Abstract

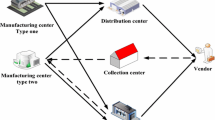

With the growth of multinational companies, increasing international and domestic competition between companies, upgrading information technology, and increasing customer expectations, accurate supply chain (SC) planning is essential. In such an environment, pollution has become more severe in recent decades, and with the weakening of the environment and global warming, green SC management strategies have become significant issues in recent decades. In this research, we consider the integrated production and distribution planning problem of a multi-level green closed-loop SC system, which includes multiple recycling, manufacturing/ remanufacturing, and distribution centers. We present a three-level bi-objective programming model to maximize profit and minimize the amount of greenhouse gas emissions. A hierarchical iterative approach utilizing the LP-metric method and the non-dominated sorting genetic algorithm (NSGA-II) is introduced to solve the proposed model. The Taguchi approach is applied to find optimum control parameters of NSGA-II. Moreover, Monte Carlo (MC) simulation is applied to tackle uncertainty in demand, and the NSGA-II algorithm is integrated with MC simulation (MCNSGA-II). Through numerical experiments on randomly generated instances, we observe that the average of the relative gaps NSGA-II and LP-metric method are 7%, 7%, and 1% for the three levels, respectively. Furthermore, it is observed that the value of convergence (C) and spacing (S) metrics of the MCNSGA-II algorithm are 0 and 1.82E + 07, which are better than NSGA-II.

Similar content being viewed by others

Data availability

All the data used in this study are artificial and can be used in any research project by just citing this article.

References

Aazami A, Saidi-Mehrabad M (2021) A production and distribution planning of perishable products with a fixed lifetime under vertical competition in the seller-buyer systems: a real-world application. J Manuf Syst 58:223–247

Barbarosoğlu G, Özgür D (1999) Hierarchical design of an integrated production and 2-echelon distribution system. Eur J Oper Res 118(3):464–484

Brandimarte P (2014) Handbook in Monte Carlo simulation: applications in financial engineering, risk management, and economics. Wiley

Casas-Ramírez MS, Camacho-Vallejo JF, González-Ramírez RG, Marmolejo-Saucedo JA, Velarde-Cantú JM (2018) Optimizing a biobjective production-distribution planning problem using a GRASP. Complexity. https://doi.org/10.1155/2018/3418580

Chen M, Wang W (1997) A linear programming model for integrated steel production and distribution planning. Int J Oper Prod Manag 17(6):592–610

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6(2):182–197

Dekker R, Bloemhof J, Mallidis I (2012) Operations Research for green logisticseAn overview of aspects, issues, contributions and challenges. Eur J Oper Res 219(3):671–679

Devapriya P, Ferrell W, Geismar N (2017) Integrated production and distribution scheduling with a perishable product. Eur J Oper Res 259(3):906–916

Ensafian H, Yaghoubi S (2017) Robust optimization model for integrated procurement, production and distribution in platelet supply chain. Transp Res Part E Logist Transp Rev 103:32–55

Fahimnia B, Farahani RZ, Marian R, Luong L (2013) A review and critique on integrated production–distribution planning models and techniques. J Manuf Syst 32:1–19

Farahani M, Rahmani D (2017) Production and distribution planning in petroleum supply chains regarding the impacts of gas injection and swap. Energy 141:991–1003

Geoffrion AM, Graves GW (1974) Multicommodity distribution system design by Benders decomposition. Manage Sci 20(5):822–844

Goodarzian F, Shishebori D, Nasseri H, Dadvar F (2021) A bi-objective production-distribution problem in a supply chain network under grey flexible conditions. RAIRO-Oper Res 55:1287–1316

Hansen P, Jaumard B, Savard G (1992) New branch and bound rules for linear bilevel programming. SIAM J Sci Stat Comput 13(5):1194–1217

Haq AN, Vrat P, Kanda A (1991) An integrated production–inventory–distribution model for manufacture of urea: a case. Int J Prod Econ 25:39–49

Hassanzadeh HR, Rouhani M (2010) A multi-objective gravitational search algorithm. Paper presented at the 2nd international conference on computational intelligence, communication systems and networks

Heidary MH, Aghaie A (2019) Risk averse sourcing in a stochastic supply chain: a simulation-optimization approach. Comput Ind Eng 130:62–74

Jing Y, Li W (2018) Integrated recycling-integrated production-distribution planning for decentralized closed-loop supply chain. J Ind Manag Optim 14(2):511–539

Kang HY, Pearn WL, Chung IP, Lee AH (2016) An enhanced model for the integrated production and transportation problem in a multiple vehicles environment. Soft Comput 20(4):1415–1435

Kheiri F (2018) A review on optimization methods applied in energy-efficient building geometry and envelope design. Renew Sustain Energy Rev 92:897–920

Kumar V, Minz S (2014) Multi-objective particle swarm optimization: an introduction. SmartCR 4(5):335–353

Lee YH, Kim SH (2000) Optimal production-distribution planning in supply chain management using a hybrid simulation-analytic approach. In Simulation Conference, IEEE

Liang TF, Cheng HW (2009) Application of fuzzy sets to manufacturing/distribution planning decisions with multi-product and multi-time period in supply chains. Expert Syst Appl 36(2):3367–3377

Lin C, Choy KL, Chung SH (2014) Survey of green vehicle routing problem: past and future trends. Expert Syst Appl 41(1):1118–1138

Ma Y, Yan F, Kang K, Wei X (2016) A novel integrated production-distribution planning model with conflict and coordination in a supply chain network. Knowl-Based Syst 105:119–133

