Abstract

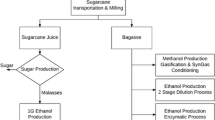

Researchers are developing new techniques for clean fuel production due to environmental problems such as global warming. In this respect, bioethanol is considered among the most important renewable fuels. This study aims to investigate the energy cycle and estimate the potential environmental effects of ethanol production from sugarcane bagasse in Iran. To this end, ethanol’s life cycle assessment (LCA) was conducted based on the “cradle to gate” approach. This assessment includes three stages of sugarcane farming, transportation to the factory, and bioethanol production. This study defines three scenarios for bioethanol production from sugarcane bagasse using the fermentation conversion process: fermentation, bagasse burning for electricity, and combined bioethanol and electricity production. The third scenario was chosen as the best. However, in environmental analysis, it showed the most negative effects on environmental indicators, especially in cases of abiotic depletion and global warming potential. Scenario 1 showed better results than the others. The results showed that electricity, diesel fuel, and nitrogen fertilizer had the greatest environmental impact in the mentioned process. Moreover, by replacing fossil fuels with clean energies, more energy efficiency and less environmental consequences can be achieved because fossil fuels cause air pollution leading to acid rain, eutrophication, damage to forests, and harm to wildlife. Our results show that the bioethanol production process using sugarcane bagasse as feedstock requires 27.13 MJ/L input energy, while the total output energy is 40.44 MJ/L. Energy indices were calculated, with values of 1.49, 0.037, 27.13, and 13.31 for energy ratio, efficiency, intensity, and net energy addition, respectively.

Similar content being viewed by others

References

Liew WH, Hassim MH, Ng DK (2014) Review of evolution, technology and sustainability assessments of biofuel production. J Clean Prod 71:11–29. https://doi.org/10.1016/j.jclepro.2014.01.006

Islam MT, Shahir S, Uddin TI, Saifullah A (2014) Current energy scenario and future prospect of renewable energy in Bangladesh. Renew Sustain Energ Rev 39:1074–1088. https://doi.org/10.1016/j.rser.2014.07.149

Mohammadi F, Roedl A, Abdoli MA, Amidpour M, Vahidi H (2020) Life cycle assessment (LCA) of the energetic use of bagasse in Iranian sugar industry. Renew Energ 145:1870–1882. https://doi.org/10.1016/j.renene.2019.06.023

Park SH, Yoon SH, Lee CS (2014) Bioethanol and gasoline premixing effect on combustion and emission characteristics in biodiesel dual-fuel combustion engine. Appl Energ 135:286–298. https://doi.org/10.1016/j.apenergy.2014.08.056

Demirbas A (2008) Biodiesel. Springer, p 111

Zhang Z, O’Hara IM, Mundree S, Gao B, Ball AS, Zhu N, Bai Z, Jin B (2016) Biofuels from food processing wastes. Curr Opin Biotechnol 38:97–105. https://doi.org/10.1016/j.copbio.2016.01.010

Shakiba A, Aliasghar A, Moazeni K, Pazoki M (2023) Hydrothermal carbonization of sewage sludge with sawdust and corn stalk: optimization of process parameters and characterization of hydrochar. BioEnerg Res 1-12. https://doi.org/10.1007/s12155-022-10552-9

Najafi G, Ghobadian B, Tavakoli T, Yusaf T (2009) Potential of bioethanol production from agricultural wastes in Iran. Renew Sustain Energ Rev 13(6-7):1418–1427. https://doi.org/10.1016/j.rser.2008.08.010

Azadbakht M, Safieddin Ardebili SM, Rahmani M (2021) Potential for the production of biofuels from agricultural waste, livestock, and slaughterhouse waste in Golestan province Iran. Biomass Conv Bioref 13:3123–3133. https://doi.org/10.1007/s13399-021-01308-0

Ardebili SMS (2020) Green electricity generation potential from biogas produced by anaerobic digestion of farm animal waste and agriculture residues in Iran. Renew Energ 154:29–37. https://doi.org/10.1016/j.renene.2020.02.102

Rahman A, Asnawi A, Putra R, Radian H, Waluyo T (2022) The effect of hydrogen enrichment on the exhaust emission characteristic in a spark ignition engine fueled by gasoline-bioethanol blends. Int J Eng, Sci Inform Technol 2(2):8–13. https://doi.org/10.52088/ijesty.v1i1.234

Dineshkumar C, Jeyakumar P, Arvinda Pandian C, Rajmohan N, Elumalai P, Kamesh N, Shaik S, Sharifpur M, Khalilpoor N (2022) Assessment on performance and emission characteristics of the CRDI engine fueled with ethanol/diesel blends in addition to EGR. Int J Chem Eng 2022. https://doi.org/10.1155/2022/4413617

