Abstract

The aim of the study was to determine the effect of Aloe vera (AV) and modified atmosphere packaging (MAP) applications on post-harvest fruit quality in ‘Ankara’ pear cultivar. Fruit treated with MAP, AV (33%) and MAP + AV were stored for 120 days at 1 °C and 90 ± 5% relative humidity. The quality analyses and measurements such as weight loss, decay rate, fruit firmness, soluble solids content (SSC), titratable acidity (TA), pH, total phenolic compounds, antioxidant capacity, organic acids and specific phenolic compounds were made on the 30th, 60th, 90th and 120th days of the cold storage. The losses in fruit firmness were less with MAP and MAP + AV applications, but these applications were found to significantly reduce weight loss and decay rate. It was determined that fruit color characteristics were maintained in all applications. With MAP and AV applications, the increase in SSC and the decrease in TA ratios were lower in fruit, so fruit ripening was delayed. However, the changes in the individual phenolics and organic acids content during cold storage were lower in fruit treated with MAP and AV. As a result of the study, it was concluded that MAP and AV applications on pear can be effectively used in delaying maturity and maintaining quality during cold storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

-

Aloe vera (AV) and modified atmosphere packaging (MAP) treatments reduced the storage losses and decay ratio during cold storage in pear.

-

AV and MAP treatments maintained the fruit quality and bioactive compounds content of pear during cold storage.

-

AV and MAP treatments have a significant effect on extending the post-harvest life of pear.

Introduction

Pear ripens rapidly in the post-harvest period due to its climacteric characteristic, followed by significant quality losses with a decrease in flesh firmness, water, flavor and nutrients and their interiors tend to brown. This shortens the shelf life of pear fruit and causes significant economic losses (Huang et al. 2022). Techniques such as low temperature (Xu et al. 2020), modified atmosphere packaging (Wang et al. 2020), melatonin (Zheng et al. 2019), 1‑methylcyclopropene (Latt et al. 2023), boric acid (Kaur and Kaur 2019), methyl salicylate (Zhang et al. 2020a), acibenzolar-S-methyl (Huang et al. 2022), carbon dioxide (Wang et al. 2021), candida oleophila (Nie et al. 2019), and Wickerhamomyces anomalus (Zhang et al. 2020b) are used to delay ripening in pears by slowing down respiration and pigment degradation, maintain storage quality, and control post-harvest rot.

Edible coating applied to the surface of the fruit, providing a partial barrier to water molecules and gas movement, thus reducing water loss and changing the micro atmosphere around the fruit (Zhang et al. 2023), is an environmentally friendly and health-friendly coating applied to many fruit species to prevent post-harvest losses. These are applications that do not pose any risks. Aloe vera (AV) gel application is a frequently used technique for this purpose. Previous studies have shown that AV application found to be effective in preserving post-harvest fruit quality in fruit species such as sweet cherry (Martínez-Romero et al. 2006), nectarine (Ahmed et al. 2009), pomegranate (Martínez-Romero et al. 2013), kiwifruit (Benítez et al. 2013), grapes (Shweta et al. 2014), raspberry (Hassanpour 2015), plum (Avcı et al. 2023), peach (Guillén et al. 2013), blueberry (Vieira et al. 2016), papaya (Mendy et al. 2019), cherry laurel (Ozturk et al. 2019), and jujube (Islam et al. 2022).

MAP application, which can change the gas concentration around the fruit and create a suitable atmosphere to limit respiration and metabolic activity by affecting humidity rates (Mendoza et al. 2016), can provide significant advantages (Petracek et al. 2002) by reducing water loss, respiration activity, ethylene production, enzymatic reactions, physiological changes and by preserving fruit flesh firmness (Moradinezhad and Dorostkar 2021) during storage of the fruit. In previous studies, it has been demonstrated that MAP has a positive effect on maintaining fruit quality after harvest in fruit species such as kiwi (Hertog et al. 2004),sweet cherry (Aglar et al. 2017), pomegranate (Candir et al. 2018), jujube (Islam et al. 2022), cornelian cherry (Ozturk and Aglar 2019) and plum (Avcı et al. 2023). However, it has been reported that the effect is further increased with the combination of AV and MAP (Ozkaya et al. 2016).Nevertheless, there is no study on the application of AV and MAP in pear. In this study, we aimed to determine the effect of AV and MAP applications on post-harvest fruit quality in ‘Ankara’ pear cultivar.

Materials and Methods

The plant material used for this research consists of fruit harvested from the orchard established with ‘Ankara’ pear cultivar (late ripening) trees grafted on quince A rootstock in Tokat province, Turkey, in 2010 year. Fruit harvested at commercial maturity were placed in 10-kg capacity plastic boxes (Plasta¸s, Turkey) and quickly brought to GAPUTAEM Quality and Technology Laboratory with a refrigerated vehicle (12 ± 1.0 °C and 75 ± 5.0% relative humidity [RH]). The injured or damaged fruit were eliminated and excluded from evaluation. The fruit selected by considering fruit color and size were divided into four groups: 1: fruit stored without any application (control); 2: fruit stored by placing them in Xtend® modified atmosphere packaging (MAP application); 3: fruit stored after being immersed in 33% AV solution for 10 min and dried at room conditions for 20 min (AV application); 4: fruit stored in Xtend® modified atmosphere bags after being immersed in 33% AV solution for 10 min and dried at room conditions for 20 min (AV + MAP application). In fruit that were stored at 0 ± 0.5 °C and 90 ± 5% RH for 120 days, measurements and analyses were performed in three replicates on the 30th, 60th, 90th and 120th days of storage, and six fruit were used for each repetition.

