Abstract

Polyhedral Bunsen flames, induced by hydrodynamic and thermo-diffusive instabilities, are characterized by periodic trough and cusp cellular structures along the conical flame front. In this study, the effects of flow velocity, hydrogen content, and equivalence ratio on the internal cellular structure of premixed fuel-lean hydrogen/methane/air polyhedral flames are experimentally investigated. A high-spatial-resolution one-dimensional Raman/Rayleigh scattering system is employed to measure the internal scalar structures of polyhedral flames in troughs and cusps. Planar laser-induced fluorescence of hydroxyl radicals and chemiluminescence imaging measurements are used to quantify the flame front morphology. In the experiments, stationary polyhedral flames with varying flow velocities from 1.65 to 2.50 m/s, hydrogen contents from 50 to 83%, and equivalence ratios from 0.53 to 0.64 are selected and measured. The results indicate that the positively curved troughs exhibit significantly higher hydrogen mole fractions and local equivalence ratios compared to the negatively curved cusps, due to the respective focusing/defocusing effect of trough/cusp structure on highly diffusive hydrogen. The hydrogen mole fraction and local equivalence ratio differences between troughs and cusps are first increased and then decreased with increasing measurement height from 5 to 13 mm, due to the three-dimensional effect of the flame front. With increasing flow velocity from 1.65 to 2.50 m/s, the hydrogen mole fraction and local equivalence ratio differences between troughs and cusps decrease, which is attributed to the overall decreasing curvatures in troughs and cusps due to the decreased residence time and increased velocity-induced strain. With increasing hydrogen content from 50 to 83%, the hydrogen mole fraction and local equivalence ratio differences between troughs and cusps are amplified, due to the enhanced effects of the flame front curvature and the differential diffusion of hydrogen. With increasing equivalence ratio from 0.53 to 0.64, a clear increasing trend in hydrogen mole fraction and equivalence ratio differences between troughs and cusps is observed at constant flow velocity condition, which is a trade-off result between increasing effective Lewis number and increasing curvatures in troughs and cusps.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With growing concerns on the energy crisis and global warming, environmental legislation has reinforced the demand for clean and renewable energy. Hydrogen (H2) generated from excess solar and wind power is a carbon-free energy carrier, which can be used in internal combustion engines (Schefer 2003; Dimitriou and Tsujimura 2017) and gas turbines (Gunasekar et al. 2021). In a transition scenario, H2 can be used in mixture with methane (CH4). The cellular flame structures in H2-based combustion are governed by hydrodynamic instability, thermo-diffusive instability, and buoyancy-driven instability (Law 2006). Hydrodynamic instabilities originate from density changes across the flame front. Thermo-diffusive instabilities are caused by the nonequal diffusion of the heat and mass in a mixture with Lewis number (Le; defined as ratio of thermal diffusivity of the mixture to the mass diffusivity of the deficient reactant) not equal to unity. Buoyancy-driven instabilities are attributed to the density gradient in the direction of a body force such as gravity (Quinard et al. 1984). Experimental and numerical studies have been conducted to investigate the cellular instabilities for planar flames (Yu et al. 2013; Jin et al. 2015), spherical flames (Law et al. 2005; Chen 2009), tubular flames (Hall and Pitz 2013, 2016), and polyhedral flames (Lulic et al. 2022; Weng et al. 2023).

Premixed fuel-lean H2/CH4/air flames with effective Lewis number (Leeff) lower than unity feature strong intrinsic thermo-diffusive instabilities, as H2 has a relatively higher mass diffusivity compared to the thermal diffusivity of the mixture. In fuel-lean H2/CH4/air Bunsen-type flames, cellular instabilities occur as so-called polyhedral flames. The polyhedral flame is characterized by periodic positively curved troughs and negatively curved cusps, and the cellular flame front structure is stabilized as the reactivity in troughs is enhanced due to the enhancement of local H2 concentration, while the reactivity in cusps is suppressed in contrast. The wrinkled flame front was reported to further affect the flame propagation and local reaction rate by increasing the flame surface area and modifying the thermo-chemical states in turbulent premixed fuel-lean H2/CH4/air flames (Dinkelacker et al. 2011) and H2/air flames (Berger 2022). Fundamental investigations on the differential diffusion effect of H2 on the internal structure of fuel-lean H2/CH4/air flames are essential for a comprehensive understanding, validation of combustion models, and optimization of combustion systems.

Several experimental investigations have been conducted to study the effects of flow velocity and fuel concentration on the flame front structure and behavior of polyhedral flames stabilized on a Bunsen burner, since they were first observed by Smithells and Ingle (1892) in fuel-rich benzene/air flames. Smith and Pickering (1928) then observed that the cell number of polyhedral flames increased as the percentage of fuel in the fuel-rich propane/air mixture was decreased. Sohrab and Law (1985) performed a systematic investigation on the effects of flow velocity and mixture composition on the flame structure and behavior of fuel-rich butane/air polyhedral flames. Their results indicate that the cell number increases with increasing flow velocity, while the cell number is sensitive to the fuel concentration. Li and Kaoru (2011) reproduced and extended the experiments conducted by Sohrab and Law (1985), and their results revealed that the cell number decreases with the increase of equivalence ratio (Le decreases toward unity) in fuel-rich butane/air flames. Weng et al. (2023) investigated the effects of flow rate and Le on the stability and morphology of fuel lean H2/N2/O2 polyhedral flames. Their results indicate that the cell number decreases with increasing equivalence ratio and decreasing flow rate. It has also been reported that the relationship between mixture residence time and instability growth rate is related to the transition between smooth and polyhedral flame front structures. For H2/CH4/air polyhedral flames, the cellular structure is expected to be affected by the flow velocity and mixture composition, which includes both H2 content and equivalence ratio in dual-fuel mixtures.

Spontaneous Raman/Rayleigh scattering (SRS) and planar laser-induced fluorescence of hydroxyl radicals (OH-PLIF) have been used recently to investigate the flame front structure of H2/CH4/air polyhedral flames (Shi et al. 2023). The results show that the internal flame structure is significantly altered by the differential diffusion of H2 and the wrinkled flame front. The H2 mole fraction (XH2) and local equivalence ratio (ϕ) measured in positively curved troughs are higher than those measured in negatively curved cusps. However, previous measurements were limited to only three flames having different H2 content and only a single axial position within each polyhedral flame.

The present experimental study was conducted to resolve the axial evolution of the cellular structure in H2/CH4/air polyhedral flames and explore the effects of flow velocity, H2 content, and equivalence ratio on internal flame structures. The internal scalar structures (temperature and major species mole fractions) of cellular troughs and cusps in the target flames were measured with a high-spatial-resolution one-dimensional (1D) SRS system. The cell number, characteristic cell size, cell width, and flame front curvature were quantified by chemiluminescence and OH-PLIF imaging measurements. The performance of the 1D SRS system was verified by comparing measurements of temperature and major species mole fractions in laminar premixed counter flow H2/CH4/air twin flames to corresponding numerical simulations. To resolve the 3D cellular structure in the polyhedral flames, measurements were first performed from 5 to 13 mm downstream of the nozzle exit in a H2/CH4/air polyhedral flame operated with 60% H2 (vol.-% in the dual-fuel mixture). A comprehensive parametric experimental study was conducted by varying flow velocity, H2 content, and equivalence ratio to investigate the effects of these flame parameters on the cellular structure.

