Abstract

The low cross-linked porous polymers were prepared using terpene compounds (citral, limonene and pinene) and divinylbenzene with a suspension method. The prepared materials were characterized by: ATR-FTIR, low temperature nitrogen adsorption–desorption, TGA, swelling ratio and solid phase extraction (SPE) experiments. ATR-FTIR verified the chemical structures of the polymers. All the materials had developed internal structure with SBET in the range of 45–190 m2/g and high thermal stability. Sorption properties of the terpene-based polymers were tested for phenolic compounds (phenol, 2-chlorophenol, 2,4-dichlorophenol and 2,4,6-trichlorophenol) and popular non-steroidal anti-inflammatory drugs (aspirin, paracetamol and ibuprofen) and an antibiotic (ampicillin) with a dynamic solid phase extraction (SPE) method. The recoveries of 2,4-dichlorophenol and 2,4,6-trichlorophenol remained at a level 80–100% for all new materials even for 10–13 concentration cycles. Very high recoveries (70–100%) were also obtained for ibuprofen and aspirin from the citral- and limonene-based polymers using one-component solutions. However, when using ternary component solutions, the maximum recoveries of ibuprofen reached 70%. Paracetamol recoveries did not exceed 20%, while these for ampicillin ranged from 40 to 80%. The performed studies have proven that the process is affected by both chemical nature of adsorbents and adsorbates. Especially in the case of multicomponent solutions, the acid—base balance of solutes in the solution and on the polymer—solution interface should be taken into account as an important factor determining obtained recoveries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, the use of renewable energy sources in chemical syntheses has become increasingly common. This trend is also evident in the synthesis of polymers, in which monomers derived from petroleum are being replaced by monomers of natural origin like fatty acids, vegetable oils, essential oils, polysaccharides or lignin [1,2,3,4,5,6,7,8,9,10].

Terpenes and terpenoids, which are the main components of plant essential oils are more and more popular among natural compounds used in synthesis of polymers. The greatest natural source of these compounds is turpentine that is a product manufactured during distillation of resins from coniferous trees, especially pine [11, 12].

Many terpene compounds have a cyclic structure. Their basic structural unit is isoprene. Depending on the number of isoprene units included in the molecule, terpenes can be divided into hemiterpenes (1 unit), monoterpenes (2) sesquiterpenes (3), diterpenes (4), sesterpenes (5), triterpenes (6), tetraterpenes (8) and polyterpenes (N) [13]. The latter can also be found in nature as polyisoprene which is the main component of gutta-percha and natural rubber. There are many works on terpene-based polymers [12,13,14,15,16]. Generally, there are three types of terpene unit positions in the polymer structure: main chain (polyterpenes), terminal or central group and pendant group (terpene-polymer conjugates).

Monoterpenes like limonene, pinene and myrcene are most readily used as monomers for the synthesis of polymers, due to their high availability, low price, and ease of isolation [12]. Besides isoprene, only limonene, pinene, ocimene or myrcene undergo chain-growth polymerization (radical, cationic or anionic) to a greater or lesser extent. Myrcene is particularly reactive, as it contains three double bonds. It can be polymerized and copolymerized particularly easily by the radical mechanism. Triterpenes like cholic acid or betulin can be polymerized via step-growth polymerization (polycondensation) in which their COOH and OH functional groups are used [12,13,14, 17, 18].

Terpenes whose polymerization rate is not satisfactory or those which do not polymerize directly at all can be chemically modified, e.g. carvone or menthone subjected to oxidation convert to a lactone that readily undergoes ring opening polymerization. Other modification reactions include carbonation, esterification or amination, but are not limited just to them [14, 16, 19, 20]. Commercially, terpene based polymers are used in the production of adhesives as (co-)tackifiers or modifiers [21]. There were also made attempts to use terpenes for the synthesis of sorbents [22].

Terpenoids possessing functional groups like hydroxyl or carboxylic can by covalently attached to synthetic polymers that are end-functionalized. The attachment point can be in the middle, as well as, at the end of the chain. In this way the terpene-polymer conjugates are formed. These materials possess very attractive properties, e.g. conjugates of bile acids with poly(ethylene glycol) (PEG) exhibit self-assembly behavior in water, which creates the possibility of using them as drug carriers. Terpenoids with functional groups can also be used as central core to form star-shaped polymers, e.g. the hydroxyl groups of cholic acid may be used as the sites on which the arms of a polymer, such as polyester, can grow [14].

Another type of terpene-polymer conjugates are polymers with pedant terpenoids entities which are not included in the main chain. Such polymers can be obtained via „grafting of terpenes onto polymer chains” or „the polymerization of monomers comprising both chemically inert terpene entity and a readily polymerizable moiety”. A synthesis of vinyl or acetylenic monomers with cholesterol can serve as an example. The prepared polymer had chiral and liquid crystalline properties that enable to use it in electronics and optics [14]. Other synthesized terpene-polymer conjugates possessed ability to self-organization or aggregation in water, and found application in biomedicine as drug carriers or in gene transfection. Another one has been applied as imprinted polymers in chemical analytics [14].

Many essential oils, including terpene oils, are known to have antimicrobial and anti-inflammatory properties. Therefore, these compounds have been used to obtain terpene based antibacterial polymeric films. In this case a plasma polymerization was applied. In general, coatings made from essential oils exhibit desirable properties such as optical transparency, high temperature of resistance, moderate hydrophilicity and bioactivity or biocompatibility [17, 23].

The various possibilities of using terpene compounds in polymer chemistry have been presented above. However, among many papers dealing with application of terpenes in the synthesis of polymers, only a few concern the synthesis of porous polymers for potential applications in purification and separation techniques.

Recognizing some space in this area, an attempt was made to use terpenes/terpenoids, such as citral, limonene and pinene, as monomers for the synthesis of polymer sorbents. In our previous studies we managed to successfully synthesize terpene-based copolymers out of equimolar mixture of the terpenes with divinylbenzene [9]. Since the obtained materials presented very promising results of sorption properties, a decision was made to prepare a new series of porous copolymers with a reduced content of divinylbenzene, which resulted in obtaining more environmentally friendly products, but with a lower degree of cross-linking compared to the previous series. The materials were prepared using suspension polymerization method. The use of toluene as a pore forming agent allowed to develop the internal structure [24]. The newly synthesized materials possessed specific surface areas and total pore volume in the range of 45–190 m2/g and 0.11–0.26 cm3/g, respectively. They also had the ability to swell in organic solvents, which indicated a low degree of cross-linking of these polymers. The undoubted advantage of these new polymers is their high thermal stability reaching 300 °C.

