Abstract

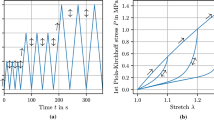

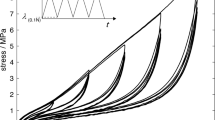

Many rubber-like materials exhibit hyperelastic, time-dependent, rate-dependent and progressive damage behaviors. In our previous work (Lu et al., 2020), we proposed a hyperelastic damage model to characterize the strain-softening behavior of soft materials. The model modifies the strain energy function of a single chain by introducing an internal damage variable D and then maps the deformation of chains to the macroscopic deformation. In this work, we extend this model to incorporate the time-dependent viscous effect using the Prony series-based nonlinear theory. We further implement the finite strain visco-hyperelastic damage model into finite element software ABAQUS by a user material subroutine UMAT. We use the experimental data of a kind of acrylic polymer under uniaxial tension in literature to calibrate the model parameters, including 4 time-independent parameters and 6 time-dependent parameters. We then use the calibrated parameters to simulate the uniaxial tension and stress relaxation of the acrylic polymer specimen with a complex geometry. The simulated results agree with the experimental data with a remarkable accuracy.

摘要

橡胶类材料存在着超弹性、时间相关性、率相关性和渐进损伤行为. 作者之前的工作提出了一种超弹性损伤模型去描述软材料的应变软化行为(Lu et al., 2020). 模型在单根分子链应变能函数中引入损伤变量D, 然后将宏观变形和单链分子的伸长率联系在一起. 本文改进了之前的模型, 通过引入以Prony级数为基础的非线性黏弹性理论使得模型可以表征时间相关黏性效应. 本文进一步将建立的有限变形黏-超弹性损伤本构模型在有限元软件ABAQUS中通过用户自定义子程序UMAT实现. 本文利用文献中丙烯酸聚合物在单轴拉伸下的实验数据来校准本构模型的10个参数: 包括4个弹性参数和6个黏性参数. 利用ABAQUS模拟丙烯酸聚合物复杂几何形状试样的单轴拉伸和应力松弛, 仿真结果与实验数据一致性较好.

Similar content being viewed by others

References

P. Calvert, Hydrogels for soft machines, Adv. Mater. 21, 743 (2009).

S. Coyle, C. Majidi, P. LeDuc, and K. J. Hsia, Bio-inspired soft robotics: Material selection, actuation, and design, Extreme Mech. Lett. 22, 51 (2018).

C. Yang, and Z. Suo, Hydrogel ionotronics, Nat. Rev. Mater. 3, 125 (2018).

C. S. Tsai, T. C. Chiang, B. J. Chen, and S. B. Lin, An advanced analytical model for high damping rubber bearings, Earthquake Engng. Struct. Dyn. 32, 1373 (2003).

A. R. Bhuiyan, Y. Okui, H. Mitamura, and T. Imai, A rheology model of high damping rubber bearings for seismic analysis: Identification of nonlinear viscosity, Int. J. Solids Struct. 46, 1778 (2009).

E. Tubaldi, S. A. Mitoulis, and H. Ahmadi, Comparison of different models for high damping rubber bearings in seismically isolated bridges, Soil Dyn. Earthquake Eng. 104, 329 (2018).

L. M. Kachanov, Time of the rupture process under creep conditions, Izy Akad, Nank SSR Otd Tech Nauk 8, 26 (1958).

J. Lemaitre, A continuous damage mechanics model for ductile fracture, Trans. Asme J. Eng. Mater. Technol. 107, 83 (1985).

T. J. Wang, Unified CDM model and local criterion for ductile fracture—I. Unified CDM model for ductile fracture, Eng. Fract. Mech. 42, 177 (1992).

T. J. Wang, Unified CDM model and local criterion for ductile fracture—II. Ductile fracture local criterion based on the CDM model, Eng. Fract. Mech. 42, 185 (1992).

F. Xu, N. Aravas, and P. Sofronis, Constitutive modeling of solid propellant materials with evolving microstructural damage, J. Mech. Phys. Solids 56, 2050 (2008).

M. Lei, J. Wang, J. Cheng, J. Xiao, L. Wen, H. Lu, and X. Hou, A constitutive model of the solid propellants considering the interface strength and dewetting, Compos. Sci. Tech. 185, 107893 (2020).

G. Marckmann, E. Verron, L. Gornet, G. Chagnon, P. Charrier, and P. Fort, A theory of network alteration for the Mullins effect, J. Mech. Phys. Solids 50, 2011 (2002).

X. Zhao, A theory for large deformation and damage of interpenetrating polymer networks, J. Mech. Phys. Solids 60, 319 (2012).

Q. Wang, and Z. Gao, A constitutive model of nanocomposite hydrogels with nanoparticle crosslinkers, J. Mech. Phys. Solids 94, 127 (2016).

P. Zhu, and Z. Zhong, Modelling the mechanical behaviors of double-network hydrogels, Int. J. Solids Struct. 193–194, 492 (2020).

R. Xiao, N. Han, D. Zhong, and S. Qu, Modeling the mechanical behaviors of multiple network elastomers, Mech. Mater. 161, 103992 (2021).