2 Experimental Setup

2.1 Burners

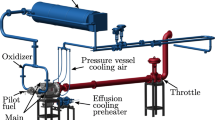

Figure 1 shows the laminar jet Bunsen-type burner used to generate premixed H2/CH4/air polyhedral flames. The burner consists of a central jet nozzle and a concentric coflow annulus with internal diameters of Djet = 16 and Dcoflow = 67 mm, respectively. The jet nozzle used in the experiment was made of stainless steel with a wall thickness of 0.5 mm to minimize recirculation and heat transfer from the flame to the wall. Nitrogen was used as the surrounding coflow. Meshes and honeycombs were used to homogenize the streams of jet and coflow. Contoured contractions produced block-shaped flow profiles at the outlet of the jet and coflow nozzles.

To evaluate the performance of the 1D SRS system, a laminar opposed jet burner was used to stabilize vertically aligned, planar laminar premixed H2/CH4/air twin flames. A detailed description of the burner was given by Trabold et al. (2022).

2.2 Measurement Techniques

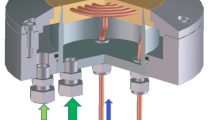

A high-spatial-resolution 1D SRS system was used to measure the temperature (Rayleigh scattering) and major species mole fraction of CO2, O2, CO, N2, CH4, H2O and H2 (Raman scattering) in the trough and cusp domains of the polyhedral flames. Detailed parameters of the 1D SRS system, including laser cluster, spectrometer, and low noise CCD cameras, have been described previously in Shi et al. (2023), Trabold et al. (2022), and a brief description is given here. For excitation, four frequency-doubled Q-switched Nd:YAG lasers were used. The four individual pulses, separated by 125 ns, were temporally stretched to approximately 500 ns (FWHM) by three optical delay lines to avoid optical breakdown in the laser path. The stretched laser pulse was focused into the probe volume by a planoconvex lens (f = 600 mm). The focused beam had a Gaussian-like profile with a diameter of 190 ± 10 µm (1/e2) along the 6 mm probe volume and a combined energy of approximately 1.8 J/pulse. The Raman/Rayleigh scattered light was collected by a custom designed achromatic lens pair (LG 1) and focused into the custom spectrometer. The schematic of the spectrometer is shown in Fig. 2. Five multi-element photographic lenses (LG 2–5) were used to consecutively focus and collimate the signal rays. The spatial resolution of the combined lens group (LG 1–5) is approximately 60 µm. The Rayleigh scattering signal was spectrally separated from the Raman scattering signal by a custom-made dichroic long pass filter and recorded by a thermo-electrically cooled frontside illuminated CCD camera (Pixis 400, Princeton Instrument). On the Raman path, the s-polarized part of the signal was transmitted by a polarization filter and a second long pass filter. A custom-made transmission grating was used to disperse the Raman signal, which was then recorded by a low-noise, thermo-electrically cooled backside illuminated CCD camera (Pixis 1300B, Princeton Instrument). To reduce the background noise, gating for Raman and Rayleigh cameras was provided by custom-built rotating mechanical shutters, resulting in an exposure time of 3.4 µs and 361 µs (FWHM), respectively. The frequency of gating was synchronized to the laser by a third rotating wheel opening at a frequency of 5 Hz. To achieve a suitable compromise between spatial resolution and signal-to-noise ratio on the Raman camera, on-chip binning by four pixels was applied in the spatial direction, yielding a projected spacing in the line data of 50 µm/super-pixel. Rayleigh scattering was recorded spatially binned by two pixels, resulting in a projected line spacing of 20 µm/super-pixel. The spatial resolution in the axial (vertical) direction was determined by the laser beam diameter. The Raman and Rayleigh signal were mapped to each other in the data evaluation. The single shot energy of the combined laser beam was measured by a laser energy detector at the end of the laser path.

A separate horizontal OH-PLIF measurement was performed to quantify the cell number and flame front geometry of H2/CH4/air polyhedral flames, as described in Shi et al. (2023). A Nd:YAG-pumped dye-laser beam at 283 nm was formed into a light sheet, and horizontally focused into the probe volume with a thickness of 110 µm. The fluorescence signal from OH radicals was imaged from the top of the flame by an intensified CMOS camera equipped with a 105 mm UV lens and a bandpass filter (315 nm, ± 15). The OH fluorescence images shown in this paper were averaged over 300 images for each flame case. The spatial resolution of the OH-PLIF measurement system was 125 µm, which was determined by a sector star at a cut-off-ratio of 14%.

Two CMOS cameras were used to capture chemiluminescence images of the polyhedral flame from top and side views. To visualize the interaction position of the laser beam and the cellular structure (trough or cusp), the top view camera was synchronized to the laser during the experiment. A remote-controlled rotational stage was used to rotate the burner to align the trough or cusp structure with the laser beam. Mass flow controllers (Bronkhorst) were used to vary the gas supply to the jet and coflow (accuracy 0.5% reading plus 0.1% full scale error). Thermocouples (K type, OMEGA) were used to measure the nozzle outer surface temperature at 2, 5 and 10 mm upstream the nozzle exit.

2.3 Data Evaluation

The hybrid matrix inversion method described by Fuest et al. (2011) was used to process the Raman/Rayleigh data. In this method, spectral libraries of CO2, O2, CO, N2, H2O and H2 for temperature ranging from 250 to 2500 K were calculated with RAMSES (Geyer 2005; Lill et al. 2023), and integrated according to the corresponding on-chip pixel binning region to account for the temperature dependence of the Raman cross-sections and cross-talks of different species. The response function of CH4 was generated by using extensive calibrations, as reliable quantum mechanical models for CH4 Raman scattering are not yet available for the entire temperature range. Normalization curves were used to correct the non-uniform throughput of Raman signal along the 1D probe volume. Different gas flows (CH4, H2, CO2/N2, CO/N2/H2) at ambient temperature were measured to obtain the calibration factors of Raman responses and cross-talks of different species. To optimize these calibration factors at high temperatures, the product gases of two calibration flames with known temperature and compositions were measured. The calibration flames used were (1) nearly adiabatic premixed CH4/air flat flames (0.65 < ϕ < 1.3), and (2) quasi-premixed H2/air flames stabilized on a Hencken-type burner (0.3 < ϕ < 1.5), of which a detailed description can be found in Schneider (2017).

Representative values for precision and accuracy from the calibration flame measurements are listed in Table 1. The precision of single-shot data is represented by the standard deviation divided by the estimated mean value of 100 samples in the product gas of the CH4/air flat flame at the listed equivalence ratio. The accuracy (estimated bias in measured mean values) is based on deviations of the flat flame measurements from the corresponding numerical laminar flame simulation, as well as the repeatability of the calibration. Additional comments on measurement uncertainty are included in the discussion of results.

2.4 Operating Conditions

The flow configurations are listed in Table 2 for the four laminar premixed H2/CH4/air twin flames measured to verify the performance of the multi-scalar Raman/Rayleigh measurement system. The global strain rate, K, of the measured cases, defined as K = 2U/L, where U = (U1 + U2)/2 is the average bulk velocity of the two nozzle and L is the nozzle separation distance, was increased from 400 to 820 s−1 with the increase of the H2 content to compensate for the increasing laminar flame speed and maintain a suitable distance between the two flame branches for the multi-scalar measurements.