Weight Loss

At the beginning of the cold storage, initial weights (Wi) of the fruit were determined by a digital scale with a precision of 0.01 g (Radwag, Poland). Then, on day 10, 20 and 30 of cold storage, the final weights (Wf) were determined. The weight loss that occurred in fruit was based on the weight at the beginning of each measurement period and determined as a percentage through the equation given below (Eq. 1):

Decay Rate

Before cold storage, the fruit (about 0.5 kg of fruit) were counted in each replication and the total number of fruit (TF) was determined. Then, during each measurement period, the decayed fruit (DF) in each replication were determined. If the development of mycelium on shell occurred, the fruit were considered rotten. Finally, with the following equation (Eq. 2), the decay rate (DR, %) was detected:

Fruit Firmness

Five fruit from each replication were used to determine firmness. The fruit skin was cut at two different points (on the cheeks) along the equatorial part of the fruit and the firmness was determined by using an Effegi penetrometer (FT–327; McCormick, WA, USA) with a 7.9-mm penetrating tip. Firmness was expressed in kilograms.

Soluble Solids Content (SSC), Titratable Acidity (TA) and pH

Five fruit in each replication were washed with distilled water. Fruit were homogenized by a blender (Promix HR2653, Philips, Turkey) and the homogenate was filtered through cheesecloth to obtain juice filtrate. SSC was determined with a digital refractometer (Atago PAL‑1, USA) and recorded as a percentage (%). pH was determined with a pH meter. For TA measurement, 10 mL of distilled water was added to 10 mL of juice. Then, 0.1 N sodium hydroxide (NaOH) was added until the solution’s pH reached 8.2. Based on the amount of NaOH consumed in titration, TA was determined and expressed as g malic acid kg−1. For vitamin C measurement, 0.5 mL juice was added to 5 mL of 0.5% oxalic acid (Ozturk et al. 2019).

Total Phenolics and Antioxidant Capacity

During each measurement period, five fruit taken from each replication were first washed with distilled water. The fruit were homogenized by a blender (Promix HR2653 Philips, Turkey). About 30 mL of homogenate was taken and placed into a 50-ml falcon tube. The prepared tubes were kept at −20 C until the time of analyses. Before the analyses, the frozen samples were dissolved under room temperature (21 °C). Pulp and juice were separated from each other by a centrifuge at 12,000 × g at 4 °C for 35 min. The resultant filtrate was used to determine the content of total phenolics and antioxidant capacity. Spectrophotometric measurements for total phenolics and antioxidant capacity were performed using a UV-Vis spectrophotometer (Shimadzu, Kyoto, Japan) at 734 nm wavelength (Ozturk et al. 2019).

Organic Acids

Extraction of organic acids in fresh and dried samples was carried out with the modification of the method reported by Bevilacqua and Califano (1989). A volume of 10 g of sample was taken into centrifuge tubes and then 10 mL of 0.009 N H2SO4 was added to the samples and homogenized. The samples were mixed for 1 h and centrifuged at 14,000 rpm for 15 min. The liquid remaining at the top of the centrifuge tube was filtered through filter paper, then passed through a 0.45-μm membrane filter and finally through the SEP-PAK C18 cartridge. It was injected into the high-performance liquid chromatography (HPLC) (Agilent HPLC 1100 series G 1322 A, Germany) device and the separations were performed on the appropriate column (Aminex HPX—87 H, 300 mm × 7.8 mm). Organic acids were determined at wavelengths of 214 and 280 nm. As mobile phase, 0.009 N H2SO4 solution was used.

Specific Phenolic Compounds

These were analyzed as follows: Homogeneously selected fresh fruit samples were weighed as 1 g and extracted with methyl alcohol (5 mL) in a test tube for 6 h. The extract was analyzed by HPLC (Perkin-Elmer series 200, Norwalk, USA). The HPLC system was equipped with a UV detector (Series 200, UV/Vis detector) and quaternary solvent dispensing system (Series 200, analytical pump) and used at 280 nm. Analytes were separated by a Phenomenex Kromasil (Phenomenex, Torrance, USA) 100A C18 (250 mm × 4.60 mm, 5 μm) column. The clone temperature was maintained at 26 °C using a water bath (Wisebath, WB-22, Daihan Scientific, Seoul, Korea). The mobile phase was formed from water and acetonitrile (A) containing 2.5% formic acid (B). The mobile phase flow rate was maintained at 1 mL/min and 20 μL of the sample was injected and expressed in g 100 g−1 in light of the results of the peak areas obtained.

