Abstract

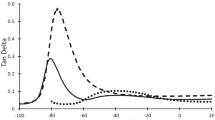

As an inherent property of the shape memory polymers (SMPs), relaxation plays a crucial role in their mechanical deformation and shape memory effect (SME). During the shape memory processes, relaxation behavior can be divided into short-, medium-, and long-term mechanisms that collectively contribute to the multiple relaxation mechanisms. In this study, based on the multiple relaxation mechanisms, we establish a thermo-mechanical constitutive model for the thermo-induced shape memory polyurethane (TSMPU) within the finite deformation framework. Additionally, the effect of temperature on mechanical deformation is further optimized by considering the change of viscosity with temperature. To further characterize the cyclic transition behavior between the rubbery and the frozen phases, we employ the storage strain ratio to describe the storage and release of deformation during the cyclic SME. The proposed cyclic thermo-mechanical model effectively captures the cyclic SME of TSMPU as demonstrated through comparison with the experimental results at various strain amplitudes and strain rates.

摘要

松弛作为形状记忆聚合物的固有特性, 在其机械变形和形状记忆行为中起着至关重要的作用. 在形状记忆过程中, 松弛行为包含了短期、中期和长期机制, 这些机制共同组成了多级松弛机制. 基于多级松弛机制, 结合热弹性行为和相转变模型, 在有限变形框架下建立了热致形状记忆聚氨酯的循环热-力学本构模型. 在此模型中, 着重考虑黏度随温度的变化, 优化了相转变模型框架中温度对机械变形的影响. 为了进一步描述橡胶相和冻结相之间的循环转变行为, 引入循环的储存应变比, 表征了循环形状记忆过程中变形的储存和释放机制与相转变之间的关系. 与不同应变幅值和应变速率下的循环形状记忆实验结果对比, 验证了所建立的基于多级松弛机制的循环热-力学本构模型能合理地描述形状记忆聚氨酯的循环形状记忆行为.

Similar content being viewed by others

References

Z. Shen, F. Chen, X. Zhu, K. T. Yong, and G. Gu, Stimuli-responsive functional materials for soft robotics, J. Mater. Chem. B 8, 8972 (2020).

H. Li, X. Liang, and W. Song, Buckling-controlled two-way shape memory effect in a ring-shaped bilayer, Acta Mech. Sin. 35, 1217 (2019).

H. M. Dou, J. H. Ding, H. Chen, Z. Wang, A. F. Zhang, and H. B. Yu, Bio-based, biodegradable and amorphous polyurethanes with shape memory behavior at body temperature, RSC Adv. 9, 13104 (2019).

A. Lendlein, and O. E. C. Gould, Reprogrammable recovery and actuation behaviour of shape-memory polymers, Nat. Rev. Mater. 4, 116 (2019).

L. Tan, J. Hu, K. Ying Rena, Y. Zhu, and P. Liu, Quick water-responsive shape memory hybrids with cellulose nanofibers, J. Polym. Sci. Part A-Polym. Chem. 55, 767 (2017).

L. Fang, T. Fang, Z. Fang, C. Lu, and Z. Xu, Solar light responsive polymer composites with three shape-memory effects, Macro Mater. Eng. 301, 267 (2016).

B. K. Kim, S. Y. Lee, and M. Xu, Polyurethanes having shape memory effects, Polymer 37, 5781 (1996).

H. Tobushi, H. Hara, E. Yamada, and S. Hayashi, Thermomechanical properties in a thin film of shape memory polymer of polyurethane series, Smart Mater. Struct. 5, 483 (1996).

J. Gu, H. Zeng, Z. Cai, and H. Sun, Modeling the laminated carbon fiber reinforced shape memory polymer composites by using a refined plate theory, Smart Mater. Struct. 29, 095005 (2020).

J. Leng, H. Lu, Y. Liu, W. M. Huang, and S. Du, Shape-memory polymers—a class of novel smart materials, MRS Bull. 34, 848 (2009).

X. Zhang, J. Li, Z. Liang, and Q. Kan, Design and finite element simulation of shape memory polyurethane self-deforming structures, Eng. Fail. Anal. 139, 106446 (2022).

G. Scalet, S. Pandini, M. Messori, M. Toselli, and F. Auricchio, A one-dimensional phenomenological model for the two-way shape-memory effect in semi-crystalline networks, Polymer 158, 130 (2018).

