Abstract

The epoxidation of 2,5-dimethyl furan leads to the production of hex-3-ene-2,5-dione via a ring opening rearrangement reaction. A second epoxidation reaction could then enable a further ring closing rearrangement to form 4-hydroxy-2,5-dimethyl-3-furanone (furaneol). In this paper we report the use of gold and gold palladium supported on graphite and titania as catalysts for the ring opening reaction of 2,5-dimethyl furan. We show that by tuning the reaction conditions high selectivity towards hex-3-ene-2,5-dione can be achieved using green chemical methods and mild reaction conditions.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently there has been considerable interest in the use of supported gold as catalysts for oxidation reactions [1,2,3,4,5,6]. This is due to its high activity and the green nature of using catalysis for chemical transformations. Studies have shown that cyclohexene and cyclooctene can be oxidised to their respective epoxides using supported gold catalysts [7]. High selectivity can be achieved to the epoxide by tuning the reaction conditions, primarily the solvent. Hetrogeneous catalysis is a key process in the manufacture of a large range of bulk and fine chemicals. Since the discovery that supported Au nanoparticles can be used in catalysis [8, 9] there has been increased interest in the application of Au in oxidation catalysis. Supported gold catalysts have been shown to be highly stable under oxidation reaction conditions and nano-particulate gold on a range of oxide supports has been used for a range of applications such as CO oxidation [10,11,12], CO oxidation in the presence of H2, H2O and CO2 for fuel cells [13, 14], the oxidation of alkenes [15,16,17,18] and alcohols [19, 20], including polyols such as glycerol [21]. Gold supported on TiO2 and TS-1 have been shown to be very active for the epoxidation of propene to propene oxide in the presence of H2 and O2 via the formation of a peroxy intermediate [22, 23]. However, the use of a sacrificial reductant is not ideal for green applications, and the use of pure O2 is preferred. Caps and co-workers [24] have shown that supported gold catalysts can be used to convert trans-stilbene into trans-stilbene oxide in the presence of molecular oxygen. In this case titania was found to be the a better support than carbon or iron oxide in terms of epoxide yield.

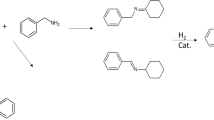

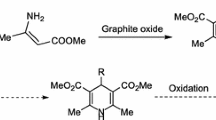

The initial oxidation of 2,5-dimethylfuran to form hex-3-ene-2,5-dione has been reported using several different methods (Scheme 1). One of the most successful was reported by Adger et al. [25] who used dimethyldioxirane as an oxidant at room temperature using acetone as a solvent. With one equivalent of dimethyldioxirane quantitative yield of hex-3-ene-2,5-dione was obtained. Finlay et al. [26] found that methytrioxoruthenium in combination with urea hydrogen peroxide could also be used to ring open furan systems. The reaction was carried out at room temperature and gave a yield of 97% of hex-3-ene-2,5-dione. Massa et al. [27] used a Mo(CO)6/cumyl hydroperoxide system to oxidise 2,5-dimethyl furan, 2 mmol of 2,5-dimethyl furan was converted by Mo(CO)6 in chloroform at 50 °C with a yield of 94%. Wahlen et al. [28] used titanium silicate (TS-1) and hydrogen peroxide to oxidise various furan derivatives achieving 94% conversion with a selectivity of 85% to hex-3-ene-2,5-dione. While these processes give high yields of hex-3-ene-2,5-dione they are often carried out on a small scale, with large amounts of solvent and therefore cannot be called green processes. The further oxidation of hex-3-ene-2,5-dione could lead to 3,4-dihydroxyhexane-2,5-dione. Briggs et al. [29] have shown that 3,4-dihydroxyhexane-2,5-dione can be converted into furaneol; refluxing an aqueous solution of 3,4-dihydroxyhexane-2,5-dione for 7 days with piperidinium acetate resulted in the production of furaneol with a 48% yield. In this paper we show that by tuning the reaction conditions it is possible to achieve a high conversion and high selectivity towards hex-3-ene-2,5-dione while applying the principles of green chemistry using gold-containing heterogeneous catalysts.

