Abstract

Reductive amination of cyclohexanone with benzylamine was investigated at 100 °C under 30 bar hydrogen in toluene with five different gold catalysts prepared by deposition–precipitation method and supported on TiO2, La2O3/TiO2, CeO2/TiO2, La2O3 and CeO2. Size of metallic gold varied in the range of 2.6–3.6 nm. The best catalysts in reductive amination of cyclohexanone with benzylamine were 4 wt% Au/TiO2 and 4 wt% Au/CeO2/TiO2 giving 72% and 79% yield of the desired amine. The most acidic and basic catalysts were also unselective and exhibited low activity towards imine hydrogenation. The best catalyst 4 wt% Au/CeO2/TiO2 gave in reductive amination of propiophenone 56% selectivity to the corresponding amine at 20% conversion in 5 h.

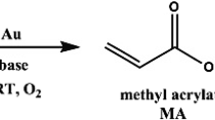

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Secondary amines are important intermediates used for production of pharmaceuticals. Several methods can be used for their production, such as hydroamination of alkynes using homogeneous metal complexes [1], ethylmagnesiation of imines with homogeneous metal complexes [2], reductive amination in ionic liquids [3], reductive allylation of amides using homogeneous catalysts [4], as well as reductive amination using heterogeneous metal catalysts [5,6,7].

Hydroamination of alkynes has been conducted using titanium indenyl complexes. In the first step of the reaction 1-phenylpropyne reacted with benzylamine with [Ind2TiMe2] complex as a catalyst at 105 °C in 2 h in toluene followed by hydrogenation of imine in methanol for 20 h using NaBH3CN as a reducing agent in the presence of ZnCl2 at 25 °C giving N-benzyl-1-phenylpropan-1-amine. As a result a mixture of regio-isomers was obtained [1]. In addition, α-ethyl-N-(phenylmethyl)benzenemethaneamine was produced via ethylmagnesiation (EtMgCl) of the corresponding imine in the presence of a homogeneous catalyst, zirconocene dichloride (di(cyclopentadienyl)zirconium(IV) dichloride, Cp2ZrCl2) in tetrahydrofuran under argon atmosphere giving 90% yield at 20 °C after 8 h [2].

N-benzyl-1-phenylpropan-1-amine with 86% yield after 3 h at room temperature has been synthesized via reductive allylation of N-benzylbenzamide using a homogeneous iridium complex as a catalyst in dichloromethane [4]. In addition, N-alkylation of aromatic alcohols over non-noble metal catalysts for production of amines such as via hydrogen borrowing mechanism [8], was done with benzyl alcohol and cyclohexylamine as reactants over NiCuFeO in xylene under reflux giving 89% yield of cyclohexylbenzenemethaneamine in 24 h.

Heterogeneous catalysts, such as Pd/C, Pt/C and Rh/C [5] and Au/TiO2 [6] have been used in reductive amination of ketones. In particular Pd/C, Pt/C and Rh/C [5] were active in amination of aldehydes and ketones in the absence of hydrogen, requiring, however, high pressure of CO. Reductive amination of benzaldehyde with p-anisidine was performed in the presence of 95 bar CO at 140 °C in tetrahydrofuran over Rh/C catalyst giving 50% of the corresponding amine after 42 h [5]. A carbon based solid acid catalyst of the overall composition CH0.6O0.35S0.14 prepared by sulfonation of naphthalene with sulfuric acid at 200–300 °C [9] was used in reductive amination of cyclohexanone with benzylamine allowing 90% yield of N-benzylcyclohexyamine in 10 min at room temperature with NaBH4 as a reducing agent [10]. Au/TiO2 was reported as an efficient catalyst for reductive amination of cyclohexanone with benzylamine at 60 °C in tert-butanol using formic acid as a hydrogen source [6]. Unsupported ionic liquid (carboxymethyl)-1-methyl-1H-imidazol-3-ium-bis(trifluoromethyl)sulfonyl)amine has also been applied as a catalyst in the same reaction using formic acid and triethylamine as hydrogen sources at 40 °C in acetonitrile as a solvent [3]. The authors [3] achieved the yield of amine of 30% after 5 h.

Imines have been hydrogenated using isopropanol as a hydrogen source in transfer hydrogenation and Funk’s iron complex together with Fe(acac)3 as a catalyst under nitrogen atmosphere at 110 °C under 48 h facilitating formation of N(E)-N-(1-phenylpropylidene)-benzenemethaneamine with 98% yield [11].

Based on a recent study [6], describing Au/TiO2 and formic acid as a catalyst and a hydrogen source in reductive amination of cyclohexanone with benzylamine, it was decided to explore catalytic behavior of different Au supported catalysts in reductive amination of cyclohexanone and propiophenone with benzylamine using instead of formic acid as a hydrogen source molecular hydrogen, which has clear advantages in the case of industrial implementation compared to formic acid, namely lower costs and no CO2 release.