C. Y. Hui, and R. Long, A constitutive model for the large deformation of a self-healing gel, Soft Matter 8, 8209 (2012).

R. W. Ogden, and D. G. Roxburgh, A pseudo-elastic model for the Mullins effect in filled rubber, Proc. R. Soc. Lond. A 455, 2861 (1999).

D. Simulia, Abaqus 6.11 analysis user’s manual, 2011.

L. Boltzmann, Zur theorie der elastischen nachwirkung, Annalen der Physik 241, 430 (1878).

B. D. Coleman, and W. Noll, Foundations of linear viscoelasticity, Rev. Mod. Phys. 33, 239 (1961).

R. Christensen, Theory of Viscoelasticity: An Introduction (Academic Press, New York, 1982).

M. Kaliske, and H. Rothert, Formulation and implementation of three-dimensional viscoelasticity at small and finite strains, Comput. Mech. 19, 228 (1997).

J. Shim, and D. Mohr, Rate dependent finite strain constitutive model of polyurea, Int. J. Plast. 27, 868 (2011).

J. C. Simo, On a fully three-dimensional finite-strain viscoelastic damage model: Formulation and computational aspects, Comput. Methods Appl. Mech. Eng. 60, 153 (1987).

M. S. Green, and A. V. Tobolsky, A new approach to the theory of relaxing polymeric media, J. Chem. Phys. 14, 80 (1946).

F. Sidoroff, Un modèle viscoélastique non linéaire avec configuration intermédiaire, 13, 674 (1974).

F. Sidoroff, Incremental constitutive equation for large strain elasto plasticity, Int. J. Eng. Sci. 20, 19 (1982).

S. Reese, and S. Govindjee, A theory of finite viscoelasticity and numerical aspects, Int. J. Solids Struct. 35, 3455 (1998).

J. Bergstrom, and M. Boyce, Constitutive modeling of the large strain time-dependent behavior of elastomers, J. Mech. Phys. Solids 46, 931 (1998).

J. S. Bergström, and M. C. Boyce, Large strain time-dependent behavior of filled elastomers, Mech. Mater. 32, 627 (2000).

S. Reese, A micromechanically motivated material model for the thermo-viscoelastic material behaviour of rubber-like polymers, Int. J. Plast. 19, 909 (2003).

S. Wang, M. Decker, D. L. Henann, and S. A. Chester, Modeling of dielectric viscoelastomers with application to electromechanical instabilities, J. Mech. Phys. Solids 95, 213 (2016).

J. Zhou, L. Jiang, and R. E. Khayat, A micro-macro constitutive model for finite-deformation viscoelasticity of elastomers with nonlinear viscosity, J. Mech. Phys. Solids 110, 137 (2018).

S. Özüpek, and E. B. Becker, Constitutive equations for solid propellants, J. Eng. Mater. Tech. 119, 125 (1997).

B. Tunç, and Ş. Özüpek, Constitutive modeling of solid propellants for three dimensional nonlinear finite element analysis, Aerosp. Sci. Tech. 69, 290 (2017).

B. Tunç, and Ş. Özüpek, Implementation and validation of a three dimensional damaging finite strain viscoelastic model, Int. J. Solids Struct. 102–103, 275 (2016).

M. Sasso, G. Chiappini, M. Rossi, L. Cortese, and E. Mancini, Visco-hyper-pseudo-elastic characterization of a fluoro-silicone rubber, Exp. Mech. 54, 315 (2014).

T. Lu, J. Wang, R. Yang, and T. J. Wang, A constitutive model for soft materials incorporating viscoelasticity and Mullins effect, J. Appl. Mech. 84, 021010 (2017).

T. Lu, Z. Wang, J. Tang, W. Zhang, and T. Wang, A pseudo-elasticity theory to model the strain-softening behavior of tough hydrogels, J. Mech. Phys. Solids 137, 103832 (2020).

J. E. Marsden, and T. J. Hughes, Mathematical Foundations of Elasticity (Courier Corporation, 1994).

E. Stein, and G. Sagar, Convergence behavior of 3D finite elements for Neo-Hookean material, Eng. Comput. 25, 220 (2008).

K. Alkhoury, N. Bosnjak, Y. Wang, H. Lee, S. Nadimpalli, and S. A. Chester, Experiments and modeling of the thermo-mechanically coupled behavior of VHB, Int. J. Solids Struct. 242, 111523 (2022).

S. Wang, and S. A. Chester, Experimental characterization and continuum modeling of inelasticity in filled rubber-like materials, Int. J. Solids Struct. 136–137, 125 (2018).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 11922210).

Author information

Authors and Affiliations

Contributions

Zhenjiang Du created the constitutive model, achieved the UMAT, processed the numerical simulations and wrote the first draft of the manuscript. Yang Yan, Zhongtong Wang and Xinggui Fan revised the final version. Tongqing Lu supervised the whole project and revised the manuscript.

Corresponding author

Rights and permissions

About this article

Cite this article

Du, Z., Yang, Y., Wang, Z. et al. A finite strain visco-hyperelastic damage model for rubber-like materials: theory and numerical implementation. Acta Mech. Sin. 39, 222473 (2023). https://doi.org/10.1007/s10409-023-22473-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-023-22473-x