2 Experimental

2.1 Catalyst Preparation

Gold nanoparticle catalysts were prepared supported on titania (P25 Degussa) or graphite (Aldrich), using a wet impregnation technique. The monometallic 2.5 wt%Au and bimetallic 2.5 wt%Au–2.5 wt%Pd were prepared by impregnation of the support using aqueous solutions of palladium chloride (Johnson Matthey) and HAuCl4·3H2O (Johnson Matthey). The detailed procedure for the preparation of the 2.5 wt%Au–2.5 wt%Pd/support catalyst (2 g) is as follows: palladium chloride (83.3 mg) was dissolved in a stirred and heated aqueous solution (5 ml) of HAuCl4 (5 g in 250 ml water). The resultant solution was added to the support (1.9 g) and stirred until it formed a slurry, this was dried at 80 °C for 16 h. The resultant powder was ground and calcined (1 g, 15 cm quartz boat) in static air at 400 °C for 3 h at a ramp rate of 20 °C min−1. We have previously reported the characterisation of Au–Pd catalysts prepeared by this methodology, and have shown that the metal particles are bi-modal in their size distribution with the majority of metal particles in the < 15 nm range, but with a significant amount of the metal present as large particles 15–300 nm [30,31,32]. Catalyst recovery for resue testing was attempted however the catalyst proved disfficult to sperate from the product mixture.

2.2 Catalyst Testing

Catalyst testing was performed using a Parr Instruments stainless steel autoclave with a nominal volume of 50 ml and a maximum working pressure of 207 bar. The reactor was charged with 2,5-dimethyl furan (20 ml, Sigma Aldrich), catalyst and radical initiator (TBHP, when required, 70% in water, Sigma Aldrich). The autoclave was then purged three times with oxygen leaving the vessel at the desired pressure (5–30 bar). The pressure was maintained at a constant level throughout the experiment; as the oxygen was consumed in the reaction it was replenished. The effect of pressure during the reaction was studied by varying the initial O2 pressure in the reactor. The reaction was carried out at a number of temperatures (3–75 °C, temperatures > 85 °C resulted in exothermic reaction run-away). The stirrer speed was set at 1500 rpm and the reaction mixture was raised and maintained at the required temperature. Samples were taken from the final reaction mixture and analysed by GC (Varian star 3800) using a CP-Wax column. Carbon balances were calculated and for all the experiments reported were in the range of 80–120% except when reaction run away occurred where it is anticipated that it was significantly lower.

3 Results and Discussion

Following the work of Hughes et al. [7], who successfully demonstrated that 1%Au/graphite is an effective catalyst for the epoxidation of cyclohexene a 2.5%Au/graphite catalyst was used to investigate the oxidation of 2,5-dimethylfuran. Initial attempts to oxidise 2,5-dimethylfuran were carried out at low temperature, either ambient (23 °C) or cooled by ice (3 °C). Under these conditions, the conversion of 2,5-dimethylfuran was negligible after 2 h (Fig. 1).

When the temperature was raised to 50 °C, around 10% conversion was observed after 2 h, however, when the temperature was further raised to 75 °C almost complete conversion of the 2,5-dimethylfuran was achieved (Fig. 1). For all the reported temperatures the selectivity towards hex-3-ene-2,5-dione remained constant (around 60%). Above 85 °C reaction runaway occurred, resulting in a rapid and uncontrollable spike in temperature and pressure. The result of this experiment was a mixture of hex-3-ene-2,5-dione and a black tar-like substance. The tar-like substance was insoluble so could not be analysed, this also meant the mass balance could not be calculated in this experiment, however we anticipate it would be very low. Further reactions were restricted to a maximum temperature of 75 °C to avoid this problem. The formation of hex-3-ene-2,5-dione could occur if the initial oxidation reaction leads to the epoxidation of one of the double bonds in the furan. The epoxidation of cyclohexene by supported gold catalysts is a known reaction [7] and the epoxidation mechanism for this ring opening has been proposed by Whalen et al. [28] who used titania silicate as a catalyst and hydrogen peroxide as an oxidant to oxidise various furan derivatives.

As we have previously reported TiO2 as an effective support for gold catalysts we also synthesised an analogous 2.5%Au/TiO2 catalyst and contrasted this with the graphite supported gold. At 20 bar O2 pressure and at 75 °C the initial activity of the 2.5 wt%Au/graphite catalyst was higher than the 2.5%Au/TiO2, however, as shown in Fig. 2, at longer reaction times the activity of the TiO2 increased and reached 97% 2,5-dimethylfuran conversion compared to 72% for the graphite supported catalyst. The initially slower rwaction, followed by a faster reaction is indicative of a readical pathway occurring when the titania supported catalyst is used, while this leads to a higher activiy at longer times the results are more variable, the selectivities towards hex-3-ene-2,5-dione (Fig. 3) of the two catalysts were similar, the differences between the selectivities can be attributed to the differences in conversion in the sequential reaction shown in Scheme 1. At iso-conversion (20%) the selectivity towards 2,5-dimethyl furan is almost the same (~ 61%) suggesting that the same products are being formed whether there are redical pathways in operation or not.

