Abstract

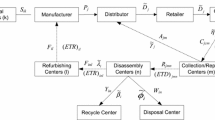

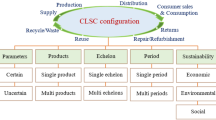

Immense concern for sustainability and increasing stakeholders’ involvement has sparked tremendous interest towards designing optimal supply chain networks with significant economic, environmental, and social influence. Central to the idea, this study aims to design a closed loop supply chain (CLSC) network for an Indian laptop manufacturer. The network configuration, which involves a manufacturer, suppliers, third party logistics providers (forward and reverse), retailers, customers and a non-government organisation (NGO), is modelled as a mixed integer linear programming problem with fuzzy goals of minimising environmental impact and maximising net profit and social impact, subject to fuzzy demand and capacity constraints. Profit is generated from the sale of primary and secondary laptops, earned tax credits, and revenue sharing with reverse logistics providers. The environmental implications are investigated by measuring the carbon emitted due to activities of manufacturing, assembling, dismantling, fabrication, and transportation. The social dimension is quantified in terms of the number of jobs created, training hours, community service hours, and donations to NGO. The novelty of the model rests on its quantification of the three triple bottom line (TBL) indicators and on its use of AHP–TOPSIS for modelling the multi-criteria perspectives of the stakeholders. Numerical weights for the triple lines of sustainability are utilized. Further, a fuzzy multi-objective programming approach that integrates fuzzy set theory with goal programming techniques is utilised to yield properly efficient solutions to the multi-objective problem and to provide a trade-off set for conflicting objectives. The significance of the CLSC model is empirically established as a decision support tool for improving the TBL performance of a particular Indian laptop manufacturer. Practical and theoretical implications are derived from the result analysis, and a generalised quantitative closed-loop model can be effectively adapted by other electronic manufacturers to increase their competitiveness, profitability, and to improve their TBL.

Similar content being viewed by others

References

Accorsi, R., Manzini, R., Pini, C., & Penazzi, S. (2015). On the design of closed-loop networks for product life cycle management: Economic, environmental and geography considerations. Journal of Transport Geography, 48, 121–134.

Altmann, M. (2015). A supply chain design approach considering environmentally sensitive customers: The case of a German manufacturing SME. International Journal of Production Research, 53(21), 6534–6550.

Amin, S. H., & Zhang, G. (2013). A multi-objective facility location model for closed-loop supply chain network under uncertain demand and return. Applied Mathematical Modelling, 37(6), 4165–4176.

Battini, D., Persona, A., & Sgarbossa, F. (2014). A sustainable EOQ model: Theoretical formulation and applications. International Journal of Production Economics, 149, 145–153.

Bellman, R. E., & Zadeh, L. A. (1970). Decision-making in a fuzzy environment. Management Science, 17(4), B-141.

Boukherroub, T., Ruiz, A., Guinet, A., & Fondrevelle, J. (2015). An integrated approach for sustainable supply chain planning. Computers & Operations Research, 54, 180–194.

Brandenburg, M., & Rebs, T. (2015). Sustainable supply chain management: A modeling perspective. Annals of Operations Research, 229(1), 213–252.

Brandenburg, M., Govindan, K., Sarkis, J., & Seuring, S. (2014). Quantitative models for sustainable supply chain management: Developments and directions. European Journal of Operational Research, 233(2), 299–312.

Cassen, R. H. (1987). Our common future: Report of the World Commission on Environment and Development. International Affairs, 64(1), 126–126.

Chaabane, A., Ramudhin, A., & Paquet, M. (2012). Design of sustainable supply chains under the emission trading scheme. International Journal of Production Economics, 135(1), 37–49.

Chen, Z., & Andresen, S. (2014). A multiobjective optimization model of production-sourcing for sustainable supply chain with consideration of social, environmental, and economic factors. Mathematical Problems in Engineering, 2014, 616107. https://doi.org/10.1155/2014/616107.

Chuang, C. H., Wang, C. X., & Zhao, Y. (2014). Closed-loop supply chain models for a high-tech product under alternative reverse channel and collection cost structures. International Journal of Production Economics, 156, 108–123.

CPCB (2014). List of registered E-waste dismantler/recycler in the country. http://www.cpcb.nic.in/Ewaste_Registration_List.pdf. Accessed 24 Nov 2016.

Cruz, J. M. (2013). Modeling the relationship of globalized supply chains and corporate social responsibility. Journal of Cleaner Production, 56, 73–85.

