Abstract

Given the ongoing crisis of depleting fossil fuel reserves and rising demand for biofuels, scientists are increasingly driven to explore more environmentally friendly and sustainable energy options in today’s global landscape. Consequently, the utilization of solid catalysts, specifically Metal–Organic Frameworks (MOFs), in the transesterification process to produce biodiesel emerges as a promising avenue. This marks the innovative adoption of the metal–organic catalyst MIL-68 (Al) in the context of biodiesel production. This study focuses on the generation of green and efficient biodiesel using Waste Cooking Oil (WCO) as the primary raw material which involves a transesterification process utilizing of MIL-68 (Al). Using the Box-Behnken Design (BBD), a well-established method in Response Surface Methodology (RSM), we optimized key variables including catalyst quantity, duration, and temperature in the transesterification process. The optimization study includes parameter ranges: time (3–8 h), temperature (100–150 °C), and catalyst dosage (5–25%).

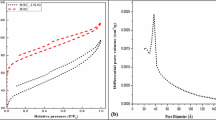

The catalyst characteristics were investigated through AFM, BET, DLS, SEM, ICP, FTIR, NH3-TPD, TEM, TGA, and XRD analyses. Using a temperature of 145 °C and incorporating a catalyst quantity of 24.18%, a maximum oil conversion efficiency of 98.8% was attained within 7.5 h. Kinetic analysis showed that the experimental behavior followed a pseudo-first-order reaction kinetic model (R2 = 0.9991), and the transesterification reaction demanded an activation energy of Ea = 65.47 kJ/mol. The catalyst demonstrates excellent stability, maintaining consistent performance over four cycles without any noticeable decline. The yield after four cycles of reusability remains high at 92.6%.

Similar content being viewed by others

Data Availability

The datasets utilized and/or examined in the current study are available from the corresponding author upon reasonable request.

References

Ghanadi M, Kah M, Kookana RS, Padhye LP (2023) Formation of disinfection by-products from microplastics, tire wear particles, and other polymer-based materials. Water Res 230:119528. https://doi.org/10.1016/j.watres.2022.119528

Mautschke HH, Drache F, Senkovska I, Kaskel S, i Xamena FL (2018) Catalytic properties of pristine and defect-engineered Zr-MOF-808 metal organic frameworks. Catal Sci Technol 8(14):3610–3616. https://doi.org/10.1039/C8CY00742J

Varol P, Çakan A, Kiren B, Ayas N (2021) Microwave-assisted catalytic transesterification of soybean oil using KOH/γ-Al2O3. Biomass Convers Biorefinery 1–13. https://doi.org/10.1007/s13399-020-01253-4

Mandari V, Devarai SK (2022) Biodiesel Production Using Homogeneous, Heterogeneous, and Enzyme Catalysts via Transesterification and Esterification Reactions: a Critical Review. BioEnergy Res 15(2):935–961. https://doi.org/10.1007/s12155-021-10333-w

Dibazar AS, Aliasghar A, Behzadnezhad A, Shakiba A, Pazoki M (2023) Energy cycle assessment of bioethanol production from sugarcane bagasse by life cycle approach using the fermentation conversion process. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-04288-5

Shakiba A, Aliasghar A, Moazeni K, Pazoki M (2023) Hydrothermal Carbonization of Sewage Sludge with Sawdust and Corn Stalk: Optimization of Process Parameters and Characterization of Hydrochar. BioEnergy Res. https://doi.org/10.1007/s12155-022-10552-9

Venkataramana SH, Shivalingaiah K, Davanageri MB, Selvan CP, Lakshmikanthan A, Chandrashekarappa MPG, Razak A, Anand PB, Linul, E (2022) Niger seed oil-based biodiesel production using transesterification process: experimental investigation and optimization for higher biodiesel yield using box–behnken design and artificial intelligence tools. Appl Sci 12(12):5987. https://doi.org/10.3390/app12125987