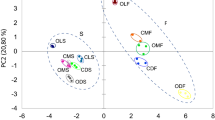

Statistical Analysis

The normality of the data was confirmed by the Kolmogorov–Smirnov test and the homogeneity of variances by the Levene’s test. (P > 0.05). Therefore, the Pearson correlation test was performed. Data were analyzed by two-way ANOVA with SAS Version 9.1 (SAS Institute Inc., Cary, NC, USA) software. When the F test was significant, means were compared with Tukey’s range test.

Results and Discussion

Weight Loss, Decay Ratio and Fruit Firmness

The weight loss that occurs as a result of water evaporation through transpiration in fruit (Kader and Yahia 2011) and increases in proportion to storage time (Ozturk et al. 2021) causes significant economic damage (Sandhya 2010). It can be reduced by the use of MAP and AV coating (Ozturk et al. 2020), which delay the degradation of the cell wall in fruit (Wang et al. 2019) and cause reduced respiration in fruit. There were differences between the applications in terms of weight loss, which increased in parallel with the storage time. The lowest weight loss at the end of the cold storage was obtained in the MAP application with 1.01%, and the highest weight loss was obtained in the control application with 3.13%. AV applications had the highest weight loss after control. There was no difference between the control and AV applications on the 30th day of cold storage, but the difference between applications was significant in other measurement days (Table 1). AV application reduced weight loss during cold storage in fruit species including apple (Ergun and Satici 2012), papaya (Sharmin et al. 2015), sweet cherry (Huyuklu 2014) plum (Díaz-Mula et al. 2012), jujube (Gün 2017; Islam et al. 2022), grape (Valverde et al. 2005) and peach (Hazrati et al. 2017). Avcı (2016) suggested that MAP and AV applications reduced weight loss in black amber plum cultivar due to their effectiveness in reducing respiration rate, and Kablan et al. (2008) reported that the loss of carbon atoms in the respiration cycle can lead to weight loss.

MAP and AV applications have the potential to control disease severity in fruit by preventing fungal rot in the fruit and reducing fruit softening during cold storage. The fruit decay ratio was lower in fruits treated with MAP and AV. At the end of the cold storage, the highest decay ratio was obtained in the control application with 90%, and the lowest decay ratio was obtained in the MAP + AV and AV applications with 40%. MAP was not effective in decay ratio on the 30th day of the cold storage, but it was lower with MAP + AV and AV applications. There were significant differences between applications on the 60th and 90th days of the cold storage; the lowest decay ratio was recorded with MAP + AV applications (Table 1). Martínez-Romero et al. (2006) reported that AV application in sweet cherry slowed down the darkening of the fruit stem and fruit rot compared to the control application, while Valverde et al. (2005) reported that spoilage was faster in control fruit and the storage life of the control group was limited to only 7 days. Singh et al. (2011) determined that fruit browning and quality losses in strawberries were lower with 33% AV application, and Ergun and Satici (2012) claimed that AV application caused lower decay damage in apples, but this varied depending on the cultivar. Zapata et al. (2012) reported that 25% AV application reduced the decay ratio in peach, sweet cherry and nectarine, and Ates et al. (2022) determined that the decay ratio was lower with 33 and 66% AV application in ‘Bluecrop’ blueberry cultivar.

Fruit softening, which increases with ripening and occurs as a result of structural changes in the pectin matrix leading to loss of cell wall structure (Posé et al. 2015), is an important problem that affects the post-harvest life of the fruit and the marketing process. However, MAP and AV applications can reduce fruit softening by reducing the respiration rate and water loss in post-harvest storage. The fruit flesh firmness decreased with increasing cold storage time. However, the fruit flesh firmness values were higher in fruit treated with MAP and AV. There was no difference between the treatments on the 30th and 90th days of cold storage, and the fruit firmness values were higher in the fruit treated with AV + MAP on the 60th day. At the end of the cold storage, the control treatment fruit had significantly lower fruit flesh firmness values than the other treatments. The effect of AV + MAP applications on fruit flesh firmness was higher compared to AV applications (Table 1). Ergun and Satici (2012) emphasized that 1%, 5%, 10% AV gel applications did not differ significantly from control applications in preserving fruit flesh firmness during cold storage in ‘Red Chief’ and ‘Granny Smith’ apple cultivars. Khan et al. (2008) stated that the decrease in fruit flesh firmness is directly proportional to ethylene synthesis and that this effect occurs when ethylene increases the enzyme activity that hydrolyzes the cell wall, and MAP applications can be slowed down the fruit softening by reducing O2 concentration and preventing ethylene synthesis. Previous studies reported that fruit softening was lower with AV application in fruit species such as pear (Jawandha et al. 2017), cherry laurel (Ozturk et al. 2020), cornelian cherry (Ozturk and Aglar 2019) and jujube (Islam et al. 2022).

