Abstract

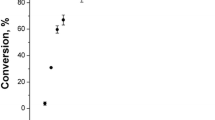

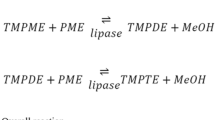

Propan-2-ol was used as an acyl acceptor for immobilized lipase-catalyzed preparation of biodiesel. The optimum conditions for transesterification of crude jatropha (Jatropha curcas), karanj (Pongamia pinnata) and sunflower (Helianthus annuus) oils were 10% Novozym-435 (immobilized Candida antarctica lipase B) based on oil weight, alcohol to oil molar ratio of 4:1 at 50 °C for 8 h. The maximum conversions achieved using propan-2-ol were 92.8, 91.7 and 93.4% from crude jatropha, karanj and sunflower oils, respectively. Reusability of the lipase was maintained over 12 repeated cycles with propan-2-ol while it reached to zero by 7th cycle when methanol was used as an acyl acceptor, under standard reaction conditions.

Similar content being viewed by others

References

M Basri AC Heng CNA Razak WMZ Wan Yunus M Ahmad RNA Rahman K Ampon AB Salleh (1997) ArticleTitleAlcoholysis of palm oil mid-fraction by lipase from Rhizopus rhizopodiformis J. Am. Oil Chem. Soc. 74 113–116 Occurrence Handle1:CAS:528:DyaK2sXhsVems7w%3D

JW Chen WT Wu (2003) ArticleTitleRegeneration of immobilized Candida antarctica lipase for transesterification J. Biosci. Bioeng. 95 466–469 Occurrence Handle16233441 Occurrence Handle1:CAS:528:DC%2BD3sXlslajurY%3D

DS Clark (1994) ArticleTitleCan immobilization be exploited to modify enzyme activity? Trends Biotechnol. 12 439–443 Occurrence Handle10.1016/0167-7799(94)90018-3 Occurrence Handle7765542 Occurrence Handle1:CAS:528:DyaK2MXhvFWntbk%3D

D Cowan (1996) ArticleTitleIndustrial enzyme technology Trends Biotechnol. 14 177–178 Occurrence Handle10.1016/0167-7799(96)30009-7 Occurrence Handle1:CAS:528:DyaK28XjsVWisbc%3D

H Fukuda A Kondo H Noda (2001) ArticleTitleBiodiesel fuel production by transesterification of oils J. Biosci. Bioeng. 92 405–416 Occurrence Handle16233120 Occurrence Handle10.1263/jbb.92.405 Occurrence Handle1:CAS:528:DC%2BD38XnvVWitw%3D%3D

D Kusdiana S Saka (2004) ArticleTitleEffects of water on biodiesel fuel production by supercritical methanol treatment Bioresour. Technol. 91 289–295 Occurrence Handle10.1016/S0960-8524(03)00201-3 Occurrence Handle14607489 Occurrence Handle1:CAS:528:DC%2BD3sXos1OntL0%3D

I Lee LA Johnson EG Hammond (1995) ArticleTitleUse of branched-chain esters to reduce the crystallization temperature of biodiesel J. Am. Oil Chem. Soc. 72 1155–1160 Occurrence Handle1:CAS:528:DyaK2MXos1Sitrk%3D

M Mittelbach (1990) ArticleTitleLipase catalyzed alcoholysis of sunflower oil J. Am. Oil Chem. Soc. 67 168–170 Occurrence Handle1:CAS:528:DyaK3cXitlCitL0%3D

LA Nelson TA Foglia WN Marmer (1996) ArticleTitleLipase-catalyzed production of biodiesel J. Am. Oil Chem. Soc. 73 1191–1195 Occurrence Handle1:CAS:528:DyaK28XlslGisr4%3D

Official Methods and Recommended Practices of the American Oil Chemists’ Society (2004), Saponification Value, Method Cd 3–25, 5th edn., Champaign, Illinois: AOCS Press

T Samukawa M Kaieda T Matsumoto K Ban A Kondo Y Shimada H Noda H Fukuda (2000) ArticleTitlePretreatment of immobilized Candida antarctica lipase for biodiesel fuel production from plant oil J. Biosci. Bioeng. 90 180–183 Occurrence Handle16232839 Occurrence Handle1:CAS:528:DC%2BD3cXntlyjtb0%3D

MM Soumanou UT Bornscheuer (2003) ArticleTitleLipase-catalyzed alcoholysis of vegetable oils Eur. J. Lipid Sci. Technol. 105 656–660 Occurrence Handle10.1002/ejlt.200300871 Occurrence Handle1:CAS:528:DC%2BD3sXpsFCks7s%3D

Y Warabi D Kusdiana S Saka (2004) ArticleTitleReactivity of triglycerides and fatty acids of rapeseed oil in supercritical alcohols Bioresour. Technol. 91 283–287 Occurrence Handle10.1016/S0960-8524(03)00202-5 Occurrence Handle14607488 Occurrence Handle1:CAS:528:DC%2BD3sXos1OntLw%3D

Y Zhang MA Dube DD McLean M Kates (2003) ArticleTitleBiodiesel production from waste cooking oil. 1. Process design and technological assessment Bioresour. Technol. 89 1–16 Occurrence Handle10.1016/S0960-8524(03)00040-3 Occurrence Handle12676496 Occurrence Handle1:CAS:528:DC%2BD3sXis1aqu7o%3D

Author information

Authors and Affiliations

Corresponding author

Additional information

Revisions requested 22 December 2005; Revisions received 26 January 2006

Rights and permissions

About this article

Cite this article

Modi, M.K., Reddy, J.R.C., Rao, B.V.S.K. et al. Lipase-mediated Transformation of Vegetable Oils into Biodiesel using Propan-2-ol as Acyl Acceptor. Biotechnol Lett 28, 637–640 (2006). https://doi.org/10.1007/s10529-006-0027-2

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10529-006-0027-2