Abstract

Metal organic frameworks (MOFs) are multi-dimensional network of crystalline material held together by bonding of metal atoms and organic ligands. Owing to unique structural, chemical, and physical properties, MOFs has been used for enzyme immobilization to be employed in different catalytic process, including catalytic degradation of antibiotics. Immobilization process other than providing large surface provides enzyme with enhanced stability, catalytic activity, reusability, and selectivity. There are various approaches of enzyme immobilization over MOFs including physical adsorption, chemical bonding, diffusion and in situ encapsulation. In situ encapsulation is one the best approach that provides extra stability from unfolding and denaturation in harsh industrial conditions. Presence of antibiotic in environment is highly damaging for human in particular and ecosystem in general. Different methods such as ozonation, oxidation, chlorination and catalysis are available for degradation or removal of antibiotics from environment, however these are associated with several issues. Contrary to these, enzyme immobilized MOFs are novel system to be used in catalytic degradation of antibiotics. Enzyme@MOFs are more stable, reusable and more efficient owing to additional support of MOFs to natural enzymes in well-established process of photocatalysis for degradation of antibiotics aimed at environmental remediation. Prime focus of this review is to present catalytic degradation of antibiotics by enzyme@MOFs while outlining their synthetics approaches, characterization, and mechanism of degradation. Furthermore, this review highlights the significance of enzyme@MOFs system for antibiotics degradation in particular and environmental remediation in general. Current challenges and future perspective of research in this field are also outlined along with concluding comments.

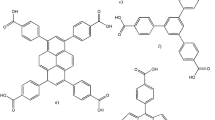

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metal organic frameworks (MOFs), also known as one, two or three-dimensional infinite networks of crystalline materials that are constructed from metal clusters held together by multi-dentate organic ligands [1]. These contain periodic networks structure containing central metal atom that is bridged by multi-dentate organic ligand [2]. Metal–ligand bond is formed by donation of electron pair from ligand to metal and thus they are also known as coordination polymers(CPs) [3]. MOFs are characterized by large surface area, biocompatibility, non-toxicity, tunable pore size and functional group. Owing to these properties MOFs have various application such as catalysis, drug delivery, antimicrobial bio-sensing, point of care diagnostic wastewater treatment, proton conduction and adsorption [4,5,6,7]. For instance, zinc imadozolate framework-8(ZIF-8) is one of the widely used owing to it high porosity, large surface area and catalytic efficiency. It is employed in various process such as bio-imaging, bone marrow engineering, anticancer therapy, biosensing, biocatalysis and drug delivery [8,9,10,11]. Due to tunable and regular pore size, MOFs has been used in wastewater treatment by employing adsorption, filtration and degradation mechanism [12].

Due to large surface area, high porosity, pore volume and high chemical, structural and physical stability in certain environments, MOFs have been used for immobilization of biomolecules such as enzymes [13], deoxyribonucleic acid (DNA) [14], drugs [15] and various proteins [16] for multiple applications [17, 18]. Natural enzymes are excellent catalysts that are being used widely in several industrial fields for providing better catalysis than artificial catalysts. These enzymes offer high selectivity, high efficiency (106 times) and excellent working in mild working conditions, these features make natural enzyme better than chemical catalysts in which these are absent [19, 20]. To achieve better and sustainable future for all as envisaged by United Nations (UN) in sustainable development goal, natural enzymes can play crucial role in its attainment due to their green nature [21]. Application of natural enzyme catalysts are increasing day by day and it is suitable alternative to chemical catalysts due to ecofriendly nature and efficiency. Reports suggest that market of industrial enzyme is rapidly flourishing and it is expected to jump up to 7.0 billion dollars by year 2023 [22]. Natural enzyme catalysts are also better than chemical catalyst in terms of degradability, compatibility and synthesis as this offer biodegradability, biocompatibility and these are synthesized from natural, renewable and inexpensive resources. Comparing with natural enzymes, metal catalysts are very expensive and results in post-production complications such as difficult removal of metal traces from product in purification process [23]. Despite being so efficient and ecofriendly, large-scale applications of enzyme at industrial scale faces a lot of challenges that are thwarting their use in industrial areas. Major challenges of enzyme catalysis include instability in industrial conditions, expensiveness, reusability and recovery difficulties [24]. Natural enzymes offer very limited stability in harsh industrial conditions and they cannot work in situations where high temperature, extreme pH and non-aqueous solvents are involved [25]. To bring natural enzymes in industrial application, there was need of stabilizing and protecting these enzymes from harsh conditions. For production of efficient and stable enzyme, immobilization is an effective and excellent technique. A lot of reports suggest enhancement of life cycles of enzymes after immobilization even in harsh industrial conditions. Additionally operational cost can be reduced and product quality can be improved by immobilization because immobilization offers easy recovery and reusability with minimum activity loss [23, 25,26,27,28]. To overcome aforementioned drawbacks, scientist came up with immobilization of enzymes on MOFs for better stability and catalytic performance [5]. Literature survey indicated that MOFs has been used extensively for enzyme immobilization owing to their unique and intriguing features in recent years, as summarized in referenced reviews [29,30,31,32,33,34]. Stability of natural enzymes is dependent upon working media and MOFs impose structural restrictions on natural enzymes and protect them for denaturing [35]. MOFs having highly ordered framework defend enzymes in harsh conditions such as excessive acidic or basic pH, high temperature and presence of organic solvents resulting in enhanced stability and catalytic activity of enzymes [36, 37]. There are various method for immobilization including surface immobilization by chemical bonding [38] and physical interaction [39], diffusion [40] or encapsulation [41].