2 Experimental

2.1 Catalyst Preparation and Characterization

Aeroxide® Titania P25 (Evonik Degussa GmbH), lanthanum(III) oxide (Merck), cerium(IV) oxide (Merck) were used as supports. For comparative studies, titania was modified with ceria and lanthana by impregnating with aqueous solutions of the corresponding nitrates (molar ratio Ti/M = 40, M–Ce or La). The catalysts (4wt%Au/TiO2, 4wt%Au/MxOy/TiO2 (where MxOy–CeO2 or La2O3), 4wt%Au/CeO2 and 4wt%Au/La2O3) were prepared by the deposition–precipitation method with urea, previously described in ref. [12]. Gold(III) chloride trihydrate (Merck) was used as a gold precursor. The nominal gold content in all catalysts was 4 wt%. After the gold deposition and drying procedure, the materials were treated in a reducing atmosphere (H2) at 300 °C for 1 h.

The specific surface area (SBET) of the supports and catalysts was measured by nitrogen adsorption method (“TriStar 3000” analyzer, Micromeritics, USA). The phase composition of the materials was studied by XRD (Philips XPert PRO diffractometer). The measured diffractograms were analyzed with the ICDD-2013 powder diffraction database and Inorganic Crystal Structure Database (ICSD) [13]. Catalysts morphology and the gold cluster size were investigated by transmission electron microscopy and scanning transmission electron microscopy-High Angle Annular Dark Field (JEOL JEM-2100F). The gold content was measured by energy dispersive spectroscopy (JEOL JEM-2100F with an Oxford INCA X-sight system detector) and inductively coupled plasma optical emission spectrometry (Perkin Elmer ICP-OES Optima 3300 DV spectrometer). The electronic state of gold on the support surface was determined by XPS (SPECS Surface Nano Analysis GmbH, Berlin, Germany). The concentration of basic and acid sites, and their distribution in supports and catalysts were investigated by temperature programmed desorption (TPD) of CO2 (Autochem 2900 apparatus) and NH3 (Chemosorb–chemisorption analyzer), respectively.

Details on the catalysts preparation and characterization are reported in the Electronic supplementary material.

2.2 Catalyst Testing

Reductive amination of cyclohexanone (Sigma Aldrich ≥ 99.5%) and propiophenone (Kebo Lab > 99%) with benzylamine (Fluka ≥ 99%), was performed in an autoclave using toluene as a solvent. In a typical experiment 6.6 mmol of ketone and 6.6 mmol of benzylamine in 50 ml solvent were mixed with 100 mg of catalyst. Thereafter, the reactor was flushed with hydrogen and after reaching the desired temperature and pressure, the reaction was started. The stirring rate was 900 rpm and small catalyst particles, below 63 µm were used to suppress the external and internal mass transfer limitations. The samples were taken from the reactor and analyzed by GC equipped with a FID detector and a capillary column, HP-5 (length 30 m, internal diameter 320 µm, film thickness 0.50 µm) with the following temperature programme: 100 °C (5 min)–5 °C/min–320 °C (5 min). The products were confirmed by GC–MS.

NMR spectra were recorded on a Bruker AVANCE III spectrometer equipped with a BB/1H SmartProbe operating at 500.10 MHz (1H) and 125.8 MHz (13C). 15N-1H HMBC were recorded on a Bruker AVANCE III spectrometer equipped with a Prodigy BBO CryoProbe operating at 500.20 MHz (1H) and 50.59 MHz (15N). The spectra were calibrated against an internal standard TMS (tetramethylsilane, δ1H = 0.0 ppm, δ13C = 0.0 ppm) or residual solvent signals (DMSO-d6: δ1H = 2.50 ppm, δ13C = 39.5 ppm). All spectra were recorded at 25 °C and a standard set of 1H, 13C, DQF-COSY, HSQC (multiplicity edited, CH/CH3 signals positive, CH2 signals negative) and HMBC (with a threefold low-pass J-filter to suppress one-bond correlations) experiments was acquired.

2.3 Quantum Mechanical Calculations

The stability of imine structures (1D) (E)-N-(cyclohexylmethyl)-1-phenylpropan-1-imine and (1C) N-(cyclohexylmethyl)-1-phenylpropan-1-imine was studied by a multi-level deterministic structural optimization using the Forcite, Conformers and DMol3 modules in the software Materials studio version 7.0 [14, 15]. At molecular mechanics (MM) level, the Universal Force Field was applied as implemented in the Conformers module. The most stable conformers were optimized with density functional theory applying the B3LYP hybrid functional [16,17,18,19] the DNP basis set and Grimme’s method for DFT-D (dispersion) correction [20] as implemented in the DMol3 module. Vibrational frequencies were also calculated in order to obtain thermodynamic data of the stabilities.

3 Results and Discussion

3.1 Catalyst Characterization Results

The phase composition of the studied catalysts was investigated by XRD (Fig. 1). Analysis of diffractograms of 4wt%Au/TiO2, 4wt%Au/La2O3/TiO2, 4wt%Au/CeO2/TiO2 and their corresponding supports (Fig. 1a, b, c) showed absence of any diffraction peaks characteristic for gold, ceria or lanthana, implying that their size is lower than 3–4 nm (i.e. sensitivity of XRD) or that they are X-ray amorphous. For these samples, only reflections characteristic of titania (P25) were observed [21]. Previously, this was also reaffirmed by XRD-SR [22], where the reflections related to additives (CeO2) were only detected for 4wt%Au/CeO2/TiO2.