Soluble Solids Content (SSC), Titratable Acidity (TA) and pH

SSC and TA are significant quality characteristics that determine the storage period of the fruit (Mahto and Das 2013). During post-harvest storage, the acid metabolism converts starch and acid into sugar, causing TA to decrease and total water-soluble dry matter to increase (Duan et al. 2011). The SSC and pH ratios increased in proportion to the storage time, while the TA ratio decreased. The changes in SSC, TA and pH ratios were lower in fruit treated with MAP and AV. On the 30th and 60th days of the cold storage, the control fruit had higher SSC values compared to AV and MAP applications. On the 30th day, the fruit of control and AV treatments had similar SSC values, and the SSC content was lower in MAP-treated fruit. At the end of the cold storage, the lowest SSC values were recorded with control fruit, followed by MAP application. In the same period, there was no difference between AV and AV + MAP applications. However, the fluctuations occurred in SSC values during cold storage (Table 2). In all applications, TA values decreased during cold storage. The lowest TA value was recorded with the control application during storage; there was generally no difference between the other applications. It was determined that the titratable acid content of fruits treated with MAP + AV was higher than those treated with AV and MAP only on the 30th day of the cold storage. The pH value generally increased in all applications during cold storage. MAP and MAP + AV applications had the highest pH values on the 30th day of storage, but AV application had a significantly higher pH content on the 60th day (Table 2). The increases and decreases in the SSC content during cold storage are based on events such as the transformation of sugar into CO2 and H2O in parallel with the increase in respiration rate, the transformation of starch into sugar, the increase in the dry matter content in parallel with the decrease in the amount of water in the fruit and the disintegration of polysaccharides in the cell wall (Martinez-Romero et al. 2006; Dang et al. 2010; Díaz-Mula et al. 2012; Vieira et al. 2016). Ozturk and Aglar (2019) reported that MAP and AV applications in cranberry fruit increased SSC compared to the control. Ozturk et al. (2018) conducted a study of pre-harvest aminoethoxyvinylglycine (AVG) and post-harvest 20% AV in ‘Piraziz’ apples and only post-harvest AV application, and found that the SSC content first increased and then decreased during cold storage and shelf life in all applications, but AVG + AV application was more effective in preserving the SSC content. Hazrati et al. (2017) reported that AV-applied peach fruit had lower SSC content, while Valero et al. (2014) found that AV application did not have a significant effect on SSC values in peach and sweet cherry. Khan et al. (2013) reported MAP application maintained SSC compared to control fruit. Hazrati et al. (2017) found that TA content in AV applied peach fruit was lower than the control fruit, and Ates et al. (2022) reported that TA content of the blueberry fruit treated with 33 and 66% was higher. However, Islam et al. (2022) suggested that TA content in AV-applied jujube was lower than control fruit.

Total Phenolics and Total Antioxidant Capacity

Total phenolics content increased in all treatments on the 30th day of the cold storage, and then it decreased at later times. AV + MAP and MAP applications significantly maintained the total phenolic content compared to the control, but the total phenol content in the AV application gave similar statistical results to the control application. At the end of the cold storage, the lowest total phenolic content was measured in the control application and the highest content was measured in the MAP + AV application. Total antioxidant content increased in applications other than MAP application on the 30th day of the cold storage, but it increased in MAP and AV applications on the 60th day, and total antioxidant content decreased in control and MAP + AV applications. In the measurements made on the 90th and 120th days of the cold, the antioxidant content decreased in all applications and the lowest values were measured in the control application at the end of the cold storage (Table 3). Previous studies have shown that total phenolic loss was lower in fruits treated with an edible coating (Rasouli et al. 2019) and MAP (Aglar et al. 2017). The effect of the edible coating applications on total phenolics during cold storage is explained by the limitation of cellular division in the fruit peel (Ali et al. 2019) and the slowing down of oxidation and degradation in phenolic compounds by the edible coating applications (Ouyang et al. 2019). The effect of MAP application is due to the change in the gas composition around the fruit (Aglar et al. 2017). However, Carrilo-Lopez et al. (2000) and Guan and Dou (2010) reported that MAP and AV applications inhibited ethylene synthesis and reduced the accumulation of phenolic compounds and anthocyanins.

Organic Acids and Specific Phenolic Compounds

Organic acids, which enable the digestion of nutrients and stimulate blood circulation and whose type and content may vary depending on the fruit species, are important fruit quality parameters and decrease as maturity increases (Kiralan and Gundogdu 2021). The amount of organic acids, one of the main substrates required for respiration, decreases as the respiration rate increases. The organic acid that was found in the highest amount in pear was malic acid, followed by succinic, formic, adipic and shikimic acids (Table 4). Gao et al. (2004) stated that malic acid is the main organic acid in different pear fruit. With increasing fruit maturity, the amount of the organic acid naturally decreased in general; however, although there were fluctuations in the amount of shikimic acid, this generally increased with the prolongation of storage time. AV and MAP applications caused changes in the amount of organic acids during cold storage; it has been determined that this effect varied depending on the type of organic acid and the cold storage time, and there are inconsistencies in the effect. At the end of the cold storage, the lowest values of all organic acids except shikimic acid were recorded in the fruit of the control application (Table 4).