Bahena-Molina K A, Sunder S, Ganesan A, Saini R, Osorio-González C S, and Kaur Brar S (2022) Pretreatment technologies for second-generation bioethanol production liquid biofuels: bioethanol, springer, pp 209-241

Behzadnezhad A, Ebadi T, Taheri S, Kowsari E (2020) Batch adsorption of methyl tert-butyl ether (MTBE) from aqueous solution by combined CNT and zeolite. Desalinat Water Treat 191:213–220. https://doi.org/10.5004/dwt.2020.25381

Sakai S, Nakashimada Y, Yoshimoto H, Watanabe S, Okada H, Nishio N (2004) Ethanol production from H2 and CO2 by a newly isolated thermophilic bacterium, Moorella sp. HUC22-1. Biotechnol Lett 26:1607. https://doi.org/10.1023/B:BILE.0000045661.03366.f2

Hidzir N S, Som A, and Abdullah Z (2014) Ethanol production via direct hydration of ethylene: a review. in International conference on global sustainability and chemical engineering (ICGSE), 1-6.

Darunde Dhiraj S, Deshmukh Mangesh M (2012) Biodiesel production from animal fats and its impact on the diesel engine with ethanol-diesel blends: a review. Int J Emerg\ Technol Adv Eng 2(10):179–185

Minier M, Goma G (1982) Ethanol production by extractive fermentation. Biotechnol Bioeng 24(7):1565–1579. https://doi.org/10.1002/bit.260240710

Duque A, Álvarez C, Doménech P, Manzanares P, Moreno AD (2021) Advanced bioethanol production: from novel raw materials to integrated biorefineries. Processes 9(2):206. https://doi.org/10.3390/pr9020206

Stephenson A, Dupree P, Scott S, Dennis J (2010) The environmental and economic sustainability of potential bioethanol from willow in the UK. Bioresourc Technol 101(24):9612–9623. https://doi.org/10.1016/j.biortech.2010.07.104

Araghi MK, Barkhordari S, Hassannia R (2023) Economic impacts of producing bioethanol in Iran: a CGE approach. Energy 263:125765. https://doi.org/10.1016/j.energy.2022.125765

Awoyale AA, Lokhat D (2019) Harnessing the potential of bio-ethanol production from lignocellulosic biomass in Nigeria–a review. Biofuels, Bioprod Bioref 13(1):192–207. https://doi.org/10.1002/bbb.1943

Singh AD, Gajera B, Sarma A (2022) Appraising the availability of biomass residues in India and their bioenergy potential. Waste Manag 152:38–47. https://doi.org/10.1016/j.wasman.2022.08.001

Balador Z, Gjerde M, Isaacs N, Imani M (2019) Thermal and acoustic building insulations from agricultural wastes. In: Torres Martínez LM, Oxana Vasilievna K, Boris Ildusovich K (eds) Handbook of Ecomaterials. Springer, pp 1–20. https://doi.org/10.1007/978-3-319-48281-1_190-1

Alfonso A, Herryman D (1990) Pulping from agro-based resources. Holzforschung 44:58–63

Zabed H, Sahu J, Suely A, Boyce A, Faruq G (2017) Bioethanol production from renewable sources: current perspectives and technological progress. Renew Sustain Energ Rev 71:475–501. https://doi.org/10.1016/j.rser.2016.12.076

Cornago S, Tan YS, Ramakrishna S, Low JSC (2022) Temporal hotspot identification using dynamic life cycle inventory: which are the critical time-spans within the product life cycle? Procedia CIRP 105:249–254. https://doi.org/10.1016/j.procir.2022.02.041

Bjørn A, Owsianiak M, Molin C, Hauschild MZ (2018) LCA history Life cycle assessment. Springer, pp 17–30

Kheradmand A, Negarestani M, Mollahosseini A, Shayesteh H, Farimaniraad H (2022) Low-cost treated lignocellulosic biomass waste supported with FeCl3/Zn (NO3) 2 for water decolorization. Sci Rep 12(1):16442. https://doi.org/10.1038/s41598-022-20883-4

Kadam K (2000) Environmental life cycle implications of using bagasse-derived ethanol as a gasoline oxygenate in Mumbai (Bombay). National Renewable Energy Lab. https://doi.org/10.2172/772426

