Abstract

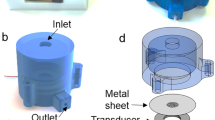

Clinically relevant studies of cell function in vitro require a physiologically-representative microenvironment possessing aspects such as a 3D extracellular matrix (ECM) and controlled biochemical and biophysical parameters. A polydimethylsiloxane (PDMS) microfluidic system with a 3D collagen gel has previously served for analysis of factors inducing different responses of cells in a 3D microenvironment under controlled biochemical and biophysical parameters. In the present study, applying the known commercially-viable manufacturing methods to a cyclic olefin copolymer (COC) material resulted in a microfluidic device with enhanced 3D gel capabilities, controlled surface properties, and improved potential to serve high-volume applications. Hot embossing and roller lamination molded and sealed the microfluidic device. A combination of oxygen plasma and thermal treatments enhanced the sealing, ensured proper placement of the 3D gel, and created controlled and stable surface properties within the device. Culture of cells in the new device indicated no adverse effects of the COC material or processing as compared to previous PDMS devices. The results demonstrate a methodology to transition microfludic devices for 3D cell culture from scientific research to high-volume applications with broad clinical impact.

Similar content being viewed by others

References

S.H. Ahn, L.G. Guo, ACS Nano. 3(8), 2304–2310 (2009)

H. Becker, L.E. Locascio, Talanta 56(2), 267–287 (2002)

A. Bhattacharyya, C.M. Klapperich, Anal. Chem. 78(3), 788–792 (2006)

J.T. Borenstein, H. Terai et al., Biomedical Microdevices 4(3), 167–175 (2002)

N.B. Bowden, M. Weck et al., Accounts Chem. Res. 34(3), 231–238 (2001)

J.L. Charest, L.E. Bryant et al., Biomaterials 25(19), 4767–4775 (2004)

J.L. Charest, M.T. Eliason et al., J. Vac. Sci. Tech. B 23(6), 3011–3014 (2005)

J.L. Charest, M.T. Eliason et al., Biomaterials 27(11), 2487–2494 (2006)

J.L. Charest, A.J. Garcia et al., Biomaterials 28(13), 2202–2210 (2007)

S. Chung, R. Sudo et al., Lab. Chip 9(2), 269–275 (2009a)

S. Chung, R. Sudo et al., Adv. Mater. 21(47), 4863–4867 (2009b)

S. Chung, R. Sudo et al., Ann. Biomed. Eng. 38(3), 1164–1177 (2010)

S.P. Desai, D.M. Freeman et al., Lab. Chip 9(11), 1631–1637 (2009)

G.A. Diaz-Quijada, R. Peytavi et al., Lab. Chip 7(7), 856–862 (2007)

M. A. Eddings, M. A. Johnson, et al., J. Micromech. Microeng. 18(6): (2008)

J. El-Ali, P.K. Sorger et al., Nature 442(7101), 403–411 (2006)

K.R. Hawkins, P. Yager, Lab. Chip 3(4), 248–252 (2003)

M.L. Hupert, W.J. Guy et al., Microfluid. Nanofluid 3(1), 1–11 (2007)

B.G. Keselowsky, D.M. Collard et al., Biomaterials 25(28), 5947–5954 (2004)

B.G. Keselowsky, D.M. Collard et al., Proc. Natl. Acad. Sci. USA 102(17), 5953–5957 (2005)

P. W. Leech, J. Micromech. Microeng. 19(5) (2009)

P.J. Mack, Y. Zhang et al., J. Biol. Chem. 284(13), 8412–8420 (2009)

L. Martynova, L.E. Locascio et al., Anal. Chem. 69(23), 4783–4789 (1997)

G. Mehta, J. Lee et al., Anal. Chem. 81(10), 3714–3722 (2009)

J. Narasimhan, I. Papautsky, J. Micromech. Microeng. 14(1), 96–103 (2004)

A. Piruska, I. Nikcevic et al., Lab. Chip 5(12), 1348–1354 (2005)

K.J. Regehr, M. Domenech et al., Lab. Chip 9(15), 2132–2139 (2009)

J. Steigert, S. Haeberle et al., J. Micromech. Microeng. 17(2), 333–341 (2007)

R. Sudo, S. Chung et al., FASEB J. 23(7), 2155–2164 (2009)

C.W. Tsao, D.L. DeVoe, Microfluid. Nanofluid. 6(1), 1–16 (2009)

V. Vickerman, J. Blundo et al., Lab. Chip 8(9), 1468–1477 (2008)

G.M. Whitesides, E. Ostuni et al., Annu. Rev. Biomed. Eng. 3, 335–373 (2001)

Acknowledgement

The research is supported by Award Number R21CA140096 from the National Cancer Institute and Draper Laboratories Inc. (IR&D Grant). The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Cancer Institute or the National Institue of Health. Seok Chung was supported by the International Research & Development Program (Grant number: 2009-00631).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeon, J.S., Chung, S., Kamm, R.D. et al. Hot embossing for fabrication of a microfluidic 3D cell culture platform. Biomed Microdevices 13, 325–333 (2011). https://doi.org/10.1007/s10544-010-9496-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-010-9496-0