Yücesu H, Topgül T, Okur M (2006) Effect of ethanol–gasoline blends on engine performance and exhaust emissions in different compression ratios. Appl Therm Eng - APPL THERM ENG 26:2272–2278. https://doi.org/10.1016/j.applthermaleng.2006.03.006

Ahmed M, Abdullah A, Patle D, Shahadat M, Ahmad Z, Athar M, Aslam, M, Vo D-V (2021) Feedstocks, catalysts, process variables and techniques for biodiesel production by one‑pot extraction‑transesterifcation: a review. Environ Chem Lett 20:335–378. https://doi.org/10.1007/s10311-021-01358-w

Karmakar B, Hossain A, Jha B, Sagar R, Halder G (2021) Factorial optimization of biodiesel synthesis from castor-karanja oil blend with methanol-isopropanol mixture through acid/base doped Delonix regia heterogeneous catalysis. Fuel 285:119197. https://doi.org/10.1016/j.fuel.2020.119197

Zhang Q, Yue C, Ao L, Lei D, Ling D, Yang D, Zhang Y (2021) Facile one-pot synthesis of Cu-BTC metal-organic frameworks supported Keggin phosphomolybdic acid for esterification reactions. Energy Sources Part A: Recover Utilization Environ Eff 43:3320–3331. https://doi.org/10.1080/15567036.2019.1651794

Danane F, Bessah R, Alloune R, Tebouche L, Madjene F, Kheirani AY, Bouabibsa R (2022) Experimental optimization of waste cooking oil ethanolysis for biodiesel production using Response Surface Methodology (RSM). Sci Tech Energ Transit 77:14. https://doi.org/10.2516/stet/2022014

Wan H, Chen C, Wu Z, Que Y, Feng Y, Wang W, Wang L, Guan G, Liu X (2014) Cover picture: encapsulation of heteropolyanion-based ionic liquid within the metal-organic framework MIL-100(Fe) for biodiesel production (ChemCatChem 3/2015). ChemCatChem 7. https://doi.org/10.1002/cctc.201402800

Hosseini SA (2022) Nanocatalysts for biodiesel production. Arab J Chem 15(10):104152. https://doi.org/10.1016/j.arabjc.2022.104152

Kalita P, Basumatary B, Saikia P, Das B, Basumatary S (2022) Biodiesel as renewable biofuel produced via enzyme-based catalyzed transesterification. Energy Nexus 6:100087. https://doi.org/10.1016/j.nexus.2022.100087

Marso M, Kalpage S, Udugala-Ganehenege M (2020) Application of chromium and cobalt terephthalate metal organic frameworks as catalysts for the production of biodiesel from calophyllum inophyllum oil in high Yield under mild conditions. J Inorg Organomet Polym Mater 30:1243–1265. https://doi.org/10.1007/s10904-019-01251-8

Huang G, Chen F, Wei D, Zhang X, Chen G (2010) Biodiesel production by microalgal biotechnology. Appl Energy 87(1):38–46. https://doi.org/10.1016/j.apenergy.2009.06.016

Zhang Q, Yang T, Liu X, Yue C, Ao L, Deng T, Zhang Y (2019) Heteropoly acid-encapsulated metal–organic framework as a stable and highly efficient nanocatalyst for esterification reaction. RSC Adv 9(29):16357–16365. https://doi.org/10.1039/C9RA03209F

Suzihaque MUH, Alwi H, Ibrahim U, Abdullah S, Haron N (2022) Biodiesel production from waste cooking oil: A brief review. Mater Today: Proc 63:S490–S495. https://doi.org/10.1016/j.matpr.2022.04.527

Hazrat MA, Rasul MG, Khan MMK, Ashwath N, Fattah IMR, Ong HC, Mahlia TMI (2022) Biodiesel production from transesterification of Australian Brassica napus L. oil: optimisation and reaction kinetic model development. Environ Dev Sustain. https://doi.org/10.1007/s10668-022-02506-0