Antibiotics are extensively used class of pharmaceutical and personal care products (PPCPs). These are emerging environmental pollutants particularly in water bodies. Antibiotics are used in treatment of bacterial infections and humans where they enter in ecosystem through fecal and water. Owing to slow metabolic rate, these pollutants spread slowly and results in physiological effect in human even in low dose. Abuse of antibiotics is an emerging and serious threat to ecosystem and heath of living organisms [42,43,44]. Proper treatment and degradation of antibiotics from wastewater is challenging problem that need immediate attention to reduce health risks and environmental hazards. There are various methods for the removal of antibiotics from wastewater such as ozonation, catalytic oxidation, membrane filtration and surface adsorption [45] but the biodegradation of antibiotics is one of the novel technique for removal of antibiotics via enzyme linked MOFs [46]. In spite of several studies in this domain, the literature still lacks a consolidated and comprehensive review on the biocatalytic degradation of antibiotics using enzyme based natural catalysts. Therefore, this work is aimed to provide readers with fundamental knowledge on enzyme immobilization approaches using MOFs along with the harmful effects of antibiotics on the environment. The main focus of this review is to discuss the recent research on the catalytic degradation of antibiotics through enzyme@MOFs. Finally, article is summed up with current challenges and future recommendations in this field.

2 Enzyme Immobilization Methods

There are multiple method of enzyme immobilizations but all follow one of the three routes i.e.; carrier binding, cross linking and encapsulation as exhibited in Fig. 1 [24].

Principal routes for enzyme immobilization. Reprinted from [24]. This article is licensed under the creative commons attribution 3.0 unported license. (https://creativecommons.org/licenses/by/3.0/)

Doonan et al. categorized immobilization techniques on the base of binding mechanism between enzymes and MOFs into encapsulation, bioconjugation and infiltration as presented in Fig. 2 [47]. In this review, immobilization approaches are divided in various methods based on their basic interaction between enzymes and MOFS.

Categorization of immoblization method on the base of binding mechanism. Reprinted from [47] with permission from American chemical society.

2.1 Physical Adsorption

Enzymes are immobilized on the surface through hydrogen bonding, van der walls forces, electrostatic interaction without any chemical modification (Fig. 3). This method of enzyme immobilization is considerably easy to handle, cost effect and efficient [48, 49]. Enzymes are immobilized by simple bringing of enzyme and MOFs close together thus resulting immobilization. This process is reversible, and enzymes can be removed at any time from MOFs. This method is beneficial in terms of reusing costly MOFs after removing unfixed enzymes. There are different factors (dipole moment, magnetic susceptibility, polarizability and electric charge) that determine surface properties of both materials and subsequently the strength of adsorption between enzymes and MOFs. These strength governing factors are [50]. Immobilization by physical adsorption is considered better methods than other due to various reasons. Physical adsorption effectively confine enzymes and prevent them from leaching [48]. By maintaining balance in hydrophilic-hydrophobic structure of MOFs prevent aggregation, denaturation and passivation of enzymes in certain environment and furthermore this process protect active sites of enzyme from deactivation and keep catalytic activity intact [51,52,53]. Physical adsorption is green, cost effective and facile method for enzymes immobilization due to less number of steps and no requirement of any additional chemical for the said process [49]. Figure 3 shows different physical forces and construction of physical adsorption of enzyme on MOFs surface [54].

Physical adsorption of enzyme on MOFs surface. Reprinted from [54] with permission from Elsevier. License Number: 5422500974765

2.2 Covalent Linkage

Contrast to physical adsorption links, there is a need of strong linkage between enzyme and MOFs in real industrial situations to avoid denaturation of enzyme. Stronger bonding can be attained by involving chemical bod between enzyme and MOFs (Fig. 4). For instance, covalent linkage gives tight immobilization of enzyme on MOFs and prevent denaturation [24]. Commonly employed linkage between enzymes MOFs involve formation of peptide bond between free amino group on enzyme or on the surface of MOFs with carboxyl group on enzyme or surface of MOFs [4]. In direct covalent linkage, catalytic performance of enzymes is affected due to steric hindrance, charge interaction and presence of reactive groups. However, it can prevented by prior modification of enzymes with molecule having capability to form bond with MOFs [36, 55, 56]. This enzyme modification strategy provides alternative route for immobilization in the absence of ideal binding site between MOFs and enzymes. Covalent linkage immobilization provides better stability, reusability, structural rigidification and easy enzyme accessibility. Drawbacks of this method are complicated synthesis, require additional expensive chemicals, time consuming and partially reduced enzyme activity [54]. Figure 4 is reproduced below to illustrate the immobilization of enzyme onto MOF surface through covalent linkage [57]

Immobilization of soybean epoxide hydrolase onto UiO-66-NH2 through covalent linkage. Reprinted from [57] with permission from American chemical society.

2.3 Infiltration

Infiltration is novel phenomenon occurring in mesoporous MOFs in which enzymes are encapsulated inside MOFs. Enzyme penetration is alternative route for enzyme immobilization in MOFs. MOFs behave as cages having pore size in accordance with size of enzymes and these pores are used to accommodate enzymes inside MOFs. Owing to large pore volume and expansive surface, Infiltration of enzymes in MOFs offers high enzyme loading as compared to surface conjugation [54, 58, 59]. In infiltration method, enzymes are surrounded by MOFs that prevent aggregation or unfolding and provides protection against harsh environment such as organic solvents, extreme acidity, denaturants and high temperature resulting in minimum protein unfolding and enhanced activity [60,61,62]. Synthetic process of MOFs allow tunability in pore size and volume and the resulting tailored pore volume provide excellent size selectivity which is very advantageous for catalytic purposes [63]. Limitations of this method include requirement of compatible size, less efficient heat and mass transfer [54]. Figure 5 illustrates the enzyme infiltration in MOFs [46].

Schematic illustaration of enzyme infiltration in MOFs. Reprinted from [111] with permission from Elsevier. License Number: 5422520239353

2.4 One Pot Embedding

Infiltration is no doubt efficient method of enzyme immobilization inside MOFs, but a large number of available MOFs have smaller pore size as compared to size of target enzyme resulting in impossibility of diffusion of enzyme. To cope with this challenge and prevent unfolding and leakage of enzyme, recently a new strategy of one pot embedding has been developed to immobilize enzyme inside MOFs. This single step method involve nucleation and crystallization of MOFs fabrication and enzyme encapsulated immobilization simultaneously [64]. One post embedding is also known as in situ encapsulation and this technique involve process of bio-mineralization and co-precipitation simultaneously [65]. General procedure of one pot embedding involves mixing of metal ions, organic ligands and enzymes in specially designed solvents that leads to nucleation and crystallization of MOFs with encapsulated enzymes. Sometime special kind of additives are also used to expedite and facilitate the process. Immobilization of enzymes inside MOFs is often accompanied by cross linking of enzyme molecules [41, 64]. This method eliminates shortcomings of infiltration technique by offering reduction in reaction steps, reduction in leaching and enhancement in stability, reusability and last but not least, there is no requirement of size compatibility. Requirement of strictly controlled environment and partially decreased catalytic activity of enzymes are identified as limitations of this method [54]. Figure 6 shown below depicts a good overview of one pot embedding of enzymatic proteins in MOFs [66].

