Abstract

Stability-indicating reverse-phase HPLC analytical method for the quantification of Paclitaxel (PTX) in the bulk and cationic liposomes was developed. The optimized method was validated according to the ICH Q2 (R1) guidelines by following a 2-level–4-factor interaction Box–Behnken design using Design-Expert® software. The responses measured at 228 nm were retention time (Rt), peak area, tailing factor (Tf10%), and the number of theoretical plates (NTP). PTX was eluted best using the Luna® C18 LC Column along with a mobile phase of methanol and 25 mM ammonium acetate buffer (pH 6) 75:25 v/v mixture at 25 ± 2 °C temperature. The currently developed method was linear in the 2.5–100 µg/mL range with a detection limit of 0.062 µg/mL and a quantification limit of 0.188 µg/mL. The optimized method was utilized to evaluate the stability of PTX in different stress conditions by performing forced degradation studies. The results from the degradation study stipulated that on exposure to various stressors, namely acid, alkali, oxidative, thermal, and UV light, the PTX did not show considerable degradation except alkali exposure. Further, the method was successfully used for the quantification of PTX in cationic liposomes. The particle size, zeta potential, and polydispersity index of the PTX-loaded liposomes were 219.25 ± 7.566 nm, 57.15 ± 12.374 mV, and 0.807 ± 0.1958 respectively. The percent of drug entrapped was quantified and was found to be 59 ± 1.414%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Paclitaxel is a diterpenoid pseudoalkaloid (Fig. 1) originally isolated from the bark of Taxus brevifolia in the early 1960s [1, 2]. It belongs to the BCS class IV category drugs having very low aqueous solubility (log P-3.96) and has a molecular weight of 853.91 g/mol, and a pKa value of 10.36 [3]. Paclitaxel is approved for the treatment of various cancers including breast, ovarian, lung, head and neck, and AIDS-related Kaposi's sarcoma [4]. Paclitaxel is associated with several adverse effects, such as bone marrow suppression, alopecia, arthralgia, myalgias, peripheral neuropathy, etc. [5, 6]. Several nano-based formulations, such as Abraxane (albumin-bound paclitaxel), LIPUSU (a liposomal paclitaxel formulation), and Genexol‐PM (a polymeric micelle-based paclitaxel formulation), have been tested and approved for the efficient delivery of paclitaxel to the tumor site and to reduce the unwanted side effects [6]. However, still, there is a lack of target specificity and selectivity in these approved nano-formulations and thus may produce some serious side effects. Further, these issues give the way to design tumor-specific nano-formulations to kill the cancer cells efficiently.

Large-scale separations are possible with liquid chromatographic techniques, and the results are repeatable. In the analysis of diverse phenolic compounds, reversed-phase HPLC takes the lead. Traditional HPLC has commonly been used in conjunction with simple ultraviolet, diode array, or UV–fluorescence detection; however, mass spectrometry has also been used in conjunction with HPLC to identify phenolic chemicals. The use of superficially porous particles has attracted a lot of attention in the recent development of particle technology for liquid chromatography, which allows enantiomeric resolution, separation of peptides, and other chemicals. This new generation of columns allows for quick separations utilizing traditional HPLC instruments, as well as a minimum amount of solvent and handling time, making them cost-effective and environmentally friendly [7,8,9,10,11].

Liquid chromatographic methods, as well as gas chromatographic methods, have been reported for the estimation of PTXl in analytical samples [12,13,14,15,16]. A few reports are also reported for the quantification of PTX in rat and human plasma samples using HPLC, HPLC–MSMS, and UPLC–MS/MS techniques [17,18,19], but no reports indicate the use of statistical design to develop and validate a suitable stability-indicating analytical method for the quantification of PTX in the bulk and dosage forms. Therefore, a suitable rapid, sensitive, and accurate stability-indicating method is needed for the estimation of PTX in bulk and nano-formulations. Moreover, the development of the analytical method necessitates a thorough investigation of various factors that may affect the sensitivity and specificity, making the process difficult. A systematic approach toward using a statistical design such as the Box–Behnken design (BBD) to generate scientifically valid results would be possible. BBD is a strategy for systematically identifying and analyzing essential qualities in the process of method development [20]. BBD is used to generate higher-order response surfaces using fewer required runs than a normal factorial technique. The BBD approach has been used in analytical methods at several different stages, including initial screening, selecting evaluative chromatographic variables, optimization, and robustness testing [21,22,23,24,25].