Daghigh, R., Jabalameli, M., Amiri, A., & Pishvaee, M. (2016). A multi-objective location-inventory model for 3PL providers with sustainable considerations under uncertainty. International Journal of Industrial Engineering Computations, 7(4), 615–634.

Darbari, J. D., Agarwal, V., Chaudhary, K., & Jha, P. C. (2015). Multi-criteria decision approach for a sustainable reverse logistics network under fuzzy environment. In International Conference on Industrial Engineering and Operations Management (IEOM) 2015, (pp. 1–7). IEEE.

De Giovanni, P. (2014). Environmental collaboration in a closed-loop supply chain with a reverse revenue sharing contract. Annals of Operations Research, 220(1), 135–157.

Dehghanian, F., & Mansour, S. (2009). Designing sustainable recovery network of end-of-life products using genetic algorithm. Resources, Conservation and Recycling, 53(10), 559–570.

Devika, K., Jafarian, A., & Nourbakhsh, V. (2014). Designing a sustainable closed-loop supply chain network based on triple bottom line approach: A comparison of metaheuristics hybridization techniques. European Journal of Operational Research, 235(3), 594–615.

Diabat, A., Abdallah, T., Al-Refaie, A., Svetinovic, D., & Govindan, K. (2013). Strategic closed-loop facility location problem with carbon market trading. IEEE Transactions on engineering Management, 60(2), 398–408.

Dwivedy, M., & Mittal, R. K. (2010). Future trends in computer waste generation in India. Waste management, 30(11), 2265–2277.

Elhedhli, S., & Merrick, R. (2012). Green supply chain network design to reduce carbon emissions. Transportation Research Part D: Transport and Environment, 17(5), 370–379.

Elkington, J. (1998). Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environmental Quality Management, 8(1), 37–51.

Ernst, D. (2014). Upgrading India’s electronics manufacturing industry: Regulatory reform and industrial policy, a special stusy. Honolulu, Hawaii: East-West Centre.

Erol, I., Sencer, S., & Sari, R. (2011). A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecological Economics, 70(6), 1088–1100.

Eskandarpour, M., Dejax, P., Miemczyk, J., & Péton, O. (2015). Sustainable supply chain network design: An optimization-oriented review. Omega, 54, 11–32.

Fahimnia, B., Sarkis, J., Dehghanian, F., Banihashemi, N., & Rahman, S. (2013). The impact of carbon pricing on a closed-loop supply chain: An Australian case study. Journal of Cleaner Production, 59, 210–225.

Fattahi, M., & Govindan, K. (2017). Integrated forward/reverse logistics network design under uncertainty with pricing for collection of used products. Annals of Operations Research, 253(1), 193–225.

Gaur, J., Subramoniam, R., Govindan, K., & Huisingh, D. (2016). Closed-loop supply chain management: From conceptual to an action oriented framework on core acquisition. Journal of Cleaner Production, 30, 1e10.

Gimenez, C., Sierra, V., & Rodon, J. (2012). Sustainable operations: Their impact on the triple bottom line. International Journal of Production Economics, 140(1), 149–159.

Govindan, K., Jafarian, A., & Nourbakhsh, V. (2015). Bi-objective integrating sustainable order allocation and sustainable supply chain network strategic design with stochastic demand using a novel robust hybrid multi-objective metaheuristic. Computers & Operations Research, 62, 112–130.

Govindan, K., Jafarian, A., Khodaverdi, R., & Devika, K. (2014). Two-echelon multiple-vehicle location-routing problem with time windows for optimization of sustainable supply chain network of perishable food. International Journal of Production Economics, 152, 9–28.

Govindan, K., Jha, P. C., & Garg, K. (2016a). Product recovery optimization in closed-loop supply chain to improve sustainability in manufacturing. International Journal of Production Research, 54(5), 1463–1486.

Govindan, K., Khodaverdi, R., & Jafarian, A. (2013). A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. Journal of Cleaner Production, 47, 345–354.

Govindan, K., Fattahi, M., & Keyvanshokooh, E. (2017). Supply chain network design under uncertainty: A comprehensive review and future research directions. European Journal of Operational Research, 263(1), 108–141.

Govindan, K. (2017). Sustainable consumption and production in the food supply chain: A conceptual framework. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2017.03.003.

Govindan, K., Paam, P., & Abtahi, A. R. (2016b). A fuzzy multi-objective optimization model for sustainable reverse logistics network design. Ecological Indicators, 67, 753–768.