The XRD pattern of CeO2 (Fig. 1d) revealed all of the major characteristic peaks of CeO2 corresponding to the (111), (200), (220), (400), (311), (222) and (420) planes, which are very close to the face centered cubic CeO2 crystal [23] indicating the cubic fluorite structure (JCPDS file No: 81-0792). No changes in the phase composition or the support structure were detected after gold deposition. Moreover, no reflections related to the Au NPs were observed as mentioned above.

The diffractogram of La2O3 (Fig. 1e) consisted of peaks related to hexagonal [24] and monoclinic [25] polymorphs of La2O2(CO3). Deposition of gold on La2O3 surface leads to a change in its structure and composition. The diffractogram of 4 wt%Au/La2O3 consisted of peaks related to La(OH)3 (hexagonal) [26] and La2(CO3)2(OH)2 (orthorhombic) [27], while no peaks related to Au were seen.

The highest specific surface area (SBET) was measured for 4 wt%Au/TiO2 being 50 m2/gcat (Table 1). Loading of 4 wt% Au on TiO2 decreased its surface area by 15%. Both addition of CeO2 and La2O3 decreased the specific surface area of 4wt%Au/La2O3/TiO2 and 4wt%Au/CeO2/TiO2 in comparison with 4wt%Au/TiO2. The lowest specific surface area was determined for 4wt%Au/La2O3 and 4wt%Au/CeO2. In comparison with data reported by Demidova et al. [28] the SBET of La2O3 and CeO2 are much lower than in the current work, however, following the same trends.

The mean size of gold particle was determined by TEM (Table 1, Electronic supplementary material, Figure S1). The largest value was measured for 4wt%Au/La2O3, which also exhibited the lowest specific surface area. On the other hand, the average gold particle sizes for other studied catalysts were in the narrow range of 2.6–2.9 nm. Morphology of different catalysts was also investigated (Fig. S1). In particular, 4 wt% Au/TiO2 exhibited irregular shape particles in the range of 10–35 nm (Fig. S1a). Morphology of 4 wt% Au/CeO2/TiO2 and 4 wt% Au/La2O3/TiO2 did not change remarkably after ceria and lanthana modification because to their small amounts (Fig. S1 b, c). Irregular shaped particles in 4 wt% Au/CeO2 exhibited the size of 8- 25 nm (Fig. S1d). Particles in 4 wt% Au/La2O3 were not clearly separated in the TEM image most probable due to changes in La2O3 after gold modification (Fig. S1 e) identified by XRD (see above).

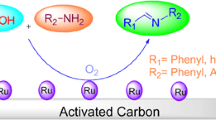

It is noted in the literature [28,29,30] that the acid–base properties of the support play a very important role in the amination of oxygen-containing compounds. The acidic and basic properties of supports and respective gold catalysts were investigated by NH3-TPD (Table 2, Fig. 2) and CO2-TPD (Table 3, Fig. 3).

Three types of acid sites with different strength and concentrations were observed for the initial supports (Table 2, Fig. 2). Among the used supports, unmodified titania has the highest acidity, characterized by the presence of both weak and medium strong Brønsted acid sites (acidic OH groups), according to [31,32,33]. The presence of strong acid sites may be due to the existence of Lewis (aprotic sites—tetrahedral coordinated Ti4+) and/or Brønsted sites. The total acidity of ceria and lanthana was 1.5 and 2.1 fold lower than the acidity of titania. The main difference is in the concentration of weak acid sites the amount of which for TiO2 is 2.3 fold higher than for CeO2 and La2O3, both latter ones exhibiting the same amounts. In contrast to ceria, the concentration of medium and strong acid sites for lanthana was slightly higher than for titania.

After modification of the pristine titania surface with ceria and lanthana, a decrease in the concentration of both weak and medium acidic centers was observed, which is caused by dehydration of the surface under high temperature (550 °C) during preparation. In the case of the Ce-modified material, the concentration of strong acid centers increases almost two fold, compared to modification with lanthana, for which a sevenfold decrease in the concentration of strong acid sites was observed. It should be noticed that on the contrary to lanthana ceria is a reducible oxide with variable valence states. It can be suggested that after modification of titania with ceria, new Lewis acid sites Ce4+/Ce3+ can be formed, which presence being indirectly confirmed by TPR [34]. Deposition of gold on the supports results in redistribution of acid sites strength. This was most pronounced for 4wt%Au/La2O3, which acidity increased 16 fold compared with the corresponding support. Such significant changes are most likely associated with changes in the phase composition of lanthana after gold deposition (formation of lanthanum hydroxide and hydroxycarbonate observed by XRD, Fig. 1e). For all other studied catalysts, acidity alteration was much less noticeable and was not associated with changes in the phase composition according to XRD (Fig. 1). For 4wt%Au/TiO2 the amount of weak sites moderately increased, while the concentration of medium sites slightly decreased, at the same time strong acid sites almost vanished. Similar trends in the change of support acidity after the introduction of the metal were previously discussed [35,36,37]. The origin of such changes was related to the mutual influence of the support and the metal crystallites on each other through their interactions at the catalyst preparation step. Furthermore, it was found [38,39,40,41] that during the gold deposition, the support surface is protonated, which leads to formation of additional OH groups, which can remain on the surface even after drying and redox pretreatments. Moreover, a part of the acid sites previously present on the surface can be blocked by formed gold nanoparticles. The amount of blocked sites depends on the nanoparticles size. Moreover, acidity can also affect the particle size, as previously found [42]. For Ce-modified titania catalysts, a decrease in the amount of strong acid sites after deposition of gold was also observed. In this case, however, the concentration of weak and medium acid sites increases. For 4wt%Au/La2O3/TiO2 and 4wt%Au/CeO2 the concentration of strong acid sites significant increased. When comparing XPS (Table 4) and NH3-TPD (Table 2) data, it can be assumed that a part of these sites (39 µmol/g) is due to the presence of Au+, which are Lewis acid sites, while another part is associated with Brønsted acidity and belongs to the support or the modifier. As for the acid sites of weak and medium strength, the amount of weak ones decreased for 4wt%Au/La2O3/TiO2 and increased for 4wt%Au/CeO2, while that of medium strong sites varied opposite to the weak ones.