In the study, gallic acid, catechin, hydroxybenzoic acid, ferulic acid, naringin, q‑coumaric, coumarin and quercetin were the main individual phenolic compounds detected in ‘Ankara’ cultivar fruit. In general, the examined phenolic compound values decreased at the end of the cold storage. The highest individual phenolic content in pear fruit during the harvest period was gallic acid and the lowest was coumarin. At the end of the cold storage period, the highest gallic acid values were determined from the AV application, followed by MAP + AV and MAP applications, while the control application gave significantly lower values than the other applications. The highest naringin content was detected in the MAP application at the end of the cold storage; the difference between the other applications was similar. Catechin values were generally preserved with MAP and AV applications during cold storage compared to the control application, while hydroxybenzoic acid values were significantly higher in the MAP + AV application compared to the other applications there were the differences between the applications in terms of hydroxybenzoic acids. The effect of the treatments on ferrulic acid values at the end of the cold storage was similar, while q-coumaric acid values increased significantly with MAP application, followed by AV, MAP + AV and control applications. The difference was detected between all applications based on the examined values. There were no differences between MAP, AV and MAP + AV applications in terms of coumarin values and the control group had the lowest values. Quercetin values gave the highest results in the MAP + AV application, followed by AV and MAP applications, while the control application had the lowest values (Table 5).

Conclusion

Weight loss and decay ratio, which significantly affect the economic life of the fruit and consumer preference, were reduced by modified atmosphere packaging (MAP) and Aloe vera (AV) applications. The loss of fruit flesh firmness was delayed by MAP and MAP + AV applications. MAP and AV applications delayed ripeness in pear fruit, lower soluble solids content and higher titratable acidity values were detected in the fruit, and it was observed that the color change in the fruit was lower. The changes in the content of organic acids and individual phenolics occurred in cold storage, and the changes differed depending on the type of individual phenolics and organic acids. As a result, it was concluded that MAP and AV applications can be effectively used to delay ripeness and preserve the quality of ‘Ankara’ pear fruits during cold storage.

References

Aglar E, Ozturk B, Guler S, Karakaya O, Uzun S, Saracoglu O (2017) Effect of modified atmosphere packaging and ‘Parka’ treatments on fruit quality characteristics of sweet cherry fruits (Prunus avium L. ‘0900 Ziraat’) during cold storage and shelf life. Sci Hortic 222:162–168. https://doi.org/10.1016/j.scienta.2017.05.024

Ahmed MJ, Singh Z, Khan AS (2009) Postharvest Aloe vera gel coating modulates fruit ripening and quality of ‘Arctic Snow’ nectarine kept in ambient and cold storage. Int J Food Sci Tech 44(5):1024–1033. https://doi.org/10.1111/j.1365-2621.2008.01873.x

Ali S, Khan AS, Nawaz A, Anjum MA, Naz S, Ejaz S, Hussain S (2019) Aloe vera gel coating delays postharvest browning and maintains quality of harvested litchi fruit. Postharvest Biol Technol 157:110960. https://doi.org/10.1016/j.postharvbio.2019.110960

Ates U, Islam A, Ozturk B, Aglar E, Karakaya O, Gun S (2022) Changes in Quality Traits and Phytochemical Components of Blueberry (Vaccinium Corymbosum Cv. Bluecrop) Fruit in Response to Postharvest AloeVera Treatment. International Journal of Fruit Science 22(1):2022. https://doi.org/10.1080/15538362.2022.2038341

Avcı V (2016) Japon Grubu (Prunus salicina L.) Black Amber Erik Çeşidinin Muhafaza Performansının Belirlenmesi. Ordu Üniversitesi Fen Bilimleri Enstitüsü, pp 15–71 (Yüksek Lisans Tezi)

Avcı V, Islam A, Ozturk B, Aglar E (2023) Effects of Aloe vera gel and Modified Atmosphere Packaging Treatments on Quality Properties and Bioactive Compounds of Plum (Prunus salicina L.) Fruit Throughout Cold Storage and Shelf Life. Erwerbs-Obstbau 65:71–82. https://doi.org/10.1007/s10341-022-00694-7

Benítez S, Achaerandio I, Sepulcre F, Pujolà M (2013) Aloe vera based edible coatings improve the quality of minimally processed ’Hayward’ kiwifruit. Postharvest Biol Technol 81:29–36. https://doi.org/10.1016/j.postharvbio.2013.02.009

Bevilacqua AE, Califano AN (1989) Determination of organic acids in dairy products by high performance liquid chromatography. J Food Science 54:1076–1079. https://doi.org/10.1111/j.1365-2621.1989.tb07948.x

Candir E, Ozdemir AE, Aksoy MC (2018) Effects of chitosan coating and modified atmosphere packaging on postharvest quality and bioactive compounds of pomegranate fruit cv ‘Hicaznar”. Sci Hortic 235:235–243. https://doi.org/10.1016/j.scienta.2018.03.017

Carrilo-Lopez A, Ramirez-Bustamante F, Valdez-Torrez JB, Rojas-Villegas R (2000) Ripening and quality changes in mango fruit as affected by coating with an edible film. J Food Quality 23:479–486. https://doi.org/10.1111/j.1745-4557.2000.tb00573.x

Dang QF, Yan JQ, Li Y, Cheng XJ, Liu CS, Chen XG (2010) Chitosan acetate as an active coating material and its effects on the storing of Prunus avium L. J Food Science 75:125–131. https://doi.org/10.1111/j.1750-3841.2009.01483.x

Diaz-Mula FHM, Serrano M, Valero D (2012) Alginate coatings preserve fruit quality and bioactive compounds during storage of sweet cherr. Food Bioprocess Technol 5:2990–2997. https://doi.org/10.1007/s11947-011-0599-2

