Abstract

A novel technique is presented to improve the initialization of compressible combustion LES, DNS or URANS by numerically turning the flame into a damper to quickly remove (artificial) pressure fluctuations and acoustic energy from the system. This is achieved by modifying the pressure dependency of the heat release rate, effectively modifying the Rayleigh Integral to achieve negative values, so that the acoustic energy is quickly removed from the system. The technique can (a) reduce the cost of simulations (by shortening the initialization), (b) contribute to stabilize the simulation, (c) help to avoid unrealistic thermoacoustic modes and, (d) potentially, be modified to compensate for excessive numerical dissipation of acoustic energy. Examples from LES of a thermoacoustic test case are presented to demonstrate the effective stabilization achieved.

Similar content being viewed by others

1 Introduction

Time dependent three dimensional simulations (LES or DNS) of flames are typically conducted in a compressible framework, where thermoacoustics can occur. During the initialization, the transition towards a statistically converged, stable flame will invariably lead to the formation of strong acoustic waves, pressure pulsations and oscillations within the computational domain, which can be amplified by thermoacoustic feedback of the flame. Suitable partially reflecting boundary conditions may help to reduce these oscillations by letting acoustic energy (acoustic waves) leave the computational domain—but this will normally be a slow process and may not always be sufficient to compensate for the energy added by thermoacoustic coupling. In the best of cases, these oscillations will only extend the duration of the simulation until meaningful statistics can be extracted, making the simulation more costly. In other cases, these pulsations may lead to (false) flash back, flame blow-off or causing the simulation to “crash”. In the worst of cases, these initializations may trigger and stabilize the wrong thermoacoustic modes, so that unrealistic Eigenfrequencies and Eigenmodes may be predicted.

Efforts for removing unphysical acoustic oscillations from compressible (flame) simulations have been abundant and are typically applied as non-reflecting boundary conditions (Poinsot and Lelef 1992), by adding a “sponge layer” (Israeli and Orszag 1981; Hu 2001) or by altering the conserved flow variables of the Navier–Stokes equations inside the domain, e.g. (Queguineur et al. 2019).

With the present paper, we present a simple to implement technique for damping these initial oscillations, to (a) speed up convergence and reduce the computational cost, to (b) enhance the stability of simulations during the initialization phase, and to (c) help avoid inappropriate results in simulations of thermoacoustics.

The new damping technique is based on artificially enforcing a negative Rayleigh integral, which can be easily achieved by modifying the (weak) dependency of the heat release rate \(\dot{q}\) on the pressure p, which will be demonstrated and illustrated below, after other approaches for removing acoustic energy from simulations have been reviewed.

2 Artificial Damping Based on the Rayleigh Criterion

In compressible reactive simulations, the acoustic energy balance equation (Poinsot and Veynante 2005) with an additional term accounting for numerical dissipation \(d_1\) can be written as:

with the acoustic energy \(e_1\) and flux \(f_1\), and a source term for the reaction \(r_1\). The reaction source term depends on the ratio of specific heats \(\gamma\), the pressure p, and the unsteady heat release rate \(\dot{q}_1\). The subscripts denote a decomposition of a quantity in an acoustic (fluctuating) part (subscript 1) and a mean part (0). For highly resolved large-eddy simulations with accurate numerical schemes, the numerical dissipation \(d_1\) in the volume is small. Since higher numerical damping is inherently coupled to a loss in accuracy of momentum and scalar transport leading to, e.g., wrong flame shapes, its use to dissipate acoustic energy is limited. Therefore, without altering the Navier–Stokes equations directly and therefore changing \(e_1\), acoustic energy inside the domain can, in high quality simulations, only be removed by two processes: a) acoustic energy is transported out of the domain over the boundaries, represented by \(\nabla \cdot f_1\), or b) the reaction source term \(r_1\) is negative and consequently acts as a sink term.

For (a), classic approaches include the above mentioned non-reflecting boundary conditions or sponge layers. Due to their design, which targets the acoustic flux over the boundaries, these methods are fundamentally restricted: they are not suitable to dampen acoustic modes with small acoustic flux over the boundaries of the numerical domain. In practice, an excitation due to the initialization of a simulation can lead to acoustic modes, which are confined in parts of the domain (e.g. the plenum and combustion chamber) with small acoustic flux over the boundaries. Without further intervention, these modes take a long time to decline due to the low numerical dissipation, leading to higher costs due to prolonged initialization periods.