Mirjalili S, Saremi S, Mirjalili SM, Coelho LDS (2016) Multi-objective grey wolf optimizer: a novel algorithm for multi-criterion optimization. Expert Syst Appl 47:106–119

Moon I, Jeong YJ, Saha S (2016) Fuzzy bi-objective production-distribution planning problem under the carbon emission constraint. Sustainability 8(8):798

Nasiri GR, Zolfaghari R, Davoudpour H (2014) An integrated supply chain production–distribution planning with stochastic demands. Comput Ind Eng 77:35–45

Niknamfar AH, Niaki STA, Pasandideh SHR (2015) Robust optimization approach for an aggregate production– distribution planning in a three-level supply chain. Int J Adv Manuf Technol 76(1–4):623–634

Nishizaki I, Hayashida T, Sekizaki S, Okabe J (2022) Data envelopment analysis approaches for two-level production and distribution planning problems. Eur J Oper Res 300(1):255–268

Nourifar R, Mahdavi I, Mahdavi-Amiri N, Paydar MM (2018) Optimizing decentralized production–distribution planning problem in a multi-period supply chain network under uncertainty. J Ind Eng Int 14(2):367–382

Osorio AF, Brailsford SC, Smith HK, Forero-Matiz SP, Camacho-Rodríguez BA (2017) Simulation-optimization model for production planning in the blood supply chain. Health Care Manag Sci 20(4):548–564

Ozdamar L, Yazgac T (1999) A hierarchical planning approach for a production–distribution system. Int J Prod Res 37:37–59

Pant K, Yadav VS, Singh AR (2021) Design of multi-tier multi-time horizon closed-loop supply chain network with sustainability under uncertain environment for Indian paper industry. Int J Sustain Eng 14(2):107–122

Parnianifard A, Zemouche A, Imran M, Wuttisittikulkij L (2020) Robust simulation-optimization of dynamic-stochastic production/inventory control system under uncertainty using computational intelligence. Uncertain Supply Chain Manag 8(4):633–648

Pasandideh SHR, Niaki STA, Asadi K (2015) Optimizing a bi-objective multi-product multi-period three echelon supply chain network with warehouse reliability. Expert Syst Appl 42(5):2615–2623

Peace GS (1993) Taguchi methods: a hands-on approach: Addison Wesley Publishing Company

Rafiei H, Safaei F, Rabbani M (2018) Integrated production-distribution planning problem in a competition-based four-echelon supply chain. Comput Ind Eng 119:85–99

Ramezani M, Kimiagari AM, Karimi B, Hejazi TH (2014) Closed-loop supply chain network design under a fuzzy environment. Knowl-Based Syst 59:108–120

Rezaeian J, Haghayegh S, Mahdavi I (2016) Designing an integrated production/distribution and inventory planning model of fixed-life perishable products. J Optim Ind Eng 9(19):47–60

Sadollah A, Eskandar H, Kim JH (2015) Water cycle algorithm for solving constrained multi-objective optimization problems. Appl Soft Comput 27:279–298

Sarrafha K, Rahmati SHA, Niaki STA, Zaretalab A (2015) A bi-objective integrated procurement, production, and distribution problem of a multi-echelon supply chain network design: a new tuned MOEA. Comput Oper Res 54:35–51

Scott JR (1995) Fault tolerant design using single and multi-criteria genetic algorithms. Massachusetts Institute of Technology

Seyedhosseini SM, Ghoreyshi SM (2015) An integrated production and distribution planning model for perishable products. Int J Oper Res 23(3):268–283

Sokolowski JA, Banks CM (2010) Modeling and simulation fundamentals: theoretical underpinnings and practical domains. Wiley

Srivastava SK (2008) Network design for reverse logistics. Omega 36(4):535–548

Tao J, Shao L, Guan Z, Ho W, Talluri S (2020) Incorporating risk aversion and fairness considerations into procurement and distribution decisions in a supply chain. Int J Prod Res 58(7):1950–1967

Varthanan PA, Murugan N, Kumar GM (2012) A simulation based heuristic discrete particle swarm algorithm for generating integrated production–distribution plan. Appl Soft Comput 12(9):3034–3050

Verma S, Pant M, Snasel V (2021) A comprehensive review on NSGA-II for multi-objective combinatorial optimization problems. IEEE Access 9:57757–57791

Wei W, Guimarães L, Amorim P, Almada-Lobo B (2017) Tactical production and distribution planning with dependency issues on the production process. Omega 67:99–114

Zamarripa M, Marchetti PA, Grossmann IE, Singh T, Lotero I, Gopalakrishnan A et al (2016) Rolling horizon approach for production–distribution coordination of industrial gases supply chains. Ind Eng Chem Res 55(9):2646–2660

Zheng Y, Zhang G, Han J, Lu J (2016) Pessimistic bilevel optimization model for risk-averse production-distribution planning. Inf Sci 372:677–689

Zitzler E, Thiele L (1999) Multiobjective evolutionary algorithms: a comparative case study and the strength Pareto approach. IEEE Trans Evol Comput 3(4):257–271

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest regarding the publication of this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kabiri, N.N., Emami, S. & Safaei, A.S. Simulation–optimization approach for the multi-objective production and distribution planning problem in the supply chain: using NSGA-II and Monte Carlo simulation. Soft Comput 26, 8661–8687 (2022). https://doi.org/10.1007/s00500-022-07152-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-022-07152-2