Govindan, K., Soleimani, H., & Kannan, D. (2015). Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. European Journal of Operational Research, 240(3), 603–626.

Govindan, K., & Soleimani, H. (2017). A review of reverse logistics and closed-loop supply chains: A journal of cleaner production focus. Journal of Cleaner Production, 142, 371–384.

Guide, V. D. R, Jr., & Van Wassenhove, L. N. (2009). OR FORUM—The evolution of closed-loop supply chain research. Operations Research, 57(1), 10–18.

Hassini, E., Surti, C., & Searcy, C. (2012). A literature review and a case study of sustainable supply chains with a focus on metrics. International Journal of Production Economics, 140(1), 69–82.

Hollos, D., Blome, C., & Foerstl, K. (2012). Does sustainable supplier co-operation affect performance? Examining implications for the triple bottom line. International Journal of Production Research, 50(11), 2968–2986.

Ilgin, M. A., & Gupta, S. M. (2010). Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. Journal of Environmental Management, 91(3), 563–591.

Jaehn, F. (2016). Sustainable operations. European Journal of Operational Research, 253(2), 243–264.

Jindal, A., & Sangwan, K. S. (2017). Multi-objective fuzzy mathematical modelling of closed-loop supply chain considering economical and environmental factors. Annals of Operations Research, 257(1–2), 95–120.

Kannan, D., Govindan, K., & Shankar, M. (2016). India: Formalize recycling of electronic waste. Nature, 530(7590), 281–281.

Kleindorfer, P. R., Singhal, K., & Wassenhove, L. N. (2005). Sustainable operations management. Production and Operations Management, 14(4), 482–492.

Kuehr, R. (2003). Managing PCS through policy: Review and ways to extend lifespan. In R. Kuehr & E. Williams (Eds.), Computers and the environment: Understanding and managing their impacts (pp. 253–278). Netherlands: Springer.

Kumar, R. S., Choudhary, A., Babu, S. A. I., Kumar, S. K., Goswami, A., & Tiwari, M. K. (2017). Designing multi-period supply chain network considering risk and emission: A multi-objective approach. Annals of Operations Research, 250(2), 427–461.

Kumar, S., Teichman, S., & Timpernagel, T. (2012). A green supply chain is a requirement for profitability. International Journal of Production Research, 50(5), 1278–1296.

Liang, T. F. (2008). Fuzzy multi-objective production/distribution planning decisions with multi-product and multi-time period in a supply chain. Computers & Industrial Engineering, 55(3), 676–694.

Liang, T. F., & Cheng, H. W. (2009). Application of fuzzy sets to manufacturing/distribution planning decisions with multi-product and multi-time period in supply chains. Expert systems with applications, 36(2), 3367–3377.

Mangla, S. K., Govindan, K., & Luthra, S. (2017). Prioritizing the barriers to achieve sustainable consumption and production trends in supply chains using fuzzy analytical hierarchy process. Journal of Cleaner Production, 151, 509–525.

Mathivathanan, D., Govindan, K., & Haq, A. N. (2017). Exploring the impact of dynamic capabilities on sustainable supply chain firm’s performance using Grey-analytical hierarchy process. Journal of Cleaner Production, 147, 637–653.

Millet, D. (2011). Designing a sustainable reverse logistics channel: The 18 generic structures framework. Journal of Cleaner Production, 19(6), 588–597.

Min, H., & Kim, I. (2012). Green supply chain research: Past, present, and future. Logistics Research, 4(1–2), 39–47.

Mishima, K., & Mishima, N. (2011). A study on determination of upgradability of laptop PC components. In J. Hesselbach & C. Herrmann (Eds.), Functional thinking for value creation (pp. 297–302). Berlin: Springer.

Mohamed, R. H. (1997). The relationship between goal programming and fuzzy programming. Fuzzy Sets and Systems, 89(2), 215–222.

Mota, B., Gomes, M. I., Carvalho, A., & Barbosa-Povoa, A. P. (2015). Towards supply chain sustainability: economic, environmental and social design and planning. Journal of Cleaner Production, 105, 14–27.

Mousazadeh, M., Torabi, S. A., & Pishvaee, M. S. (2014). Green and reverse logistics management under fuzziness. In C. Kahraman & B. Öztayşi (Eds.), Supply chain management under fuzziness (pp. 607–637). Berlin: Springer.

Narasimhan, R. (1980). Goal programming in a fuzzy environment. Decision Sciences, 11(2), 325–336.