One pot embedding of enzymatic proteins in MOFs. Reprinted from [112] with permission from Springer Nature. This article is licensed under creative commons attribution 4.0 International license (http://creativecommons.org/licenses/by/4.0/.)

3 Characteristics of Enzyme Immobilized MOFs

The main purpose of enzyme immobilization is conversion of enzymes into sophisticated biocatalyst by enhancing their catalytic activity, stability, reusability and selectivity. Studies suggest that some of the desired feature has been attained particularly in terms of stability as some enzyme@MOFs can work efficiently in harsh industrial conditions. Here few improved aspects of enzyme@MOFs are discussed to justify immobilization of enzyme on MOFs.

3.1 Catalytic Activity

MOFs has been used as supporting material for enzyme immobilization, but they couldn’t play significant role in enhancement of catalytic activity of enzymes. Enzyme activity centers are shielded by dense MOFs networks that is achieving barrier towards higher catalytic activity [5]. Studies support another line of arguments that in organic solvent, enhancement in catalytic activity can be achieved significantly while in case of aqueous solvent it is a challenging task. Jung et al. proved this enhancement of catalytic activity in organic solvent by chemically bonding Candida-antarctica-lipase-B (CAL-B) on the surface of MOFs while using isopropyl ether. Catalytic performance of CAL-B@MOFs was 103 times higher than simple CAL-B. There was no change in enantioselectivity of enzyme in transesterification of 1-phenylethanol [67]. In a similar instance, microperoxidase-11 was immobilized on Cu-MOF and their catalytic activity was compared with simple microperoxidase in dimethylformamide. Microperoxidase-11@Cu-MOF exhibited 10 times better catalytic activity in catalysis of Amplex ultra red and methyl blue as compared to simple microperoxidase-11 [68]. Challenging task of catalytic activity enhancement in aqueous solvent has been performed by few but not in significant terms as compared to enhancement in organic solvent. Enhanced peroxidase catalytic activity was exhibited by Cytochrome complex (Cyt c) after its incorporation into MOF. Potassium phosphate buffer was used as aqueous solvent and immobilization was performed through one pot embedding process [41]. Protection of enzymes from denaturation, presence of maximum enzymatic active sites near MOFs surface and large surface area are important factors and enhance catalytic activity of enyzme@MOFs significantly [69].

3.2 Stability

One of the most desired features in enzymes is their stability and this can be achieved by immobilization on MOFs. Natural enzymes are sensitive material as they can’t bear a slight change in working environment. They denaturize in harsh conditions such as extreme acidity and basicity, organic solvents and high temperature ultimately. Having structural balance and controllable pore morphology MOFs act as protective shield against harsh conditions and provide enhanced thermal, OH, medium and storage stability to enzyme@MOFs [70]. Soybean epoxide hydrolase (SEH) is important catalyst for synthesis of valuable vicinal diols. Cao et al. Immobilized SEH on UiO-66-NH3 and studied its stability. SEH@ UiO-66-NH3 exhibited 88.0% enzyme activity recovery, storage stability of 97.5% of initial activity and demonstrated better pH, organic solvents and thermal stability as compared to simple SHE [57]. Horseradish peroxidase (HRP) immobilized on ZIF-8 MOF exhibited brilliant thermal stability as their activity remained intact even after heating in water at 100˚C and boiling with DMF at 153 °C for 1 h [13]. Chemical, mechanical, and thermal stabilities are determining factor for MOF stability and ultimately that of enzyme@MOFs. Enhanced stability of enzyme@MOFs can be realized by providing efficient and suitable protection to enzyme and preventing it from leaching and denaturation without creating hurdles for proper functioning of active sites of enzyme [71].

3.3 Reusability

By preventing enzyme denaturation and protecting it from harsh conditions, MOFs make sure its reusability. Immobilization is one of the main purposes to enhance reusability and make this system cost effective and commercial. Studies suggest better reusability of enzyme immobilized on MOFs than simple as demonstrated by Shih et al. where they immobilized trypsin on MOFs and studied stability and reusability of enzyme@MOFs system. These results confirmed the role of MOFs in enhancement of reusability [72]. Glucose oxidase was immobilized on MOFs and its reusability and stability was studied. Results showed that enyzme@MOFs system offered promising reusability and stability even under harsh industrial conditions. When reusability of simple glucose oxidase and glucose oxidase@MOF were compared, it was very clear that simple glucose oxidase lost 80% of its catalytic activity while glucose oxidase@MOF retains its 90% of catalytic activity [73]. In some cases to attain challenging task of enzyme and MOFs separation, magnetic ferric oxide (Fe2O3) were employed during process of synthesis, such cases CAL-B@UiO-66 [74], trypsin@Cu3(btc)2 [75] and lipase@MIL-88B [38]. This involvement of Fe2O3 in synthetic process facilitate separation and reuse of enzyme@MOFs system ultimately leading to separation of natural enzyme that can be reused with loss of catalytic activity. Studies suggest this strategy is showing great results particularly if enzyme@MOFs system is composed of nanomaterials [76].