The new terpene-based materials were tested for potential use as sorbents and the obtained results were compared with those for the homopolymer pDVB synthesized under the same conditions. The carried out tests showed that the sorption ability of the new materials is high and the recoveries for 2,4-dichlorophenol and 2,4,6-trichlorophenol reached 80–100% even in the 10–13 concentration cycle. 100% recoveries were also obtained for aspirin and ibuprofen from the LIM-DVB polymer.

2 Experimental

2.1 Reagents and solvents

97% (R)-( +)limonene (LIM) were from Aldrich (Steinheim, Germany). 96% cis/trans citral (CIT) and 97% (1R)-( +)-alfa-pinene (PIN) bought from SAFC. 98% α,α’-Azoiso-bis-butyronitrile (AIBN) from Fluka (Busch, Switzerland).

Divinylbenzene (DVB), methanol (MeOH), 2-chlorophenol (ChP), 2,4-dichlorophenol (DChP) and 2,4,6-trichlorophenol (TChP), 2-acetoxybenzoic acid (aspirin), (S)-( +)-2-(4-isobutylphenyl)propionic acid (ibuprofen), 4-Acetamidophenol (paracetamol), ampicillin sodium salt, were purchased from Merck (Darmstadt, Germany).

Poli(vinyl alcohol) (PVAL), 36% HCl, KOH, KI, Na2S2O3, starch, methylene blue, hexane, acetone, toluene, chloroform and phenol (PH) were bought from POCh (Gliwice, Poland) and methyl red from Chempur (Poland).

2.2 Synthesis of low cross-linked terpene-based polymeric microspheres

The syntheses of porous polymers with reduced amount of cross-linking agent—divinylbenzene were prepared by suspension polymerization method. First in a three-necked flask equipped with a stirrer, a thermometer and a water condenser 4% aqueous solution of PVAL was prepared as a dispersion medium. In the next step, the mixture of monomers (CIT, LIM, PIN), cross-linker (DVB), pore forming diluent (toluene) and the initiator (AIBN) was prepared and poured to the dispersion medium, amounts of the individual reactants are collected in Table 1. The reaction was carried out for 20 h at 80 °C. The obtained copolymers were washed with boiling distilled water, and then with methanol in Soxhlet apparatus. The purified polymers were left in the air to dry. For comparison purpose homopolymer pDVB was prepared, according to the same procedure.

2.3 Methods of characterization

ATR-FTIR spectra were recorded using a Bruker FTIR spectrophotometer TENSOR 27 in the frequency range of 4000 to 600 cm−1, and the resolution of the apparatus was 4 cm−1.

Due to the fact, that determination of acid number values for porous polymers by the standard titration method is not a convenient method, because of slow process of penetration of the titrant through the porous polymeric network, a back titration method was applied. A weighed polymer sample (100 mg) was mixed with1mL of methanol and next with10 mL of KOH aqueous solution (0.05 M), and left at room temperature for about 1 h. It was sufficient time for the acidic moieties to react with alkaline solution. The excess of KOH was titrated with a 0.05 M HCl solution. A mixture of methyl red and methylene blue was used as an indicator. In the same way a blank test was carried out. The equation for calculating the acid number can be found in the supplementary material.

Determination of iodine value (IV) also was performed using back titration. About 200 mg of a polymer sample was suspended in 10 mL of chloroform and 15 mL of Hanus reagent was added. The sample was left in the dark for 30 min to allow iodine to saturate the double bonds present in the polymer structure. Next, 50 mL of distilled water and 15 mL of 10% aqueous KI solution was added to the vessel and the obtained mixture was titrated with 0.179 M Na2S2O3 solution until its turned orange. Then 1 mL of 1% starch indicator was added and the titration was continued until starch was completely discolored. According to the same procedure the blank test was carried out. The equation for calculating the iodine value is also placed in the supplementary material.

The porous structure parameters of the studied polymers were evaluated using standard nitrogen adsorption–desorption isotherms measurements at – 196 °C with adsorption analyser ASAP 2405 (Micrometrics Inc., USA). Before analyses, the samples were outgassed at 70 ºC.

The specific surface area (SBET) was calculated using the BET method while the total pore volume (Vtot) was evaluated as the volume of liquid adsorbate at a relative pressure of 0.99. The pore size distribution (PSD) was calculated from the adsorption branch of the isotherm using 2D-NLDFT model available as free version from the SAIEUS 3.0 software (Micromeritics) www.nldft.com.

Swelling capacity tests were performed using water, methanol, acetone, toluene and hexane as swelling solvents. Weighed amount of a polymer (approx. 50 mg) was placed in a special graduated syringe and immersed in solvent for 24 h. The scale was used to determine the volume of the polymer before and after swelling. The swelling capacity (swelling ratio) was expressed as the percentage value of the increase in the sample volume after swelling in relation to its volume before swelling.

Average Contact Angle (ACAwater) measurements were performed using a contact angle measuring apparatus (DGD ADR, GBX S.A.R.L, Romans-sur-Isére, France), equipped with a camera and a table controlled by Windrop + + software. For the experiment, Milli-Q water was settled as 6 µL droplet. The result was presented as average value of 5–10 measurements for each tested polymer.

TG/DTG studies were carried out using STA 449 F1 Jupiter thermal analyzer (Netzsch, Selb, Germany) in the temperature range of 30 to 800 °C under helium atmosphere (40 mL/min), heating rate was set at 10 °C/min. Al2O3 crucibles were used for analyses. The weight of the polymer sample was about 7 mg.