The flow configurations of examined premixed H2/CH4/air polyhedral flames are listed in Table 3. Stationary polyhedral flames with representative features were selected from the stability map, in which a wider range of H2 content variations can be reached when keeping a fixed flame angle, whereas the operating region is limited by the blow-off and the flash-back to a small range when varying only the H2 content. The operating equivalence ratio is limited to an overall narrow range with 79% H2 content due to the disappearance of the cellular structure at high equivalence ratios. Different flame groups with varying flow velocity, H2 content and equivalence ratio are highlighted in Table 3 to support discussion in the following sections. The flow velocity (Ujet) is increased from 1.65 to 2.50 m/s with an equivalence ratio of 0.53, and a H2 content of 79% (C1–C3) to investigate the effect of flow velocity. The H2 content is increased from 50 to 83% with equivalence ratios of 0.65 ± 0.1 and a constant half flame angle of α ~ 15° (C4–C8) to investigate the effect of H2 content over a wide H2 range. The equivalence ratio is increased from 0.53 to 0.64 with a constant half flame angle of α ~ 15° (C1, C9 and C7) to investigate the effect of equivalence ratio. Additionally, the H2 content is increased from 74 to 83% or the equivalence ratio is increased from 0.53 to 0.64 with a constant flow velocity of 2.50 m/s to further explore the effects of H2 content or equivalence ratio, and the corresponding results are presented and discussed in the Supplementary Material for completeness. Measurements were performed from z = 5 mm to z = 13 mm downstream of the nozzle exit with an interval of 2 mm in the flame with 60% H2 (C5) to investigate the axial evolution of the cellular structures, and only at z = 5 mm for the other cases.

Flame properties of the measured polyhedral flames are listed in Table 3. The nozzle exit temperature (Tn) was extrapolated from the nozzle temperatures measured at 2, 5 and 10 mm upstream of the nozzle exit with an exponential fit. The Leeff of the fuel-lean H2/CH4/air dual-fuel mixtures were calculated based on the Le for H2/air (LeH2) and CH4/air (LeCH4) single fuel mixtures with the volumetric fraction weighted average formulation recommended by Bouvet et al. (2013):

The unstretched planar laminar flame speed (SL), thermal flame thickness (lF), and 1D scalar profiles of the flame configurations (shown in Sect. 3) were calculated by Cantera 2.5 (Goodwin et al. 2021), using the GRI-Mech 3.0 mechanism (Smith et al. 1999) and multi-component diffusion with the Soret effect included. Local equivalence ratio shown for both the experiments and simulations was calculated based on the fuel/oxygen balance derived from mole fractions \({X}_{i}\) of the major species, which can be derived from SRS measurement, as follows (Barlow et al. 2012):

where Xi represents the mole fraction of species i in the mixture. The parameters derived from the OH-PLIF measurements, including cell number (nc), characteristics cell size (l), maximum curvature in troughs (κt) and cusp (κc), are defined in Sect. 3.2.

3 Results and Discussion

3.1 Performance of Multi-scalar Diagnostics System

To verify the performance of the 1D SRS system in resolving the internal structure of laminar premixed H2/CH4/air flames over a wide range of H2 content (49% to 90%), the laminar flames listed in Table 2 were measured and simulated. The 1D Raman/Rayleigh probe volume was centered between the opposing nozzles to minimize vignetting and reflections. The twin flame structure was shifted axially by adjusting the flows on both sides and one flame branch was centered between the two nozzles during the measurement. The measured and simulated species mole fraction of CH4, H2, O2, CO and H2O, temperature, equivalence ratio and C/H-atom ratio over the flame coordinate for the 49% H2 cases are shown in Fig. 3 (the other three cases showed similar agreement with simulations, and the corresponding results are presented in the Supplementary Material). Conditional statistics are determined from 500 laser shots. The maximum CO mole fraction is a marker for the reaction zone and is defined here as the origin of the flame coordinate. Species profiles were aligned to this origin for each single laser shot. Error bars plotted around each measured conditional mean represents the ± 1 standard deviation in the conditional data, and error bars are plotted for every third data point for better visualization. The corresponding simulation results were derived from a counter flow twin flame (CFTF).

Comparison of experimental and simulated results for planar laminar premixed H2/CH4/air twin flames with 49% H2 and an equivalence ratio of 0.63. Simulation results were derived from a counter flow twin flame (CFTF). Shown are selected species mole fractions, temperature, equivalence ratio and C/H-atom ratio over the flame coordinate

The measured mean results in Fig. 3 (blue lines) show excellent overall agreement with the simulated results (red lines) on the selected species mole fractions and temperature, as well as the derived equivalence ratio and C/H-atom ratio. The latter two quantities are particularly sensitive to effects of differential diffusion. In general, both precision and accuracy of Raman scattering measurements depend on local conditions, and both are degraded in a relative sense as the concentration of the species in question decreases. The signal on a given Raman species channel includes the crosstalk from other species, whose Raman scattering spectrum overlaps the spectral binning range of the given channel, as well as fluorescence interference and flame luminosity. These additional signals are imperfectly corrected in the matrix inversion method, such that species measurements at very low concentration have relatively larger uncertainty than for the representative values in Table 1. Overall, the agreement between experiment and simulation over the flame coordinate highlights the capability of the experimental system for highly resolved diagnostics of flame structures.

3.2 Cellular Structure of Polyhedral Flames

Chemiluminescence images of measured H2/CH4/air polyhedral flames from side (a) and top (b) views and corresponding OH-PLIF images (c) measured at z = 5 mm above the nozzle exit are shown in Fig. 4. Note that OH-PLIF images and the corresponding curvature measurements (Table 3) are not available for C6 and C8 because the OH-PLIF experiments were conducted before the Raman/Rayleigh experiments, and cases C6 and C8 were later added to gain more complete information on the effects of H2 content on the internal scalar structure of the flames. Clear cellular structures can be observed from the side view chemiluminescence images as presented in Fig. 4a. In Fig. 4b, the bright regions are identified as troughs, and the dark regions are identified as cusps. The cellular structures and wrinkled flame fronts are better visible from the OH-PLIF images in Fig. 4c. To calculate the flame front parameters, the detected flame front from the original OH-PLIF image was projected from the measurement plane, perpendicular to the burner axis, onto a plane perpendicular to the flame cone, by which the angular differences between flames of different lengths are compensated. The cell numbers (nc) of the polyhedral flames were calculated by counting the trough/cusp pairs. The local flame front curvature (κ), defined as the inverse of the radius of a fitted circle, was derived from the contour of the maximum OH gradient. The maximum local flame front curvatures in troughs (κt) and cusps (κc) of the target flames were calculated and are listed in Table 3, in which the troughs are characterized by positive curvature (κ > 0), and the cusps are characterized by negative curvature (κ < 0). For fuel-lean H2/CH4/air polyhedral flame with Leeff < 1, the positively curved trough focuses the mass diffusion of reactant H2 into the local reaction zone, which increases the local equivalence ratio and the flame speed. This stabilizes the convex flame front toward the unburned side. Conversely, the negatively curved cusp defocuses the mass diffusion of reactant H2 toward the product side, which decreases the local equivalence ratio and flame speed. Consequently, the concave flame front toward the unburned side is stabilized. A trough/cusp pair of the wrinkled flame front derived from the OH-PLIF image of case C5 is magnified in Fig. 5. The average flame radius (rf) is defined as the average of flame radius in trough (rt) and cusp (rc). The characteristic cell size l is defined as the average flame circumference divided by the cell number l = π (rt + rc)/nc. The cell width w is defined as the radial distance between cusp and trough (rc–rt). The flame front parameters of measured flames are listed in Table 3 for further discussion.