3.4 Selectivity

Natural enzymes are highly selective for natural substrate but there are chances of loss of this selectivity in case on other substrate such as antibiotics. At industrial process such as catalysis of antibiotics demands higher level of substrate selectivity. Given the demand of highly selective catalyst and relevant industrial products, it is significant to get highly selective enzymes, and this can be achieved through immobilization of enzyme on MOFs. Studies support that immobilization of enzyme using different techniques results in improvement of enzyme selectivity [77]. Selectivity of enzyme can be enhanced by stabilizing enzyme conformation, changing structure of enzyme active sites and elimination of substrate diffusion limitation [78, 79]. Selectivity of glucose oxidase@ZIF-8 was investigated by employing it on other glucose analogues such as fructose and galactose. The result revealed that enzyme@MOFs system didn’t respond to these analogues indicating highest level of selectivity [80]. Other such system with higher selectivity for glucose are glucose oxidase and horseradish peroxidase@ZIF-8 [76] and glucose dehydrogenase@ZIF-70 [81]. Immobilization of microperoxidase-8 on materials institute Lavoisier-101 (MIL-101) produce synergistic effect with higher selectivity of enzyme toward degradation of methylene blue dye, huge change was observed in oxidation rate of dye after immobilization of enzyme [82]. There is another approach toward enhancing selectivity of encapsulated enzyme in MOF by tuning their pore size and structure according to dimensions of substrate. This novel approach was reported by Kenedel et al. in their work, where they produced laccase@ZIF-8 through in situ encapsulation and activity toward 2, 6-dimethoxyphenol (2, 6-DMP) and 2, 2ʹ-azino-bis (3-ethylbenzothiazoline-6-sulphonic acid) (ABTS). Results showed that original enzyme efficiency was 55% as determined by atomic absorption spectroscopy while efficiency of laccase@ZIF-8 toward 2, 6-DMP was 13% and toward substrate of larger size ABTS efficiency was zero. This proved that substrate size selectivity can be achieved in enzyme encapsulated MOFs [83].

4 Characteristics of Enyzme@MOFs

Characteristics of enzyme@MOFs are determined by immobilization approach because in different immobilization approaches different bonding or connecting forces are involved. These connecting forces have been elaborated in earlier section of immobilization methods in this review. If one immobilization technique is advantageous for one application, it is also disadvantageous for other. Immobilization approaches come with both merits and demerits; a comparison has been presented in Table 1.

5 Sources and Health Risks of Antibiotics

Since 1980s presence of antibiotics is acknowledged but these were not considered a concern. A decade later due development of new analytic techniques such as liquid chromatography/tandem mass spectroscopy, their presence particularly in water was considered an emerging concern for humans and environment owing to their toxic effects [84]. Reportedly 100 000 and 200 000 tons of antibiotics are consumed annually, and a large quantity of these antibiotics is disposed in sewage system unused. If these antibiotics are no eliminated or degraded during wastewater treatment, they move into ground water, surface water and potentially into drinking water. As these antibiotics can pass into aquatic environment through wastewater this results in disaster for aquatic life. Antibiotics used for microbial infection in human and animals are excreted and ultimately enter into wastewater unmetabolized causing unfathomable risks to environment [85, 86]. Report suggest the presence of cephalexin and amoxicillin in the range of 170–5070 and 64–1670 ng/L in wastewater and 6.1–493 and 0.64–76 ng/L in sea water [87]. Presence of antibiotics at this level is enough to produce resistance in pathogens resulting epidemic diseases [88]. Aquatic life is mainly affected by these materials because they cause reproduction problem, breathing and skin diseases in fishes and other aquatic organisms [89]. Antibiotics in environment cause bioaccumulation and pseudo-resistance leading to problems in treating pathological infections and imbalance in microbial ecosystem. Considering the problem posed by presence of antibiotics, it is necessary to eliminate or degraded them. Municipal wastewater treatment can’t degrade them and there are some advanced methods that degrade them such as ozonation, electrochemical oxidation, chlorination and catalysis. These methods have been reviewed thoroughly for deep understanding [46]. There is novel approach employed for catalytic degradation of antibiotics by using enzyme immobilized MOF. Although at present, there is scarcity in research in this area but this approach is promising and effective for proper disposal and degradation of antibiotics in environment to eliminate serious threat posed by these toxic substance to ecosystem and human health [46].

6 Application of Enzyme@MOFs for Antibiotics Removal

Owing to enhanced stability, catalytic activity, reusability, and selectivity enzyme@MOF system has been employed for catalytic degradation of penicillin. Yang et al. employed self-assembly method to synthesize ZIF-8 and encapsulated β-lactamase for catalytic degradation of penicillin. Degradation was performed in water and target antibiotic was degraded 45% in first 10 min. Degradation percentage increases with increase in time and this percentage reached to 94% after 1 h. This is excellent efficiency for degradation in wastewater. Without immobilization, same enzyme can degrade only 10% antibiotics proving enhancement of catalytic activity due to immobilization. Stability of enzyme@MOF system was determined by changing pH 5.0–10.0 and there was no significant change in catalytic performance until pH was 6.0. At pH 5.0 in buffer solution due to influence of environment on enzyme activity, there was significant loss in degradation efficiency. This loss in degradation efficiency is attributed to partial destruction of structure of β-lactamase@ZIF-8 in acidic medium [90, 91]. Mechanism of catalysis of simple enzyme involve attack of β-lactamase on amide bond of 4-membered ring of β-lactam resulting in breakage of amide bond and penicilloic acid is formed [92]. Mechanism of action of β-lactamase@ZIF-8 slightly different than simple enzyme (Fig. 7). In this case, metal organic framework is involved in degradation. Zinc ion of MOFs form complexes with two parts of antibiotic, one is carbonyl group on β-lactam ring and other position is amino group nitrogen. Participation of ZIF-8 MOFs improve degradation efficiency of antibiotic because formation of complex of zinc ion and carbonyl group weakens the amide bond of β-lactam’s 4-membered ring. This weak amide bond is more easy to break leading to degraded product penicillioic acid [46].

