Abstract

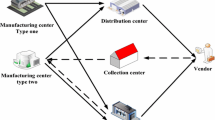

Configuration of a supply chain network is a critical issue that contributes to choose the best combination for a set of facilities in order to attain an effective and efficient supply chain management (SCM). Designing a closed-loop distribution network of products is an important field in supply chain network design, which offers a potential factor for reducing costs and improving service quality. In this research, the question concerns a closed-loop supply chain (CLSC) network design considering suppliers, assembly centers, retailers, customers, collection centers, refurbishing centers, disassembly centers and disposal centers. It aims to design a distribution network based on customers’ needs in order to simultaneously minimize the total cost and total CO2 emission. To tackle the complexity of the problem, a self-adaptive non-dominated sorting genetic algorithm II (NSGA-II) algorithm is designed, which is then evaluated against the ε-constraint method. Furthermore, the performance of the algorithm is then enhanced using the Taguchi design method to tune its parameters. The results indicate that the solution time of the self-adaptive NSGA-II approach performs better than the epsilon constraint method. In terms of the self-adaptive NSGA-II algorithm, the average number of Pareto solutions (NPS) for small and medium-sized problems is 6.2 and 11, respectively. The average mean ideal distance (MID) for small and medium-sized problems is 2.54 and 5.01, respectively. Finally, the average maximum spread (MS) for small and medium-sized problems is 3100.19 and 3692.446, respectively. The findings demonstrate that the proposed self-adaptive NSGA-II is capable of generating efficient Pareto solutions. Moreover, according to the results obtained from sensitivity analysis, it is revealed that with increasing the capacity of distribution centers, the amount of shortage of products decreases. Moreover, as the demand increases, the number of established retailers rises. The number of retailers is increasing to some extent to establish 7 retailers.

Similar content being viewed by others

References

Amin SH, Zhang G (2012) An integrated model for closed-loop supply chain configuration and supplier selection: multi-objective approach. Expert Syst Appl 39(8):6782–6791

Amin SH, Zhang G, Akhtar P (2017) Effects of uncertainty on a tire closed-loop supply chain network. Expert Syst Appl 73:82–91

Atta S, Sen G (2020) Multiple allocation p-hub location problem for content placement in VoD services: a differential evolution based approach. Appl Intell 50(5):1573–1589

Aydin N (2020) Designing reverse logistics network of end-of-life-buildings as preparedness to disasters under uncertainty. J Clean Prod 256:120341

Ayvaz B, Görener A (2020) Reverse logistics in the electronics waste industry waste management: concepts, methodologies, tools, and applications, pp 1664-1680. IGI Global

Babaeinesami A, Tohidi H, Seyedaliakbar SM (2020a) Designing a data-driven leagile sustainable closed-loop supply chain network. Int J Manag Sci Eng Manag:1–13

Babaeinesami A, Tohidi H, Seyedaliakbar SM (2020b) A closed loop Stackelberg game in multi-product supply chain considering information security: a case study. Adv Prod Eng Manag 15(2)

Chiba Z, Abghour N, Moussaid K, El Omri A, Rida M (2019) A clever approach to develop an efficient deep neural network based IDS for cloud environments using a self-adaptive genetic algorithm. In: 2019 international conference on advanced communication technologies and networking (CommNet), pp 1-9. IEEE

De M, Giri B (2020) Modelling a closed-loop supply chain with a heterogeneous fleet under carbon emission reduction policy. Transportation Research Part E: Logistics and Transportation Review 133:101813

Deb K, Sundar J (2006) Reference point based multi-objective optimization using evolutionary algorithms. Proceedings of the 8th Annual Conference on Genetic and Evolutionary Computation, 12, pp 635-642

Deb K, Pratap A, Agarwal S, Meyarivan TAMT (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6(2):182–197

Djatna T, Amien G (2020) Bi-objective freight scheduling optimization in an integrated forward/reverse logistic network using non-dominated sorting genetic algorithm-II. Decis Sci Lett 9(1):91–106

Fu L, Meng F (2020) A human disease transmission inspired dynamic model for closed-loop supply chain management. Transportation Research Part E: Logistics and Transportation Review 134:101832

Ghani JA, Choudhury IA, Hassan HH (2004) Application of Taguchi method in the optimization of end milling parameters. J Mater Process Technol 145(1):84–92

Ghasemi P, Khalili-Damghani K (2021) A robust simulation-optimization approach for pre-disaster multi-period location–allocation–inventory planning. Math Comput Simul 179:69–95

Ghasemi P, Khalili-Damghani K, Hafezalkotob A, Raissi S (2020) Stochastic optimization model for distribution and evacuation planning (a case study of Tehran earthquake). Socio Econ Plan Sci 71:100745

Ghoushchi SJ, Hushyar I (2020) Designing a closed-loop supply chain network and providing a multi objective mathematical model to select a third-party logistics company and supplier simultaneously. Int J Ind Eng 27(2)

Goodarzian F, Hosseini-Nasab H, Muñuzuri J, Fakhrzad MB (2020) A multi-objective pharmaceutical supply chain network based on a robust fuzzy model: a comparison of meta-heuristics. Appl Soft Comput 92:106331

Goodarzian F, Taleizadeh AA, Ghasemi P, Abraham A (2021a) An integrated sustainable medical supply chain network during COVID-19. Eng Appl Artif Intell 100:104188