Etim AO, Musonge P, Eloka-Eboka AC (2022) Process optimization of bio-alkaline catalysed transesterification of flax seed oil methyl ester. Sci Afr 16:e01275. https://doi.org/10.1016/j.sciaf.2022.e01275

Miladinović MR, Zdujić MV, Veljović DN, Krstić JB, Banković-Ilić IB, Veljković VB, Stamenković OS (2020) Valorization of walnut shell ash as a catalyst for biodiesel production. Renew Energy 147:1033–1043. https://doi.org/10.1016/j.renene.2019.09.056

Lima AC, Hachemane K, Ribeiro A, Queiroz A, Gomes M, Brito P (2022) Evaluation and kinetic study of alkaline ionic liquid for biodiesel production through transesterification of sunflower oil. Fuel 324:124586. https://doi.org/10.1016/j.fuel.2022.124586

Cirujano FG, Corma A, Xamena FXLI (2015) Zirconium-containing metal organic frameworks as solid acid catalysts for the esterification of free fatty acids: Synthesis of biodiesel and other compounds of interest. Catal Today 257:213–220. https://doi.org/10.1016/j.cattod.2014.08.015

Zhou K, Chaemchuen S (2017) Metal-organic framework as catalyst in esterification of oleic acid for biodiesel production. Int J Environ Sci Dev 8:251–254. https://doi.org/10.18178/ijesd.2017.8.4.957

Farzaneh F, Mortazavi S-S (2016) Zn metal organic framework as a heterogeneous catalyst for the alkylation of toluene with benzyl bromide. React Kinet Mech Catal 120:333–344. https://doi.org/10.1007/s11144-016-1077-7

Nikseresht A, Daniyali A, Ali-Mohammadi M, Afzalinia A, Mirzaie A (2017) Ultrasound-assisted biodiesel production by a novel composite of Fe(III)-based MOF and phosphotangestic acid as efficient and reusable catalyst. Ultrason Sonochem 37:203–207. https://doi.org/10.1016/j.ultsonch.2017.01.011

Peña-Rodríguez R, Lopez E, Guerrero A, Chiñas L, Hernández-González D, Rivera J (2018) Hydrothermal synthesis of Cobalt (II) 3D Metal-Organic Framework acid catalyst applied in the transesterification process of vegetable oil. Mater Lett 217:117–119. https://doi.org/10.1016/j.matlet.2018.01.052

Rahmani A, Shabanloo A, Zabihollahi S, Salari M, Leili M, Khazaei M, Alizadeh S, Nematollahi D (2022) Facile fabrication of amino-functionalized MIL-68(Al) metal–organic framework for effective adsorption of arsenate (As(V)). Sci Rep 12(1):11865. https://doi.org/10.1038/s41598-022-16038-0

Tan Y, Sun Z, Meng H, Han Y, Wu J, Xu J, Xu Y, Zhang X (2019) A new MOFs/polymer hybrid membrane: MIL-68(Al)/PVDF, fabrication and application in high-efficient removal of p-nitrophenol and methylene blue. Sep Purif Technol 215. https://doi.org/10.1016/j.seppur.2019.01.008

Wu SC, You X, Yang C, Cheng JH (2017) Adsorption behavior of methyl orange onto an aluminum-based metal organic framework, MIL-68(Al). Water Sci Technol 75(12):2800–2810. https://doi.org/10.2166/wst.2017.154

Wang C, Liu X, Keser Demir N, Chen JP, Li K (2016) Applications of water stable metal–organic frameworks. Chem Soc Rev 45(18):5107–5134. https://doi.org/10.1039/C6CS00362A

Zhao X, Zheng M, Xinli G, Zhang J, Wang E, Gao Z (2021) The application of MOFs-based materials for antibacterials adsorption. Coord Chem Rev 440:213970. https://doi.org/10.1016/j.ccr.2021.213970

Georgiadis AG, Charisiou N, Yentekakis IV, Goula MA (2020) Hydrogen Sulfide (H2S) Removal via MOFs. Materials 13(16):3640 (https://www.mdpi.com/1996-1944/13/16/3640)