Reaction pathway and mechanism of penicillins bio-degradation by β-lactamase and β-lactamase@ZIF-8. Reprinted from [46] with permission from Elsevier. License Number: 5422480981917

Triclosan is an efficient antibacterial agent and essential part of pharmaceuticals and personal care products (PCPs) such as cosmetics, antibacterial soaps and toothpastes etc. [93, 94]. Owing to the extensive use of PCPs, triclosan can enter in water bodies massively and it has been confirmed by several studies reporting its concentration in wastewater in the range of L−1 to µ L−1 [95, 96]. To prevent bioaccumulation and avoid subsequent hazardous effects its degradation is necessary. Jia et al. applied physically adsorbed laccase enzyme on the surface of MIL-53(Al) to use this enzyme@MOFs system for conversion of triclosan into innocuous 2, 4-dichlorophenol (2, 4-DCP). By employing enzyme@MOFs, 99.24% of triclosan was degraded due to the excellent adsorption phenomenon of MOFs and laccase. Stability and reusability test resulted in retention of 60% of initial catalytic activity after 8 cycles, proving that enyzme@MOFs not only provided excellent catalytic activity but also offered unmatched stability and reusability. Proposed mechanism involved the cleavage of ether bond of triclosan and further oxidation and alternatively self-coupling of phenoxyl radicals and this mechanism was also supported by other studies for conversion of triclosan into dimers, trimmers and tetramers [97]. Zhang et al. employed in situ method for laccase immobilization on copper trimesic acid framework (Cu-BTC) and used them in degradation of tetracycline and ampicillin. MOFs immobilized laccase provided almost 100% degradation efficiency of both ampicillin and tetracycline into nontoxic products. Compared to free laccase immobilized system showed 16.5-fold better activity with high temperature tolerance, stability in acidic conditions and reusability. Recycling of laccase@Cu-BTC and its employment in real water showed no change in catalytic activity even after 6 cycles. They employed technical method for determination of nontoxic nature of degraded products in which they measured antibacterial efficacy of products and results proved complete degradation of antibiotics into nontoxic products [98]. Diclofenac belongs to non-steroidal anti-inflammatory class of drugs but studies reported it antibiotic activity, particularly against gram positive and gram negative bacteria [99]. Ren et al. prepared laccase immobilized MOFs through three-dimensional modification and employed them for the degradation of wastewater micro pollutant diclofenac. Results showed that enzyme@MOFs provided better permeability, acid/base environment tolerance, reusability and excellent selectivity with remarkable degradation of diclofenac [100]. Compared to other antibiotics degradation process such photocatalysis by semiconductor photocatalyst this system is more efficient and cost effective as in photocatalyst narrowband gap and structural suitability requirement are major limitation. These problems are reasons that make semiconductor based photocatalysts less viable than enzymes linked MOFs [101, 102]. A more greener approach of employing microalgae, ligninolytic fungi and bio-chars for antibiotics degradation is slower process and dependent upon conditions such as temperature and PH, minor changes in conditions can halt the degradation reaction [103, 104]. Adsorption of antibiotics by adsorbent is highly expensive owing to cost of adsorbents and employment of natural adsorbent system such as microalgae leads to low efficiency. Disposal of adsorbent is another limitation that makes adsorption process not suitable at industrial scale [105]. As compared to other materials, enzyme@MOFs could provide excellent stability, reusability, catalytic activity and selectivity as proved by aforementioned works elaborated here and it is evincible from efficiency and cost effectiveness that these systems are ideal for biocatalytic antibiotics removal from wastewater as an environmental remediation process. More enzyme@MOFs systems and their degradation efficiencies are presented in Table 2.

7 Current Challenges

Scarcity of research in catalytic degradation of antibiotics employing enzyme immobilized MOFs is fundamental challenge. There are a lot of enzyme@MOFs system but their application in degradation of antibiotics is very limited. Requirement of specific working medium i.e., organic or aqueous is major hurdle toward making these as versatile catalytic systems. Strict pore size compatibility leads to diffusion problem resulting in limitation of catalytic activity and this is huge challenge. To make enzyme@MOFs system to work in harsh industrial conditions without compromising catalytic activity, there is urgent need of work to be done on potential, availability and flexibility of enzyme center. To make this system versatile and efficient new adsorption method are needed to develop and there is need of bringing diversity in both enzymes and MOFs materials. Antibiotics are present in environment at industrial scale and present research is not enough to move toward industrialization of process.

8 Conclusion

In this review, recent works on catalytic degradation of antibiotics by employment of enzyme immobilized MOFs have been summarized. This review primarily focusses on immobilization approaches of enzyme, enhancement of properties of enzyme@MOFs and catalytic mechanism of degradation of antibiotics while providing a brief on fundamentals of MOFs and their structural, physical and chemical uniqueness. Literature survey is evincing the scarcity of research in this field particularly immobilization of enzyme MOFs aimed at degradation of antibiotics. Although present research in this filed is very limited but it is enough to support enzyme@MOFs as promising catalysts for degradation of antibiotics at industrial scale. For sophisticated removal of antibiotics as environmental remediation process, we suggest future research should be focused on producing variety of enzyme@MOFs for degradation of antibiotics in all compartments of environment with enhanced efficiency so that this process should be applied at industrial scale. Furthermore diversification of enzyme@MOFs system in terms of enzymes, MOFs and antibiotics is necessary to upgrade this process. Owing to uniqueness and research gap, we believe this direction will predominate future research with results having long lasting impacts on environmental remediation process.

References

Lin Z-J et al (2014) Metal–organic frameworks based on flexible ligands (FL-MOFs): structures and applications. Chem Soc Rev 43(16):5867–5895

Zhang Y et al (2022) Application of MOFs and COFs for photocatalysis in CO2 reduction, H2 generation, and environmental treatment. EnergyChem. https://doi.org/10.1016/j.enchem.2022.100078

Silva AR et al (2022) The chemistry and applications of metal-organic frameworks (MOFs) as industrial enzyme immobilization systems. Molecules 27(14):4529

Zhu Q-L, Xu Q (2014) Metal–organic framework composites. Chem Soc Rev 43(16):5468–5512

Hu Y et al (2018) Progress & prospect of metal-organic frameworks (MOFs) for enzyme immobilization (enzyme/MOFs). Renew Sust Energ Rev 91:793–801

Rezaee T et al (2022) Metal-organic frameworks for pharmaceutical and biomedical applications. J Pharm Biomed Anal. https://doi.org/10.1016/j.jpba.2022.115026

