’s modulus of bacterial cellulose filaments. Cellulose 15:507–513. doi:10.1007/s10570-008-9206-8

Janardhnan S, Sain M (2011) Bio-treatment of natural fibers in isolation of cellulose nanofibres: impact of pre-refining of fibers on bio-treatment efficiency and nanofiber yield. J Polym Environ 19:615–621. doi:10.1007/s10924-011-0312-6

Kekäläinen K, Liimatainen H, Niinimäki J (2014) Disintegration of periodate–chlorite oxidized hardwood pulp fibres to cellulose microfibrils: kinetics and charge threshold. Cellulose 21:3691–3700. doi:10.1007/s10570-014-0363-7

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15:425–433. doi:10.1007/s10570-007-9184-2

Liimatainen H, Sirviö J, Haapala A et al (2011) Characterization of highly accessible cellulose microfibers generated by wet stirred media milling. Carbohydr Polym 83:2005–2010. doi:10.1016/j.carbpol.2010.11.007

Liimatainen H, Visanko M, Sirviö JA et al (2012) Enhancement of the nanofibrillation of wood cellulose through sequential periodate–chlorite oxidation. Biomacromolecules 13:1592–1597. doi:10.1021/bm300319m

Liimatainen H, Ezekiel N, Sliz R et al (2013) High-strength nanocellulose-talc hybrid barrier films. ACS Appl Mater Interfaces 5:13412–13418. doi:10.1021/am4043273

Liu A, Walther A, Ikkala O et al (2011) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromolecules 12:633–641. doi:10.1021/bm101296z

Loranger E, Piché A-O, Daneault C (2012) Influence of high shear dispersion on the production of cellulose nanofibers by ultrasound-assisted TEMPO-Oxidation of kraft pulp. Nanomaterials 2:286–297. doi:10.3390/nano2030286

Meier MM, Kanis LA, de Lima JC et al (2004) Poly(caprolactone triol) as plasticizer agent for cellulose acetate films: influence of the preparation procedure and plasticizer content on the physico-chemical properties. Polym Adv Technol 15:593–600. doi:10.1002/pat.517

Nair SS, Zhu JY, Deng Y, Ragauskas AJ (2014) Characterization of cellulose nanofibrillation by micro grinding. J Nanoparticle Res. doi:10.1007/s11051-014-2349-7

Özgür Seydibeyoğlu M, Oksman K (2008) Novel nanocomposites based on polyurethane and micro fibrillated cellulose. Compos Sci Technol 68:908–914. doi:10.1016/j.compscitech.2007.08.008

Palacio L, Pradanos P, Calvo JI, Hernandez A (1999) Porosity measurements by a gas penetration method and other techniques applied to membrane characterization. Thin Solid Films 348:22–29

Rattaz A, Mishra SP, Chabot B, Daneault C (2011) Cellulose nanofibres by sonocatalysed-TEMPO-oxidation. Cellulose 18:585–593. doi:10.1007/s10570-011-9529-8

Saito T, Nishiyama Y, Putaux J-L et al (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691. doi:10.1021/bm060154s

Saxena A, Elder TJ, Pan S, Ragauskas AJ (2009) Novel nanocellulosic xylan composite film. Compos B Eng 40:727–730. doi:10.1016/j.compositesb.2009.05.003

Segal L, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sehaqui H, Liu A, Zhou Q, Berglund LA (2010) Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures. Biomacromolecules 11:2195–2198. doi:10.1021/bm100490s

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494. doi:10.1007/s10570-010-9405-y

Sirvio J, Hyvakko U, Liimatainen H et al (2011) Periodate oxidation of cellulose at elevated temperatures using metal salts as cellulose activators. Carbohydr Polym 83:1293–1297. doi:10.1016/j.carbpol.2010.09.036

Sirviö JA, Liimatainen H, Niinimäki J, Hormi O (2013) Sustainable packaging materials based on wood cellulose. RSC Adv 3:16590. doi:10.1039/c3ra43264e

Sirviö JA, Kolehmainen A, Visanko M et al (2014) Strong, self-standing oxygen barrier films from nanocelluloses modified with regioselective oxidative treatments. ACS Appl Mater Interfaces 6:14384–14390. doi:10.1021/am503659j

Suopajärvi T, Liimatainen H, Niinimäki J (2012) Fragment analysis of different size-reduced lignocellulosic pulps by hydrodynamic fractionation. Cellulose 19:237–248. doi:10.1007/s10570-011-9615-y

Taipale T, Österberg M, Nykänen A et al (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. doi:10.1007/s10570-010-9431-9

Vidéki B, Klébert S, Pukánszky B (2007) External and internal plasticization of cellulose acetate with caprolactone: structure and properties. J Polym Sci B Polym Phys 45:873–883. doi:10.1002/polb.21121

Vishtal A, Retulainen E (2012) Deep-drawing of paper and paperboard: the role of material properties. Bioresources 7:4424–4450

Wågberg L, Decher G, Norgren M et al (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:784–795. doi:10.1021/la702481v

Acknowledgments

This work was financed by The Academy of Finland (Postdoctoral Project No. 250940). We thank Ms. Jenni Granroth for her help during the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liimatainen, H., Sirviö, J.A., Kekäläinen, K. et al. High-consistency milling of oxidized cellulose for preparing microfibrillated cellulose films. Cellulose 22, 3151–3160 (2015). https://doi.org/10.1007/s10570-015-0700-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0700-5