S. Pisani, I. Genta, T. Modena, R. Dorati, M. Benazzo, and B. Conti, Shape-memory polymers hallmarks and their biomedical applications in the form of nanofibers, Int. J. Mol. Sci. 23, 1290 (2022).

F. Puza, and K. Lienkamp, 3D printing of polymer hydrogels—from basic techniques to programmable actuation, Adv. Funct. Mater. 32, 2205345 (2022).

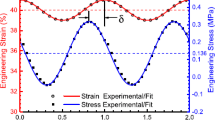

J. Li, Z. Liang, X. Zhang, and Q. Kan, Experimental investigation on the thermo-mechanical deformation of thermo-induced shape memory polyurethane, Polymer 237, 124337 (2021).

M. Staszczak, M. Nabavian Kalat, K. M. Golasiński, L. Urbański, K. Takeda, R. Matsui, and E. A. Pieczyska, Characterization of polyurethane shape memory polymer and determination of shape fixity and shape recovery in subsequent thermomechanical cycles, Polymers 14, 4775 (2022).

X. Wang, H. Lu, X. Shi, K. Yu, and Y. Q. Fu, A thermomechanical model of multi-shape memory effect for amorphous polymer with tunable segment compositions, Compos. Part B-Eng. 160, 298 (2019).

F. Liu, J. Wang, S. Long, H. Zhang, and X. Yao, Experimental and modeling study of the viscoelastic-viscoplastic deformation behavior of amorphous polymers over a wide temperature range, Mech. Mater. 167, 104246 (2022).

Z. Liang, J. Li, X. Zhang, and Q. Kan, A viscoelastic-viscoplastic constitutive model and its finite element implementation of amorphous polymers, Polym. Testing 117, 107831 (2023).

Y. Qin, X. Li, Y. Chen, and M. Lu, Tunable auxetic mechanical metamaterials with “arch-shaped” units, Phys. Rapid Res. Ltrs 13, 1800376 (2019).

D. Chen, H. Wu, J. S. Wei, S. L. Xu, and Q. Fang, Nonlinear visco-hyperelastic tensile constitutive model of spray polyurea within wide strain-rate range, Int. J. Impact Eng. 163, 104184 (2022).

N. Roudbarian, E. Jebellat, S. Famouri, M. Baniasadi, R. Hedayati, and M. Baghani, Shape-memory polymer metamaterials based on triply periodic minimal surfaces, Eur. J. Mech.-A Solids 96, 104676 (2022).

A. Krairi, I. Doghri, J. Schalnat, G. Robert, and W. Van Paepegem, Thermo-mechanical coupling of a viscoelastic-viscoplastic model for thermoplastic polymers: Thermodynamical derivation and experimental assessment, Int. J. Plast. 115, 154 (2019).

Q. Kan, J. Li, G. Kang, and Z. Zhang, Experiments and Models of Thermo-Induced Shape Memory Polymers, in: Shape-Memory Materials (IntechOpen, Rijeka, 2018).

R. Xiao, G. Ghazaryan, T. A. Tervoort, and T. D. Nguyen, Modeling energy storage and structural evolution during finite viscoplastic deformation of glassy polymers, Phys. Rev. E 95, 63001 (2017).

R. Xiao, C. Tian, Y. Xu, and P. Steinmann, Thermomechanical coupling in glassy polymers: An effective temperature theory, Int. J. Plast. 156, 103361 (2022).

Y. Liu, K. Gall, M. L. Dunn, A. R. Greenberg, and J. Diani, Thermomechanics of shape memory polymers: Uniaxial experiments and constitutive modeling, Int. J. Plast. 22, 279 (2006).

H. J. Qi, T. D. Nguyen, F. Castro, C. M. Yakacki, and R. Shandas, Finite deformation thermo-mechanical behavior of thermally induced shape memory polymers, J. Mech. Phys. Solids 56, 1730 (2008).

Y. C. Chen, and D. C. Lagoudas, A constitutive theory for shape memory polymers, Part I: Large deformations, J. Mech. Phys. Solids 56, 1752 (2008).

Y. C. Chen, and D. C. Lagoudas, A constitutive theory for shape memory polymers, Part II: A linearized model for small deformations, J. Mech. Phys. Solids 56, 1766 (2008).