Dlamini ML et al (2022) Zeolitic imidazolate frameworks as effective crystalline supports for aspergillus-based laccase immobilization for the biocatalytic degradation of carbamazepine. Chemosphere. https://doi.org/10.1016/j.chemosphere.2022.137142

Xu W et al (2021) Metal–organic frameworks enhance biomimetic cascade catalysis for biosensing. Adv Mater 33(22):2005172

Fan M et al (2021) Molecularly imprinted polymer coated Mn-doped ZnS quantum dots embedded in a metal–organic framework as a probe for selective room temperature phosphorescence detection of chlorpyrifos. RSC Adv 11(45):27845–27854

Meng J et al (2017) General oriented formation of carbon nanotubes from metal–organic frameworks. J Am Chem Soc 139(24):8212–8221

Issaka E et al (2022) Zinc imidazolate metal–organic frameworks-8-encapsulated enzymes/nanoenzymes for biocatalytic and biomedical applications. Catal Lett. https://doi.org/10.1007/s10562-022-04140-x

Li J et al (2020) Metal-organic framework membranes for wastewater treatment and water regeneration. Coord Chem Rev 404:213116

Liang K et al (2015) Biomimetic mineralization of metal-organic frameworks as protective coatings for biomacromolecules. Nat Commun 6(1):1–8

Cui L et al (2015) Electrochemical sensor for lead cation sensitized with a DNA functionalized porphyrinic metal–organic framework. Anal Chem 87(20):10635–10641

Liédana N et al (2012) CAF@ ZIF-8: one-step encapsulation of caffeine in MOF. ACS Appl Mater Interfaces 4(9):5016–5021

Deng H et al (2012) Large-pore apertures in a series of metal–organic frameworks. Science. https://doi.org/10.1126/science.1220131

Fracaroli AM et al (2016) Seven post-synthetic covalent reactions in tandem leading to enzyme-like complexity within metal–organic framework crystals. J Am Chem Soc 138(27):8352–8355

Liu X et al (2017) A facile strategy for enzyme immobilization with highly stable hierarchically porous metal–organic frameworks. Nanoscale 9(44):17561–17570

Hauer B (2020) Embracing nature’s catalysts: a viewpoint on the future of biocatalysis. ACS Catal 10(15):8418–8427

Wu S et al (2021) Biocatalysis: enzymatic synthesis for industrial applications. Angew Chem Int Ed 60(1):88–119

Prather KL (2020) Accelerating and expanding nature to address its greatest challenges. Nat Catal 3(3):181–183

Fasim A, More VS, More SS (2021) Large-scale production of enzymes for biotechnology uses. Curr Opin Biotechnol 69:68–76

Sheldon RA, Basso A, Brady D (2021) New frontiers in enzyme immobilisation: robust biocatalysts for a circular bio-based economy. Chem Soc Rev 50(10):5850–5862

Sheldon RA, van Pelt S (2013) Enzyme immobilisation in biocatalysis: why, what and how. Chem Soc Rev 42(15):6223–6235

Bilal M, Fernandes CD, Mehmood T, Nadeem F, Tabassam Q, Ferreira LFR (2021) Immobilized lipases-based nano-biocatalytic systems—a versatile platform with incredible biotechnological potential. Int J Biol Macromol 175:108–122

Qamar SA, Qamar M, Bilal M, Bharagava RN, Ferreira LFR, Sher F, Iqbal HM (2021) Cellulose-deconstruction potential of nano-biocatalytic systems: a strategic drive from designing to sustainable applications of immobilized cellulases. Int J Biol Macromol 185:1–19

Barbosa O et al (2015) Strategies for the one-step immobilization–purification of enzymes as industrial biocatalysts. Biotechnol Adv 33(5):435–456

Liu S et al (2021) Smart chemistry of enzyme immobilization using various support matrices–a review. Int J Biol Macromol 190:396–408

Wu X, Liu S, Lou WY, Xiong J, Zong MH, Bilal M (2022) Metal organic frameworks for biocatalysis. In: Castro GR, Nadda AK, Yasin G (eds) Nanomaterials for biocatalysis. Elsevier, Amsterdam, pp 267–300

Han Z et al (2022) Metal-organic frameworks (MOFs): a novel platform for laccase immobilization and application. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2022.108795

Wang X, Lan PC, Ma S (2020) Metal–organic frameworks for enzyme immobilization: beyond host matrix materials. ACS Cent Sci 6(9):1497–1506

Drout RJ, Robison L, Farha OK (2019) Catalytic applications of enzymes encapsulated in metal–organic frameworks. Coord Chem Rev 381:151–160

Liang W et al (2021) Metal–organic framework-based enzyme biocomposites. Chem Rev 121(3):1077–1129

Du Y et al (2022) Metal-organic frameworks with different dimensionalities: an ideal host platform for enzyme@ MOF composites. Coord Chem Rev 454:214327

Liao F-S et al (2017) Shielding against unfolding by embedding enzymes in metal–organic frameworks via a de novo approach. J Am Chem Soc 139(19):6530–6533

Mehta J et al (2016) Recent advances in enzyme immobilization techniques: metal-organic frameworks as novel substrates. Coord Chem Rev 322:30–40

Li P et al (2018) Hierarchically engineered mesoporous metal-organic frameworks toward cell-free immobilized enzyme systems. Chem 4(5):1022–1034

Samui A et al (2016) Fabrication of a magnetic nanoparticle embedded NH2-MIL-88B MOF hybrid for highly efficient covalent immobilization of lipase. RSC Adv 6(71):66385–66393

Liu W-L et al (2013) Novel trypsin–FITC@ MOF bioreactor efficiently catalyzes protein digestion. J Mater Chem B 1(7):928–932

Chen Y et al (2012) Size-selective biocatalysis of myoglobin immobilized into a mesoporous metal–organic framework with hierarchical pore sizes. Inorg Chem 51(17):9156–9158

Lyu F et al (2014) One-pot synthesis of protein-embedded metal–organic frameworks with enhanced biological activities. Nano Lett 14(10):5761–5765

Karkman A, Pärnänen K, Larsson D (2019) Fecal pollution can explain antibiotic resistance gene abundances in anthropogenically impacted environments. Nat Commun 10(1):1–8