According to the literature [43,44,45,46] CO2 adsorption on metal-oxide materials results in formation of various carbonate species (bicarbonate, bidentate and monodentate carbonates), which are desorbed at different temperatures giving information about the strength and nature of the basic sites. CO2 desorption in the low-temperature range (25–200 °C) is usually associated with the interactions of CO2 with surface hydroxyl groups, which are basic sites of weak strengths. Medium strong basicity is related to the presence of metal-oxide pairs, in this case CO2 desorption is observed in the range of 200–400 °C. Desorption peaks appearing in the range of 400–600 °C are caused by monodentate carbonate species formed on low-coordination oxygen anions which correspond to strong basic sites.

Three types of basic sites of different strength and concentrations were observed on the surface of studied supports in similar temperature ranges mentioned above (Table 3, Fig. 3). Among the used supports, CeO2 and La-modified titania possess the highest and approximately the same basicity, with a small difference in the distribution of the basic sites in strength. For ceria weak/medium/strong site ratio is 2:2:1, while for La2O3/TiO2, the ratio is 3:3:1. Titania and lanthana have intermediate basicity, for them the W/M/S ratio is 6:10:1 and 2:1:1, respectively. The lowest basicity was determined for Ce-modified titania, with the predominant contribution of the basic sites of medium strength (W/M/S ratio is 9:13:1).

Similar to acidic properties, after gold deposition a redistribution of basic sites was observed. For almost all studied catalysts, except 4wt%Au/TiO2, a significant increase in the concentration of the basic sites was observed compared to the corresponding supports, while the number of strong basic sites increased for all materials without any exception. Since the acid–base properties of materials are interrelated, such changes could occur for the reasons described above for acidity. The 18-fold increase in the basicity of 4wt%Au/La2O3 after gold deposition should be noted separately, associated with changes in the phase composition as described above for acidity. Moreover, CO2 desorption can be originated from carbonates, which are incorporated in the structure of lanthanum hydroxycarbonate. Thus, evaluation of basic sites is not straightforward, as these residual carbonates contribute to the overall released CO2 in addition to carbon dioxide desorbed from basic sites. Furthermore, these data explain the formation of Au d−n sites (38%, Table 4, Fig. 4a) due to increased interactions between gold and the support accompanied by changes in the structure and phase composition of the support.

XPS results from different catalysts (a–e). d and e from [34]

XPS was used to determine the electronic state of gold. XPS spectra of Au4f are shown in Fig. 4. A relative atomic concentration of various electronic states of gold, as well as the corresponding binding energies (BE), identified according to the literature [25,26,27,28,29,30,31,32,33, 47,48,49,50,51,52,53,54,55,56,57,58,59,60,61] are given in Table 4. Relative values of the various gold states depend strongly on the support nature. On the surfaces of all studied materials, most of gold (50–81%) is in a metallic state with BE (Au4f7/2) in the range of 84.1–84.3 eV, part of gold (12–21%) is present as Au+ with BE (Au4f7/2) in the range of 85.0–85.3 eV. In the case of unmodified and Ce-modified samples, another state related to Au3+ with BE of Au4f7/2 = 86.1 and 86.2 eV appears in XPS spectra (11 and 12%, respectively). It is notable that for 4wt%Au/La2O3 and 4wt%Au/CeO2 within BE range 83.3–83.5 eV, related to Au d−n states (38 and 22%, respectively), was observed. Such a shift towards lower BE as compared with the metallic state can be explained by several reasons. A negative particle charge may occur due to an electron transfer from the support to gold [54, 55, 60]. Another possible explanation is stronger interactions between gold and the support accompanied by local changes in the structure and phase composition of the support [43, 44, 48]. Finally, the particle shape determined by the size of gold nanoparticles may also be a reason of a lower BE shift [57].

