Abstract

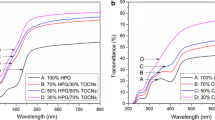

Polylactic acid (PLA) nanocomposites were prepared using cellulose nanowhiskers (CNW) as a reinforcing element in order to asses the value of this filler to reduce the gas and vapour permeability of the biopolyester matrix. The nanocomposites were prepared by incorporating 1, 2, 3 and 5 wt% of the CNW into the PLA matrix by a chloroform solution casting method. The morphology, thermal and mechanical behaviour and permeability of the films were investigated. The CNW prepared by acid hydrolysis of highly purified alpha cellulose microfibers, resulted in nanofibers of 60–160 nm in length and of 10–20 nm in thickness. The results indicated that the nanofiller was well dispersed in the PLA matrix, did not impair the thermal stability of this but induced the formation of some crystallinity, most likely transcrystallinity. CNW prepared by freeze drying exhibited in the nanocomposites better morphology and properties than their solvent exchanged counterparts. Interestingly, the water permeability of nanocomposites of PLA decreased with the addition of CNW prepared by freeze drying by up to 82% and the oxygen permeability by up to 90%. Optimum barrier enhancement was found for composites containing loadings of CNW below 3 wt%. Typical modelling of barrier and mechanical properties failed to describe the behaviour of the composites and appropriate discussion regarding this aspect was also carried out. From the results, CNW exhibit novel significant potential in coatings, membranes and food agrobased packaging applications.

Similar content being viewed by others

References

Angle’s MN, Dufresne A (2001) Plasticized starch/tunicin whiskers nanocomposites: 2. Mechanical behavior. Macromolecules 34(9):2921–2931

Auras R, Kale G, Singh SP (2006) Degradation of commercial biodegradable packages under real composting and ambient exposure conditions. J Environ Polym Degr 14(3):317–334

Ayuk JE, Mathew AP, Oksman K (2009) The effect of plasticizer and cellulose nanowhisker content on the dispersion and properties of cellulose acetate butyrate nanocomposites. J Appl Polym Sci 114:2723–2730

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Bastiolo C, Bellotti V, Del Tredici GF, Lombi R, Montino A, Ponti R (1992) Int Pat Appl WO92/19680

Dufresne A, Kellerhals MB, Witholt B (1999) Transcrystallization in mcl-PHAs/cellulose whiskers composites. Macromolecules 32(22):7396–7401

Favier V (1995) Ph.D. Thesis, properties of films composed of cellulose nanowhiskers and a cellulose matrix regenerated. Joseph Fourier University, Grenoble, France

Fricke HA (1924) Mathematical treatment of the electric conductivity and capacity of disperse systems I. The electric conductivity of a suspension of homogeneous spheroids. Phys Rev 24:575

Ganster J, Fink HP (1999) Physical constants of cellulose. In: Brandrup J, Immergut EH, Grulke EA (eds) Polymer handbook, 4th edn, vol 1. Wiley, USA

Hajji P, Cavaille JY, Favier V, Gauthier C, Vigier G (1996) Tensile behavior of nanocomposites from latex and cellulose whiskers. Polym Compos 17(4):612–619

Helbert W, Cavaille JY, Dufresne A (1996) Thermoplastic nanocomposites filled with wheat straw cellulose whiskers. Part I: Processing and mechanical behaviour. Polym Compos 17:604–611

Jeffrey R, Capadona KS, Trittschuh S, Scott S, Stuart JR, Weder C (2009) Polymer nanocomposites with nanowhiskers isolated from microcrystalline cellulose. Biomacromolecules 10:712–716

Jiang L, Morelius E, Zhang J, Wolcott M (2008) Study of the poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhisker composites prepared by solution casting and melt processing. J Compos Mater 42:24

Koening MF, Huang SJ (1995) Biodegradable blends and composites of polycaprolactone and starch derivatives. Polymer 36:1877

Kvien I, Tanem BS, Oksman K (2005) Characterization of cellulose whiskers and their nanocomposites by atomic force and electron microscopy. Biomacromolecules 6:3160–3165

Lagaron JM, Gimenez E, Catala R, Gavara R (2003) Mechanisms of moisture sorption in barrier polymers used in food packaging: amorphous polyamide vs. high barrier ethylene-vinyl alcohol copolymer studied by vibrational spectroscopy. Macromol Chem Phys 204(4):704–713

Lagaron JM, Catalá R, Gavara R (2004) Structural characteristics defining high barrier polymeric materials. Mater Sci Technol 20(1):1–7

Liu X, Dever M, Fair N, Benson RS (1997) Thermal and mechanical properties of poly(lactic Acid) and poly(ethylene/butylene Succinate) Blends. J Environ Polym Degrad 5:4