Cellular structures of the polyhedral flames at fixed axial position z = 5 mm have been discussed in previous work (Shi et al. 2023). To further explore the axial evolution of the cellular structures, measurements were conducted in a polyhedral flame with 60% H2, an equivalence ratio of 0.65, and a flow velocity of 1.70 m/s (C5) from 5 to 13 mm above the nozzle exit with an interval of 2 mm. Case C5 was selected because it has an intermediate value of most of the parameters listed in Table 3. As presented in Fig. 4a, primary cellular structures are apparent in case C5 at flame axial positions z < 15 mm, above which cells start to merge, and a clear secondary cellular structure is observed. Horizontal OH-PLIF images measured from 5 to 13 mm above the nozzle exit are shown in Fig. 6, in which the corresponding maximum curvatures in troughs and cusps, the characteristics cell size and the cell width are summarized. As shown in Fig. 6, with the increase of measurement position from 5 to 13 mm, the average flame radius of the polyhedral flame decreases from 6.41 to 4.53 mm while the cell number remains constant at 15, which results in a near linearly decreasing characteristics cell size from l = 2.68 to 1.92 mm. The cell width is first increased then decreased with the increasing measurement height, and the maximum cell width is observed between 7 and 9 mm. With the increase of measurement height, κt increases nearly linearly, while κc first increases and then decreases, reaching the peak approximately at z = 9 mm. Note that the maximum curvature in cusps is larger than that in troughs, which indicates that the cusp is more compressed along its circumference compared to the trough. The curvature variation in the cusps and troughs along the flow axis is a combined result of the changing cell size and cell width, as the wrinkled flame front becomes more curved with the decrease of cell size, while the flame front is smoothed with the decrease of cell width.

Horizontal PLIF images of the OH radicals measured from z = 5 mm to z = 13 mm downstream of the nozzle exit in a polyhedral flame with 60% H2, an equivalence ratio of 0.65, and a flow velocity of 1.70 m/s (C5). The flame parameters, including maximum curvatures in troughs (κt) and cusps (κc), average flame radius (rf), characteristics cell size (l) and cell width (w), derived from the OH-PLIF images are listed

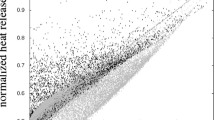

Multi-scalar results measured by 1D SRS in troughs and cusps ranging from z = 5 mm to z = 13 mm are shown in Fig. 7. Simulation results from a corresponding planar, unstretched freely propagating flame (FPF) are displayed for qualitative reference. Conditional mean values were calculated from 1000 laser shots for each case. Uncertainty in the conditional mean scalar profiles can be interpreted from the comparisons of measured and simulated results from laminar premixed counter flow H2/CH4/air twin flames in Fig. 3 (systematic uncertainty) and from fluctuations along the measured curves (statistical uncertainty), which are most obvious in the results for the equivalence ratio, ϕ. Note that systematic uncertainty at similar measurement conditions applies to both cusp and trough, such that the magnitude of the differences between the cusp and trough profiles is relatively insensitive to experimental uncertainty. The origin of the flame coordinate corresponds to the maximum CO mole fraction for each single shot data in each flame. In the spatial profiles (four columns at left in Fig. 7), the positively curved troughs have narrower profiles with higher XH2, higher local ϕ, and lower O2 mole fraction (XO2) compared to the negatively curved cusps for all axial positions. The flame temperature of troughs is slightly higher than that of cusps in the post-flame region. The local ϕ of troughs peaks shortly downstream of the origin of the flame coordinate (r = 0 mm), and then decreases within the post-flame region asymptotically towards the ϕ of the inlet. In the temperature profiles (three columns at right in Fig. 7), the XH2 and ϕ differences between troughs and cusps are easier to see, where the FPF simulation results lie between the measurement results of the troughs and cusps.

Comparison of measured results from the cusp (c) and trough (t) regions of laminar premixed H2/CH4/air polyhedral flame C5 with 60% H2, an equivalence ratio of 0.65, and a flow velocity of 1.70 m/s at measurement heights range from z = 5 mm to z = 13 mm. The four columns at left are in spatial domain and the three columns at right are in temperature domain. Corresponding simulation results from a freely propagating flame (FPF) are included as reference

Quantitative H2 distribution results along the axial coordinate between troughs and cusps in the temperature domain are shown in Fig. 8. Figure 8a presents the absolute XH2 difference between troughs and cusps (XH2_diff), \({X}_{H2\_diff }= {X}_{H2\_t}-{X}_{H2\_c}\). Uncertainty in the derived scalar results (i.g. XH2_diff) is calculated based on the estimated accuracy presented in Table 1, as well as fluctuations around an expected smooth curve in a laminar flame. For example, representative error bars at 500 K, 1000 K and 1500 K, estimated with the accuracy for H2 (i.e. 8%) in Table 1, and fluctuations around an expected smooth curve for the XH2_diff profile in a laminar flame, are shown along the XH2_diff profile for z = 5 mm in Fig. 8a. Similar error bars are included in the other figures with derived scalar results in this paper. Note again that systematic uncertainties in calibrations and crosstalk corrections are common to all profiles in these comparisons, so they do not significantly affect the trends seen in the difference profiles. Generally, the absolute XH2 difference between troughs and cusps first increases rapidly within the preheat zone, then decreases slowly with further increase of temperature. With the increase of axial position, the XH2 difference between troughs and cusps first increases and then slightly decreases after peaking at 9 mm. Note that the XH2 difference trend with increasing measurement height is more consistent with the flame front curvature trend in the cusps, which is consistent with the varying cell width along the flow axis. Although the maximum curvature in the troughs increases with measurement height, which is consistent with the variation in cell size along the axial direction, a slight decrease in curvature is observed in the center of the troughs, and the curvature in the center of the troughs fluctuates with increasing measurement height, which may explain the decrease in the XH2 difference downstream the peak at 9 mm. A more comprehensive analysis of the flame front curvature will be the topic of another paper.

Figure 8b shows the corresponding relative XH2 difference between troughs and cusps (XH2_relative_diff), defined as \({X}_{H2\_relative\_diff }= 2({X}_{H2\_t}-{X}_{H2\_c})/{(X}_{H2\_t}+{X}_{H2\_c})\). With increasing axial position, XH2_relative_diff shows a similar trend as observed in the absolute XH2 difference results, in which the maximum value is observed at 9 mm. Figure 9 shows the relative equivalence ratio difference between troughs and cusps (ϕrelative_diff), defined similarly as \({\phi }_{relative\_diff}= 2({\phi }_{t}-{\phi }_{c})/{(\phi }_{t}+{\phi }_{c})\). The results of absolute ϕ difference between troughs and cusps are not shown as they have a similar trend with the relative ϕ difference result. In Fig. 9, ϕrelative_diff increases rapidly within the preheat zone, and then remains nearly constant with the further increase of temperature. ϕrelative_diff increases with the axial position from 5 to 9 mm, and decreases with the further increase of the measurement height to 13 mm, which is consistent with the XH2 results.

3.3 Overview of Parametric Trends

Before presenting the quantitative results from the parametric experiments, it is useful to briefly outline the qualitative effects of each of the relevant parameters as well as their interaction or dependencies. Most importantly, the strength of the instability in terms of the number and amplitude of cells formed is driven primarily by differential diffusion of H2 and is affected by changes in H2 content and equivalence ratio, both of which enter the calculation of Leeff. Changes in either H2 content or equivalence ratio also change the flame speed. Therefore, the flame angle will change unless the reactant flow velocity is adjusted to compensate. A change in flame angle will change the flame radius at a given height above the burner, which will correspondingly affect local curvature of the trough and cusp structures even when the cell number is unchanged. Conversely, if flow velocity is adjusted to maintain a fixed flame angle, then the residence time for cell formation near the flame base is affected. When flow velocity is varied with other parameters fixed, then the flame angle will change as will the flame radius at the measurement location, which again can affect curvature within the trough and cusp structures even when cell number remains unchanged.