Sorption properties of the prepared materials were investigated by means of dynamic solid phase extraction method (SPE). Polypropylene laboratory cartridges were filled with 250 mg of the studied polymer and protected with porous teflon frits. Before using the cartridge was conditioned with 10 mL of methanol and 5 mL of distilled water. Next, aqueous solutions of test compounds were passed through the cartridges, mean flow rate was about 3 mL/min. First, a mixture of phenols was used for the sorption test. The mixture consisted of 2 mg/L: phenol (Ph), 2-chlorophenol (CPh), 2,4-dichlorophenol (DCPh) and 2,4,6-trichlorophenol (TCPh). After sorption the cartridge was rinsed with 1 mL of water and dried for 5 min. The adsorbed compounds were desorbed with appropriate amount of methanol. The volume of the sample determined the amount of methanol consumed so as to obtain a 50-fold concentration after elution. Then eluates were analyzed using HPLC system. The details of SPE procedures and HPLC analysis of phenolic compounds were already described in previous works [8, 25, 26]. After each use the cartridge was regenerated in the same way as in the conditioning step.

Then, sorption studies of single-component pharmaceutical solutions were carried out in a similar way as for phenols. For this purpose, separate solutions of aspirin, ibuprofen, paracetamol, ampicillin with a concentration of 0.02 mg/L and 200 mL volume were prepared. The adsorbed pharmaceuticals were eluted with 4 mL of methanol. Finally, a pharmaceutical mixture sorption test was performed. The mixture was prepared by dissolving 4 mg of aspirin, ibuprofen and paracetamol in 200 mL distilled water. In this case also 4 mL of methanol was used for elution. Concentration of pharmaceuticals in eluates was determined by HPLC according to procedure described previously (Magdalena [27],M. [28]. The detector was set at λ = 210 nm for phenolic eluates analysis and at λ = 222 nm for pharmaceuticals ones. The collected results are presented as graphs showing the percent recovery value versus the sample volume.

3 Results and discussion

3.1 Synthesis and chemical characteristics of the low cross-linked terpene-based polymers

Porous terpene-based polymeric microspheres were synthesized with suspension radical polymerization. In order to verify chemical structure of the prepared terpene-based polymers ATR-FTIR analyses were performed. Figure 1 presents collected spectra. The lowest spectrum belongs to the homopolymer obtained from DVB. Its most intense characteristic bands are those at 703 and 794 cm−1 originating from the C–H vibrations out of the aromatic ring plane. C–H stretching bands can be observed in the region 3080–3010 cm−1 and they are weak. The in-plane and out-of-plane ring deformation vibrations give their bands in the ranges of 1095–989 and 820–900 cm−1, respectively. The several medium intensity vibrations attributed to stretching C–C bonds in the ring occur in the range from 1625 to 1430 cm−1. Above this range overtones and weak combination bands are present. The presence of vinyl group as the ring substituent lead to conjugation which results in a doublet at 1625–1575 cm−1. Other bands confirming the presence of vinyl bonds are those at 902 and 998 cm−1. However, very low intensity of these bands indicates the residual presence of these moieties which is additionally evidenced by low values of the iodine numbers (Table 1). Aliphatic chains composed of methyl and methylene groups formed during polymerization can be identified on the basis of symmetric and asymmetric stretching bands of medium intensities in the region 3000–2800 cm−1 and weak C-H deformation vibrations observed as one broad band between 1470 and 1350 cm−1.

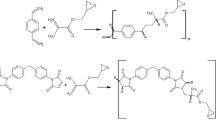

The characteristic bands described above can also be found in the spectra of terpene-based polymers as DVB was used as the cross-linking agent. However, some differences can be noticed for the bands at 707 and 793 cm−1 and they concern their broadening as well as the ratio of their intensity. Minor changes are also visible in the bands characteristic of the CH3 and CH2 groups. This is a consequence of the presence of aliphatic and cycloaliphatic chains contributed to the polymer structure by terpene monomers. Characteristic skeletal bands of branched alkanes lie ca. 780 and 900 cm−1, at the same wave numbers the strongest characteristic bands of cyclohaxane and cyclobutane occur confirming the presence of these structures in the polymer. Substituted cyclobutane is structural fragment of pinene molecule, however such cyclic system can be also created in e.g. termination reaction. Scheme of such process is shown in Fig. 2.

In the range of 1300–1000 cm−1 weak and medium intensity bands characteristic of terpenes should be visible. Unfortunately, they are covered by much stronger bands of oxygenated species. The strongest of them is observed at 1095 cm−1 the other at 989, 1018, 1164 and 1260 cm−1 are weaker and overlapped. Their presence shows that during polymerization some of double bonds yield oxidation to peroxides (800–900 and 1030–1150 and 1230–1270 or 1120–1200 cm−1). Broadening of the bands in the regions 805–880,785–865 and 860–950 cm−1 may also suggest the formation of epoxy groups. Different pathways of structural changes (including isomerizations, cyclizations, and oxidations) in terpenes under the influence of air, elevated temperature or during polymerization are reported in the literature [3, 5, 7, 14, 15, 29,30,31]. In particular, these processes can cause instability of citral in aqueous solutions [32,33,34], which explains the presence of only a residual characteristic band of carbonyl groups (1730–1650 cm−1) in the CIT-DVB polymer.

Additional information on the chemical properties of the surface of the studied materials is provided by the iodine and acid number. Their values are shown in Table 2. In case of the copolymers the iodine numbers are very low, which means that there are very few unreacted double bonds left in their structure. For the homopolymer the value is higher and reaches almost 29 mgI2/100 g. This finding shows that although pDVB is highly crosslinked, pendant vinyl bonds in its structure still are present, which may be related to steric effect in the polymer network. The acid numbers for the terpene-based polymers are in the range of 1.2 to 6.2 mg/g which confirms that small amount of acidic groups are present on the surface of the polymer. These low contents of acidic moieties in the polymers are also confirmed by the FTIR spectra (Fig. 1) in which both bands of very low intensity in the range typical of carbonyl species (1680–1730 cm−1) and a flattened region of vibrations of hydroxyl groups (3200–3600 cm−1) can be observes. Their presence is mainly the result of the oxidation of terpene compounds at the stage of the polymerization process.

3.2 Porous structure of the prepared materials

In general, low cross-liked polymers do not possess highly developed internal structure. Table 2 presents also a brief characteristic of porous structure parameters of the terpene—based polymers and pDVB homopolymer. The latter is a highly cross-linked material, therefore the values of its specific surface area and total pore volume are very high. The terpene-based polymers have much lower values of the compared parameters. However, taking into account the fact that these polymers are low-crosslinked materials, it should be emphasized that the values obtained for CIT-DVB and LIM-DVB are quite high. PIN-DVB has the lowest SBET value but its Vtot is only about half that of CIT-DVB.