Spatari S, Zhang Y, MacLean HL (2005) Life cycle assessment of switchgrass-and corn stover-derived ethanol-fueled automobiles. Environ Sci Technol 39(24):9750–9758. https://doi.org/10.1021/es048293+

Quintero J, Montoya M, Sánchez OJ, Giraldo O, Cardona C (2008) Fuel ethanol production from sugarcane and corn: comparative analysis for a Colombian case. Energy 33(3):385–399. https://doi.org/10.1016/j.energy.2007.10.001

Muñoz I, Flury K, Jungbluth N, Rigarlsford G, King H (2014) Life cycle assessment of bio-based ethanol produced from different agricultural feedstocks. Int J Life Cycle Assess 19(1):109–119. https://doi.org/10.1007/s11367-013-0613-1

Pacheco R, Silva C (2019) Global warming potential of biomass-to-ethanol: review and sensitivity analysis through a case study. Energies 12(13):2535. https://doi.org/10.3390/en12132535

Isler-Kaya A, Karaosmanoglu F (2022) Life cycle assessment of safflower and sugar beet molasses-based biofuels. Renew Energ 201:1127–1138

Deora PS, Verma Y, Muhal RA, Goswami C, Singh T (2022) Biofuels: an alternative to conventional fuel and energy source. Mater Today: Proc 48:1178–1184

Cheng G, Zhao Y, Pan S, Wang X, Dong C (2020) A comparative life cycle analysis of wheat straw utilization modes in China. Energy 194:116914. https://doi.org/10.1016/j.energy.2020.116914

Alexiades A, Kendall A, Winans KS, Kaffka SR (2018) Sugar beet ethanol (Beta vulgaris L.): a promising low-carbon pathway for ethanol production in California. J Clean Prod 172:3907–3917. https://doi.org/10.1016/j.jclepro.2017.05.059

Lask J, Wagner M, Trindade LM, Lewandowski I (2019) Life cycle assessment of ethanol production from miscanthus: a comparison of production pathways at two European sites. Gcb Bioenerg 11(1):269–288. https://doi.org/10.1111/gcbb.12551

Hasanly A, Khajeh Talkhoncheh M, Karimi Alavijeh M (2018) Techno-economic assessment of bioethanol production from wheat straw: a case study of Iran. Clean Technol Environ Pol 20(2):357–377. https://doi.org/10.1007/s10098-017-1476-0

Rathnayake M, Chaireongsirikul T, Svangariyaskul A, Lawtrakul L, Toochinda P (2018) Process simulation based life cycle assessment for bioethanol production from cassava, cane molasses, and rice straw. J Clean Prod 190:24–35. https://doi.org/10.1016/j.jclepro.2018.04.152

Salehi FA, Abdoli MA, Shokouhmand H, Jafari HR (2013) Techno-economic assessment for energy generation using bagasse: case study. Int J Energ Res 37(8):982–990. https://doi.org/10.1002/er.2907

Gonzalez MNG, Björnsson L (2022) Life cycle assessment of the production of beet sugar and its by-products. J Clean Prod 346:131211. https://doi.org/10.1016/j.jclepro.2022.131211

Santoyo-Castelazo E, Santoyo E, Zurita-García L, Luengas DC, Solano-Olivares K (2023) Life cycle assessment of bioethanol production from sugarcane bagasse using a gasification conversion process: bibliometric analysis, systematic literature review and a case study. Appl Therm Eng 219:119414. https://doi.org/10.1016/j.applthermaleng.2022.119414

Maga D, Thonemann N, Hiebel M, Sebastião D, Lopes TF, Fonseca C, Gírio F (2019) Comparative life cycle assessment of first-and second-generation ethanol from sugarcane in Brazil. Int J Life Cycle Assess 24:266–280. https://doi.org/10.1007/s11367-018-1505-1

Amezcua-Allieri MA, Martínez-Hernández E, Anaya-Reza O, Magdaleno-Molina M et al (2019) Techno-economic analysis and life cycle assessment for energy generation from sugarcane bagasse: case study for a sugar mill in Mexico. Food Bioprod Proc 118:281–292. https://doi.org/10.1016/j.fbp.2019.09.014

Reza B, Sadiq R, Hewage K (2011) Sustainability assessment of flooring systems in the city of Tehran: an AHP-based life cycle analysis. Const Build Mater 25(4):2053–2066. https://doi.org/10.1016/j.conbuildmat.2010.11.041

Stavarache C, Vinatoru M, Maeda Y (2007) Aspects of ultrasonically assisted transesterification of various vegetable oils with methanol. Ultrasonics Sonochem 14(3):380–386. https://doi.org/10.1016/j.ultsonch.2006.08.004

Kitani O (1999) CIGR Handbook of Agricultural Engineering, Volume V Energy and Biomass Engineering, Chapter 1 Natural Energy and Biomass, Part 1.3 Biomass Resources.