Nikolaou, I. E., Evangelinos, K. I., & Allan, S. (2013). A reverse logistics social responsibility evaluation framework based on the triple bottom line approach. Journal of Cleaner Production, 56, 173–184.

Önüt, S., & Soner, S. (2008). Transshipment site selection using the AHP and TOPSIS approaches under fuzzy environment. Waste Management, 28(9), 1552–1559.

Özkır, V., & Başlıgil, H. (2013). Multi-objective optimization of closed-loop supply chains in uncertain environment. Journal of Cleaner Production, 41, 114–125.

Paksoy, T., Bektaş, T., & Özceylan, E. (2011). Operational and environmental performance measures in a multi-product closed-loop supply chain. Transportation Research Part E: Logistics and Transportation Review, 47(4), 532–546.

Perçin, S. (2009). Evaluation of third-party logistics (3PL) providers by using a two-phase AHP and TOPSIS methodology. Benchmarking: An International Journal, 16(5), 588–604.

Pérez-Fortes, M., Laínez-Aguirre, J. M., Arranz-Piera, P., Velo, E., & Puigjaner, L. (2012). Design of regional and sustainable bio-based networks for electricity generation using a multi-objective MILP approach. Energy, 44(1), 79–95.

Pinto-Varela, T., Barbosa-Póvoa, A. P. F., & Novais, A. Q. (2011). Bi-objective optimization approach to the design and planning of supply chains: Economic versus environmental performances. Computers & Chemical Engineering, 35(8), 1454–1468.

Pishvaee, M. S., & Razmi, J. (2012). Environmental supply chain network design using multi-objective fuzzy mathematical programming. Applied Mathematical Modelling, 36(8), 3433–3446.

Pishvaee, M. S., Razmi, J., & Torabi, S. A. (2012). Robust possibilistic programming for socially responsible supply chain network design: A new approach. Fuzzy Sets and Systems, 206, 1–20.

Pishvaee, M. S., Razmi, J., & Torabi, S. A. (2014). An accelerated Benders decomposition algorithm for sustainable supply chain network design under uncertainty: A case study of medical needle and syringe supply chain. Transportation Research Part E: Logistics and Transportation Review, 67, 14–38.

Qin, X. S., Huang, G. H., Chakma, A., Nie, X. H., & Lin, Q. G. (2008). A MCDM-based expert system for climate-change impact assessment and adaptation planning—A case study for the Georgia Basin Canada. Expert Systems with Applications, 34(3), 2164–2179.

Rajeev, A., Pati, R. K., Padhi, S. S., & Govindan, K. (2017). Evolution of sustainability in supply chain management: A literature review. Journal of Cleaner Production, 162, 299–314.

Ramos, T. R. P., Gomes, M. I., & Barbosa-Póvoa, A. P. (2014). Planning a sustainable reverse logistics system: Balancing costs with environmental and social concerns. Omega, 48, 60–74.

Rathore, P., Kota, S., & Chakrabarti, A. (2011). Sustainability through remanufacturing in India: A case study on mobile handsets. Journal of Cleaner Production, 19(15), 1709–1722.

Rubin, P. A., & Narasimhan, R. (1984). Fuzzy goal programming with nested priorities. Fuzzy Sets and Systems, 14(2), 115–129.

Rubio, S., Chamorro, A., & Miranda, F. J. (2008). Characteristics of the research on reverse logistics (1995–2005). International Journal of Production Research, 46(4), 1099–1120.

Saaty, T. L. (2008). Decision making with the analytic hierarchy process. International Journal of Services Sciences, 1(1), 83–98.

Santibañez-Aguilar, J. E., González-Campos, J. B., Ponce-Ortega, J. M., Serna-González, M., & El-Halwagi, M. M. (2014). Optimal planning and site selection for distributed multiproduct biorefineries involving economic, environmental and social objectives. Journal of Cleaner Production, 65, 270–294.

Sarkis, J., Helms, M. M., & Hervani, A. A. (2010). Reverse logistics and social sustainability. Corporate Social Responsibility and Environmental Management, 17(6), 337–354.

Selim, H., & Ozkarahan, I. (2008). A supply chain distribution network design model: An interactive fuzzy goal programming-based solution approach. The International Journal of Advanced Manufacturing Technology, 36(3–4), 401–418.

Seuring, S. (2013). A review of modeling approaches for sustainable supply chain management. Decision Support Systems, 54(4), 1513–1520.

Seuring, S., & Müller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production, 16(15), 1699–1710.