Figure 10 shows the measured flame shapes for four cases (C1, C3, C4, C7) at z = 5 mm and illustrates how changes in local flame curvature affect the focusing/defocusing of fast diffusing H2 in trough/cusp regions of the polyhedral cell structure. The color shading alongside the flame surface indicates the local intensity of flame surface curvature, and the color shade is proportional to the intensity of the focusing (red) or defocusing (blue) effect of the flame surface on H2. Comparing Fig. 10a and b, an increase in bulk velocity (1.65–2.50 m/s) at fixed H2 content, ϕ, and cell number causes the flame to push outward, decreasing the cell width and flame front curvature. As a result, the focusing/defocusing effects on H2 are weakened. Following the theoretical discussions in Lulic et al. (2022) and Weng et al. (2023), an increase in bulk velocity corresponds to a decrease in the ratio of residence time (convective time to the flame tip) to the timescale of the instability (inverse of the maximum growth rate), which is argued to weaken the instability. Comparing Fig. 10c and d, an increase in H2 content (50–79%) at fixed ϕ and flame angle reduces Leeff and strengthens the instability, such that the cell number increases from 11 to 19. This significantly increases local flame curvature and thereby amplifies the focusing/defocusing of H2. This happens despite of an increase in bulk velocity, which clearly has a lesser influence than H2 content. This observed effect of increasing H2 content (decreasing Leeff) is also qualitatively consistent with the theoretical analysis in Lulic et al. (2022) and Weng et al. (2023).

Conceptual diagrams illustrating the focusing/defocusing of fast diffusing H2 by trough/cusp regions of the flame surface. Four flame cases: a C1, b C3, c C4 and d C7 are used to represent the effects of varying bulk velocity (a, b), H2 content (c, d), and equivalence ratio (a, d). The flame surface shapes are derived from the maximum OH contour measured at z = 5 mm in each flame. The arrows indicate the mass diffusion of H2 through the flame surface. The shading indicates the local intensity of flame surface curvature

More generally, Weng et al. (2023) have demonstrated that qualitative trends in the behavior of polyhedral flames can be predicted by theory, and Lulic et al. (2022) have shown that numerical linear stability analysis of planar flames gives reasonably good quantitative agreement of cell spacing observed experimentally in premixed H2/CH4/air flames similar to those studied here. However, these theoretical approaches cannot quantitatively predict the magnitude of local flame curvature or its effects on H2 transport and the internal scalar structure of the flame.

The following sections document the quantitative effects on the scalar structure of troughs and cusps of variations in (1) flow velocity at fixed H2 content and equivalence ratio (C1–C3), (2) H2 content at constant equivalence ratio and constant flame angle (C4–C8), and (3) equivalence ratio at constant H2 content in the fuel and constant flame angle (C1, C9 and C7). Results are discussed in terms of the general trends outlined above and the specific physical mechanisms involved. Overall, the differences in scalar profiles between troughs and cusps are most strongly affected by the H2 content in the fuel. However, significant changes in polyhedral flame structures are also induced by variations in equivalence ratio and flow velocity.

3.4 Effects of Flow Velocity on Cellular Structure

In this section, stationary polyhedral flames with 79% H2, an equivalence ratio of 0.53, and flow velocities of 1.65, 2.00 and 2.50 m/s were selected to study the effects of flow velocity on cellular structures, shown in Fig. 4 as cases C1, C2 and C3. With the increase of the flow velocity from 1.65 to 2.50 m/s, the flame height increased, and the flame angle decreased due to the balance between the flame propagating speed and the flow velocity component normal to the flame front. The cell number remains the same at 17, while the average flame radius at z = 5 mm is increased with increasing flow velocity from 1.65 to 2.50 m/s. As a result, the characteristic cell size is increased from 2.28 to 2.52 mm. Note that with the increase of flow velocity from 1.65 to 2.00 m/s, the average flame radius increases significantly, while the flame boundary is slightly extended outward, and the cellular structure is radially flattened with the further increasing flow velocity from 2.00 to 2.50 m/s due to the geometrical limit of the nozzle. The wrinkled flame surface of the polyhedral flame is flattened with increasing flow velocity due to the enhanced velocity-induced strain and decreased residence time. The curvatures in troughs and cusps show an overall decreasing trend with the increase of flow velocity, except of the maximum curvature in the trough for case C2.

Multi-scalar results measured by 1D SRS in troughs and cusps at z = 5 mm above the nozzle exit in flames with increasing flow velocity are presented in Fig. 11. In the spatial profiles (four columns at the left), the troughs have higher XH2 and local ϕ compared to the cusps for all cases. The local equivalence ratio in troughs peaks at about 0.4 mm in radial direction from the local flame origin with an enhancement of approximately 10% compared to the equivalence ratio of the inlet fuel/air mixture. At low flow rates, the FPF simulation results are in the middle of the measurement results of the troughs and cusps. However, XH2, temperature, and local equivalence ratio are slightly underestimated by the FPF results at high flow velocity conditions. With increasing flow velocity, the velocity-induced strain on the flame surface is enhanced, but this effect is not included in the FPF results. Moreover, effects of the flame geometric differences between simulation and experiment are not included in the FPF results. Comprehensive 3D simulations are necessary to cover the aforementioned differences from the experiments, however this is beyond the scope of the present study.

Comparison of measured results from the cusp (c) and trough (t) regions of laminar premixed H2/CH4/air polyhedral flames (C1–C3) with 79% H2, an equivalence ratio of 0.53, and flow velocities of 1.65, 2.00 and 2.50 m/s. The four columns at left are in the spatial domain and the three columns at right are in the temperature domain. Corresponding simulation results from freely propagating flames (FPF) are attached for all cases as references

To quantify the effects of flow velocity on the H2 distribution, the radial XH2 gradients dXH2/dr, where r represents the flame coordinate along radial direction, from reactant to product in troughs and cusps are shown in Fig. 12a. Since the flame normal gradient is more physically relevant to the differential diffusion process, the derived radial gradients have been corrected for flame angle in each case to approximate the flame normal gradient. The correction is less than 5% in all cases. Compared to cusps, the XH2 gradient in troughs has a narrower spatial profile and a higher absolute maximum value, which indicates that the mass transportation of H2 in troughs is faster than that in cusps. The absolute maximum of the XH2 gradient is slightly increased with increasing flow velocity, and this trend is consistent with the enhanced velocity-induced strain effect on the flame front. The absolute XH2 difference between troughs and cusps (XH2_diff) along the spatial domain is presented in Fig. 12b. As H2 is consumed along the radial direction, the absolute XH2 difference between troughs and cusps first increases, and then decreases after passing the peak. With increasing flow velocity from 1.65 to 2.50 m/s, the maximum XH2 difference between troughs and cusps decreases. This is consistent with the overall decreasing trend in curvatures, which is explained by shorter residence times at higher velocities.

In the temperature domain, the absolute XH2 difference between troughs and cusps is presented in Fig. 13a. The absolute XH2 difference between troughs and cusps decreases with increasing flow velocity from 1.65 to 2.50 m/s. As Leeff remains the same for the cases with increasing flow velocity, the decreasing trend in XH2 difference is mainly attributed to the overall decreasing curvatures in troughs and cusps, resulting in weakened focusing and defocusing effects for the highly diffusive H2 perpendicular to the flame surface. The relative XH2 difference between troughs and cusps is shown in Fig. 13b. With increasing flow velocity, the XH2_relative_diff shows a decreasing trend. At 1200 K, the XH2_relative_diff is 89%, 80% and 71% for the 1.65, 2.00 and 2.50 m/s case, respectively. Figure 14 shows the relative local equivalence ratio difference between troughs and cusps. ϕrelative_diff decreases with increasing flow velocity, which is consistent with the decreasing trend in XH2. Specifically, the average relative ϕ difference between 600 and 1400 K is 15.4%, 14.3% and 12.7% for 1.65, 2.00 and 2.50 m/s case, respectively.