J. Gu, H. Sun, and C. Fang, A phenomenological constitutive model for shape memory polyurethanes, J. Intell. Mater. Syst. Struct. 26, 517 (2015).

J. Liu, H. Lu, A. Elmarakbi, and Y. Q. Fu, An extended shoving model for dynamic fluctuation of glass transition in amorphous polymer towards cooperative shape-memory effect, Proc. R. Soc. A 479, 20230067 (2023).

Y. Li, Y. He, and Z. Liu, A viscoelastic constitutive model for shape memory polymers based on multiplicative decompositions of the deformation gradient, Int. J. Plast. 91, 300 (2017).

W. Zhao, L. Liu, J. Leng, and Y. Liu, Thermo-mechanical behavior prediction of shape memory polymer based on the multiplicative decomposition of the deformation gradient, Mech. Mater. 143, 103263 (2020).

J. Kim, S. Y. Jeon, S. Hong, Y. An, H. Park, and W. R. Yu, Three-dimensional constitutive model for shape-memory polymers considering temperature-rate dependent behavior, Smart Mater. Struct. 30, 035030 (2021).

Y. Xue, J. Lei, and Z. Liu, A thermodynamic constitutive model for shape memory polymers based on phase transition, Polymer 243, 124623 (2022).

J. Li, Z. Liang, K. Chen, X. Zhang, G. Kang, and Q. Kan, Thermo-mechanical deformation for thermo-induced shape memory polymers at equilibrium and non-equilibrium temperatures: Experiment and simulation, Polymer 270, 125762 (2023).

H. Lu, and W. M. Huang, On the origin of the Vogel-Fulcher-Tammann law in the thermo-responsive shape memory effect of amorphous polymers, Smart Mater. Struct. 22, 105021 (2013).

J. Wang, L. F. Peng, Y. J. Deng, X. M. Lai, M. W. Fu, and J. Ni, A finite strain thermodynamically-based constitutive modeling and analysis of viscoelastic-viscoplastic deformation behavior of glassy polymers, Int. J. Plast. 122, 135 (2019).

H. Pouriayevali, Y. B. Guo, and V. P. W. Shim, A visco-hyperelastic constitutive description of elastomer behaviour at high strain rates, Procedia Eng. 10, 2274 (2011).

J. Li, Q. Kan, Z. Zhang, G. Kang, and W. Yan, Thermo-mechanically coupled thermo-elasto-visco-plastic modeling of thermo-induced shape memory polyurethane at finite deformation, Acta Mech. Solid Sin. 31, 141 (2018).

T. D. Nguyen, C. M. Yakacki, P. D. Brahmbhatt, and M. L. Chambers, Modeling the relaxation mechanisms of amorphous shape memory polymers, Adv. Mater. 22, 3411 (2010).

M. Baniasadi, P. Fareghi, F. Darijani, and M. Baghani, Finite strain relaxation and creep in coupled axial and torsional deformation, Mech. Based Des. Struct. Mach. 50, 2795 (2022).

Z. Du, Y. Yang, Z. Wang, X. Fan, and T. Lu, A finite strain visco-hyperelastic damage model for rubber-like materials: theory and numerical implementation, Acta Mech. Sin. 39, 222473 (2023).

J. Lin, L. Dai, J. Qian, and R. Xiao, Modeling the rate-dependent ductile-brittle transition in amorphous polymers, Acta Mech. Sin. 38, 121438 (2022).

F. Castro, K. K. Westbrook, K. N. Long, R. Shandas, and H. J. Qi, Effects of thermal rates on the thermomechanical behaviors of amorphous shape memory polymers, Mech. Time-Depend Mater. 14, 219 (2010).

C. Zhang, X. Gou, and R. Xiao, Controllable shape-memory recovery regions in polymers through mechanical programming, J. Appl. Polym. Sci 135, 45909 (2018).

H. Tobushi, T. Hashimoto, S. Hayashi, and E. Yamada, Thermomechanical constitutive modeling in shape memory polymer of polyurethane series, J. Intell. Mater. Syst. Struct. 8, 711 (1997).

X. Zheng, B. Zhou, and S. Xue, A viscoelastic-plastic constitutive model of shape memory polymer, J. Mech. 35, 601 (2019).