More information about internal structure of these polymers provide analysis of nitrogen sorption isotherm (Fig. 3). The presence of the hysteresis loop prove that all the materials are mesoporous. The forms of the adsorption isotherms and the hysteresis loops are complex, which means that they cannot be clearly assigned to one specific type [35]. The adsorption isotherms have a shape most similar to type IV(a) which suggests that the porous structure of the polymers is created by a system of connected pores of irregular shapes or, more likely, pores form disordered network. The characteristic feature of this isotherm is the presence of a final saturation plateau, which in this case is reduced to just an inflection point. The courses of the desorption branches in the range of relative pressures from 1 to 0.5 are gently sloping, which make the shapes of the hysteresis loops similar to the H4 type, representative of materials containing meso or macroporosity. However, in the range of 0.4–0.6 p/p0 there is a fairly sharp decrease typical of the H2b hysteresis, indicating the occurrence of cavitation or pore blocking phenomena in pores of narrow cavity size distribution [36, 37].

Figure 4 presents pore size distributions of the studied polymers. As all the polymers were synthesized by the same method and using the same pore forming solvent, their pore size distributions are very similar. The PSD curves for terpene-based polymers are bimodal with one narrow maximum at about 19–20 Å and another wide maximum in the range of 30 to 140 Å. In PSD of homopolymer, peak at 15 Å dominates, and in the range of wide pore widths two regions can be distinguished, one from 29 to 55 Å and the other from 60 to 190 Å.

In Fig. 5 SEM images show outer surface of the studied materials. Their morphology resembles tightly packed tiny globules. The porous structure is formed by interparticle voids interconnected into a network of channels of various shapes, widths and lengths. Such a structure is the result of polymerization carried out by the dispersive method [24, 38,39,40,41]. For this reason, all the polymers have similar globular surface structure with pore entrances arranged in an irregular manner. In the case of CIT-DVB and LIM-DVB, the entrances are small but numerous, while those of PIN-DVB are larger and wider. In comparison to the copolymers, the surface of the homopolymer (pDVB) seems to be smoother as the particles are smaller, which cause formation of narrower pores. Consequently, the macropores are finer and greater in number than e.g. LIM-DVB.

3.3 The ability to swell

The swellability is a consequence of the degree of cross-linking of the polymeric network. Low cross-linked polymers have a more flexible network, therefore after immersing in a solvent they are able to increase its volume even many times.

The comparison of the swelling ratios gives some information:

-on the wettability of the polymer and.

-shows ease of the molecule to penetrate the polymer network.

-and also allow to compare the tested polymers in terms of their hydrophilic and lipophilic properties.

Figure 6 and Table 3 allow to compare the obtained results of ability to swell. Due to the low degree of cross-linking the terpene-based polymers significantly increased their volume in the tested solvents. The polymer that swelled the most was CIT-DVB irregardless the used solvent was polar or non-polar in nature, which proves that the cross-linking degree of this polymer is the lowest. In comparison to CIT-DVB, swelling capacities of LIM-DVB and PIN-DVB are lower indicating a slightly higher degree of cross-linking. These polymers showed a tendency to stronger absorption of non-polar solvents. However, this trend is more pronounced with the former. In case of the highly cross-linked pDVB its network is rigid and therefore swelling occurs only to a very limited extent for organic solvents. In case of water swelling does not occur due to the completely hydrophobic nature of this polymer. On the other hand, the oxygen functional groups present on the surface of terpene-based polymers generate polar active centers on it, favoring the accumulation of water molecules around them and the creation of larger associations in the form of layers or clusters, consequently causing a slight swelling of these polymers.

This statement is further supported by the contact angles measured for water (Table 3). The highest value was obtained for pDVB, which proves its most hydrophobic chemical character. In case of the copolymers the average values of contact angles were lower that indicates a slightly lower hydrophobicity of their surfaces and contributes to a slightly better contact between water molecules and the polymers. Preferable wettability of the polymer may be a useful feature when such a material would be used, for example, in the purification of aqueous solutions.

3.4 Thermal properties of the studied polymers

Thermal stability is important property that have to be taken into account when the polymeric material (sorbent) will be exposed to elevated temperatures (e.g. thermal desorption).

The results of thermogravimetric analyses are shown in Fig. 7 and in Table 4.

The tested terpene-based materials have very similar or slightly lower thermal stability parameters compared to the pDVB homopolymer. The temperature of 2% mass loss of the sample (T2%) was defined as initial decomposition temperature the exceeding of which causes irreversible changes in the structure of the polymer. In all cases, the polymers are sTable up to about 300 °C under inert atmosphere. Above this temperature decomposition takes place which ends at about 450 °C. The temperatures of T10% and T50% next to the value of DTG at Tmax allow to determine the rate of the material decomposition. The comparison of this data shows that the decomposition of terpene-based copolymers proceeds more slowly than that of a highly cross-linked homopolymer. Such thermal characteristics is related to the amount of divinylbenzene used as cross-linking agent. In the case of terpene-based polymers, its amount is only a quarter of the monomers weight, while in the homopolymer it is 100%. It was reported in literature [42] that too high content of DVB in the reaction mixture (above 55%) results in unreacted vinyl bonds remaining in the polymer. Under the influence of elevated temperature, they may undergo, coupling reactions as well as oxidation with air entrapped in the porous structure of the material. This process contributes to the formation of radicals that decrease the stability of the polymeric structure, which facilitates the degradation processes.

High thermal stability of the new terpene-based polymers allows them to be safely used in the temperature range up to 300 °C.

3.5 The sorption properties

The studies on sorption properties of the terpenes-based polymers have been started with the determination of their sorption ability towards phenolic compounds. The uptake process was carried out from a multi-component solution, and the obtained recovery results are presented in Fig. 8. For comparison, the result obtained for the homopolymer has also been added.