We have previously reported a strong synergistic effect of combining gold and palladium, therefore 2.5%Au2.5%Pd catalysts were prepared on both graphite and titania. The activity trend for the supports follows the same pattern as the monometallic gold catalysts (Fig. 4). Whilst the conversion after 1 h is similar the initial activity of the bimetallic catalysts is higher, suggesting there is some synergistic effect of combining the two metals. It is worth noting, that these catalysts contained more metal so higher activity would be expected in this case. The selectivity towards hex-3-ene-2,5-dione (Fig. 4) was similar to that observed with the monometallic catalyst, the small difference in selectivity is directly related to the difference in the conversion (Fig. 5).

In our previous work [7] we have shown that using a radical initiator can increase the initial rate of reaction. To investigate whether it is advantageous to use a radical initiator for this oxidation, reactions were carried out with the addition of tertiarybutylhydroperoxide (TBHP). As the AuPd catalyst had shown the highest activity this catalyst was selected for this study. The addition of TBHP [0.116 cm3, 205 mol/mol (substarte/TBHP)] led to an increase in the initial reaction rate for both the TiO2 and graphite supported AuPd catalysts (Fig. 6), however, the conversion of 2,5-dimethyl furan over the 60 min reaction run the initiator did not lead to a significant improvement in the conversion of 2,5-dimethylfuran. In each case the selectivity towards hex-3-ene-2,5-dione was similar for each catalyst (Fig. 7; Scheme 2).

The effect of oxygen pressure was studied next, however, to investigate the effects of pressure on the product selectivity of the sequential reaction longer timescale experiments were required, due to the previously described problems with exothermic reaction run-away, longer reactions were limited to 50 °C. The catalyst selected for this study was 2.5%Au–2.5%Pd/graphite as this catalyst had displayed the highest initial activities in the previous reactions. Initially the oxygen pressure was increased to 20 and subsequently 30 bar, however, the selectivity towards hex-3-ene-2,5-dione decreased as the pressure increased (Fig. 8), most likely due to over-oxidation to form furaneol. The conversion of 2,5-dimethyl furan is shown in Fig. 9 and it is clear that increasing the pressure to 20 and 30 bar did not lead to an increase in the conversion. Subsequently the pressure of oxygen was reduced to 5 bar, again shown in Figs. 8 and 9.

The decrease in the oxygen pressure did not have a detrimental effect on the conversions of 2,5-dimethyl furan but did, however, have a positive effect on the selectivity towards hex-3-ene-2,5-dione with a maximum selectivity of ~ 80% towards hex-3-ene-2,5-dione achieved. In view of these results a longer reaction was carried out at 1 bar O2 pressure (Figs. 10, 11), under these conditions the conversion of 2,5-dimethylfuran was almost complete after 24 h and the selectivity towards hex-3-ene-2,5-dione was consistently the highest displayed under any of the reaction conditions studied in this work suggesting that the ring opening reaction to give hex-3-ene-2,5-dione is zero order with respect to oxygen pressure but the subsequent sequential reaction to form furaneol is more favourable under high pressures of oxygen.

4 Conclusions

We have demonstrated that the ring opening oxidation of 2,5-dimethylfuran to yield hex-3-ene-2,5-dione can be carried out using various gold catalysts, most likely occurring via the epoxidation of one of the furan double bonds. By tuning the reaction conditions, specifically the use of different supports, the addition of a radical initiator and control of the oxygen pressure high selectivity to hex-3-ene-2,5-dione can be achieved. By using heterogeneous catalysts, solvent free conditions and eliminated sacrificial reactants the reaction is considerably more environmentally benign than those that have been reported previously. The highest selectivity towards hex-3-ene-2,5-dione was achieved at the lowest pressure of oxygen, this suggests that the formation of sequential oxidation products is more favourable at higher pressures.