3.2 Catalytic Results

3.2.1 Reductive Amination of Cyclohexanone

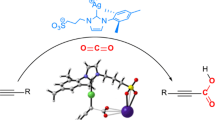

The results revealed that imines 1C/1D were instantaneously formed already after mixing of cyclohexanone with benzylamine at room temperature. According to GC analysis high conversion of cyclohexanone was obtained already after few minutes when a mixture of reactants and a solvent was prepared. Since the imine formation kinetics was very rapid, it was not quantified. Two different imines were formed, 1C and 1D (Table 5, Fig. 5) with D being the main product in line with quantum mechanical calculations for the Gibbs free energy also showing that this product is more stable than 1C by 19.5 kJ/mol at DFT/B3LYP/DNP level (Fig. 6). Standard thermodynamic quantities in the range 275–475 are shown in Table 6. At 298.15 K, the Gibb’s free energy was 620.3 and 614.4 kJ/mol for the two conformers of the 1D structure and 613.8 and 618.0 kJ/mol for 1C.

The reaction scheme for the reductive amination of cyclohexanone with benzylamine. Notation is in Table 5

The product distribution in amination was analyzed by NMR for 4wt% Au/TiO2 (Table 5). Besides the anticipated products the mixture contained also 9% unreacted cyclohexanone. The molar ratio between unreacted benzylamine to cyclohexanone was 0.44 showing that amine not only reacts with a ketone, but also undergoes self- condensation forming E-(N)-benzyl-1-phenylmethanimine (Table 5). Kinetics of amine formation over different catalysts is shown in Fig. 7.

Concentrations of amine as a function of time in reductive amination of cyclohexanone with benzylamine at 100 °C under 30 bar hydrogen. Notation: (filled triangle) Au/CeO2/TiO2, (filled cicle) Au/La2O3, (open circle) Au/CeO2, (filled square) Au/La2O3/TiO2 and (x) Au/TiO2. Catalyst amount 100 mg, the initial concentrations of reactants were 0.13 mol/l

The results illustrate that the lowest produced total concentration is obtained for 4wt%Au/La2O3/TiO2, which exhibited also a high amount of strong acid sites (Table 2).The highest initial rate for amine formation was obtained by 4wt%Au/TiO2 followed by 4wt%Au/CeO2/TiO2 (Table 7). The initial formation rates for three other catalysts were very small resulting also in low conversion after 4 h (Fig. 7). The three most active catalysts, 4wt%Au/TiO2, 4wt%Au/CeO2/TiO2 and 4wt%Au/La2O3/TiO2 were retaining their activity also after 1 h reaction time resulting in 72%, 79% and 27% yield of N-benzylcyclohexanamine after 4 h. The concentration of amine increased in the liquid phase for other catalysts as follows: 4wt%Au/CeO2 < 4wt%Au/La2O3 < 4wt%Au/TiO2 < 4wt%Au/CeO2/TiO2.

It is important to note here that rather high yields of amine were obtained with the supported gold catalysts containing small gold particle, below 3 nm (Tables 1 and 7). As a comparison with literature, relatively large gold particles, 8.4 nm were active in reductive amination of aldehydes over gold supported on mesoporous silica functionalized by an amine [62]. In that work [62] the reduction was, however, performed at room temperature with a slight excess of the stoichiometric reducing agent, dimethylphenylsilane in 2-propanol as a solvent.

When using molecular hydrogen as a reducing agent, Au/SiO2–SO3H catalyst with 4.1 nm gold particles was rather inactive in reductive amination of furfural with aniline under 50 bar hydrogen at room temperature in ethyl acetate, giving mainly imine and only 3% yield of amine in 8 h [63]. In the latter study the gold particle size was rather large, 4.1 nm, which can decrease the hydrogenation rate as activity of gold catalysts is typically very sensitive to the cluster size. Moreover, a low BE of 83.4 eV indicated the presence of Auδ− [63], while in the current work gold was mainly in the metallic state (Table 4).

The catalyst giving the highest yield for the desired amine, i.e. 4wt%Au/CeO2/TiO2 contained twofold more basic sites and 1.3 fold more acidic sites in comparison with 4wt%Au/TiO2 (Tables 2, 3). A lower amine yield was obtained with 4wt%Au/LaO2/TiO2 which also exhibited 2.5 fold strong acid sites in comparison with 4wt%Au/CeO2/TiO2. When comparing the amount of strong acid sites for these catalysts and the corresponding amine yields, it can be stated that a lower amount of strong acid sites was beneficial for amine production. It can also be noted that a large fraction of metallic gold exists in 4wt%Au/TiO2 and 4wt%Au/CeO2/TiO2 and 4wt%Au/La2O3/TiO2, The latter one exhibited a lower activity compared to the two former ones, despite a larger amount of metallic gold. 4wt%Au/TiO2 was more active, but less selective than 4wt%Au/CeO2/TiO2.

In addition to imine and amine, several other products were also identified by NMR (Table 5). No cyclohexanol was observed in the reaction mixture after 4 h for reductive amination of cyclohexanone with benzylamine in toluene on 4wt%Au/TiO2 opposite to the results where reductive amination was performed in water using a homogeneous reducing agent, such as NaBH4 and water as a solvent [64]. Absence of cyclohexanol among the products in reductive amination of cyclohexanone with benzylamine in the current work can be partially explained by low ability of metallic gold, produced via reduction with hydrogen at 300 °C, to dissociate hydrogen [65].

