Abstract

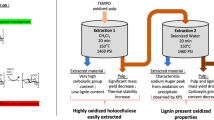

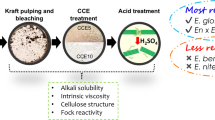

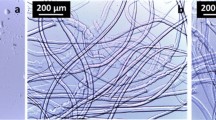

The reactivity of dissolving pulps towards derivatization or dissolution is a crucial quality parameter and is mainly determined by the accessibility of the hydroxyl groups. When dissolving pulps are produced from paper-grade pulps by cold caustic extraction (CCE), their reactivity is often inferior as compared to commercial prehydrolysis kraft dissolving pulps. It was hypothesized that pulp reactivity can be enhanced by the introduction of small amounts of substituents to facilitate interchain accessibility. In this study, CCE-treated Eucalyptus globulus kraft paper pulp was subjected to TEMPO-mediated oxidation to initiate partial oxidation of the C6-hydroxyl groups to carboxyl groups. The effect of this pulp modification on the reactivity towards xanthation and the subsequent dissolution in diluted aqueous alkali solution (viscose process) as well as the dissolution in complexing and non-complexing solvents, respectively, was thoroughly examined. The results revealed that the oxidized pulps rich in C6-carboxylate groups impeded the xanthation reaction obviously because of the reduced availability of hydroxyl groups. When N-methylmorpholine-N-oxide monohydrate was used as a direct solvent, a very high content of C6-carboxylate groups was found to reduce the solubility of the pulp fibers as less hydrogen bonds can be formed with NMMO·H2O. In the case of dissolution in the complexing solvent cupriethylenediamine, the dissolution mechanism of cellulose was not deteriorated by the high content of C6-carboxylate groups. Instead, the oxidation procedure increased the hydrophilic character and the swelling capacity of the outer cell wall layers allowed homogeneous dissolution.

Similar content being viewed by others

Abbreviations

- [η]:

-

Intrinsic viscosity

- A:

-

Acid catalyzed hydrolysis

- AHG:

-

Anhydroglucose

- CCE:

-

Cold caustic extraction

- CCOA:

-

Carbazole-9-carboxylic acid [2-(2-aminooxyethoxy)ethoxy]amide

- Cell II:

-

Cellulose II content

- Cuen:

-

Cupriethylenediamine

- DP:

-

Degree of polymerization

- FDAM:

-

9H-fluoren-2-yl-diazomethane

- FT-IR:

-

Fourier transform infrared spectroscopy

- FT-Raman:

-

Fourier transform Raman spectroscopy

- MB:

-

Methylene blue

- MW:

-

Molecular weight

- MWD:

-

Molecular weight distribution

- NMMO:

-

N-methylmorpholine-N-oxide

- odp:

-

Oven dried pulp

- P:

-

Peroxide bleaching

- PHK:

-

Prehydrolysis kraft

- PW:

-

Primary wall

- SEC:

-

Size exclusion chromatography

- TEMPO:

-

2,2,6,6-tetramethylpiperidine-1-oxyl

- WRV:

-

Water retention value

References

Bohrn R, Potthast A, Schiehser S, Rosenau T, Sixta H, Kosma P (2006) The FDAM method: determination of carboxyl profiles in cellulosic materials by combining group-selective fluorescence labeling with GPC. Biomacromol 7:1743–1750

Chaudemanche C, Navard P (2011) Swelling and dissolution mechanisms of regenerated lyocell cellulose fibers. Cellulose 18:1–15

Cuissinat C, Navard P (2006) Swelling and dissolution of cellulose. Part 1: free floating cotton and wood fibres in N-methylmorpholine-N-oxide-water mixtures. Macromol Symp 244:1–18

Dang Z, Zhang J, Ragauskas AJ (2007) Characterizing TEMPO-mediated oxidation of ECF bleached softwood kraft pulps. Carbohydr Polym 70:310–317

DIN 54355 (1977) Bestimmung der Beständigkeit von Zellstoff gegen Natronlauge (Alkaliresistenz)

Fernandes Diniz JMB, Gil MH, Castro JAAM (2004) Hornification—its origin and interpretation in wood pulps. Wood Sci Technol 37:489–494

Fujisawa S, Okita Y, Fukuzumi H, Saito T, Isogai A (2011) Preparation and characterization of TEMPO-oxidized cellulose nanofibril films with free carboxyl groups. Carbohydr Polym 84:579–583

Gehmayr V, Sixta H (2012) Pulp properties and their influence on enzymatic degradability. Biomacromolecules 13:645–651

Götze K (1967a) Die Herstellung des Xanthogenats sowie die Herstellung und Behandlung der Viskose. In: Götze K (ed) Chemiefasern nach dem Viskoseverfahren—Zweiter Band, 3rd edn. Springer, Berlin, pp 806–831

Götze K (1967b) Die Sulfidierung der Alkalizellulose und das Xanthogenat. In: Götze K (ed) Chemiefasern nach dem Viskoseverfahren—Erster Band, 3rd edn. Springer, Berlin, pp 395–420

Hakansson H, Ahlgren P (2005) Acid hydrolysis of some industrial pulps: effect of hydrolysis conditions and raw material. Cellulose 12:177–183

Hirota M, Tamura N, Saito T, Isogai A (2009) Oxidation of regenerated cellulose with NaClO2 catalyzed by TEMPO and NaClO under acid–neutral conditions. Carbohydr Polym 78:330–335

Hüpfl J, Zauner J (1966) Prüfung von Chemiefaserzellstoffen an einer Viskose-Kleinstanlage. Das Papier 20:125–132