Duan J, Wu R, Strik BC, Zhao Y (2011) Effect of edible coatings on the quality of fresh blueberries (Duke and Elliott) under commercial storage conditions. Postharvest Biol Technol 59:71–79. https://doi.org/10.1016/j.postharvbio.2010.08.006

Ergun M, Satici F (2012) Use of AV gel as biopreservative for ‘Granny Smith’and ‘Red Chief’ apples. J Animal Plant Sci 22(2):363–368

Gao HY, Liao XJ, Hu XS (2004) Study on determination and correlation of soluble sugars and organic acids in pear juice from different cultivars. Acta Agric Boreali Sinca 19(2):104–107. https://doi.org/10.3321/j.issn:1000-7091.2004.02.026

Guan JF, Dou S (2010) The effect of MAP on quality and browning of cold-stored plum fruits. J Food Agric Environ 8:113–116. https://doi.org/10.1234/4.2010.1574

Guillén F, Diaz-Mula HM, Zapata PJ, Valero D, Serrano M, Castillo S, Martinez-Romero D (2013) Aloe arborescens and Aloe vera gels as coatings in delaying postharvest ripening in peach and plum fruit. Postharvest Biol Technol 83:54–57. https://doi.org/10.1016/j.postharvbio.2013.03.011

Gun S (2017) Hünnap Meyvesinin (Ziziphus jujuba mill.) Soğukta Muhafaza Performansı Üzerine Farklı Olgunluk Safhası ve Modifiye Atmosfer Paketlemenin (MAP) Etkisi. Fen Bilimleri Enstitüsü, Ordu, p 70 (Yüksek Lisans Tezi)

Hassanpour H (2015) Effect of Aloe vera gel coating on antioxidant capacity antioxidant enzyme activities and decay in raspberry fruit. LWT Food Sci Technol 60:495–501. https://doi.org/10.1016/j.lwt.2014.07.049

Hazrati S, Kashkooli AB, Habibzadeh F, Tahmasebi-Sarvestani Z, Sadeghi AR (2017) Evaluation of AV gel as an alternative edible coating for peach fruits during cold storage period. Gesunde Pflanz 69(3):131–137. https://doi.org/10.1007/s10343-017-0397-5

Hertog ML, Nicholson SE, Jeffery PB (2004) The effect of modified atmospheres on the rate of firmness change of ‘Hayward’ kiwifruit. Postharvest Biol Technol 31:251–261. https://doi.org/10.1016/j.postharvbio.2003.09.005

Huang R, Cheng Y, Li C, Guo M, Zhu J, Ge Y, Sun T (2022) Postharvest application of acibenzolar- S‑methyl delays the senescence of pears by mediating the ascorbate-glutathione cycle. Sci Hortic 293:11074. https://doi.org/10.1016/j.scienta.2021.110741

Huyuklu C (2014) Modifiye Atmosfer Ambalajlarının Kiraz Muhafazası Süresine Etkisi. Sütçü İmam Üniversitesi Fen Bilimleri Enstitüsü Bahçe Bitkileri Anabilimdalı, Kahramanmaraş, p 39 (Yüksek Lisans Tezi)

Islam A, Acikalin R, Ozturk B, Aglar E, Kaiser C (2022) Combined effects of AV gel and modified atmosphere packaging treatments on fruit quality traits and bioactive compounds of jujube (Ziziphus jujuba mill.) fruit during cold storage and shelf life. Postharvest Biol Technol 187:111855. https://doi.org/10.1016/j.postharvbio.2022.111855

Jawandha S, Gill P, Kaur N, Verma A, Chawla N (2017) Effect of edible surface coatings on the storability of pear fruits. Indian J Hortic 74(2):271–275. https://doi.org/10.5958/0974-0112.2017.00054.8

Kablan T, Koffi NR, Marina K, Oule MK (2008) The effects of different storage temperatures on the quality of bell pepper (Capsicum annuum L.). Agric J 3(2):157–162

Kader AA, Yahia EM (2011) Postharvest biology of tropical and subtropical fruits. In: Yahia EM (ed) Postharvest biology and technology of tropical and subtropical fruits, 1st edn. Woodhead Publishing, pp 79–111

Kaur M, Kaur A (2019) Improvement in storability and quality of peach cv. flordaprince with postharvest application of various chemicals. J Pharma Phytochem 8:460–464

Khan AS, Singh Z, Abbasi NA, Swinny EE (2008) Pre-or post-harvest applications of putrescine and low temperature storage affect fruit ripening and quality of “Angelino” plum. Journal of Science Food Agriculture 88:1686–1695. https://doi.org/10.1002/jsfa.3265

Khan MS, Zeb A, Rahatullah K, Ihsanullah AN, Ahmed S (2013) Storage life extension of plum fruit with different colored packaging and storage temperatures. J Environ Sci Toxic Food Technol 7:86–93. https://doi.org/10.9790/2402-0738693

Kiralan M, Gundogdu M (2021) Dut Türlerine Ait Meyvelerin Organik Asit ve C vitamini İçerikleri Üzerine Farklı Kurutma Tekniklerinin Etkisi. Uluslararası Tarım Yaban Hayatı Bilim Derg 7(3):404–411. https://doi.org/10.24180/ijaws.990049