Low activity of 4wt%Au/La2O3/TiO2 is related to its high acidity and basicity. From the mechanistic point of view reductive amination of ketones proceeds differently than amination of alcohols through borrowing hydrogen. In the latter case some acidity is required for dehydrogenation of an alcohol and formation of a corresponding aldehyde. For reductive amination of ketones, it has been stated that the carbonyl bond is activated by homogeneous Lewis acid catalysts, forming an aminol followed by activation of the imine towards nucleophilic attack [64]. Furthermore, it was proposed in ref. [65] for reductive amination of benzaldehyde with aniline using heterogeneous B(OSO3H)3/SiO2 as a catalyst, that Brønsted acidity plays a role in increasing the electrophilic character of the carbonyl compound leading to formation of an intermediate which further dehydrates to imine.

Selectivity in amination has also been correlated with electronegativity of the support metal ions in [28, 30]. The results of [28] in amination of myrtenol showed that gold supported on La2O3 and CeO2 exhibited low conversion and selectivity to secondary amines, whereas in N-alkylation of aniline with benzyl alcohol the selectivity to secondary amine was slightly higher with Ti4+ ion in comparison to Ce4+ ion [30]. The electronegativity of Ti4+, Ce4+ and La3+ is decreasing as follows: 14, 10 and 8.23, respectively [28, 30]. In reductive amination of cyclohexanone with benzylamine the highest amine yield was obtained over 4wt%Au/TiO2 with the highest support ion electronegativity in comparison to CeO2 and La2O3, which gave low amine yields. The best catalysts in the current work are Au/TiO2 and Au/CeO2/TiO2 which could also be related to their high electronegativity.

As a comparison the yields of N-benzylcyclohexanamine produced via reductive amination (Table 8, entries 1–3) and N-alkylation of cyclohexylamine with benzylalcohol (Table 8, entry 4) with the current results (Table 8, entry 5) agree very well with the work of Liang et al. [6]. In the latter work it was reported that a commercial 1 wt% Au/TiO2 with 2–3 nm Au particles was very active and selective for production of N-benzylcyclohexanamine using 1:4 molar ratio of cyclohexanone to benzylamine with formic acid as a reductant at 60 °C in tert-butanol as a solvent giving after 5 h 97% yield of amine [6]. The TOF for formation of N-benzylcyclohexanimine, defined as moles of formed amine divided by moles of the surface gold over 1 wt% Au/TiO2 [6] was 1.1 s−1, while in the current work it was 52 s−1. The main difference between these studies is the use of formic acid as a reducing agent [3, 6], whereas hydrogen was applied in the current study. The gold particle size was about the same in the current work and in [6]. In addition to formic acid [3, 6], also NaBH4 [10] has been used as a reducing agent for production of N-cyclohexylbenzylamine as illustrated in Table 8. Furthermore, N-alkylation of cyclohexylamine with benzylalcohol is rather slow reaction, although giving a high yield of the desired product (Table 8, entry 4). Thus it can be concluded that Au/CeO2/TiO2 using hydrogen as a reducing agent can be considered as a viable alternative to chemical reducing agents.

3.2.2 Reductive Amination of Propiophenone

In reductive amination of propiophenone with benzylamine the initial reaction mixture was analyzed by GC–MS showing that a small fraction of propiophenone has already reacted to the corresponding imine, α-ethyl-N-(phenylmethyl)benzenemethaneimine (2C/2D) at room temperature. Together with this imine a small amount of E-(N)-benzyl-1-phenylmethanimine was also present in the initial mixture and the molar ratio between the unreacted benzylamine to propiophenone was 0.48.

Reductive amination of propiophenone over 4wt%Au/CeO2/TiO2 resulted in 20% conversion after 4 h (Table 9, Fig. 8). The ratio of unreacted benzylamine to propiophenone over this catalyst was 0.5 showing the benzylamine reacts not only with propiophenone. The yield of the desired amine was 11.2% corresponding to TOF of 6.3 s−1 for formation of amine.

The reaction scheme in the reductive amination of propiophenone with benzylamine over 4wt% Au/CeO2/TiO2.The notation is the same as in NMR results (Table 9)

The formed imines (2C/2D) were to a substantial extent hydrogenated to the corresponding amine (2E) over 4wt%Au/CeO2/TiO2. The final amine selectivity at 20% conversion was 56%, defined as the yield of amine divided by converted propiophenone determined based on NMR analysis It is known that especially Brønsted acidity promoted the reaction between aniline and furfural under 50 bar hydrogen at room temperature in ethyl acetate [50], when the imine was formed in the first step followed by hydrogenation to corresponding amine.

Hydrogenation of the carbonyl bond in ketone was very minor, 2% yield, over 4wt%Au/CeO2/TiO2 catalyst in comparison to formation of imine with subsequent hydrogenation to amine, which was analogous to the case of cyclohexanone reductive amination. In addition to the desired imines, amines and phenyl-1-propanol, minor amounts of unidentified side products were formed (Table 9).