Isogai A, Kato Y (1998) Preparation of polyuronic acid from cellulose by TEMPO-mediated oxidation. Cellulose 5:153–164

Kitaoka T, Isogai A, Onabe F (1999) Chemical modification of pulp fibers by TEMPO-mediated oxidation. Nord Pulp Pap Res J 14:279–284

Krässig HA (1993a) Accessibility in intercrystalline reactions. In: Krässig HA (ed) Cellulose: structure, accessibility and reactivity, 1st edn. Gordon and Breach Science, Amsterdam, pp 187–214

Krässig HA (1993b) Methods of activation. In: Krässig HA (ed) Cellulose: structure, accessibility and reactivity, 1st edn. Gordon and Breach, Amsterdam, pp 215–276

Le Moigne N, Navard P (2010) Dissolution mechanisms of wood cellulose fibres in NaOH–water. Cellulose 17:31–45

Michels C, Kosan B (2005) Contribution to the dissolution state of cellulose and cellulose derivatives. Lenzinger Berichte 84:62–70

Navard P, Cuissinat C (2006) Cellulose swelling and dissolution as a tool to study the fiber structure In: 7th International symposium “Alternative cellulose: manufacturing, forming, properties”, Rudolstadt, Germany, September 6–7

Philipp B, Rehder W, Lang H (1965) Zur Carboxylbestimmung in Chemiezellstoffen. Das Papier 19:1–9

Rahkamo L, Siika-aho M, Vehviläinen M, Dolk M, Viikari L, Nousiainen P, Buchert J (1996) Modifications of hardwood dissolving pulp with purified Trichoderma reesei cellulases. Cellulose 3:153–163

Röder T, Moosbauer J, Fasching M, Bohn A, Fink H-P, Baldinger T, Sixta H (2006) Crystallinity determination of native cellulose—comparison of analytical methods. Lenzinger Berichte 86:85–89

Röhrling J, Potthast A, Rosenau T, Lange T, Borgards A, Sixta H, Kosma P (2002a) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 2. Validation and applications. Biomacromolecules 3:969–975

Röhrling J, Potthast A, Rosenau T, Lange T, Ebner G, Sixta H, Kosma P (2002b) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 1. Method development. Biomacromolecules 3:959–968

Rosenau T, Potthast A, Sixta H, Kosma P (2001) The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (lyocell process). Prog Polym Sci 26:1763–1837

Ruland W (1961) X-ray determination of crystallinity and diffuse disorder scattering. Acta Crystallogr 14:1180–1185

Saito T, Isogai A (2005) A novel method to improve wet strength of paper. Tappi J 4:3–8

SCAN-CM 15:99 (1999) Viscosity in cupriethylenediamine solution

Schild G, Sixta H (2011) Sulfur-free dissolving pulps and their application for viscose and lyocell. Cellulose 18:1113–1128

Schild G, Sixta H, Gehmayr V (2010) Production of a novel generation of sulphur-free dissolving pulps In: Zellcheming Cellulose-Symposium, Wiesbaden, Germany, June 29–30

Schwaighofer A, Zuckerstätter G, Schlagnitweit J, Sixta H, Müller N (2011) Determination of the xanthate group distribution on viscose by liquid-state 1H NMR spectroscopy. Anal Bioanal Chem 400:2449–2456

Sears KD, Hinck JF, Sewell CG (1982) Highly reactive wood pulps for cellulose acetate production. J Appl Polym Sci 27:4599–4610

Sixta H, Schelosky N, Milacher W, Baldinger T, Röder T (2001) Characterization of alkali-soluble pulp fractions by chromatography In: The 11th ISWPC, Nice, France, June 11–14

Spinu M, Dos Santos N, Le Moigne N, Navard P (2011) How does the never-dried state influence the swelling and dissolution of cellulose fibres in aqueous solvent? Cellulose 18:247–256

TAPPI T 430 om-49 (1994) Copper number of pulp, paper, and paperboard

Treiber E, Rehnström J, Ameen C, Kolos F (1962) Über eine Laboratoriums-Viskose-Kleinstanlage zur Testung von Chemiefaserzellstoffen. Das Papier 16:85–94

Vehviläinen M, Kamppuri T, Nousiainen P, Kallioinen A, Siika-aho M, Christoffersson KE, Rom M, Janicki J (2010) Effect of acid and enzymatic treatments of TCF dissolving pulp on the properties of wet spun cellulosic fibres. Cellul Chem Technol 44:147–151

Weigert J, Gruber E (1998) Chemische Modifizierung von Zellstoffen zur Verminderung ihrer Verhornungsneigung. Das Papier 52:1–23

Weightman DA, Fischer HK, Mobius H (2009) Pulp reactivity enhancement. Sappi Manufacturing (PTY)-Ltd. Patent PCT/IB2007/052212

Zellcheming Merkblatt III/21/72 (1972) Prüfung von Viskose—Veresterungsgrad (Gammawert) des Zellulosexanthogenates nach dem Ionenaustauschverfahren (Batch-Methode)

Zellcheming Merkblatt IV/33/57 (1957) Bestimmung des Wasserrückhaltevermögens (Quellwertes) von Zellstoffen

Acknowledgments

Financial support was provided by the Austrian government, the provinces of lower Austria, upper Austria, and Carinthia as well as by Lenzing AG. We also express our gratitude to the Johannes Kepler University, Linz, the University of Natural Resources and Life Sciences, Vienna, and Lenzing AG for their in-kind contribution.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gehmayr, V., Potthast, A. & Sixta, H. Reactivity of dissolving pulps modified by TEMPO-mediated oxidation. Cellulose 19, 1125–1134 (2012). https://doi.org/10.1007/s10570-012-9729-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9729-x