To the knowledge of the authors, (b) has not been used to actively remove acoustic energy from simulations. Instead, the reaction source term \(r_1\) is a usually used as a quantitative measure to gauge the thermoacoustic stability of a combustion system, via the Rayleigh Criterion (Rayleigh 1878). Physically, if the pressure and heat release rate oscillations are sufficiently in phase so that \(r_1\) is positive, energy is added by combustion to the acoustic energy. Vice versa, if the pressure and heat release rate oscillations are out of phase \(r_1\) is negative and acoustic energy is removed.

The authors propose to extend the heat release \(\dot{q}\) formulation of an arbitrary combustion model to include a scaling factor a for the pressure dependent change:

with subscript ref denoting a reference value for a given state of the mixture at the reference pressure in the combustion chamber. For a suitably chosen scaling factor, \(a < 0\) in Eq. 2, a negative correlation between pressure and heat release rate is introduced. Therefore, the proposed method will enforce a negative \(r_1\) and remove energy from the acoustic modes. It is necessary to consider the conservation of the integral total heat release during implementation, since Eq. 2 could change the heat release if the mean pressure \(p_0\) differs from the reference pressure \(p_{ref}\).

3 Implementation in a Combustion Model

In the following, the implementation in the context of the flame-surface density (FSD) approach is demonstrated. In this approach, the heat release rate is modeled as:

with the density of the unburned mixture \(\rho _u\), the laminar flame speed \(s_l\), the efficiency function \(\Xi\), the reaction regress variable b, the heat of reaction per mass of fuel H, the fuel mass fraction \(Y_f\) and the source term of the reaction regress variable \(\dot{\omega }_b\).

To impose the conservation of the total heat release rate, the alteration of the laminar flame speed \(s_l\) is chosen as an alternative to directly modify \(\dot{q}_{FSD}\). Modifications of \(s_l\) will take effect on heat release rate \(\dot{q}_{FSD}\) via the reaction regress source \(\dot{\omega }_b\). Therefore, the modifications do not violate mass, energy or species balances and will at most alter the flame length and shape. This modeling procedure is similar to the use of efficiency functions \(\Xi\), which account for effects of subgrid wrinkling, but now applied for the effects of pressure changes. Furthermore, since the laminar flame speed is calculated during pre-processing, the alteration is straightforward to implement. Finally, the heat release rate is then calculated as:

During pre-processing, pressure dependency of the laminar flame speed is computed for the nominal operating conditions of the chosen test case using one-dimensional freely propagating flame simulations. The pressure change due to the acoustic waves is assumed to be isentropic, therefore the inlet temperature is calculated acc. to \(T_{in} = T_{ref} (p/p_{ref})^{(\gamma -1 / \gamma )}\). For the reference case with \(a=1\), the rightmost term in Eq. 4 is positive for \(p_1 > 0\). Since \(\dot{q} \propto s_l\), this means the effect of pressure changes onto the laminar flame speed transfers energy from the combustion into the acoustic modes. Notably, a pressure wave with an amplitude of 1 % of the reference pressure only changes the laminar flame speed by approx. 0.2 %. The pre-processed laminar flame speeds are scaled and tabulated for a range of equivalence ratios and pressure levels and accessed at runtime based on the local conditions.

The above presented implementation can be adopted for all combustion models which use the laminar flame speed. For complex combustion models, which are based on kinetic reaction rates, another implementation is necessary. Using the isentropic pressure temperature relation, the temperature change caused by the pressure field can be calculated at runtime. This information can be used to alter the temperature, at which the chemical reactions are evaluated, to reduce the influence of pressure waves on the reaction progress and therefore also on the flame speed.

4 Demonstration of the Damping Technique

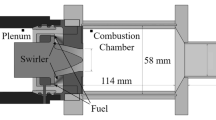

Compressible, reactive large eddy simulations of a high frequency thermoacoustics test case have been carried out to examine the initialization of the simulation. For a detailed introduction of the test case and the modeling approach, the reader is referred to Sharifi et al. (2021).

The test case has been designed for experimentally investigating self-excited high-frequency thermoacoustics and features a single methane air jet flame. The numerical domain includes the full geometry of the test case, including the outer and inner plenum, combustion chamber, downstream plenum and exhaust passage. The outer and inner plenum are separated by four inlet holes, restricting the acoustic energy flux in the upstream direction. In this work, the unstable operating point is simulated using a coarser mesh with higher numerical damping, leading to a slowly declining acoustic mode in the combustion chamber after the initialization. Combustion is modeled using the flame-surface density approach, and non-reflecting boundary conditions are used at the outlet to allow acoustic flux over the boundary.