Shah MS, Tsapatsis M, Siepmann JI (2017) Hydrogen sulfide capture: From absorption in polar liquids to oxide, zeolite, and metal-organic framework adsorbents and membranes. Chem Rev 117(14):9755–9803. https://doi.org/10.1021/acs.chemrev.7b00095

Bayat A, Baghdadi M, Bidhendi GN (2018) Tailored magnetic nano-alumina as an efficient catalyst for transesterification of waste cooking oil: Optimization of biodiesel production using response surface methodology. Energy Convers Manage 177:395–405. https://doi.org/10.1016/j.enconman.2018.09.086

Dehghan A, Aliasghar A, Rahmati R, Delnavaz M, Khoshvaght H (2024) Green synthesis of ZnO/αFe2O3 Nano-photocatalyst for efficient removal of carbamate pesticides in wastewater: Optimization, mineralization, and financial analysis. Korean J Chem Eng 41(1):249–269. https://doi.org/10.1007/s11814-024-00073-w

Moazeni K, Mirzaei M, Baghdadi M, Torabian A (2023) Sequential treatment of textile industry wastewater using electrocoagulation and photo electro-fenton processes. Water Air Soil Pollut 234(7):413. https://doi.org/10.1007/s11270-023-06406-5

Farooq M, Ramli A, Naeem A (2015) Biodiesel production from low FFA waste cooking oil using heterogeneous catalyst derived from chicken bones. Renew Energy 76:362–368. https://doi.org/10.1016/j.renene.2014.11.042

Rahmani E, Mohammad R (2017) Al-based MIL-53 Metal Organic Framework (MOF) as the new catalyst for friedel-crafts alkylation of benzene. Ind Eng Chem Res 57:169–178. https://doi.org/10.1021/acs.iecr.7b04206

Baghdadi M, Ghaffari E, Aminzadeh B (2016) Removal of carbamazepine from municipal wastewater effluent using optimally synthesized magnetic activated carbon: Adsorption and sedimentation kinetic studies. J Environ Chem Eng 4:3309–3321. https://doi.org/10.1016/j.jece.2016.06.034

Liu J, Zhang F, Zou X, Zhou S, Li L, Sun FX, Qiu S (2012) Facile synthesis of MIL-68(In) films with controllable morphology. Eur J Inorg Chem 2012. https://doi.org/10.1002/ejic.201200642

Goldman M, Huang Y (2018) Conformational analysis of 1, 2-dichloroethane adsorbed in metal-organic frameworks. Vib Spectrosc 95:68–74. https://doi.org/10.1016/j.vibspec.2018.02.002

Latchubugata CS, Kondapaneni RV, Patluri K, Virendra U, Vedantam S (2018) Kinetics and optimization studies using response surface methodology in biodiesel production using heterogeneous Catalyst. Chem Eng Res Des 135:129–139. https://doi.org/10.1016/j.cherd.2018.05.022

Ong LK, Kurniawan A, Suwandi AC, Lin CX, Zhao XS, Ismadji S (2013) Transesterification of leather tanning waste to biodiesel at supercritical condition: Kinetics and thermodynamics studies. J Supercrit Fluids 75:11–20. https://doi.org/10.1016/j.supflu.2012.12.018

Rathore V, Madras G (2007) Synthesis of biodiesel from edible and non-edible oils in supercritical alcohols and enzymatic synthesis in supercritical carbon dioxide. Fuel 86:2650–2659. https://doi.org/10.1016/j.fuel.2007.03.014

Maeda H, Hagiwara S, Nabetani H, Sagara Y, Surawidjaja T, Tambunan A, Abdullah K (2008) Biodiesel fuels from palm oil via the non-catalytic transesterification in a bubble column reactor at atmospheric pressure: A kinetic study. Renew 33:1629–1636. https://doi.org/10.1016/j.renene.2007.08.011