Goodarzian F, Kumar V, Abraham A (2021b) Hybrid meta-heuristic algorithms for a supply chain network considering different carbon emission regulations using big data characteristics. Soft Comput:1–31

Govindan K, Mina H, Esmaeili A, Gholami-Zanjani SM (2020) An integrated hybrid approach for circular supplier selection and closed loop supply chain network design under uncertainty. J Clean Prod 242:118317

Gu Q, Wang R, Xie H, Li X, Jiang S, Xiong N (2021) Modified non-dominated sorting genetic algorithm III with fine final level selection. Appl Intell:1–34

Hasanov P, Jaber M, Tahirov N (2019) Four-level closed loop supply chain with remanufacturing. Appl Math Model 66:141–155

Hosseini-Motlagh S-M, Nouri-Harzvili M, Johari M, Sarker BR (2020) Coordinating economic incentives, customer service and pricing decisions in a competitive closed-loop supply chain. J Clean Prod 255:120241

Jahani N, Sepehri A, Vandchali HR, Tirkolaee EB (2021) Application of industry 4.0 in the procurement processes of supply chains: a systematic literature review. Sustainability 13(14):7520

Jiang G, Wang Q, Wang K, Zhang Q, Zhou J (2020) A novel closed-loop supply chain network design considering enterprise profit and service level. Sustainability 12(2):544

Kim J, Do Chung B, Kang Y, Jeong B (2018) Robust optimization model for closed-loop supply chain planning under reverse logistics flow and demand uncertainty. J Clean Prod 196:1314–1328

Kong F, Li J (2018) The promotion strategy of supply chain flexibility based on deep belief network. Appl Intell 48(5):1394–1405

Kuvvetli Y, Erol R (2020) Coordination of production planning and distribution in closed-loop supply chains. Neural Comput Appl:1–19

Li B, Wang Y, Wang Z (2021) Managing a closed-loop supply chain with take-back legislation and consumer preference for green design. J Clean Prod 282:124481

Mehranfar N, Bakhshandeh S (2021) Sustainable dual-channel closed-loop supply chain network design problem: a lighting industry case study. J Res Sci Eng Technol 9(3):1–41

Mehrjerdi YZ, Shafiee M (2021) A resilient and sustainable closed-loop supply chain using multiple sourcing and information sharing strategies. J Clean Prod 289:125141

Mohtashami Z, Aghsami A, Jolai F (2020) A green closed loop supply chain design using queuing system for reducing environmental impact and energy consumption. J Clean Prod 242:118452

Nasr AK, Tavana M, Alavi B, Mina H (2021) A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. J Clean Prod 287:124994

Papen P, Amin SH (2019) Network configuration of a bottled water closed-loop supply chain with green supplier selection. Journal of Remanufacturing 9(2):109–127

Samuel CN, Venkatadri U, Diallo C, Khatab A (2020) Robust closed-loop supply chain design with presorting, return quality and carbon emission considerations. J Clean Prod 247:119086

Santander P, Sanchez FAC, Boudaoud H, Camargo M (2020) Closed loop supply chain network for local and distributed plastic recycling for 3D printing: a MILP-based optimization approach. Resources, Conservation and Recycling 154:104531

Sitek P, Wikarek J (2018) A multi-level approach to ubiquitous modeling and solving constraints in combinatorial optimization problems in production and distribution. Appl Intell 48(5):1344–1367

Son D, Kim S, Jeong B (2021) Sustainable part consolidation model for customized products in closed-loop supply chain with additive manufacturing hub. Addit Manuf 37:101643

Taheri-Bavil-Oliaei M, Zegordi SH, Tavakkoli-Moghaddam R (2021) Bi-objective build-to-order supply chain network design under uncertainty and time-dependent demand: an automobile case study. Comput Ind Eng 154:107126

Tirkolaee EB, Dashtian Z, Weber GW, Tomaskova H, Soltani M, Mousavi NS (2021) An integrated decision-making approach for green supplier selection in an agri-food supply chain: threshold of robustness worthiness. Mathematics 9(11):1304

van der Laan EA (2019) Closed Loop Supply Chain Management Operations, Logistics and Supply Chain Management, pp. 353-375. Springer

Wu CH (2021) A dynamic perspective of government intervention in a competitive closed-loop supply chain. Eur J Oper Res 294(1):122–137

Yadegari E, Alem-Tabriz A, Zandieh M (2019) A memetic algorithm with a novel neighborhood search and modified solution representation for closed-loop supply chain network design. Comput Ind Eng 128:418–436

Yavari M, Zaker H (2020) Designing a resilient-green closed loop supply chain network for perishable products by considering disruption in both supply chain and power networks. Comput Chem Eng 134:106680

Yun Y, Chuluunsukh A, Gen M (2020) Sustainable closed-loop supply chain design problem: a hybrid genetic algorithm approach. Mathematics 8(1):84

Zhao Z, Liu B, Zhang C, Liu H (2019) An improved adaptive NSGA-II with multi-population algorithm. Appl Intell 49(2):569–580

Zhu Q, Sarkis J (2020) Product deletion and sustainable supply chains global perspectives on green business administration and sustainable supply chain management, pp 1-15. IGI global

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babaeinesami, A., Tohidi, H., Ghasemi, P. et al. A closed-loop supply chain configuration considering environmental impacts: a self-adaptive NSGA-II algorithm. Appl Intell 52, 13478–13496 (2022). https://doi.org/10.1007/s10489-021-02944-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10489-021-02944-9