In all cases, the highest recoveries were achieved for DCPh and TCPh, slightly lower for CPh, and the lowest for Ph. The recovery values for CIT-DVB and PIN-DVB are very similar, for DCPh and TCPh they range from 80 to 95% and remain at this level up to a volume of 1200 mL for the former and about 900 mL for the latter. This difference results from the fact that PIN-DVB has a specific surface area three times smaller than CIT-DVB. For LIM-DVB polymer recoveries of DCPh, reach even 90–100% and are maintained at this level even for sample volumes as large as 1400 mL. The recoveries for TCPh from this polymer are in the range of 60–90%, with their values increasing gradually to the maximum at a volume of 1300 mL. Also on this sorbent, the recoveries for all chlorophenols at 100 mL are about 15–40% lower than those at 200 mL, which may be due to irreversible adsorption of these compounds in the first step of the concentration process. The sorption of CPh on the tested sorbents is not as effective as that of chlorophenols with a higher number of chlorine substituents. For this compound, the maximum values are about 60–70% at 100 mL and gradually decrease for larger sample volumes, proving that a breakthrough occurred. A similar trend can be observed for Ph. However, its recoveries are about half lower than those for CPh for small sample volumes, but as the volume of the concentrated solution increases, the difference become greater. This effect can be easily seen in Fig. 9, which shows comparative recovery data for 200 and 1000 mL samples.

It should be emphasized that pDVB, despite the largest surface area (594 m2/g), was not as effective in removing phenols from water as the terpene-based polymers, and its recoveries do not exceed 60% even for DCPh. The explanation of this phenomenon should be sought in the way of interaction of adsorbates with the surface of the polymers.

The pDVB is a highly cross-linked polymer composed of phenyl rings linked by aliphatic chains. Therefore, the retention of adsorbates on its surface is possible only through hydrophobic interactions, e.g. Van der Waals or π-electron of aromatic rings of the adsorbent and the adsorbate. Which correlates well with the increase in the Log P values and the decrease in solubility in water (Fig. 10).

In the case of terpene-based polymers, some oxygen functional groups are also present on their surface. Although the amount of these oxygen moieties is not very high, their beneficial effect on the sorption process can be clearly observed. This phenomenon can be explained by considering two aspects. The first, is the common interaction of the polymer and adsorbates, which, in addition to hydrophobic forces, is also supported by polar groups (e.g. hydrogen bonds). The other aspect concerns better wettability of the polymer by an aqueous solution, which in turn facilitates the contact of adsorbates with sorbent surface. As previously described, there is also a small amount of acidic groups on the surface of terpene-based polymers. They also can participate in the sorption process not only by direct interaction with adsorbates through acid–base interactions, but also by affecting the equilibrium state in the solution.

The Fig. 10 compares the chemical properties of adsorbates, such as log P, pKa and solubility in water, determining their characteristics in aqueous solutions. The analysis of this data for phenolic compounds justifies high recoveries for DCPh and TCPh, lower for CPh and very low for Ph. With the increase in the number of chlorine substituents in the aromatic ring, the solubility of phenols in water decreases but their lipophilicity (logP) increases. This means that their affinity to the organic phase (including the polymer surface) increases. The pKa values for phenols are decreasing. Thus, TCPh with a pKa of about 7 is present in solution in a partially dissociated form under experimental conditions. For this reason, its recoveries are lower than expected.

Aspirin and ibuprofen have carboxyl groups in their structures, which give them an acidic character. However, the acetyl group present in aspirin enhances the acidity of this compound. Whereas, ibuprofen, due to the presence of an aliphatic isobutyl group, is more lipophilic than aspirin. In the paracetamol molecule, the phenolic and amide groups are substituted in para position to each other. Strong negative potentials occur on the carbonyl and phenolic groups, while the amide nitrogen atom remains a slightly positive part of the molecule [43]. Such distribution of charges in the molecule makes it highly hydrophilic. Ampicillin has the largest and most structurally complex molecule among the discussed drugs. In its structure there are both a carboxyl group giving it an acidic character (pKa ~ 2.8), as well as amide and amino groups, the latter of which is basic in nature (pKa ~ 8.42).

Figure 11 shows the results of pharmaceutical sorption from single-component solutions. The LIM-DVB polymer turned out to be the most effective in removing drugs from water. 100% recoveries were achieved for aspirin and ibuprofen and 75% for ampicillin. Paracetamol showed a low affinity to the surface of this polymer, as its recovery did not exceeding 20%.

Such results may indicate that both hydrophobic and polar interactions have a significant impact on the sorption process on this polymer.

The sorption of acidic molecules of aspirin and ibuprofen is very effective. As mentioned earlier, the polymer on its surface also has some acidic functional groups, the presence of which stabilizes the pH of the solution at a lower level. Under these conditions, the undissociated forms of aspirin and ibuprofen predominate in the solution, which uptake is more efficient. The acidity of the polymer surface also favorably influences the sorption of ampicillin. The amino group and to a lesser extent the amide groups of ampicillin can interact with the polymer by hydrogen bonding or acid–base interactions. The amide group present in the paracetamol molecule also takes part in these interactions, contributing to the increase in recovery results. Nevertheless, the hydrophilic nature of this drug results in its low affinity to the polymer.

CIT-DVB has a slightly lower specific surface area than LIM-DVB but a higher concentration of acid functional groups, which is reflected in the pharmaceuticals sorption results. 100% recovery was achieved only for ibuprofen, but for aspirin and ampicillin the sorption results were lower and amounted 70% and approx. 40%, respectively. However, in the case of paracetamol, the recoveries were even twice as high as on the LIM-DVB polymer. The reasons for this phenomenon can be seen in the more acidic nature of the surface of this polymer. On the one hand, dissociation of the surface functional groups of CIT-DVB increases the acidity of the solution, which in turn affects the acid–base balance of the solutes. On the other hand, the surface of the polymer becomes negatively charged, causing a repulsive interaction with the adsorbate (Fig. 12). This effect may explain why aspirin recovery on this sorbent was only 70%.

The situation is even more complex with ampicillin, which in its molecule has a carboxyl group in addition to amino and amide groups. In the case of this antibiotic, neutral molecules, ionized on one functional group and zwitterions coexist in solution, and any change in pH significantly affects the acid–base balance between these forms [44, 45]. Each of them interact with the polymer surface in a different way depending on whether the forces are attractive or repulsive.