Qiao M et al (2018) Review of antibiotic resistance in China and its environment. Environ Int 110:160–172

Ebele AJ, Abdallah MA-E, Harrad S (2017) Pharmaceuticals and personal care products (PPCPs) in the freshwater aquatic environment. Emerg contam 3(1):1–16

Homem V, Santos L (2011) Degradation and removal methods of antibiotics from aqueous matrices–a review. J Environ Manage 92(10):2304–2347

Yang L et al (2021) Biodegradation pathway of penicillins by β-lactamase encapsulated in metal-organic frameworks. J Hazard Mater 414:125549

Doonan C et al (2017) Metal–organic frameworks at the biointerface: synthetic strategies and applications. Acc Chem Res 50(6):1423–1432

Brady D, Jordaan J (2009) Advances in enzyme immobilisation. Biotech Lett 31(11):1639–1650

Raja DS et al (2015) Immobilization of protein on nanoporous metal-organic framework materials. Comments Inorg Chem 35(6):331–349

Patra S et al (2015) Design of metal organic framework–enzyme based bioelectrodes as a novel and highly sensitive biosensing platform. J Mater Chem B 3(46):8983–8992

Liang W et al (2019) Enhanced activity of enzymes encapsulated in hydrophilic metal–organic frameworks. J Am Chem Soc 141(6):2348–2355

Hernandez K, Fernandez-Lafuente R (2011) Control of protein immobilization: coupling immobilization and site-directed mutagenesis to improve biocatalyst or biosensor performance. Enzyme Microb Technol 48(2):107–122

Jesionowski T, Zdarta J, Krajewska B (2014) Enzyme immobilization by adsorption: a review. Adsorption 20(5):801–821

Liang S et al (2020) Metal-organic frameworks as novel matrices for efficient enzyme immobilization: an update review. Coord Chem Rev 406:213149

Pedroche J et al (2007) Effect of the support and experimental conditions in the intensity of the multipoint covalent attachment of proteins on glyoxyl-agarose supports: correlation between enzyme–support linkages and thermal stability. Enzyme Microb Technol 40(5):1160–1166

Wu X, Hou M, Ge J (2015) Metal–organic frameworks and inorganic nanoflowers: a type of emerging inorganic crystal nanocarrier for enzyme immobilization. Catal Sci Technol 5(12):5077–5085

Cao S-L et al (2016) Novel nano-/micro-biocatalyst: soybean epoxide hydrolase immobilized on UiO-66-NH2 MOF for efficient biosynthesis of enantiopure (R)-1, 2-octanediol in deep eutectic solvents. ACS Sustain Chem Eng 4(6):3586–3595

Choi S, Oh M (2019) Well-arranged and confined incorporation of PdCo nanoparticles within a hollow and porous metal-organic framework for superior catalytic activity. Angew Chem 131(3):876–881

Lian X et al (2017) Enzyme–MOF (metal–organic framework) composites. Chem Soc Rev 46(11):3386–3401

Li P et al (2016) Nanosizing a metalorganic framework enzyme carrier for accelerating nerve agent hydrolysis. ACS Nano 10:9174–9182

Nguyen DT et al (2002) Stabilization of creatine kinase encapsulated in silicate sol−gel materials and unusual temperature effects on its activity. Chem Mater 14(10):4300–4306

Vinogradov VV, Avnir D (2014) Exceptional thermal stability of therapeutical enzymes entrapped in alumina sol–gel matrices. J Mater Chem B 2(19):2868–2873

Tranchemontagne DJ et al (2009) Secondary building units, nets and bonding in the chemistry of metal–organic frameworks. Chem Soc Rev 38(5):1257–1283

Gkaniatsou E et al (2017) Metal–organic frameworks: a novel host platform for enzymatic catalysis and detection. Mater Horiz 4(1):55–63

Liang K et al (2016) Enzyme encapsulation in zeolitic imidazolate frameworks: a comparison between controlled co-precipitation and biomimetic mineralisation. Chem Commun 52(3):473–476

Chen G et al (2019) A convenient and versatile amino-acid-boosted biomimetic strategy for the nondestructive encapsulation of biomacromolecules within metal–organic frameworks. Angew Chem Int Ed 58(5):1463–1467

Jung S et al (2011) Bio-functionalization of metal–organic frameworks by covalent protein conjugation. Chem Commun 47(10):2904–2906

Pisklak TJ et al (2006) Hybrid materials for immobilization of MP-11 catalyst. Top Catal 38(4):269–278

Xu C et al (2019) Functional metal–organic frameworks for catalytic applications. Coord Chem Rev 388:268–292

Liu X et al (2018) Rational design of mimic multienzyme systems in hierarchically porous biomimetic metal–organic frameworks. ACS Appl Mater Interfaces 10(39):33407–33415

Howarth AJ et al (2016) Chemical, thermal and mechanical stabilities of metal–organic frameworks. Nat Rev Mater 1(3):1–15

Shih YH et al (2012) Trypsin-immobilized metal–organic framework as a biocatalyst in proteomics analysis. ChemPlusChem 77(11):982–986

Wu X et al (2015) Polydopamine tethered enzyme/metal–organic framework composites with high stability and reusability. Nanoscale 7(45):18883–18886

Huo J et al (2015) Magnetic MOF microreactors for recyclable size-selective biocatalysis. Chem Sci 6(3):1938–1943

Zhao M, Zhang X, Deng C (2015) Rational synthesis of novel recyclable Fe3O4@ MOF nanocomposites for enzymatic digestion. Chem Commun 51(38):8116–8119

Wu X et al (2015) Facile synthesis of multiple enzyme-containing metal–organic frameworks in a biomolecule-friendly environment. Chem Commun 51(69):13408–13411

Mateo C et al (2007) Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme Microb Technol 40(6):1451–1463

Rodrigues RC, Berenguer-Murcia Á, Fernandez-Lafuente R (2011) Coupling chemical modification and immobilization to improve the catalytic performance of enzymes. Adv Synth Catal 353(13):2216–2238