The current research was mainly focused to develop an RP-HPLC method for estimating the amount of PTX in cationic liposomes, considering the quality output from the BBD approach. With this BBD approach, the chromatographic conditions were optimized. To examine the stability parameters of the drug, forced degradation studies were conducted by purposely exposing the drug to various stress conditions. Further, the validated method was used to quantify PTX in bulk and cationic liposomes to estimate the total drug content and drug entrapment efficiency of cationic liposomes.

Experimental

Materials

Paclitaxel was obtained as a generous gift from Neon Laboratories (Mumbai, India). Chromatography grade Methanol (purity, 99.8%) was purchased from FINAR limited (Ahmedabad, India), glacial acetic acid (purity 99–100%), and ammonium acetate (purity ≥ 96%) were purchased from Merck Ltd. Mumbai, (India). Nylon filter membrane 0.22 micron was procured from Riviera Glass Pvt. Ltd. Mumbai, (India). Ultrapure water, utilized from a Millipore Direct-Q® 3 UV-purification system (MerkMillipore, USA) to prepare sample and mobile phase. For cationic liposomes preparation, soy-phosphatidylcholine (S-100) was obtained as a generous gift from Lipoid, Germany; Didodecyldimethylammonium bromide (DDAB) was procured from TCI chemicals, India, Pvt. Ltd; cholesterol was purchased from Qualigens fine chemicals India Pvt. Ltd. Unless otherwise stated, all additional materials used were analytical grade.

Instrumentation and Apparatus

The Shimadzu HPLC system (Kyoto, Japan) was fitted with binary high/low-pressure gradient pumps, degasser, SPD-M20A PDA detector, and SIL-20A/C HT autosampler. LC Solution 5.57 system control software was used to obtain, track and process output chromatograms data. Phenomenex Luna® 5 microns C18(2) 100 Å, LC Column (250 × 4.6 mm) (Hyderabad, India) was used along with a guard column to separate the drugs. Saffron SES204 analytical balance was used to weigh standard substances (Saffron Electronics scale, Surat, India). The AAB was filtered with a 0.22-micron membrane filter (Riviera Glass Private Limited Mumbai, India) using a membrane holder vacuum filtration system (Tarsons Products Pvt. Ltd., Kolkata, India) and degassed with an ultrasonic bath sonicator (Oscar Ultrasonics Pvt. Ltd., Mumbai, India). A digital pH meter-335 with an electrode (Systronics, Ahmedabad, India) was used to adjust the pH of the AAB. Ultrapure water from the direct-Q3 purification system (Millipore Corporation, USA) has been used.

Chromatographic Conditions

After extensive pH screening and the ratios of mobile phase mixture, i.e., MeOH: AAB, the best separation of PTX was obtained at the detection wavelength 228 nm by isocratic elution with 25 mM AAB (pH balanced to 6 ± 0.05 with glacial acetic acid) and MeOH mixture in the 25:75 v/v ratio was obtained as a mobile phase and a Luna® C18 column as a stationary phase. The 20 μL of PTX solution was eluted for 10 min at a 1 mL/min flow rate. The temperature of the autosampler was held at 5 °C and column/room temperature was maintained at 25 ± 2 °C.