As previously mentioned, on the more acidic surface of CIT-DVB, paracetamol was adsorbed with greater efficiency. Considering its interaction with the polymer, one should take into account both the hydrogen bonds formed between the COOH groups of the polymer and the NH or OH of paracetamol, as well as the electrostatic interactions between COO− of the polymer and NH2+ of paracetamol. As it is schematically shown in Fig. 13.

The sorption results for PIN-DVB are not as high as those for the above-described terpene-based polymers and above all, this is due to the significantly lower value of the specific surface area of this polymer. In addition, it contains much less acidic functional groups compared to CIT-DVB and LIM-DVB. However, a certain dependence of the obtained SPE results on the pKa of the adsorbates can be noticed. Namely, the lower the pKa of the drug, the greater its recovery. This suggests that not only acidic surface functional groups are active in the sorption process, but also those that do not give the surface such a character. For example, ether groups may actively participate in the formation of hydrogen bonds between the polymer and drug molecules.

On the pDVB, the most effective sorption reaching 100% was recorded only for ampicillin. For ibuprofen and aspirin, the recoveries ranged from 20 to 50%. The lowest of only a few percent were received for paracetamol. Since pDVB does not have oxygen functional groups on its surface, the recoveries obtained for this polymer are the effect of the highly developed surface of this material and its interactions with adsorbates by dispersion forces. Therefore, the SPE results for aspirin, ibuprofen and paracetamol show consistency with their log P values, which characterize the lipophilic properties of the compounds. The very high recovery of ampicillin from pDVB suggests that the process of its sorption, apart from hydrophobic and π-electron interactions, may also be affected by other interactions related to the presence of negative or positive potentials accumulated on the functional groups of its molecule.

Finally, the sorption properties of the studied materials were tested for a mixture consisting of only non-steroidal anti-inflammatory drugs: aspirin, ibuprofen and paracetamol. The obtained data is shown in the Fig. 14.

It was observed that for all polymers the recoveries show the same tendency. Namely, the highest recoveries were achieved by ibuprofen, slightly lower by paracetamol, and the lowest by aspirin. Interestingly, the aspirin recoveries from this mixture were 50 to 90% lower than those from the solution containing aspirin as the only component. Similarly, the removal efficiency of ibuprofen was lower and reached only 70% (compared to a single-component solution). In contrast, paracetamol recoveries from the drug mixture for most sorbents were found to be 5 to 10% higher than those from the solution containing only paracetamol.

Taking into account the pKa values of the drugs, it should be stated that in the solution of the drug mixture, a series of mutually coupled dissociation equilibrium states are established. Thus, aspirin, which has the lowest pKa value, dissociates most easily in this solution, and the released hydrons inhibit the dissociation of ibuprofen. This, in turn, occurring mainly in the undissociated form, is adsorbed with greater efficiency than dissociated aspirin. In addition, hydrogen ions released as a result of aspirin dissociation may be coordinatively bound by paracetamol, which also alter its affinity for the surface of polymers.

It should also be taken into account that associates may be formed between the neutral molecules of ibuprofen and paracetamol. They are adsorbed, too. The described processes are schematically shown in Fig. 15.

This phenomenon is the most clearly marked for PIN-DVB. In case of this polymer an increase in the uptake of ibuprofen and paracetamol accompanied by a significant decrease in sorption of aspirin was noted.

4 Conclusions

In this work a way of synthesis and properties of new terpene—based polymers has been presented. Such synthetic polymers based on components of natural origin with a reduced content of petroleum-derived cross-linking agent can be considered as sustainable polymeric materials. The described materials were characterized by low cross-linked structure but still good thermal stability. They also possessed developed porosity which allowed them to be used as sorbents. The sorption ability tests were assessed using a non-equilibrium dynamic method (SPE) for a mixture of phenolic compounds (phenol, 2-chlorophenol, 2,4-dichlorophenol and 2,4,6-trichlorophenol), single-component drug solutions (aspirin, ibuprofen, paracetamol and ampicillin) and a ternary drug solution (ibuprofen, paracetamol and aspirin). The obtained results were very promising, due to high recoveries and the possibility of regeneration and reuse of the materials without significant loss of adsorbates uptake and desorption efficiency even in 10–13 cycles. The highest recoveries at a level 80–100% were obtained for 2,4-dichlorophenol and 2,4,6-trichlorophenol for all the terpene-based polymers. Among the tested drugs, ibuprofen showed the greatest affinity to the surfaces and aspirin slightly lower. Their recoveries from the CIT-DVB and LIM-DVB were in the range of 70–100% for single-component solutions and up to 70% for ibuprofen from ternary component solutions. It has been proven that the high recoveries of these compounds are related to their acidic chemical nature. Lower recoveries were noted for compounds with weakly acidic or basic character, especially if they had low LogP values.

Taking into account the equilibrium processes in the solution and possible interactions at the solution-sorbent interface, an attempt to explain the sorption process was made.

Good sorption properties as well as high efficiency and reversibility in desorption allow to consider the studied polymers as potential sorbents in purification and separation techniques.

Data availability

The data presented in this article will be available on request from the corresponding author.

5. References

Goliszek, M., Sobiesiak, M., Fila, K., Podkościelna, B.: Evaluation of sorption capabilities of biopolymeric microspheres by the solid-phase extraction. Adsorption 25(3), 289–300 (2019). https://doi.org/10.1007/s10450-019-00008-6

Hernández, N., Christopher Williams, R., Cochran, E.W.: The battle for the ‘green’ polymer. different approaches for biopolymer synthesis: bioadvantaged vs. bioreplacement. Org. Biomol. Chem. 12(18), 2834–2849 (2014). https://doi.org/10.1039/c3ob42339e

Liu, Na., Chen, J., Zhiping, Wu., Zhan, P., Zhang, L., Wei, Q., Wang, F., Shao, L.: Construction of microporous lignin-based hypercross-linked polymers with high surface areas for enhanced iodine capture. ACS Appl. Polym. Mater. 3(4), 2178–2188 (2021). https://doi.org/10.1021/acsapm.1c00139

Liu, Na., Shao, L., Wang, C., Sun, F., Zhiping, Wu., Zhan, P., Zhang, L., Huan’ai Wan.: Preparation of lignin modified hyper-cross-linked nanoporous resins and their efficient adsorption for p-nitrophenol in aqueous solution and CO2 capture. Int. J. Biol. Macromol. 221, 25–37 (2022). https://doi.org/10.1016/j.ijbiomac.2022.08.196