Hwang ET, Gu MB (2013) Enzyme stabilization by nano/microsized hybrid materials. Eng Life Sci 13(1):49–61

Hou C et al (2015) Facile synthesis of enzyme-embedded magnetic metal–organic frameworks as a reusable mimic multi-enzyme system: mimetic peroxidase properties and colorimetric sensor. Nanoscale 7(44):18770–18779

Ma W et al (2013) Zeolitic imidazolate framework-based electrochemical biosensor for in vivo electrochemical measurements. Anal Chem 85(15):7550–7557

Gkaniatsou E et al (2018) Enzyme encapsulation in mesoporous metal–organic frameworks for selective biodegradation of harmful dye molecules. Angew Chem 130(49):16373–16378

Knedel TO et al (2019) Laccase encapsulation in ZIF-8 metal-organic framework shows stability enhancement and substrate selectivity. ChemistryOpen 8(11):1337–1344

Lissemore L et al (2006) An exposure assessment for selected pharmaceuticals within a watershed in Southern Ontario. Chemosphere 64(5):717–729

Wise R (2002) Antimicrobial resistance: priorities for action. J Antimicrob Chemother 49(4):585–586

Kümmerer K (2003) Significance of antibiotics in the environment. J Antimicrob Chemother 52(1):5–7

Minh TB et al (2009) Antibiotics in the Hong Kong metropolitan area: ubiquitous distribution and fate in Victoria Harbour. Mar Pollut Bull 58(7):1052–1062

Martinez JL (2009) The role of natural environments in the evolution of resistance traits in pathogenic bacteria. Proc Royal Soc B: Biol Sci 276(1667):2521–2530

Kostich MS, Lazorchak JM (2008) Risks to aquatic organisms posed by human pharmaceutical use. Sci Total Environ 389(2–3):329–339

Rodrigues RC et al (2013) Modifying enzyme activity and selectivity by immobilization. Chem Soc Rev 42(15):6290–6307

Gao X et al (2018) Immobilized β-lactamase on Fe3O4 magnetic nanoparticles for degradation of β-lactam antibiotics in wastewater. Int J Environ Sci Technol 15(10):2203–2212

Deng S et al (2019) Fluorescence resonance energy transfer-mediated immunosensor based on design and synthesis of the substrate of amp cephalosporinase for biosensing. Anal Chem 91(17):11316–11323

Bu Q et al (2013) Pharmaceuticals and personal care products in the aquatic environment in China: a review. J Hazard Mater 262:189–211

Liu J-L, Wong M-H (2013) Pharmaceuticals and personal care products (PPCPs): a review on environmental contamination in China. Environ Int 59:208–224

Tohidi F, Cai Z (2015) GC/MS analysis of triclosan and its degradation by-products in wastewater and sludge samples from different treatments. Environ Sci Pollut Res 22(15):11387–11400

Zhao J-L et al (2013) Evaluation of triclosan and triclocarban at river basin scale using monitoring and modeling tools: implications for controlling of urban domestic sewage discharge. Water Res 47(1):395–405

Jia Y et al (2019) Immobilization of laccase onto meso-MIL-53 (Al) via physical adsorption for the catalytic conversion of triclosan. Ecotoxicol Environ Saf 184:109670

Zhang C et al (2020) An effective in-situ method for laccase immobilization: excellent activity, effective antibiotic removal rate and low potential ecological risk for degradation products. Bioresour Technol 308:123271

Salem-Milani A et al (2013) Antibacterial effect of diclofenac sodium on Enterococcus faecalis. J dent (Tehran, Iran) 10(1):16

Ren Z, Luo J, Wan Y (2018) Highly permeable biocatalytic membrane prepared by 3D modification: metal-organic frameworks ameliorate its stability for micropollutants removal. Chem Eng J 348:389–398

Calvete MJ et al (2019) Hybrid materials for heterogeneous photocatalytic degradation of antibiotics. Coord Chem Rev 395:63–85

Wang J, Zhuan R (2020) Degradation of antibiotics by advanced oxidation processes: an overview. Sci Total Environ 701:135023

Chaturvedi P et al (2021) Recent advancement in remediation of synthetic organic antibiotics from environmental matrices: challenges and perspective. Bioresour Technol 319:124161

Russell JN, Yost CK (2021) Alternative, environmentally conscious approaches for removing antibiotics from wastewater treatment systems. Chemosphere 263:128177

Leng L et al (2020) Use of microalgae based technology for the removal of antibiotics from wastewater: a review. Chemosphere 238:124680

Lykourinou V et al (2011) Immobilization of MP-11 into a mesoporous metal–organic framework, MP-11@ mesoMOF: a new platform for enzymatic catalysis. J Am Chem Soc 133(27):10382–10385

Wen X et al (2019) Immobilized laccase on bentonite-derived mesoporous materials for removal of tetracycline. Chemosphere 222:865–871

Shao B et al (2019) Immobilization of laccase on hollow mesoporous carbon nanospheres: noteworthy immobilization, excellent stability and efficacious for antibiotic contaminants removal. J Hazard Mater 362:318–326

Zhong X et al (2021) Fabrication and application of a novel electrochemical biosensor based on a mesoporous carbon sphere@ UiO-66-NH 2/Lac complex enzyme for tetracycline detection. Analyst 146(9):2825–2833

Xu R et al (2015) Enhancement of catalytic activity of immobilized laccase for diclofenac biodegradation by carbon nanotubes. Chem Eng J 262:88–95

Li P et al (2016) Toward design rules for enzyme immobilization in hierarchical mesoporous metal-organic frameworks. Chem 1(1):154–169

Wei T-H et al (2019) Rapid mechanochemical encapsulation of biocatalysts into robust metal–organic frameworks. Nat Commun 10(1):1–8

Acknowledgements

The research leading to these results has received funding from the Norwegian Financial Mechanism 2014-2021 under the Project number 2020/37/K/ST8/03805.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saddique, Z., Imran, M., Javaid, A. et al. Enzyme-Linked Metal Organic Frameworks for Biocatalytic Degradation of Antibiotics. Catal Lett 154, 81–93 (2024). https://doi.org/10.1007/s10562-022-04261-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04261-3