Preparation of Standard Solutions of Paclitaxel and Sample Dilutions

The main stock of PTX standard solution (1 mg / mL, Stock A), was prepared by accurately weighing and dissolving 5 mg of PTX in 4 mL of 70% MeOH (diluent) using vortex for 3–5 min followed by volume makeup up to 5 mL. The stock solution of 1 mg/mL was further diluted to get a 100 µg/mL solution (Stock B). Linearity samples with concentrations varying from 2.5 to 100 µg/mL were made by properly diluting standard PTX stock solutions with the diluent. 1 mg/mL standard solution of PTX was used for forced degradation studies.

Optimization of the Analytical Method

Effect of Mobile Phase Composition, pH, and Flow Rate

Different mobile phase compositions (different ratios of MeOH and AAB), pH of AAB, and flow rate were trialed. A 25 mM solution of AAB (pH 6) was made by dissolving 1.92 g of ammonium acetate into 900 mL of Milli-Q water and the pH was set to 6 using acetic acid (glacial) followed by volume makeup to 1000 mL. The AAB solution was passed through a 0.22-micron pore size nylon membrane filter and degassed. A mixture of this AAB and MeOH in varying ratios and pH were used as the mobile phase. The responses of the chromatograms, namely retention time (Rt), peak area, tailing factor (Tf10%), and the number of theoretical plates (NTP), were calculated using LC solutions software.

Stability Assessment of Paclitaxel by Force Degradation Studies

PTX was subjected to oxidative stress (3% hydrogen peroxide), heat, and photodegradation experiments after being exposed to acidic stress (0.1 N hydrochloric acid), basic stress (0.01 N sodium hydroxide), and neutral (water) environments for vulnerable hydrolysis at various pH levels [22, 25]. Except in the photolytic degradation investigation, amber-colored volumetric flasks were used to ensure that degradation was caused mostly by introduced contents rather than light.

Acid- and Alkali-Induced Degradation Studies

1 mL (1 mg/mL) standard PTX solution was mixed with 2 mL of 0.1 N hydrochloric acid (for acid-induced degradation) or 2 mL of 0.01 N sodium hydroxide solution (for alkali-induced degradation) in a 10 mL volumetric flask and kept in a dark area for 24 h at room temperature. Thereafter, these solutions were diluted and neutralized with MeOH and made up the volume of 10 mL. As required, the diluted samples were taken and injected into an HPLC system.

Oxidative Stress-Induced Degradation Study

1 mL (1 mg/mL) standard PTX solution was mixed with 2 mL of 3% w/v hydrogen peroxide solution in a 10 mL volumetric flask, wrapped with aluminum foil, and kept in a dark area for 24 h at room temperature. Thereafter, the solution was diluted and neutralized with MeOH and made up the volume of 10 mL, and a required volume was taken and injected into an HPLC system.

Photolytic Degradation Study

1 mL (1 mg/mL) standard PTX solution was taken in a 10 mL transparent volumetric flask and kept under the long-wavelength UV radiation for 24 h and then diluted with MeOH (up to 10 mL) and the required volume was taken and injected into the HPLC system.

Thermal (Moist Heat) Degradation Study

1 mL (1 mg/mL) standard solution of PTX was mixed with 2 mL of water in a 100 mL round bottom flask, wrapped with aluminum foil, and kept at slow speed for heating on a rotary evaporator water bath at 80 °C for 24 h (21). Thereafter, the sample was cooled and diluted with MeOH up to 10 mL and injected into the HPLC system. The same test sample was also analyzed for the hydrolysis of PTX at neutral pH conditions.

Analytical Method Validation

The optimized method was validated according to the ICH Q2 (R1) guidelines to check the reliability of the method. The following validation parameters were evaluated:

System Suitability

The system suitability of the optimized method was evaluated by injecting six replicates of PTX (10 µg/mL) to evaluate whether the method is suitable for its intended use.