Liu, P., Liu, X., Saburi, T., Kubota, S., Huang, P., Wada, Y.: Thermal stability and oxidation characteristics of α-Pinene, β-Pinene and α-Pinene/β-Pinene mixture. RSC Adv. 11(33), 20529–20540 (2021). https://doi.org/10.1039/d1ra02235k

Lu, D.R., Xiao, C.M., Xu, S.J.: Starch-based completely biodegradable polymer materials. Express Polym. Lett. 3(6), 366–375 (2009). https://doi.org/10.3144/expresspolymlett.2009.46

Mülhaupt, R.: Green polymer chemistry and bio-based plastics: dreams and reality. Macromol. Chem. Phys. 214(2), 159–174 (2013). https://doi.org/10.1002/macp.201200439

Podkościelna, B., Sobiesiak, M., Zhao, Y., Gawdzik, B., Sevastyanova, O.: Preparation of lignin-containing porous microspheres through the copolymerization of lignin acrylate derivatives with styrene and divinylbenzene. Holzforschung 69(6), 769–776 (2015). https://doi.org/10.1515/hf-2014-0265

Sobiesiak, M.: New bio-based polymer sorbents out of terpene compounds or vegetable oils: synthesis, properties, analysis of sorption processes. Polymers 14(24), 5389–5416 (2022). https://doi.org/10.3390/polym14245389

Wnuczek, K., Podkościelna, B., Sobiesiak, M., Szajnecki, Ł, Goliszek, M.: Synthesis and modification by carbonization of styrene-ethylene glycol dimethacrylate-lignin sorbents and their sorption of acetylsalicylic acid. Materials 13(7), 1761 (2020). https://doi.org/10.3390/ma13071761

Silvestre, Armando J.D., and Alessandro Gandini. 2008. “Terpenes: Major Sources, Properties and Applications.” In Monomers, Polymers and Composites from Renewable Resources, 17–38. Elsevier. https://doi.org/10.1016/B978-0-08-045316-3.00002-8.

Thomsett, M.R., Storr, T.E., Monaghan, O.R., Stockman, R.A., Howdle, S.M.: Progress in the synthesis of sustainable polymers from terpenes and terpenoids. Green Mater. 4(3), 115–134 (2016). https://doi.org/10.1680/jgrma.16.00009

Mosquera, M.E.G., Jiménez, G., Tabernero, V., Vinueza-Vaca, J., García-Estrada, C., Kosalková, K., Sola-Landa, A., et al.: Terpenes and terpenoids: building blocks to produce biopolymers. Sustain. Chem. 2(3), 467–92 (2021). https://doi.org/10.3390/suschem2030026

Abe, A., Albertsson, A.C., Dus, K., Genzer, J., Kobayashi, S., South Korea, L., Leibler, et al.: Bio-Synthetic Polymer Conjugates. In: Schlaad, Helmut (ed.) Advances in Polymer Science. Springer, Heidelberg (2013)

Molina-Gutierrez, S., Ladmiral, V., Bongiovanni, R.M., Caillol, S., Lacroix-Desmazes, P.: Radical Polymerization of biobased monomers in aqueous dispersed media. Green Chem. 21, 36–53 (2018). https://doi.org/10.1039/C8GC02277A

Sahu, P., Bhowmick, A.K., Kali, G.: Terpene based elastomers: synthesis, properties, and applications. Processes 8(5), 553 (2020). https://doi.org/10.3390/pr8050553

Al-Jumaili, A., Kumar, A., Bazaka, K., Jacob, M.: Plant secondary metabolite-derived polymers: a potential approach to develop antimicrobial films. Polymers 10(5), 515 (2018). https://doi.org/10.3390/polym10050515

Nishida, T., Satoh, K., Kamigaito, M.: Biobased polymers via radical homopolymerization and copolymerization of a series of terpenoid-derived conjugated dienes with exo-methylene and 6-membered ring. Molecules 25(24), 5890 (2020). https://doi.org/10.3390/molecules25245890

Park, H.J., Ryu, C.Y., Crivello, J.V.: Photoinitiated cationic polymerization of limonene 1,2-oxide and α-pinene oxide. J. Polym. Sci., Part A: Polym. Chem. 51(1), 109–117 (2013). https://doi.org/10.1002/pola.26280

Schimpf, V., Ritter, B.S., Weis, P., Parison, K., Mülhaupt, R.: High Purity limonene dicarbonate as versatile building block for sustainable non-isocyanate polyhydroxyurethane thermosets and thermoplastics. Macromolecules 50(3), 944–955 (2017). https://doi.org/10.1021/acs.macromol.6b02460

“Isoprenoids (Terpenoids) and Derivatives (Polyterpenes)No Title.” n.d. Database. https://polymerdatabase.com/polymer classes/Isoprenoids.html.

Kekevi, Burcu, Hilal Mert, E.: Development of terpene based sorbents via emulsion templating: synthesis and swelling behavior. React. Funct. Polym. 164, 104912 (2021). https://doi.org/10.1016/j.reactfunctpolym.2021.104912

Chan, Y.W., Siow, K.S., Ng, P.Y., Gires, U., Majlis, B.Y.: Plasma polymerized carvone as an antibacterial and biocompatible coating. Mater. Sci. Eng., C 68, 861–871 (2016). https://doi.org/10.1016/j.msec.2016.07.040

Maciejewska, M., Gawdzik, B., Rogulska, M.: Regular polymeric microspheres with highly developed internal structure and remarkable thermal stability. Materials 14(9), 2240 (2021). https://doi.org/10.3390/ma14092240

Sobiesiak, M.: Bead-shaped porous polymers containing bismaleimide—their physico-chemical characteristics and sorption properties towards chlorophenols. Polish J. Appl. Chem. LV 1, 25–32 (2011)

Sobiesiak, M., Podkoscielna, B.: Preparation and characterization of porous DVB copolymers and their applicability for adsorption (solid-phase extraction) of phenol compounds. Appl. Surf. Sci. 257(4), 1222–1227 (2010). https://doi.org/10.1016/j.apsusc.2010.08.026