Shi, J., Liu, Z., Tang, L., & Xiong, J. (2017). Multi-objective optimization for a closed-loop network design problem using an improved genetic algorithm. Applied Mathematical Modelling, 45, 14–30.

Shokohyar, S., & Mansour, S. (2013). Simulation-based optimisation of a sustainable recovery network for Waste from Electrical and Electronic Equipment (WEEE). International Journal of Computer Integrated Manufacturing, 26(6), 487–503.

Soysal, M., Bloemhof-Ruwaard, J. M., & van der Vorst, J. G. A. J. (2014). Modelling food logistics networks with emission considerations: The case of an international beef supply chain. International Journal of Production Economics, 152, 57–70.

Sundarakani, B., De Souza, R., Goh, M., Wagner, S. M., & Manikandan, S. (2010). Modeling carbon footprints across the supply chain. International Journal of Production Economics, 128(1), 43–50.

Talaei, M., Moghaddam, B. F., Pishvaee, M. S., Bozorgi-Amiri, A., & Gholamnejad, S. (2016). A robust fuzzy optimization model for carbon-efficient closed-loop supply chain network design problem: A numerical illustration in electronics industry. Journal of Cleaner Production, 113, 662–673.

Tang, C. S., & Zhou, S. (2012). Research advances in environmentally and socially sustainable operations. European Journal of Operational Research, 223(3), 585–594.

Tiwari, R. N., Dharmar, S., & Rao, J. R. (1987). Fuzzy goal programming—An additive model. Fuzzy Sets and Systems, 24(1), 27–34.

Velasquez, M., & Hester, P. T. (2013). An analysis of multi-criteria decision making methods. International Journal of Operations Research, 10(2), 56–66.

Wang, J. J., Jing, Y. Y., Zhang, C. F., & Zhao, J. H. (2009). Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renewable and Sustainable Energy Reviews, 13(9), 2263–2278.

Wath, S. B., Dutt, P. S., & Chakrabarti, T. (2011). E-waste scenario in India, its management and implications. Environmental Monitoring and Assessment, 172(1), 249–262.

Wath, S. B., Vaidya, A. N., Dutt, P. S., & Chakrabarti, T. (2010). A roadmap for development of sustainable E-waste management system in India. Science of the Total Environment, 409(1), 19–32.

Wei, J., & Zhao, J. (2013). Reverse channel decisions for a fuzzy closed-loop supply chain. Applied Mathematical Modelling, 37(3), 1502–1513.

Wilson, D. C., Velis, C., & Cheeseman, C. (2006). Role of informal sector recycling in waste management in developing countries. Habitat International, 30(4), 797–808.

Winkler, H. (2011). Closed-loop production systems—A sustainable supply chain approach. CIRP Journal of Manufacturing Science and Technology, 4(3), 243–246.

Zavadskas, Edmundas Kazimieras, & Turskis, Zenonas. (2011). Multiple criteria decision making (MCDM) methods in economics: An overview. Technological and Economic Development of Economy, 17(2), 397–427.

Zhalechian, M., Tavakkoli-Moghaddam, R., Zahiri, B., & Mohammadi, M. (2016). Sustainable design of a closed-loop location–routing–inventory supply chain network under mixed uncertainty. Transportation Research Part E: Logistics and Transportation Review, 89, 182–214.

Zimmermann, H. J. (1978). Fuzzy programming and linear programming with several objective functions. Fuzzy Sets and Systems, 1(1), 45–55.

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

1.1 AHP–TOPSIS methodology

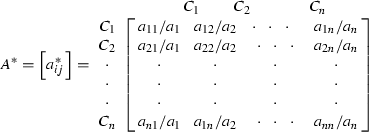

The integrated AHP–TOPSIS technique is utilised for generating the weights of importance for the three TBL objectives (Perçin 2009). AHP is used for deriving weights \(v_{i }\) (normalized) for the 11 criteria (alternatives) with respect to the TBL goals. Further, AHP is used again for finding the normalized priority vectors \(u_{i }\) representing the importance of the three TBL objectives (alternatives) with respect to each of the 11 criteria (goals). The AHP method is explained in Steps 1–4 given below. Utilising these normalized priorities in the initial decision matrix of TOPSIS, the final weights of the TBL objectives (alternatives) are then calculated as per the criteria \(\hbox {C}_{1}\)-\(\hbox {C}_{11}\), following the steps 5–10.

The steps of AHP are as follows:

-

1.