Latt TT, Lwin HP, Seo HJ, Lee J (2023) 1‑Methylcyclopropene delays degradation of peel greenness but induces internal physiological disorders in cold-stored fruit of interspecific pears. Sci Hortic 312:111852. https://doi.org/10.1016/j.scienta.2023.111852

Mahto R, Das M (2013) Effect of gamma irradiation on the physico-chemical and visual properties of mango (Mangifera indica L.), cv. “Dushehri” and “Fazli” stored at 20 °C. Postharvest Biol Technol 86:447–455. https://doi.org/10.1016/j.postharvbio.2013.07.018

Martinez-Romero D, Alburquerque N, Valverde JM, Guillen F, Castillo S, Valero D, Serrano M (2006) Postharvest sweet cherry quality and safety maintenance by aloe vera treatments: a new edible coating. Postharvest Biology and Technology 39:93–100. https://doi.org/10.1016/j.postharvbio.2005.09.006

Martinez-Romero D, Castillo S, Guillen F, Diaz-Mula HM, Zapata PJ, Valero D, Serrano M (2013) Aloe vera gel coating maintains quality and safety of ready-to-eat pomegranate arils. Postharvest Biology and Technology 86(2013):107–112. https://doi.org/10.1016/j.postharvbio.2013.06.022

Mendoza R, Castellanos DA, García JC, Vargas JC, Herrera AO (2016) Ethylene production, respiration and gas exchange modelling in modified atmosphere packaging for banana fruits. Interationl. Journal of Food Science and Technology 51(3):777–788

Mendy TK, Misran A, Mahmud TMM, Ismail SI (2019) Application of Aloe vera coating delays ripening and extend the shelf life of papaya fruit. Sci Hortic 246:769–776. https://doi.org/10.1016/j.scienta.2018.11.054

Moradinezhad F, Dorostkar M (2021) Effect of vacuum and modified atmosphere packaging on the quality attributes and sensory evaluation of fresh jujube fruit. Int J Fruit Sci 21(1):82–94. https://doi.org/10.1080/15538362.2020.1858470

Nie X, Zhang C, Jiang C, Zhang R, Gou F, Fan X (2019) Trehalose increases the oxidative stress tolerance and biocontrol efficacy of Candida oleophila in the microenvironment of pear wounds. Biol Control. https://doi.org/10.1016/j.biocontrol.2019.01.015

Ouyang Q, Kou F, Zhang N, Lian J, Tu G, Fang Z (2019) Tea polyphenols promote Fenton-like reaction: pH self-driving chelation and reduction mechanism. Chem Eng J 366:514–522. https://doi.org/10.1016/j.cej.2019.02.078

Ozkaya O, Yildirim D, Dundar O, Tukel SS (2016) Effects of 1‑methylcyclopropene (1-MCP) and modified atmosphere packaging on postharvest storage quality of nectarine fruit. Sci Hortic 198:454–461. https://doi.org/10.1016/j.scienta.2015.12.016

Ozturk B, Aglar E (2019) Effects of modified atmosphere packaging (MAP) and AV treatments on quality characteristics of cornelian cherry fruits during cold storage. Akad Ziraat Derg 8(1):1–8. https://doi.org/10.29278/azd.592897

Ozturk B, Karakaya M, Karakaya O, Gun S (2018) Piraziz elmasının soğukta muhafaza ve raf ömrü üzerine AVG ve AV uygulamalarının etkisi. Akad Ziraat Derg 7(2):121–130. https://doi.org/10.29278/azd.476107

Ozturk B, Karakaya O, Yıldız K, Saracoglu O (2019) Effects of AV gel and MAP on bioactive compounds and quality attributes of cherry laurel fruit during cold storage. Sci Hortic 249:31–37. https://doi.org/10.1016/j.scienta.2019.01.030

Ozturk B, Aglar E, Gun S, Karakaya O (2020) Change of fruit quality properties of jujube fruit (Ziziphus jujuba) without stalk and with stalk during cold storage. Int J Fruit Sci 20(3):1891–1903. https://doi.org/10.1080/15538362.2020.1834901

Ozturk B, Yıldız M, Yıldız K, Gun S (2021) Maintaining the postharvest quality and bioactive compounds of jujube (Ziziphus jujuba Mill. Cv. ‘Li’) fruit by applying 1‑methylcyclopropene. Sci Hortic 275:109671. https://doi.org/10.1016/j.scienta.2020.109671

Petracek PD, Joles DW, Shirazi A, Cameron AC (2002) Modified atmosphere packaging of sweet cherry (Prunus avium L. Cv.’ Sams’) fruit: metabolic responses to oxygen, carbon dioxide, and temperature. Postharvest Biol Technol 24:259–270. https://doi.org/10.1016/S0925-5214(01)00192-2

Posé S, Kirby AR, Paniagua C, Waldron KW, Morris VJ, Quesada MA, Mercado JA (2015) The nanostructural characterization of strawberry pectins in pectate lyase or polygalacturonase silenced fruits elucidates their role in softening. Carbohydr Polym 132:134–145. https://doi.org/10.1016/j.carbpol.2015.06.018