Sobiesiak, M., Marta, G., Joanna, O.T.: Sorption properties of polydivinylbenzene polymers towards phenolic compounds and pharmaceuticals. Colloids Interfaces 3(1), 19 (2019). https://doi.org/10.3390/colloids3010019

Sobiesiak, M.: Analysis of structure and properties of DVB–GMA based porous polymers. Adsorption 25(3), 257–266 (2019). https://doi.org/10.1007/s10450-018-9998-2

Chat, Oyais Ahmad, Parvaiz Ahmad Bhat, Nighat Nazir, and Aijaz Ahmad Dar. 2019. “Self-Assembled Systems Based on Surfactants and Polymers as Stabilizers for Citral in Beverages.” In Value-Added Ingredients and Enrichments of Beverages, edited by Alina Maria Holban Alexandru Mihai Grumezescu, 487–521. Elsevier. https://doi.org/10.1016/B978-0-12-816687-1.00015-1.

Gorzynski Smith, Janice. 2011. Organic Chemistry. Edited by McGraw-Hill. 3rd ed. New York: McGraw-Hill

Thomsett, M., Moore, J.C., Buchard, A., Stockman, R., Howdle, S.M.: New renewably-sourced polyesters from limonene-derived monomers. Green Chem. 21, 149–156 (2018). https://doi.org/10.1039/C8GC02957A

Kimura, K., Nishimura, H., Iwata, I., Mizutani, J.: Deterioration mechanism of lemon flavor. 2. formation mechanism of off-odor substances arising from citral. J. Agric. Food Chem. 31(4), 801–804 (1983). https://doi.org/10.1021/jf00118a030

Peacock, V.E., Kuneman, D.W.: Inhibition of the formation of. alpha.-p-dimethylstyrene and p-cymen-8-Ol in a carbonated citral-containing beverage system. J. Agric. Food Chem. 33(3), 330–335 (1985). https://doi.org/10.1021/jf00063a003

Ueno, T., Masuda, H., Ho, C.-T.: Formation mechanism of p -methylacetophenone from citral via a tert -alkoxy radical intermediate. J. Agric. Food Chem. 52(18), 5677–5684 (2004). https://doi.org/10.1021/jf035517j

Thommes, M., Kaneko, K., Neimark, A.V., Olivier, J.P., Rodriguez-Reinoso, F., Rouquerol, J., Sing, K.S.W.: Physisorption of gases, with Special reference to the evaluation of surface area and pore size distribution (IUPAC Technical report). Pure Appl. Chem. 87(9–10), 1051–1069 (2015). https://doi.org/10.1515/pac-2014-1117

Cychosz, K.A., Guillet-Nicolas, R., García-Martínez, J., Thommes, M.: Recent advances in the textural characterization of hierarchically structured nanoporous materials. Chem. Soc. Rev. 46(2), 389–414 (2017). https://doi.org/10.1039/c6cs00391e

Schlumberger, Carola, Thommes, Matthias: Characterization of hierarchically ordered porous materials by physisorption and mercury porosimetry—a tutorial review. Adv. Mater. Interfaces (2021). https://doi.org/10.1002/admi.202002181

Cheng, C.M., Vanderhoff, J.W., El-Aasser, M.S.: Monodisperse porous polymer particles: formation of the porous structure. J. Polym. Sci., Part A: Polym. Chem. 30(2), 245–256 (1992). https://doi.org/10.1002/pola.1992.080300209

Gokmen, M.T., Du Prez, F.E.: Porous polymer particles—a comprehensive guide to synthesis, characterization, functionalization and applications. Prog. Polym. Sci. (Oxford) 37(3), 365–405 (2012). https://doi.org/10.1016/j.progpolymsci.2011.07.006

Grochowicz, M., Szajnecki, Ł, Rogulska, M.: Crosslinked 4-vinylpyridine monodisperse functional microspheres for sorption of ibuprofen and ketoprofen. Polymers 14(10), 2080 (2022). https://doi.org/10.3390/polym14102080

Odian, G.: Principles of Polymerization. Wiley, New Jersey (2004). https://doi.org/10.1002/047147875X

Li, Y., Fan, Y., Ma, J.: The Thermal properties of porous polydivinylbenzene beads. React. Funct. Polym. 50(1), 57–65 (2002). https://doi.org/10.1016/s1381-5148(01)00090-6

Jedynak, K., Szczepanik, B., Rędzia, N., Słomkiewicz, P., Kolbus, A., Rogala, P.: Ordered mesoporous carbons for adsorption of paracetamol and non-steroidal anti-inflammatory drugs: ibuprofen and naproxen from aqueous solutions. Water 11(5), 1099 (2019). https://doi.org/10.3390/w11051099

Rao, B.R.: AM1 study of the electronic structure of zwitterions of ampicillin. Indian J. Chem.—Sect B Org. Med. Chem. 52(1), 164–168 (2013)

Komova, S., Nadezhda, N.: Immune recognition of closed and open lactam rings and their influence on immunoassays of ampicillin antibiotics. Orient. J. Chem. 36(1), 21–2 (2020). https://doi.org/10.13005/ojc/360103

Acknowledgements

Prof A Wiącek and MSc K. Szafran employees of the Department of Interfacial Phenomena in Institute of Chemical Sciences in Faculty of Chemistry at Maria Curie-Skłodowska University, (Lublin, Poland) for kind cooperation and carrying out the measurements of the ACA.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

MS gave the idea, planned and took part in synthesis the polymeric materials; performed FTIR, chromatographic and thermal analyses; analyzed all the obtained data; prepared Table 4 and all figures excluding: 7, 10 and 13; wrote the main manuscript text. P.B. took part in synthesis of the polymeric materials; performed laboratory tests in the field of: determination of acid and iodine numbers, determination of swelling ratios, sorption capacity testing using the SPE-HPLC method; made a graphical elaboration of the obtained results (Tables 1–3 and Fig.: 7, 10 and 13); wrote the introduction. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sobiesiak, M., Banaszek, P. Low cross-linked terpenes-based porous polymers with reduced content of divinylbenzene: synthesis, physicochemical properties and sorption abilities. Adsorption 30, 235–249 (2024). https://doi.org/10.1007/s10450-023-00394-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-023-00394-y