In Fig. 1, the pressure signal at a probe location inside the combustion chamber (LP3 in Sharifi et al. (2021)) after the initialization is shown. In the time series, it can be clearly seen, that simulations with higher damping factors show an accelerated decline of the characteristic high frequency acoustic mode of the test case. For a more detailed analysis, on the right side the resulting discrete Fourier transform of the pressure signal between 0.025 and 0.05 s is depicted. As in the time series, the suppression of the high frequencies is clearly visible. Furthermore, for high dampening factors (\(a=-50\)), amplitudes in the lower frequency region are also effected.

Notably, for all damped cases but \(a=-50\), a second peak at approx. 800 Hz occurs, which is not appearing in the reference case. The authors interpretation of this behaviour is, that the high-frequency mode may be suppressing the secondary mode at approx. 800 Hz.

Figure 2 shows a comparison of the instantaneous axial velocity field between the reference case and the dampened case with a = −50. Comparatively, the flow fields are nearly identical and the small structures are equally well resolved in the dampened case. Furthermore, the flame position and length, indicated by the isoline of the mean regress variable \({\bar{b}} = 0.5\) is only changed marginally. This indicates a small impact of the proposed method on the prediction accuracy of flames outside of the introduced dampening behaviour, even with the high scaling factors considered here.

5 Conclusion

A novel technique has been presented to improve the initialization of compressible flame simulations, to (a) reduce the cost, to (b) enhance stability, and to (c) help avoid incorrect results. The technique is based on artificially lowering the Rayleigh integral by modifying the dependency of the heat release rate on pressure fluctuations. The technique is easy to implement and has proven to be effective and without impact on the numerical accuracy of momentum and convective transport.

Perspectively, the approach of modifying the Rayleigh integral by tuning the pressure dependency of the heat release rate is not constrained to enhancing the initialization of a simulation: the technique might, potentially, be also used to recover thermoacoustic oscillations in over-dissipative simulations, or to establish stability margins in simulations of thermoacoustics.

Finally, the findings imply that the pressure dependency of the heat release rate may have a larger effect on thermoacoustic oscillations than is frequently assumed, and that reaction kinetics may have a greater than expected effect on thermoacoustics.

Data Availability

Data presented is available on reasonable request.

References

Hu, F.Q.: A stable, perfectly matched layer for linearized Euler equations in unsplit physical variables. J. Comput. Phys. (2001). https://doi.org/10.1006/jcph.2001.6887

Israeli, M., Orszag, S.A.: Approximation of radiation boundary conditions. J. Comput. Phys. (1981). https://doi.org/10.1016/0021-9991(81)90082-6

Poinsot, T., Lelef, S.: Boundary conditions for direct simulations of compressible viscous flows. J. Comput. Phys. (1992). https://doi.org/10.1016/0021-9991(92)90046-2

Poinsot, T., Veynante, D.: Theoretical and Numerical Combustion. Edwards, Philadelphia (2005)

Queguineur, M., Gicquel, L.Y.M., Dupuy, F., et al.: Dynamic mode tracking and control with a relaxation method. Phys. Fluids 10(1063/1), 5085474 (2019)

Rayleigh, J.W.S.: The explanation of certain acoustical phenomena. Nature (1878). https://doi.org/10.1038/018319a0

Sharifi, V., Beck, C., Janus, B., et al.: Design and testing of a high frequency thermoacoustic combustion experiment. AIAA J. 10(2514/1), J060072 (2021)

Funding

Open Access funding enabled and organized by Projekt DEAL. The work was supported by the Bundesministerium für Wirtschaft und Energie (Grant No.: 03EE5013D) and the Deutsche Forschungsgemeinschaft (Grant No.: INST 20876/209-1 FUGG, INST 20876/243–1 FUGG).

Author information

Authors and Affiliations

Contributions

J.E.: Detailed development, implementation and test of the developed method, writing the paper. A.K.: Conceptualisation, proof reading. C.B.: Discussion, proof reading.

Corresponding author

Ethics declarations

Conflict of interest

Author A.K. is Co-Editor-in-Chief, but with no access to the editorial process or the reviewer identities.

Ethics Approval

N/A.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Eigemann, J., Beck, C. & Kempf, A. A Method to Dampen Acoustic Waves in Compressible Reactive Flow Simulations. Flow Turbulence Combust (2024). https://doi.org/10.1007/s10494-024-00542-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10494-024-00542-6