In addition to the stationary polyhedral flames shown above, other flame behaviors, including flash-back, rotation around the burner axis, bimodal bifurcation, and blow-off, were observed as the flow velocity was modified during the experiment. With further decrease of the flow velocity below 1.65 m/s, the polyhedral flame starts rotating until it reaches the flash-back point. Rotation of the polyhedral flame was explained by Smith et al. (1928) by the continuous heating and cooling of the nozzle rim periphery by the trough/cusp. With the increase of flow velocity to 2.75 m/s, the polyhedral flame reaches a transition condition and becomes unstable due to a bimodal bifurcation, as observed similarly by Buckmaster (1984). With a further increase of flow velocity above 3.00 m/s, the cellular structure disappears, and a smooth flame is generated. The disappearance of the cellular structures is attributed to shorter residence times and the smoothing effect of the increasing velocity-induced strain on the flame surface.

3.5 Effects of H2 Content on Cellular Structure

To investigate the effects of H2 content over a wide range, experimental results from 50 to 83% H2 with a constant flame angle are analyzed and discussed as cases C4, C5, C6, C7 and C8 shown in Fig. 4. As the laminar flame speed of the fuel/air mixture increases with rising H2 content, the flow velocities were varied from 1.10 to 2.75 m/s to maintain a constant flame angle. As shown in Fig. 4a, a primary cellular structure originating from the nozzle exit is visible for all cases, while the secondary cellular structure near the flame tip is more visible and the flames are characterized by an opening tip for cases operated with 60% and higher H2 content. The occurrence of the secondary cellular structure is attributed to the combine effects of negative curvature on the flame tip and the cellular structure along the flame front as explained in Shi et al. (2023). Note that as the flame approaches the flash-back limit with 84% H2 content the apparent open tip is restricted. Due to the varying flame tip structures, these cases have slightly different flame heights. With the increase of H2 content from 50 to 83%, the cell number increases from 11 to 21, and Leeff decreases from 0.75 to 0.59, indicating that the differential diffusion effect of H2 is promoted.

OH-PLIF measurements were conducted on selected cases (C4, C5 and C7) to elucidate the effects of H2 content on the cellular flame front structure. The OH-PLIF results indicate that the cell structure is more wrinkled with a decreased characteristic cell size from 3.63 to 2.09 mm as of the increased cell number. The maximum curvatures increase in troughs (from 0.82 to 1.58 mm−1) and cusps (from − 1.89 to − 4.54 mm−1) with the increase of H2 content from 50 to 79%, which indicates that the focusing and defocusing effects of troughs and cusps are enhanced with increasing H2 content.

Multi-scalar results from 1D SRS measurements in troughs and cusps at z = 5 mm above the nozzle exit in the flames with increasing H2 content from 50 to 83% are presented in Fig. 15. Overall similar internal flame structures are observed in troughs and cusps, but differences increase with the H2 content due to the more pronounced differential diffusion effect. In the spatial domain, the radial XH2 gradients are presented in Fig. 16a. For the 50% H2 case, the maximum XH2 gradient in troughs and cusps is almost identical, but the difference clearly increases with rising H2 content. For both troughs and cusps, the absolute maximum XH2 gradient increases with increasing H2 content, indicating that the mass transport of H2 from reactant to product is enhanced. The absolute XH2 difference between troughs and cusps is presented in Fig. 16b. The XH2_diff profile becomes narrower, and the maximum XH2_diff increases significantly with increasing H2 content. The results indicate that the flame thickness decreases, which is consistent with the trend from FPF simulation results shown in Table 3, and the XH2 difference between troughs and cusps is enhanced with increasing H2 content in the fuel.

Comparison of measured results from the cusp (c) and trough (t) regions of laminar premixed H2/CH4/air polyhedral flames (C4–C8) with 50–83% H2 contents and a constant flame angle. The four columns at left are in the spatial domain and the three columns at right are in the temperature domain. Corresponding simulation results from freely propagating flames (FPF) are included as references

In the temperature domain, Fig. 17a presents the absolute XH2 difference between troughs and cusps, and the corresponding relative XH2 difference is shown in Fig. 17b. In Fig. 17a, the XH2_diff increases with rising H2 content in the fuel, due to the increased curvatures in troughs and cusps, and enhanced differential diffusion of H2. In Fig. 17b, an overall increasing trend is observed for the XH2_relative_diff with increasing H2 content, however, the trend between individual cases is not so clear. The relative equivalence ratio difference between troughs and cusps is shown in Fig. 18. The ϕrelative_diff increases with rising H2 content, which is consistent with the XH2 results. Specifically, the average relative ϕ difference between 600 and 1400 K is 6.6%, 9.2%, 13.3%, 16.9% and 16.8% for 50%, 60%, 74%, 79% and 83% H2 case, respectively.

To further explore the H2 content effects, corresponding measurements were made in H2/CH4/air polyhedral flames with 74%, 79%, and 83% H2 contents and a constant flow velocity of 2.50 m/s. The flow configurations and experimental results are presented and discussed in the Supplementary Material. Note that a plateau in ϕrelative_diff (Fig. 18) is reached for H2 content greater than 79% at constant flame angle due to the competing effects from higher H2 content and higher velocity. As presented in Fig. 14, the ϕrelative_diff shows a decreasing trend with increasing flow velocity, and this trend holds true if we compare the ϕrelative_diff between C8 in Fig. 18 and CS3 in the Supplementary Material.

Overall, the XH2 and ϕ differences between troughs and cusps increase with rising H2 content for constant flame angle and constant flow velocity conditions. With increasing H2 content in the fuel, the XH2 gradient between reactants and products increases; the Leeff of fuel/air mixture decreases, indicating that the differential diffusion effect is enhanced. Consistent with this, the curvatures in troughs and cusps increase, indicating that the focusing/defocusing effect of troughs/cusps is enhanced due to highly diffusive H2. The combination of these effects results in an increasing XH2 and ϕ differences between troughs and cusps.

3.6 Effects of Equivalence Ratio on Cellular Structure

In this section, polyhedral flames with a constant flame angle, 79% H2 content, and varying equivalence ratios range from 0.53 to 0.64 were selected to explore the effects of equivalence ratio on cellular structures, shown in Fig. 4 as cases C1, C9 and C7. For increasing equivalence ratio, the flow velocity was set to 1.65, 2.00 and 2.50 m/s to compensate for the increasing flame speed and maintain a constant flame angle. As shown in Fig. 4, with the increase of equivalence ratio from 0.53 to 0.64, the cell number increases consecutively from 17 to 19, and the characteristic cell size decreases slightly from 2.28 to 2.09 mm as the flame front has a similar average radius at z = 5 mm. A slightly increasing trend in curvatures of troughs (from 1.31 to 1.58 mm−1) and cusps (from − 4.41 to − 4.54 mm−1) is observed with increasing equivalence ratio, except a curvature drop in cusps of case C9.