Mohammadshirazi A, Akram A, Rafiee S, Avval SHM, Kalhor EB (2012) An analysis of energy use and relation between energy inputs and yield in tangerine production. Renew Sustain Energ Rev 16(7):4515–4521. https://doi.org/10.1016/j.rser.2012.04.047

Tabatabaie SMH, Rafiee S, Keyhani A (2012) Energy consumption flow and econometric models of two plum cultivars productions in Tehran province of Iran. Energy 44(1):211–216. https://doi.org/10.1016/j.energy.2012.06.036

Guzmán GI, Alonso AM (2008) A comparison of energy use in conventional and organic olive oil production in Spain. Agricult Syst 98(3):167–176. https://doi.org/10.1016/j.agsy.2008.06.004

Salami P, Ahmadi H, Keyhani A (2010) Estimating the equivalent energy for single super phosphate production in Iran. J Sci Rev 2(1):1–10

Mudahar MS (1987) Energy requirements, technology, and resources in fertiliser sector. Energ Plant Nutilion Pest Control:25–61

Petersen AM (2012) Comparisons of the technical, financial risk and life cycle assessments of various processing options of sugercane bagasse to biofuels in South Africa. Stellenbosch University, Stellenbosch

Prakash R, Henham A, Bhat IK (1998) Net energy and gross pollution from bioethanol production in India. Fuel 77(14):1629–1633. https://doi.org/10.1016/S0016-2361(98)00085-4

Lampridi M, Kateris D, Sørensen CG, Bochtis D (2020) Energy footprint of mechanized agricultural operations. Energies 13(3):769. https://doi.org/10.3390/en13030769

de Fraiture C, Cai X, Amarasinghe U, Rosegrant M, Molden D (2004) Does international cereal trade save water?: the impact of virtual water trade on global water use, vol 4. IWMI

Saga K, Imou K, Yokoyama S, Minowa T (2010) Net energy analysis of bioethanol production system from high-yield rice plant in Japan. Appl Energ 87(7):2164–2168. https://doi.org/10.1016/j.apenergy.2009.12.014

Vintila T, Vintila D, Neo S, Tulcan C, Hadaruga N (2011) Simultaneous hydrolysis and fermentation of lignocellulose versus separated hydrolysis and fermentation for ethanol production. Roman Biotechnol Lett 16(1):106–112

Kadam KL (2002) Environmental benefits on a life cycle basis of using bagasse-derived ethanol as a gasoline oxygenate in India. Energ Pol 30(5):371–384. https://doi.org/10.1016/S0301-4215(01)00104-5

Meisterling K, Samaras C, Schweizer V (2009) Decisions to reduce greenhouse gases from agriculture and product transport: LCA case study of organic and conventional wheat. J Clean Prod 17(2):222–230. https://doi.org/10.1016/j.jclepro.2008.04.009

Larsen AW, Vrgoc M, Christensen TH, Lieberknecht P (2009) Diesel consumption in waste collection and transport and its environmental significance. Waste Manag Res 27(7):652–659. https://doi.org/10.1177/0734242X08097

Nanaki EA, Koroneos CJ (2012) Comparative LCA of the use of biodiesel, diesel and gasoline for transportation. J Clean Prod 20(1):14–19. https://doi.org/10.1016/j.jclepro.2011.07.026

Ramjeawon T (2008) Life cycle assessment of electricity generation from bagasse in Mauritius. J Clean Prod 16(16):1727–1734. https://doi.org/10.1016/j.jclepro.2007.11.001

Kim S, Dale BE (2005) Life cycle assessment of various cropping systems utilized for producing biofuels: bioethanol and biodiesel. Biomass Bioenerg 29(6):426–439. https://doi.org/10.1016/j.biombioe.2005.06.004

Data availability

The datasets generated during and/or analyzed during the current study are not publicly available due to ethical concerns but are available from the corresponding author on reasonable request.

Author information

Authors and Affiliations

Contributions

Arman Satari Dibazar, Arash Aliasghar, Asal Behzadnezhad, Aria Shakiba, and Maryam Pazoki contributed to the design and implementation of the research, to the analysis of the results, and to the writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dibazar, A.S., Aliasghar, A., Behzadnezhad, A. et al. Energy cycle assessment of bioethanol production from sugarcane bagasse by life cycle approach using the fermentation conversion process. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04288-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04288-5