References

Kesavan L, Tiruvalam R, Ab Rahim MH, bin Saiman MI, Enache DI, Jenkins RL, Dimitratos N, Lopez-Sanchez JA, Taylor SH, Knight DW, Kiely CJ, Hutchings GJ (2011) Solvent-free oxidation of primary carbon-hydrogen bonds in toluene using Au-Pd alloy nanoparticles. Science (Washington, DC) 331(6014):195–199. https://doi.org/10.1126/science.1198458

Zhang Y, Cui X, Shi F, Deng Y (2012) Nano-gold catalysis in fine chemical synthesis. Chem Rev (Washington, DC) 112(4):2467–2505. https://doi.org/10.1021/cr200260m

Katryniok B, Kimura H, Skrzynska E, Girardon J-S, Fongarland P, Capron M, Ducoulombier R, Mimura N, Paul S, Dumeignil F (2011) Selective catalytic oxidation of glycerol: perspectives for high value chemicals. Green Chem 13(8):1960–1979. https://doi.org/10.1039/c1gc15320j

Zi W, Dean Toste F (2016) Recent advances in enantioselective gold catalysis. Chem Soc Rev 45(16):4567–4589. https://doi.org/10.1039/c5cs00929d

Zheng Z, Wang Z, Wang Y, Zhang L (2016) Au-catalysed oxidative cyclisation. Chem Soc Rev 45(16):4448–4458. https://doi.org/10.1039/c5cs00887e

Abis L, Freakley SJ, Dodekatos G, Morgan DJ, Sankar M, Dimitratos N, He Q, Kiely CJ, Hutchings GJ (2017) Highly active gold and gold–palladium catalysts prepared by colloidal methods in the absence of polymer stabilizers. ChemCatChem 9(15):2914–2918. https://doi.org/10.1002/cctc.201700483

Hughes MD, Xu Y-J, Jenkins P, McMorn P, Landon P, Enache DI, Carley AF, Attard GA, Hutchings GJ, King F, Stitt EH, Johnston P, Griffin K, Kiely CJ (2005) Tunable gold catalysts for selective hydrocarbon oxidation under mild conditions. Nature 437(7062):1132–1135

Hutchings GJ (1985) Vapor phase hydrochlorination of acetylene: correlation of catalytic activity of supported metal chloride catalysts. J Catal 96(1):292–295. https://doi.org/10.1016/0021-9517(85)90383-5

Haruta M, Kobayashi T, Sano H, Yamada N (1987) Novel gold catalysts for the oxidation of carbon monoxide at a temperature far below 0 °C. Chem Lett 16(2):405–408. https://doi.org/10.1246/cl.1987.405

Herzing AA, Kiely CJ, Carley AF, Landon P, Hutchings GJ (2008) Identification of active gold nanoclusters on iron oxide supports for CO oxidation. Science (Washington, DC) 321(5894):1331–1335 https://doi.org/10.1126/science.1159639

Lopez N, Janssens TVW, Clausen BS, Xu Y, Mavrikakis M, Bligaard T, Norskov JK (2004) On the origin of the catalytic activity of gold nanoparticles for low-temperature CO oxidation. J Catal 223(1):232–235. https://doi.org/10.1016/j.jcat.2004.01.001

Schubert MM, Hackenberg S, van Veen AC, Muhler M, Plzak V, Behm RJ (2001) CO oxidation over supported gold catalysts—“Inert” and “active” support materials and their role for the oxygen supply during reaction. J Catal 197(1):113–122. https://doi.org/10.1006/jcat.2000.3069

Bond GC, Thompson DT (1999) Catalysis by gold. Catal Rev Sci Eng 41(3 & 4):319–388. https://doi.org/10.1081/CR-100101171

Fu Q, Saltsburg H, Flytzani-Stephanopoulos M (2003) Active nonmetallic Au and Pt species on ceria-based water-gas shift catalysts. Science (Washington, DC) 301(5635):935–938. https://doi.org/10.1126/science.1085721

Hashmi ASK (2005) The catalysis gold rush: new claims. Angew Chem Int Ed 44(43):6990–6993. https://doi.org/10.1002/anie.200502735

Alshammari H, Miedziak PJ, Bawaked S, Knight DW, Hutchings GJ (2012) Solvent-free liquid-phase oxidation of 1-hexene using supported gold catalysts. ChemCatChem 4(10):1565–1571. https://doi.org/10.1002/cctc.201200273

Alshammari H, Miedziak PJ, Knight DW, Willock DJ, Hutchings GJ (2013) The effect of ring size on the selective oxidation of cycloalkenes using supported metal catalysts. Catal Sci Technol 3(6):1531–1539. https://doi.org/10.1039/c3cy20864h