Multi-scalar results measured in troughs and cusps at z = 5 mm in flames with a constant flame angle and equivalence ratios of 0.53, 0.58 and 0.64 are presented in Fig. 19. With increasing equivalence ratio, the XH2 and temperature profiles become narrower in the spatial domain, and the scalar differences between troughs and cusps are slightly increased in the temperature domain. In the spatial domain, the radial XH2 gradients in troughs and cusps are shown in Fig. 20a. Due to the high H2 content of 79%, the absolute maxima of XH2 gradients are relatively high in both troughs and cusps. With increasing equivalence ratio from 0.53 to 0.64, the gradients of XH2 are expected to be steeper as there is more H2 in the reactants. The effect of thermo-diffusive instability is slightly weaker as the corresponding effective Lewis number Leeff is slightly increased from 0.58 to 0.61 (Table 3). The absolute XH2 difference between troughs and cusps is presented in Fig. 20b. With increasing equivalence ratio, the maximum XH2_diff remains unaffected, while the peak XH2_diff radial position shifts toward the flame origin position as the XH2 gradient is steeper and the flame thickness reduces.

Comparison of measured results from the cusp (c) and trough (t) regions of laminar premixed H2/CH4/air polyhedral flames (C1, C9 and C7) with 79% H2, a constant flame angle, and equivalence ratios 0.53, 0.58 and 0.64. The four columns at left are in the spatial domain and the three columns at right are in the temperature domain. Corresponding simulation results from freely propagating flames (FPF) are attached as references

In the temperature domain, the absolute and relative XH2 differences between troughs and cusps are presented in Fig. 21a, b, respectively. The absolute XH2 difference between troughs and cusps increases with equivalence ratio. On the one hand, with the increase of equivalence ratio from 0.53 to 0.64, the flame thickness decreases and the H2 concentration increases in reactants, leading to an increased H2 gradient between reactants and products. On the other hand, Leeff is slightly increased from 0.58 to 0.61, which indicates that the effect of thermo-diffusive instability is hardly changed. The overall increasing trend in XH2_diff with equivalence ratio indicates that the effect of increased H2 gradient is more significant, compared to the Lewis number effect. However, as shown in Fig. 21b, up to 600 K the relative XH2 difference is unaffected by the equivalence ratio and only slowly diverges for higher temperatures. The corresponding relative local equivalence ratio differences are presented in Fig. 22. While these differences show a slight overall increase with increasing equivalence ratio from 0.53 to 0.64, it is not clear that this trend is significant relative to the measurement uncertainty. The average relative ϕ difference between 600 and 1400 K is 15.4%, 15.9% and 16.9% for equivalence ratio of 0.53, 0.58 and 0.64 case, respectively.

To examine the equivalence ratio effects on cellular structures at constant flow velocity, H2/CH4/air polyhedral flames with equivalence ratios of 0.53, 0.58, and 0.64, 79% H2 content, and a flow velocity of 2.50 m/s were further investigated. The flow configurations and experimental results are presented and discussed in the Supplementary Material. Compared to the constant flame angle condition, slightly larger differences between troughs and cusps in XH2_diff and ϕrelative_diff are observed at the constant flow velocity condition.

With increasing equivalence ratio, the radial XH2 gradient is increased by the increased H2 concentration in reactants and reduced flame thickness. The cell number also increases, which tends to increase the curvatures in troughs/cusps and amplify the focusing/defocusing effect on fast diffusing H2. However, the effective Lewis number Leeff slightly increases, which tends to diminish the thermo-diffusive instability. The combination of these opposing physical effects results in the overall increasing trend in the XH2 differences between troughs and cusps at constant flame angle and constant flow velocity conditions. This indicates that the slight increase in Leeff is less important than other effects.

4 Conclusions

In this study, effects of varying flow velocity, H2 content, and equivalence ratio on cellular structures of laminar premixed fuel-lean H2/CH4/air polyhedral flames were comprehensively investigated. A high-spatial-resolution 1D SRS system was employed to resolve the internal scalar structures of reaction zones, including temperature and major species mole fractions. Chemiluminescence and OH-PLIF imaging measurements were conducted to quantify the cell number, characteristics cell size, cell width, and flame front curvature. Quantitative results on the magnitude of the measured differences in both topology and scalar structure between cusps and troughs are presented in detail in the main text and are not repeated in these conclusions. Overall, the differences in scalar profiles between troughs and cusps are most strongly affected by the H2 concentration in the reactants and the radial H2 gradient between reactants and products, whereas there are multiple effects that contribute to the observed variations in flame geometry and the scalar differences between troughs and cusps. The major conclusions can be summarized as follows.

-

1.

The internal structure of a H2/CH4/air polyhedral flame is significantly modified by the wrinkled reaction zone and the differential diffusion effect of H2, in which the troughs feature significantly higher XH2 and local ϕ compared to the cusps. The XH2 and ϕ differences between troughs and cusps first increase and then decrease with the axial position from 5 to 13 mm, which is attributed to the varying flame front curvatures in troughs and cusps due to the changes in cell size and cell width along the flow axis.

-

2.

With increasing flow velocity and other parameters constant, the residence time for generating the cell structure is shortened; the velocity-induced strain on the flame front is enhanced; the flame front curvatures in troughs and cups show overall decreasing trends while the cell number remains unchanged, which diminishes the focusing and defocusing effects on H2. As a result, the XH2 and local ϕ differences between troughs and cusps decrease with increasing flow velocity.

-

3.

With increasing the H2 content, the radial XH2 gradient between reactants and products increases due to the increased H2 amount in the reactants and the reduced flame thickness; the thermo-diffusive instability is enhanced as the effective Lewis number Leeff is decreased; the focusing/defocusing effect of troughs/cusps on highly diffusive H2 is enhanced, as the curvatures in troughs and cusps are increased. The combination of the abovementioned effects results in significant increases in the XH2 and ϕ differences between troughs and cusps, and these conclusions hold for both flame series with constant flame angle and constant velocity.

-

4.

With increasing equivalence ratio, the radial XH2 gradient is increased by the increased H2 concentration in reactants and reduced flame thickness. The cell number also increases, which tends to increase the curvatures in troughs/cusps and amplify the focusing/defocusing effect on fast diffusing H2. However, the effective Lewis number Leeff slightly increases, which tends to diminish the thermo-diffusive instability. The combination of these opposing physical effects results in the overall increasing trend in the XH2 differences between troughs and cusps at constant flame angle condition. This indicates that the slight increase in Leeff is less important than other effects. A more significant increasing trend in XH2 and ϕ differences between troughs and cusps is observed at constant flow velocity condition, which is attributed to the reduced residence times with increasing flow velocity.

References

Barlow, R.S., Dunn, M.J., Sweeney, M.S., Hochgreb, S.: Effects of preferential transport in turbulent bluff-body-stabilized lean premixed CH4/air flames. Combust. Flame 159–8, 2563–2575 (2012). https://doi.org/10.1016/j.combustflame.2011.11.013

Berger, L., Attili, A., Pitsch, H.: Synergistic interactions of thermodiffusive instabilities and turbulence in lean hydrogen flames. Combust. Flame 224, 112254 (2022). https://doi.org/10.1016/j.combustflame.2022.112254

Bouvet, N., Halter, F., Chauveau, C., Yoon, Y.: On the effective Lewis number formulations for lean hydrogen/hydrocarbon/air mixtures. Int. J. Hydrog. Energy 38–14, 5949–5960 (2013). https://doi.org/10.1016/j.ijhydene.2013.02.098

Buckmaster, J.: Polyhedral flames—an exercise in bimodal bifurcation analysis. J. Appl. Math. 44–1, 40–55 (1984). https://doi.org/10.1137/0144005

Chen, Z.: Effects of hydrogen addition on the propagation of spherical methane/air flames: a computational study. Int. J. Hydrog. Energy 34–15, 6558–6567 (2009). https://doi.org/10.1016/j.ijhydene.2009.06.001