He H, Sun S, Zhu S (2007) Transesterification kinetics of soybean oil for production of biodiesel in supercritical methanol. JAOCS, J Am Oil Chem Soc 84:399–404. https://doi.org/10.1007/s11746-007-1042-8

Ridwan I, Katsuragawa N, Tamura K (2020) Process optimization, reaction kinetics, and thermodynamics studies of water addition on supercritical methyl acetate for continuous biodiesel production. J Supercrit Fluids 166:105038. https://doi.org/10.1016/j.supflu.2020.105038

Barekati-Goudarzi M, Muley P, Stepanov GV, Nde DB, Boldor D (2017) Continuous microwave-assisted in-situ transesterification of lipids in seeds of invasive Chinese tallow trees (Triadica sebifera L.): Kinetic and thermodynamic studies. Biomass Bioenerg 107:353–360. https://doi.org/10.1016/j.biombioe.2017.09.006

Jacobson K, Gopinath R, Meher LC, Dalai A (2008) Solid acid catalyzed biodiesel production from waste cooking oil. Appl Catal B: Environ 85:86–91. https://doi.org/10.1016/j.apcatb.2008.07.005

Qu S, Chen C, Guo M, Jiang W, Lu J, Yi W, Ding J (2021) Microwave-assisted in-situ transesterification of Spirulina platensis to biodiesel using PEG/MgO/ZSM-5 magnetic catalyst. J Clean Prod 311:127490. https://doi.org/10.1016/j.jclepro.2021.127490

Qu S, Chen C, Guo M, Lu J, Yi W, Ding J, Miao Z (2020) Synthesis of MgO/ZSM-5 catalyst and optimization of process parameters for clean production of biodiesel from Spirulina platensis. J Clean Prod 276:123382. https://doi.org/10.1016/j.jclepro.2020.123382

Chen C, Qu S, Guo M, Lu J, Yi W, Liu R, Ding J (2021) Waste limescale derived recyclable catalyst and soybean dregs oil for biodiesel production: Analysis and optimization. Process Saf Environ Prot 149:465–475. https://doi.org/10.1016/j.psep.2020.11.022

Guo M, Jiang W, Chen C, Qu S, Lu J, Yi W, Ding J (2021) Process optimization of biodiesel production from waste cooking oil by esterification of free fatty acids using La3+/ZnO-TiO2 photocatalyst. Energy Convers Manage 229:113745. https://doi.org/10.1016/j.enconman.2020.113745

Seaf Elnasr TA, Al-Enezi AT, Hussein MF, Bielal H, Alhumaimess MS, El-Ossaily YA, Hassan, HM, AlNahwa LH, Aldawsari AM, Alsohaimi IH (2024) Sustainable biodiesel production from waste olive oil: Utilizing olive pulp-derived catalysts for environmental and economic benefits. Sustain Chem Pharm 37:101426. https://doi.org/10.1016/j.scp.2024.101426

Mohammadi N, Ostovar N, Niromand R, Absalan F (2023) Advancing biodiesel production from pyrus glabra seed oil: Kinetic study and RSM optimization via microwave-assisted transesterification with biocompatible hydroxyapatite catalyst. Sustain Chem Pharm 36:101272. https://doi.org/10.1016/j.scp.2023.101272

Rahman WU, Khan RIA, Ahmad S, Yahya SM, Khan ZA, Rokhum SL, Halder G (2023) Valorizing waste palm oil towards biodiesel production using calcareous eggshell based heterogeneous catalyst. Bioresour Technol Rep 23:101584. https://doi.org/10.1016/j.biteb.2023.101584

Acknowledgements

We extend our sincere gratitude for the gracious support and collaboration extended by Tehran University, allowing us the privilege of utilizing their esteemed facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sabzi, M., Baghdadi, M., Aliasghar, A. et al. Synthesis of MIL-68 (Al) Catalyst and Optimization of Green Biodiesel Production from Waste Cooking Oil. Catal Lett (2024). https://doi.org/10.1007/s10562-024-04659-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-024-04659-1