Rasouli M, Saba MK, Ramezanian A (2019) Inhibitory effect of salicylic acid and Aloe vera gel edible coating on microbial load and chilling injury of orange fruit. Scientia Horticulturae 247:27–34. https://doi.org/10.1016/j.scienta.2018.12.004

Sandhya KVK (2010) Modified atmosphere packaging of fresh produce: current status and future needs. LWT Food Sci Technol 43:381–392. https://doi.org/10.1016/j.lwt.2009.05.018

Sharmin M, Islam M, Alim M (2015) Shelf-life enhancement of papaya with AV gel coating at ambient temperature. J Bangladesh Agric Univ 13(1):131–136. https://doi.org/10.3329/jbau.v13i1.28729

Shweta C, Gupta KC, Mukesh A (2014) Application of biodegradable Aloe vera gel to control post harvest decay and longer the shelf life of grapes. Int J Curr Microbiol Appl Sci 3(3):632–642

Singh D, Rajbir S, Kingsly A, Sharma R (2011) Effect of AV coatings on fruit quality and storability of strawberry (Fragaria× ananassa). Indian J Agric Sci 81(5):407–412

Valero D, Mirdehghan SH, Sayyari M, Serrano M (2014) Vapor treatments chilling storage and antioxidants in pomegranates. In: Preedy VR (ed) Processing and impact on active components in food. Academic Press, London, pp 189–196

Valverde JM, Valero D, Martinez-Romero D, Guillen F, Castillo S, Serrano M (2005) Novel edible coating based on Aloe Vera gel to maintain table grape quality and safety. J Agric Food Chem 53:7807–7813. https://doi.org/10.1021/jf050962v

Vieira JM, Flores-López ML, de Rodríguez DJ, Sousa MC, Vicente AA, Martins JT (2016) Effect of chitosan—Aloe Vera coating on postharvest quality of blueberry (Vaccinium corymbosum) fruit. Postharvest Biol Technol 116:88–97. https://doi.org/10.1016/j.postharvbio.2016.01.011

Wang C, Dai S, Zhang Z, Lao W, Wang R, Meng X (2021) Ethylene and salicylic acid synergistically accelerate leaf senescence in Arabidopsis. J Integrate Plant Biol 63:828–833. https://doi.org/10.1111/jipb.13075

Wang F, Zhang X, Yang Q, Zhao Q (2019) Exogenous melatonin delays postharvest fruit senescence and maintains the quality of sweet cherries. Food Chem 301:125311. https://doi.org/10.1016/j.foodchem.2019.125311

Wang L, Sang W, Xu R, Cao J (2020) Alteration of flesh color and enhancement of bioactive substances via the stimulation of anthocyanin biosynthesis in ‘Friar’ plum fruit by low temperature and the removal. Food Chem 310:125862. https://doi.org/10.1016/j.foodchem.2019.125862

Xu M, Yang Q, Boateng NAS, Ahima J, Dou Y, Zhang H (2020) Ultrastructure observation and transcriptome analysis of Penicillium expansum invasion in postharvest pears. Postharvest Biol Technol 165:111198. https://doi.org/10.1016/j.postharvbio.2020.111198

Zapata P, Navarro D, Guillén F, Castillo S, Martínez RD, Valero D, Serrano M (2012) Characterisation of gels from different aloe spp. as antifungal treatment: potential crops for industrial applications. Ind Crops Prod 42:223–230. https://doi.org/10.1016/j.indcrop.2012.06.002

Zhang H, Zhao L, Fan C, Wang P, Cui M, Liu L, Yang H, Wang J (2020a) Impact of methyl salicylate on storage quality, ethylene action, and protein profiling of ‘Zaosu’ pear (Pyrus bretschneideri). Scientia Horticulturae 264(5):109196

Zhang H, Zhao L, Li B, Gu X, Zhang X, Boateng NAS, Zhang H (2020b) Molecular Dissection of Defense Response of Pears Induced by the Biocontrol Yeast,Wickerhamomyces anomalusUsing Transcriptomics and Proteomics Approaches. Biological Control 148:104305. https://doi.org/10.1016/j.biocontrol.2020.104305

Zhang Y, Wang H, Shu C, Chen L, Cao J, Jiang W (2023) The combination treatment of chlorogenic acid and sodium alginate coating could accelerate the wound healing of pear fruit by promoting the metabolic pathway of phenylpropane. Food Chem 414:135689

Zheng H, Liu W, Liu S, Liu CZ (2019) Effects of melatonin treatment on the enzymatic browning and nutritional quality of fresh-cut pear fruit. Food Chem 299:125116. https://doi.org/10.1016/j.foodchem.2019.125116

Funding

This work was supported by the BAP (Project Number: SİÜFEB-033) of Siirt University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

F. Ogurlu, E. Kucuker and E. Aglar declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ogurlu, F., Kucuker, E. & Aglar, E. Effects of Aloe vera and Modified Atmosphere Packaging on the Quality and Biochemical Properties of Pear Fruit During Cold Storage. Applied Fruit Science (2024). https://doi.org/10.1007/s10341-024-01070-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10341-024-01070-3