4 Conclusions

Several gold catalysts supported on TiO2, La2O3, CeO2, and mixed oxides, La2O3/TiO2, CeO2/TiO2 were prepared by deposition–precipitation method and investigated in reductive amination of cyclohexanone and propiophenone using molecular hydrogen as a reducing agent. Typically Au was present as small particles, below 3 nm in all other catalysts except Au/CeO2 which had a slightly larger cluster size. According to XPS gold mainly the metallic state after pre-reduction with hydrogen at 300 °C. The lowest fraction of metallic Au was present in Au/La2O3 catalysts.

The catalytic results revealed that the most promising catalysts in reductive amination of cyclohexanone with benzylamine at 100 °C under 30 bar hydrogen using toluene as a solvent namely 4 wt% Au/CeO2/TiO2 exhibited mainly weak and medium strong acid sites. On the other hand, 4 wt% Au/La2O3/TiO2 was very unselective catalyst giving only 27% yield of N-benzylcyclohexanamine at 89% conversion. This catalyst contained mainly strong acid sites. The best catalyst in amination of cyclohexanone, 4 wt% Au/CeO2/TiO2, was also tested in reductive amination of propiophenone giving 56% selectivity to corresponding amine at 20% conversion in 5 h.

References

Heutling A, Pohlki F, Doye S (2004) Chem Eur J 10:3059–3071

Gandon V, Bertus P, Szymoniak J (2001) Eur J Org Chem 2001:3677–3681

Tamboli AH, Chaugule AA, Chun WJ, Kim H (2015) Chin J Catal 36:1365–1371

Ou W, Han F, Hu XN, Chen HPQ, Huang PQ (2018) Angew Chem Int Ed 57:11354–11358

Chusov D, List B (2014) Angew Chem Int Ed 53:5199–5201

Liang S, Monsen P, Hammond GB, Xu B (2016) Org Chem Front 3:505–509

Werkmeister S, Junge K, Beller M (2012) Green Chem 14:2371–2374

Cui X, Dai X, Deng Y, Shi F (2013) Chem Eur J 19:3665–3675

Hara M, Yoshida T, Takagaki A, Takata TK, Kondo JN, Hayashi S, Domen K (2004) Angew Chem Int Ed 43:2955–2958

Shokhorali A, Zali A, Keshavarz MH (2011) Green Chem Lett Rev 4(3):195–203

Pan HJ, Ng TW, Zhao Y (2016) Org Biomol Chem 14(24):5490–5493

Zanella R, Louis C, Giorgio S, Touroude R (2004) J Catal 223:328–339

Inorganic Crystal Structure Database (ICSD), version 2.1.0, http://www.fiz-karlsruhe.de/icsd.html, October 2018, Fiz Karlsruhe

Delley B (1990) J Chem Phys 92:508–517

Delley B (2000) J Chem Phys 113:7756–7764

Becke AD (1993) J Chem Phys 98:5648–5652

Lee C, Yang W, Parr RG (1998) Phys Rev B 37:785–789

Vosko SH, Wilk L, Nusair M (1980) Can J Phys 58:1200–1211

Stephens PJ, Devlin FJ, Chabalowski CF, Frischet MJ (1994) J Phys Chem 98:11623–11627

McNellis ER, Meyer J, Reuter K (2009) Phys Rev B 80:205–414

Markowska-Szczupak A, Janda K, Wang K, Morawski AW, Kowalska E (2015) Cent Eur J Public Health 23(3):198–202

Kotolevich Y, Kolobova E, Khramov E, Farías MH, Zubavichus Y, Tiznado H, Martínez-González S, Cortés Corberán V, Mota-Moralez JD, Pestryakov A, Bogdanchikova N (2017) J Mol Catal A 427:1–10

Seong G, Dejhosseini M, Adschiri T (2018) Appl Catal A 550:284–296

E. Scharfenberger Mineralogisch-Petrogr. Institut, Universität Heidelberg, Germany, ICDD Grant-in-Aid, 1985

Olafsen A, Larsson A-K, Fjellvåg H, Hauback BC (2001) J Solid State Chem 158:14–24

McMurdie H, Morris M, Evans E, Paretzkin B, Wong-Ng W, Hubbard C (1986) Powder Diffr 1:90

dal Negro A, Rossi G, Tazzoli V (1975) Am Miner 60:280–284

Demidova YuS, Simakova IL, Estrada M, Beloshapkin S, Suslov EV, Korchagina DV, Volcho KP, Salakhutdinov NF, Simakov AV, Murzin DYu (2013) Appl Catal A 464–465:348–358

Shimizu K, Nishimura M, Satsuma A (2009) ChemCatChem 1:497–503

Ishida T, Takamura R, Takei T, Akita T, Haruta M (2012) Appl Catal A 413–414:261–266

Nayak VS, Chodhary VR (1983) J Catal 81(1):26–45

Olson DH, Kokotailo GT, Lawton SL, Meier WM (1981) J Phys Chem 85(15):2238–2243

Zhu M, Zeng Y, Zhang Sh, Deng J, Zhong Q (2017) J Environ Sci 54:277–287

Pakrieva E, Kolobova E, Mamontov G, Bogdanchikova N, Farias MH, Pascual L, Cortés Corberán V, Martinez Gonzalez S, Carabineiro SAC, Pestryakov A (2019) ChemCatChem 11(6):1615–1624