López-Rubio A, Lagaron JM, Ankerfors M, Lindström T, Nordqvist D, Mattozzi A, Hedenqvist MS (2007) Enhanced film forming and film properties of amylopectin using micro-fibrillated cellulose. Carbohydr Polym 68:718–727

Luo JJ, Daniel IM (2003) Characterization and modelling of mechanical behaviour of polymer/clay nanocomposites. Compos Sci Technol 63:1607–1616

Marchessault RH, Morehead FF, Walter NM (1959) Liquid crystal systems from fibrillar polysaccharides. Nature 184:632–633

Maxwell JC (1891) Electricity and magnetism, 3rd edn. Dover, New York

Morin A, Dufresne A (2002) Nanocomposites of chitin whiskers from Riftia tubes and poly(caprolactone). Macromolecules 35(6):2190–2199

Nielsen LW (1967) Models for the permeability of filled polymer systems. J Macromol Sci 929–942

Oh SY, Yoo DI, Shin Y, Kim HC, Kim HY, Chung YS, Park WH, Youk JH (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos Sci Technol 66:2776–2784

Park ES, Kim MN, Yoon JSJ (2002) Grafting of polycaprolactone onto poly(ethylene-co-vinyl alcohol) and application to polyethylene-based bioerodable blends. Polym Sci Part B Polym Phys 40:2561

Paul DR, Bucknall CB (2000) Polymer blends, vol 2 Performance

Petersen L, Nielsen PV, Olsen MB (2001) Physical and mechanical properties of biobased materials. Starch 53(8):356

Petersson L, Oksman K (2006) Biopolymer based nanocomposites: comparing layered silicates and microcrystalline cellulose as nanoreinforcement. Compos Sci Technol 66:2187–2196

Petersson L, Kvien I, Oksman K (2007) Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos Sci Technol 67:2535–2544

Podsiadlo P, Choi S, Shim B, Lee J, Cussihy M, Kotov N (2005) Molecularly engineered nanocomposites: layer-by-layer assembly of cellulose nanocrystals. Biomacromolecules 6:2914–2918

Rhim JW, Hong SI, Ha CS (2009) Tensile, water vapor barrier and antimicrobial properties of PLA/nanoclay composite films. Food Sci Technol 42:612–617

Roohani M, Habibi Y, Belgacem NM, Ebrahim G, Karimi AN, Dufresne A (2008) Cellulose whiskers reinforced polyvinyl alcohol copolymers nanocomposites. Eur Polym J 44:2489–2498

Sanchez-Garcia MD, Gimenez E, Lagaron JM (2007) Comparative barrier performance of novel PET nanocomposites with biopolyester nanocomposites of interest in packaging food applications. J Plastic Film Sheet 23:133–148

Sanchez-Garcia MD, Gimenez E, Gimenez E, Lagaron JM (2008a) Development and characterization of novel nanobiocomposites of bacterial poly(3-hydroxybutirate), layered silicates and poly(ε-caprolactone). J Appl Polym Sci 108:2787–2801

Sanchez-Garcia MD, Gimenez E, Lagaron JM (2008b) Mophology and barrier properties of solvent cast composites of thermoplastic biopolymers and purified cellulose fibers. Carbohydr Polym 71:235–244

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432

Sturcova A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules 6:1055–1061

Tingaut P, Zimmermann T, Lopez-Suevos F (2010) Synthesis and characterization of bionanocomposites with tunable properties from poly(lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11:454–464

Tsahiro K, Kobayaski M (1991) Theorical evaluation of three-dimesional elastic constant of native and regenerated celluloses: role of hydrogen bonds. Polymer 32:1516–1526

Tsuji H, Yamada TJ (2003) Blends of aliphatic polyesters. VIII. Effects of poly(L-lactide-co-ε- caprolactone) on enzymatic hydrolysis of poly(L-lactide), poly(ε- caprolactone), and their blend films. Appl Polym Sci 87:412

Wang B, Sain M, Oksman K (2007) Study of structural morphology of hemp fiber from the micro to the nanoscale. Appl Compos Mater 14:89–103

Wu YP, Jia QX, Yu DS, Zhang LQ (2004) Modelling young’s modulus of rubber-clay nanocomposites using composites theories. Polym Test 23:903–909

Zhang G, Yan DJ (2003) Crystallization kinetics and melting behavior of nylon 10, 10 in nylon 10, 10-montmorillonite nanocomposites. Appl Polym Sci 88:2181–2188

Acknowledgments

The authors would like to thank the MICINN projects MAT2009-14533-C02-01 and EUI2008-00182 for financial support. Dr. E. Gimenez from the UPV, Valencia is acknowledged for support with the mechanical testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sanchez-Garcia, M.D., Lagaron, J.M. On the use of plant cellulose nanowhiskers to enhance the barrier properties of polylactic acid. Cellulose 17, 987–1004 (2010). https://doi.org/10.1007/s10570-010-9430-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-010-9430-x