Alshammari H, Miedziak PJ, Morgan DJ, Knight DW, Hutchings GJ (2013) Control of the selectivity in multi-functional group molecules using supported gold-palladium nanoparticles. Green Chem 15(5):1244–1254. https://doi.org/10.1039/c3gc36828a

Tsunoyama H, Sakurai H, Negishi Y, Tsukuda T (2005) Size-specific catalytic activity of polymer-stabilized gold nanoclusters for aerobic alcohol oxidation in water. J Am Chem Soc 127(26):9374–9375. https://doi.org/10.1021/ja052161e

Villa A, Janjic N, Spontoni P, Wang D, Su DS, Prati L (2009) Au-Pd/AC as catalysts for alcohol oxidation: effect of reaction parameters on catalytic activity and selectivity. Appl Catal A 364(1–2):221–228. https://doi.org/10.1016/j.apcata.2009.05.059

Brett GL, He Q, Hammond C, Miedziak PJ, Dimitratos N, Sankar M, Herzing AA, Conte M, Lopez-Sanchez JA, Kiely CJ, Knight DW, Taylor SH, Hutchings GJ (2011) Selective oxidation of glycerol by highly active bimetallic catalysts at ambient temperature under base-free conditions. Angew Chem Int Ed 50(43):10136–10139. https://doi.org/10.1002/anie.201101772

Huang J, Akita T, Faye J, Fujitani T, Takei T, Haruta M (2009) Propene epoxidation with dioxygen catalyzed by gold clusters. Angew Chem Int Ed 48(42):7862–7866. https://doi.org/10.1002/anie.200903011

Sinha AK, Seelan S, Tsubota S, Haruta M (2004) A three-dimensional mesoporous titanosilicate support for gold nanoparticles: vapor-phase epoxidation of propene with high conversion. Angew Chem Int Ed 43(12):1546–1548. https://doi.org/10.1002/anie.200352900

Lignier P, Morfin F, Piccolo L, Rousset J-L, Caps V (2007) Insight into the free-radical chain mechanism of gold-catalyzed hydrocarbon oxidation reactions in the liquid phase. Catal Today 122(3–4):284–291

Adger BM, Barrett C, Brennan J, McKervey MA, Murray RW (1991) Oxidation of furans with dimethyldioxirane. J Chem Soc Chem Commun (21):1553–1554

Finlay J, McKervey MA, Gunaratne HQN (1998) Oxidations catalyzed by rhenium(V) oxo species 1. Conversion of furans to enediones using methyltrioxorhenium and urea hydrogen peroxide. Tetrahedron Lett 39(31):5651–5654

Massa A, Acocella MR, De Rosa M, Soriente A, Villano R, Scettri A (2003) Mo(CO)6-catalyzed oxidation of furan derivatives to E- and Z-enediones by cumyl hydroperoxide. Tetrahedron Lett 44(4):835–837

Wahlen J, Moens B, De Vos DE, Alsters PL, Jacobs PA (2004) Titanium silicalite 1 (TS-1) catalyzed oxidative transformations of furan derivatives with hydrogen peroxide. Adv Synth Catal 346(2–3):333–338

Briggs MA, Haines AH, Jones HF (1985) Synthesis of 4-hydroxy-2,5-dimethylfuran-3(2H)-one (furaneol) from (2R,3R)-tartaric acid. J Chem Soc Perkin Trans 1(4):795–798

Edwards JK, Carley AF, Herzing AA, Kiely CJ, Hutchings GJ (2008) Direct synthesis of hydrogen peroxide from H2 and O2 using supported Au-Pd catalysts. Faraday Discuss 138(0):225–239. https://doi.org/10.1039/B705915A

Villa A, Dimitratos N, Chan-Thaw CE, Hammond C, Veith GM, Wang D, Manzoli M, Prati L, Hutchings GJ (2016) Characterisation of gold catalysts. Chem Soc Rev 45(18):4953–4994. https://doi.org/10.1039/c5cs00350d

Carrettin S, McMorn P, Johnston P, Griffin K, Kiely CJ, Attard GA, Hutchings GJ (2004) Oxidation of glycerol using supported gold catalysts. Top Catal 27(1–4):131–136

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Miedziak, P.J., Edwards, J.K., Taylor, S.H. et al. Gold as a Catalyst for the Ring Opening of 2,5-Dimethylfuran. Catal Lett 148, 2109–2116 (2018). https://doi.org/10.1007/s10562-018-2415-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-018-2415-3