J. Li, Z. Liang, J. Liu, C. Yu, X. Zhang, and Q. Kan, A thermoviscoelastic constitutive model addressing the cyclic shape memory effect for thermo-induced shape memory polymers, Smart Mater. Struct. 32, 035030 (2023).

M. Baghani, R. Naghdabadi, J. Arghavani, and S. Sohrabpour, A thermodynamically-consistent 3D constitutive model for shape memory polymers, Int. J. Plast. 35, 13 (2012).

C. Yan, and G. Li, Design oriented constitutive modeling of amorphous shape memory polymers and Its application to multiple length scale lattice structures, Smart Mater. Struct. 28, 095030 (2019).

K. Yu, H. Li, A. J. W. McClung, G. P. Tandon, J. W. Baur, and H. J. Qi, Cyclic behaviors of amorphous shape memory polymers, Soft Matter 12, 3234 (2016).

M. Lei, K. Yu, H. Lu, and H. J. Qi, Influence of structural relaxation on thermomechanical and shape memory performances of amorphous polymers, Polymer 109, 216 (2017).

K. K. Westbrook, P. H. Kao, F. Castro, Y. Ding, and H. Jerry Qi, A 3D finite deformation constitutive model for amorphous shape memory polymers: A multi-branch modeling approach for none-quilibrium relaxation processes, Mech. Mater. 43, 853 (2011).

J. Gu, H. Sun, and C. Fang, A multi-branch finite deformation constitutive model for a shape memory polymer based syntactic foam, Smart Mater. Struct. 24, 025011 (2015).

R. Xiao, and C. Tian, A constitutive model for strain hardening behavior of predeformed amorphous polymers: Incorporating dissipative dynamics of molecular orientation, J. Mech. Phys. Solids 125, 472 (2019).

E. M. Arruda, and M. C. Boyce, A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials, J. Mech. Phys. Solids 41, 389 (1993).

J. Chen, L. Liu, Y. Liu, and J. Leng, Thermoviscoelastic shape memory behavior for epoxy-shape memory polymer, Smart Mater. Struct. 23, 055025 (2014).

J. Bergström, Constitutive modeling of the large strain time-dependent behavior of elastomers, J. Mech. Phys. Solids 46, 931 (1998).

L. Anand, and N. Ames, On modeling the micro-indentation response of an amorphous polymer, Int. J. Plast. 22, 1123 (2006).

M. C. Boyce, D. M. Parks, and A. S. Argon, Large inelastic deformation of glassy polymers, part I: Rate dependent constitutive model, Mech. Mater. 7, 15 (1988).

Z. Liang, J. Li, K. Chen, Y. Dong, C. Yu, and Q. Kan, Multiaxial shape memory effect of thermo-induced shape memory polyurethane under proportional tension-torsion loading, Smart Mater. Struct. 32, 075018 (2023).

S. Mogharebi, R. Kazakeviciute-Makovska, H. Steeb, G. Eggeler, and K. Neuking, On the cyclic material stability of shape memory polymer, Mat.-wiss. U. Werkstofftech. 44, 521 (2013).

J. L. Hu, F. L. Ji, and Y. W. Wong, Dependency of the shape memory properties of a polyurethane upon thermomechanical cyclic conditions, Polym. Int. 54, 600 (2005).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 12102411, 12072296, and 12072295), the Applied Basic Research Project of Sichuan Province (Grant No. 2022NSFSC1957), the Research Funds from China Academy of Engineering Physics (Grant Nos. TCGH0414 and 2022YZL03), and Fundamental Research Funds for Central Universities (Grant No. 2682023CG004).

Author information

Authors and Affiliations

Contributions

Author contributions Zhihong Liang constructed the constitutive model and wrote the first draft of the manuscript; Jian Li and Qianhua Kan contributed to conceptualization, writing–review & editing, supervision, and funding acquisition. Kaijuan Chen and Chao Yu contributed to writing–review & editing.

Corresponding authors

Ethics declarations

Conflict of interest On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Liang, Z., Li, J., Chen, K. et al. Multiple relaxation mechanism-based thermo-mechanical constitutive model describing cyclic shape memory effect of shape memory polyurethane. Acta Mech. Sin. 40, 423347 (2024). https://doi.org/10.1007/s10409-023-23347-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-023-23347-x