Suppose there are ‘n’ alternatives whose importance weights need to be calculated with respect to a given goal ‘g.’ The alternatives are compared pair-wise on a scale of 1–9 representing subjective judgments: ‘1—equally important’, ‘3— moderately important’, ‘5—important’, ‘7—very important’, ‘9— extremely important’, with the intermediate subjectivities represented by 2, 4, 6, and 8. This leads to construction of nxn matrix A whose (i, j)th element (\(a_{{ ij}}\)) is the quantified value of the pair-wise comparison of the ith and jth criteria.

-

2.

Normalize the matrix A by dividing each (i, j)th element (\(a_{{ ij}}\)) by the jth column sum \(a_{j}\) to derive the matrix A* as shown below:

-

3.

Determine the consistency of the matrix A* by calculating the maximal eigen value, consistency index (CI), and the consistency ratio (CR) utilising the equations given below:

$$\begin{aligned} { Aw}= & {} \lambda w, { CI}=\frac{\lambda _{\max } -n}{n-1}, { CR}=\frac{CI}{RI} {\textit{where n is order of A}} \\ { and}\,\lambda _{\max }= & {} \max \left\{ {\lambda _i ,\;i=1,\ldots n} \right\} \end{aligned}$$

-

4.

Calculate the averages \(a_{i}*\) of rows of the matrix A*. The normalised priority vector is obtained by normalising the vector (\(a_{1}*, a_{2}*, {\ldots }.a_{n}*)\)

Using Steps 1–4, the normalised priority vector \(\{\hbox {v}_{1}, {\ldots }.\hbox {v}_{11}\}\) is determined. Based on each criterion, the normalised priority vector \(\{\hbox {u}_{1j}\), \(\hbox {u}_{2j}\), \(\hbox {u}_{3j},\}\) is determined. Table 19 provides the value of RI.

Further, to determine the importance rankings of the TBL objectives \((k=3)\) with respect to the criteria \(\hbox {C}_{1}\)–\(\hbox {C}_{11}\) using TOPSIS, the following steps are utilised:

-

5.

Construct the IDM for TOPSIS as shown in Table 20.

-

6.

Construct the nxn weighted normalised matrix \(\bar{{U}}=(\bar{{u}}_{ij} )=wU=(w_i u_{ij} )\)

-

7.

Calculate the ideal solution and the negative-ideal solution as follows:

$$\begin{aligned} \bar{{U}}^{+}= & {} \left\{ {(\mathop {\max \;\bar{{u}}_{kj} }\limits _k |\;j\in J^{{\prime }}),(\mathop {\min \;\bar{{u}}_{kj} }\limits _k |\;j\in J^{{\prime }{\prime }})|k=1,2,3} \right\} =\left\{ {\bar{{u}}_1^+ ,\bar{{u}}_2^+ ,\bar{{u}}_3^+ } \right\} ,\\ \bar{{U}}^{-}= & {} \left\{ {(\mathop {\min \;\bar{{u}}_{kj} }\limits _k |\;j\in J^{{\prime }}),(\mathop {\max \;\bar{{u}}_{kj} }\limits _k |\;j\in J^{{\prime }{\prime }})|k=1,2,3} \right\} =\left\{ {\bar{{u}}_1^- ,\bar{{u}}_2^- ,\bar{{u}}_3^- } \right\} \end{aligned}$$where \( J^{{\prime }} \,{ and}\, J^{{\prime }{\prime }}\) are associated with benefit and cost criteria respectively.

-

8.

Calculate the separation measure of each alternative as follows:

$$\begin{aligned} d_k^+= & {} \sqrt{\sum _{k=1}^3 {\left( {\bar{{u}}_{kj} -\bar{{u}}_k^+ } \right) ^{2}} },\;d_k^- =\sqrt{\sum _{k=1}^3 {\left( {\bar{{u}}_{kj} -\bar{{u}}_k^- } \right) ^{2}} }, k=1,2,3 \end{aligned}$$ -

9.

Calculate the relative closeness of each goal as:

Clearly, \(0\le CC_i^*\le \,1 i=1,2,,3\), and higher value implies closeness to the ideal solution.

-

10.

The weighting vector \(w=\{\hbox {w}_{1}, \hbox {w}_{2}, \hbox {w}_{3}\}\) of the goals is obtained by normalising the closeness vector CC*.

Rights and permissions

About this article

Cite this article

Darbari, J.D., Kannan, D., Agarwal, V. et al. Fuzzy criteria programming approach for optimising the TBL performance of closed loop supply chain network design problem. Ann Oper Res 273, 693–738 (2019). https://doi.org/10.1007/s10479-017-2701-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-017-2701-2