Dimitriou, P., Tsujimura, T.: A review of hydrogen as a compression ignition engine fuel. Int. J. Hydrog. Energy 42–38, 24470–24486 (2017). https://doi.org/10.1016/j.ijhydene.2017.07.232

Dinkelacker, F., Manickam, B., Muppala, S.: Modelling and simulation of lean premixed turbulent methane/hydrogen/air flames with an effective Lewis number approach. Combust. Flame 158–9, 1742–1749 (2011). https://doi.org/10.1016/j.combustflame.2010.12.003

Fuest, F., Barlow, R.S., Geyer, D., Seffrin, F., Dreizler, A.: A hybrid method for data evaluation in 1-D Raman spectroscopy. Proc. Combust. Inst. 33–1, 815–822 (2011). https://doi.org/10.1016/j.proci.2010.06.064

Geyer, D.: 1D-Raman/Rayleigh experiments in a turbulent opposed-jet. Dissertation, Technische Universität Darmstadt (2005)

Goodwin, D.G., Speth, R.L., Moffat, H.K., Weber, B.W.: Cantera: an object-oriented software toolkit for chemical kinetics, thermodynamics, and transport processes. Zenodo (2021). https://doi.org/10.5281/zenodo.4527812

Gunasekar, P., Manigandan, S., Praveen Kumar, T.R.: Hydrogen as the futuristic fuel for the aviation and aerospace industry—review. Aircr. Eng. Aerosp. Technol. 93–3, 410–416 (2021). https://doi.org/10.1108/AEAT-07-2020-0145

Hall, C.A., Pitz, R.W.: A structural study of premixed hydrogen-air cellular tubular flames. Proc. Combust. Inst. 34–1, 973–980 (2013). https://doi.org/10.1016/j.proci.2012.06.023

Hall, C.A., Pitz, R.W.: Numerical simulation of premixed H2–air cellular tubular flames. Combust. Theory Model. 20–2, 328–348 (2016). https://doi.org/10.1080/13647830.2015.1132010

Jin, W., Wang, J., Nie, Y., Yu, S., Huang, Z.: Experimental study on flame instabilities of laminar premixed CH4/H2/air non-adiabatic flat flames. Fuel 159, 599–606 (2015). https://doi.org/10.1016/j.fuel.2015.07.022

Law, C.K.: Combustion Physics. Cambridge University Press, Cambridge (2006). https://doi.org/10.1017/CBO9780511754517

Law, C.K., Jomaas, G., Bechtold, J.K.: Cellular instabilities of expanding hydrogen/propane spherical flames at elevated pressures: theory and experiment. Proc. Combust. Inst. 30–1, 159–167 (2005). https://doi.org/10.1016/j.proci.2004.08.266

Li, C., Kaoru, M.: Influence of burner rim configuration on polyhedral flames. Int. Conf. Electr. Inform. Control Eng. (2011). https://doi.org/10.1109/ICEICE.2011.5776914

Lill, J., Dieter, K., Koschnick, K., Dreizler, A., Magnotti, G., Geyer, D.: Measurement and simulation of temperature-dependent spontaneous Raman scattering of O2 including P and R branches. J. Quant. Spectrosc. Radiat. Transf. 297, 108479 (2023). https://doi.org/10.1016/j.jqsrt.2022.108479

Lulic, H., Breicher, A., Scholtissek, A., Lapenna, P.E., Dreizler, A., Creta, F., Hasse, C., Geyer, D., Ferraro, F.: On polyhedral structures of lean methane/hydrogen Bunsen flames: combined experimental and numerical analysis. Proc. Combust. Inst. 39–2, 1977–1986 (2022). https://doi.org/10.1016/j.proci.2022.07.251

Quinard, J., Searby, G., Boyer, L.: Cellular structures on premixed flames in a uniform laminar flow. Lect. Notes Phys. 210, 331–341 (1984). https://doi.org/10.1007/3-540-13879-X_94

Schefer, R.: Hydrogen enrichment for improved lean flame stability. Int. J. Hydrog. Energy 28–10, 1131–1141 (2003). https://doi.org/10.1016/S0360-3199(02)00199-4

Schneider, S.: Auswirkungen der Wasserstoff-Zumischung auf die Flammenstruktur turbulenter stratifizierter Methan-Luft-Flammen. Dissertation, Technische Universität Darmstadt (2017). https://tuprints.ulb.tu-darmstadt.de/6977/

Shi, S., Breicher, A., Trabold, J., Hartl, S., Barlow, R.S., Dreizler, A., Geyer, D.: Cellular structures of laminar lean premixed H2/CH4/air polyhedral flames. Appl. Energy Combust. Sci. 13, 100105 (2023). https://doi.org/10.1016/j.jaecs.2022.100105

Smith, G.P., Golden, D.M., Frenklach, M., Moriarty, N.W., Eiteneer, B., Goldenberg, M., Bowman, C.T., Hanson, R.K., Song, S., Gardiner, W.C., Jr., Lissianski, V.V., Qin, Z.: Gri 3.0 mechanism. Gas Research Institute. (1999) http://www.me.berkeley.edu/gri_mech/

Smith, F.A., Pickering, S.F.: Bunsen flames of unusual structure. Ind. Eng. Chem. 20, 1012–1013 (1928)

Smithells, A., Ingle, H.: The structure and chemistry of flames. J. Chem. Soc. Trans. 61, 204–216 (1892). https://doi.org/10.1039/CT8926100204

Sohrab, S.H., Law, C.K.: Influence of burner rim aerodynamics on polyhedral flames and flame stabilization. Combust. Flame 62–3, 243–254 (1985). https://doi.org/10.1016/0010-2180(85)90150-6

Trabold, J., Butz, D., Schneider, S., Dieter, K., Barlow, R., Dreizler, A., Geyer, D.: Fast shutter line-imaging system for dual-dispersion Raman spectroscopy in ethanol and OME flames. Combust. Flame 243, 111864 (2022). https://doi.org/10.1016/j.combustflame.2021.111864

Weng, Y., Potnis, A., Saha, A.: Regime and morphology of polyhedral Bunsen flames. Combust. Flame 248, 112585 (2023). https://doi.org/10.1016/j.combustflame.2022.112585

Yu, J.F., Yu, R., Fan, X.Q., Christensen, M., Konnov, A.A., Bai, X.S.: Onset of cellular flame instability in adiabatic CH4/O2/CO2 and CH4/air laminar premixed flames stabilized on a flat-flame burner. Combust. Flame 160–7, 1276–1286 (2013). https://doi.org/10.1016/j.combustflame.2013.02.011

Acknowledgements

D. Geyer gratefully acknowledge funding by the European Regional Development Fund (ERDF, Project Number: FPG991 0005/2019 and SAP 20008810 (WWE)) and the Research center for Sustainable Processes of the Darmstadt University of Applied Sciences. A. Dreizler was financially supported by the Gottfried Wilhelm Leibniz-Preis (DFG). R. Barlow is grateful for a related DFG Mercator Fellowship.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

SS, AB and RS conducted the investigation. SS wrote the manuscript draft. SH provided the software for data post-processing. RB, DG and AD provided supervision. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shi, S., Breicher, A., Schultheis, R. et al. Structures of Laminar Lean Premixed H2/CH4/Air Polyhedral Flames: Effects of Flow Velocity, H2 Content and Equivalence Ratio. Flow Turbulence Combust (2024). https://doi.org/10.1007/s10494-024-00561-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10494-024-00561-3