Kubicka D, Kumar N, Mäki-Arvela P, Tiitta M, Niemi V, Karhu H, Salmi T, Murzin DY (2004) J Catal 227:313–327

Kubicka D, Kumar N, Venäläinen T, Karhu H, Kubickova I, Österholm H, Murzin DYu (2006) J Phys Chem B 110:4937–4946

Villegas JL, Kubicka D, Karhu H, Österholm H, Kumar N, Salmi T, Murzin DYu (2007) J Mol Catal A 264:192–201

Zanella R, Giorgio S, Henry CR, Louis C (2002) J Phys Chem B 106:7634–7642

Hinojosa-Reyes M, Camposeco-Solis R, Zanella R, Rodríguez-González V, Ruiz F (2018) Catal Lett 148:383–396

Zanella R, Delannoy L, Louis C (2005) Appl Catal A 29:62–72

Zanella R, Louis C (2005) Catal Today 107–108:768–777

Chichova D, Mäki-Arvela P, Heikkilä T, Kumar N, Väyrynen J, Salmi T, Murzin DYu (2009) Top Catal 52:359–379

Thanh DN, Kikhtyanin O, Ramos R, Kothari M, Ulbrich P, Munshi TD, Kubicka D (2016) Catal Today 277:97–107

Di Cosimo JL, Dıez VK, Xu M, Iglesia E, Apesteguıa CR (1988) J. Catal. 178:499–510

Di Serio M, Ledda M, Cozzolino M, Minutillo G, Tesser R, Santacesaria E (2006) Ind Eng Chem Res 45:3009–3014

Veloso CO, Pérez CN, de Souza BM, Lima EC, Dias AG, Monteiro JLF, Henriques CA (2008) Microporous Mesoporous Mater 107:23–30

Martinez-Ramirez Z, Gonzalez-Calderon JA, Almendarez-Camarillo A, Fierro-Gonzalez JC (2012) Surf Sci 606:1167–1172

Pestryakov AN, Lunin VV, Kharlanov AN, Bogdanchikova NE, Tuzovskaya IV (2003) Eur Phys J D 24:307–309

Feldheim DL, Foss CA (2002) Metal nanoparticles: synthesis characterization and applications. Basel Marcel Dekker Inc, New York, p 338

Costa VV, Estrada M, Demidova Y, Prosvirin I, Kriventsov V, Cotta RF, Gusevskaya EV (2012) J Catal 292:148–156

Feng R, Li M, Liu M (2012) Coll Surf A 406:6–12

Guzmán C, del Ángel G, Gómez R, Galindo-Hernández F, Ángeles-Chavez C (2011) Catal Today 166:146–151

Galindo-Hernández F, Wang JA, Gómez R, Bokhimi X, Lartundo L, Mantilla A (2012) J Photochem Photobiol A 243:23–32

Penkova A, Chakarova K, Laguna OH, Hadjiivanov K, Saria FR, Centeno MA, Odriozola JA (2009) Catal Commun 10:1196–1202

Peters S, Peredkov S, Neeb M, Eberhardt W, Al-Hada M (2013) Surf Sci 608:129–134

Llorca J, Domínguez M, Ledesma C, Chimentão RJ, Medina F, Sueiras J, Rossell O (2008) J Catal 258:187–198

Veith GM, Lupini AR, Pennycook SJ, Ownby GW, Dudney NJ (2005) J Catal 23:151–158

Wagner ME, Davis G, Müllenberg G (1979) Handbook of X-ray Photoelectron Spectroscopy. Perkin-Elmer Corp. Physical Electronics Division, Eden Prairie, p 190

Figueiredo NM, Carvalho NJM, Cavaleiro A (2011) Appl Surf Sci 257:5793–6926

Pawelec B, Castano P, Zepeda TA (2008) Appl Surf Sci 254:4092–4102

Tuzovskaya I, Bogdanchikova N, Simakov A, Gurin V, Pestryakov A, Avalos M, Farías MH (2007) Chem Phys 338:23–32

Carrilo AI, Llanes P, Pericas MA (2018) React. Chem Eng 3:714–721

Martinez JJ, Nope E, Rojas H, Brijaldo MH, Passos F, Romanelli GJ (2014) J Mol Catal A 392:235–240

Jones AB, Studies towards combined chemo-biocatalytic reactions in water, University College London, doctoral thesis, 2011, 356

Alinezhad H, Tajbakhsh M, Hamidi N (2010) Turk J Chem 34:307–312

Acknowledgements

Open access funding provided by Abo Akademi University (ABO). The research is funded from Tomsk Polytechnic University Competitiveness Enhancement Program project VIU-RSCBMT-65/2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kolobova, E., Mäki-Arvela, P., Pestryakov, A. et al. Reductive Amination of Ketones with Benzylamine Over Gold Supported on Different Oxides. Catal Lett 149, 3432–3446 (2019). https://doi.org/10.1007/s10562-019-02917-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02917-1