Specificity

To verify whether the developed method can specifically resolve PTX, interference from excipients (used in the preparation of the cationic liposomes), and blank at the Rt of the PTX were assessed by injecting three replicates of each diluent as well as placebo samples into the HPLC system.

Linearity

Linearity refers to an analytical procedure's ability to deliver test findings that are proportionate to the concentration (amount) of the test compound in the sample (for a given range). Spiking known amounts of PTX, concentrations ranging from 2.5 to 100 µg/mL in triplicates were used to establish a linearity plot. To create the regression equation, the peak area vs drug concentrations was displayed.

Precision

Inter- and intra-day precision testing was performed by injecting six replicates into HPLC at 10 µg/mL to determine the ability of the method to produce repeatable results at a specified condition.

Accuracy

Accuracy testing was carried out by injecting three quality control samples of PTX 8 µg/mL, 10 µg/mL, and 12 µg/mL in triplicates into HPLC to check the degree to which the value was found, and the value considered as a conventional actual value, or an approved reference value agree. The percentage recovery was calculated and found under acceptance criteria.

Limit of Detection (LOD) and Limit of Quantification (LOQ)

The LOD and LOQ of PTX were calculated from the standard deviation of the regression line y-intercepts and the calibration curve slope, as per the ICH guidelines.

The LOD can be determined by the following equation:

Similarly, the LOQ is determined by the following equation:

where \(\sigma\) stands for the standard deviation of response and S stands for the slope of the regression line.

Robustness

Alteration in method parameters, such as pH of the AAB, flow rate, MeOH and AAB percentage, and injection volume in the mobile phase, and the injection volume was used to determine any alteration in method responses. For this purpose, we injected 10 µg/mL PTX solution for all the 29 trials given by Design–Expert software and evaluated the following factors, pH (6 ± 0.5) of the AAB, flow rate (1 ± 0.2 mL/min), MeOH: AAB ratio (75:25 ± 2%), and injection volume (20 ± 10µL) using a randomized multifactorial 4FI (4-Factor interaction) study design with the help of Design-Expert® v,10.0.3.1 software. A total of 29 runs were computed using Box–Behnken statistical design as shown in Table 1. Changes in responses to the method parameters, such as Rt, peak area, Tf10%, and NTP, were monitored. The significance of factors (p < 0.001) was evaluated using the analysis of variance (ANOVA) test.

Bench-Top Stability of Paclitaxel Solution

The stability of the PTX solution was determined by injecting three replicates of a freshly prepared sample (10 µg/mL) and 24- and 48-h-old samples of PTX. Thereafter, the average peak area of the PTX peak of both fresh and old samples, and the amount of PTX injected were taken and the following formula was used to compute the similarity index.

Bench-Top Stability of Mobile Phase

The stability of the AAB in the mobile phase was determined by eluting fresh PTX standard solution in both fresh as well as 24-h (or 48 h)-old mobile phase. Thereafter, the average peak area of the PTX peak in both the fresh and old mobile phases and the amount of PTX injected were taken and the following formula was used to calculate the similarity index:

Application of the Method for Quantifying Paclitaxel in Cationic Liposomes

Cationic liposomes composed of soy phosphatidylcholine (S-100), cholesterol, Dimethyldioctadecylammonium Bromide (DDAB), and loaded with PTX were prepared by thin-film hydration technique [26]. Briefly, S-100, cholesterol, and DDAB (7.5:1.75:4 molar ratio) were dissolved in 10 mL of chloroform in a dried round bottom flask. PTX was also dissolved in chloroform along with lipids. Chloroform was removed by evaporating at 45 °C under a vacuum with the help of a flash evaporator (Rotavapor® R215, Buchi, Switzerland). A thin film was formed around the walls of the flask. The flask was placed in a vacuum desiccator for 8–12 h to remove any residual solvent. The film was then hydrated at 60 °C using 10 mL of aqueous solution (PBS-7.4) followed by 10 min of sonication (Labman, India). The resulting dispersion was then taken into a Spin-X UF 6 (10 K MWCO) centrifuge tube and centrifuged at 3000 rpm for 1 h at 4 °C to separate the un-entrapped drug. The PTX-loaded cationic liposomes were ruptured with Tween 20 (5% v/v). In brief, 100 µL of PTX-loaded cationic liposomes was mixed with 200 µL of 5% tween 20 and then vortexed for 10 min followed by volume makeup with MeOH to 1 mL, and vortexed for 10 min again, centrifuged for 15 min at 14,000 rpm and the supernatant was used to estimate the unentrapped drug content in cationic liposomes. The total drug content in cationic liposomes, and entrapment efficiency, of the cationic liposomes, were calculated by the indirect method using Eqs. 3 and 4. Placebo was prepared similarly by omitting the drug, to rule out the interference of placebo with the cationic liposomes. The cationic liposomes were characterized for particle size distribution, zeta potential, and polydispersity index using Zeta Sizer (NanoZS, Malvern Instruments, UK).

Results and Discussion

Optimization of the Method

To date, no reports have been published indicating the use of statistical design and stability studies in the analytical method development of paclitaxel. The proposed method has been validated using Box–Behnken Design approach, indicates stability at different stress conditions, economic, and it has greater sensitivity, good accuracy in terms of recovery, over previously reported methods.

Effect of pH, Mobile Phase Ratio, and Flow Rate on Individual Responses

The pH of the mobile phase buffer used is an important variable to consider while developing a method, especially when separating bases in neutral form. In reversed-phase chromatography, ionization has a noticeable consequence on the retention of the test compound, unionized form retains more than the ionized form due to the ionized form's hydrophilic character [22]. Higher pH is required to separate a basic drug in neutral form, which may degrade the column’s silica packing, implying the usage of lower pH for basic compounds separation [22]. Most useful buffer systems include phosphate and acetate as they can be used at wavelengths below 220 nm. The best separation of a drug can be influenced when the pH of the mobile phase is at least 2 units above/ below the pKa of basic/acidic drugs respectively. At this pH, the drug will be completely ionized/ unionized [22]. PTX has a pKa of 10.36, therefore pH 6 was selected since slightly acidic pH is required to minimize the unwanted negatively charged siloxy groups (SiO−) on the surface by converting them to neutral silanol (SiOH) groups.

With MeOH and, 25 mM AAB (pH 6, 5.5, and 6.5) mixture at 73:27%, 75:25%, and 77:23% v/v ratio with a flow rate of 0.8, 1, and 1.2 mL/min, an increase in the retention time of PTX peak was observed when the MeOH content and flow rate was reduced, which was subjected for rejection due to our desire of short run time. The results are shown in Fig. 2 and Table 2. With a mobile phase mixture of MeOH and 25 mM AAB (pH 6) (75:25% v/v), PTX was eluted at 7.7 min with a total NTPs of 6389 and Tf10% of 1.13. Considering these factors, MeOH with AAB (pH 6) (75:25% v/v) with a 1 mL/min flow rate was selected as the optimized method and further used for validation.

Effect of mobile phase on Rt on PTX. a Flow rate-1 ml per min, pH-6, methanol: Ammonium acetate buffer ratio-75:25, b flow rate-1.2 ml per min, pH-6 methanol: Ammonium acetate buffer ratio-75: 25, c flow rate-0.8 ml per min, pH-6, methanol: ammonium acetate buffer ratio-75: 25, d flow rate-1 ml per min, pH-6.6, methanol: ammonium acetate buffer ratio-75: 25, e flow rate-1 ml per min, pH-5.5, methanol: ammonium acetate buffer-75; 25, f flow rate-1 ml per min, pH-5.5 methanol: ammonium acetate buffer ratio-77:23, g flow rate-1 ml per min, pH-6.5, methanol:ammonium acetate buffer ratio-73:27

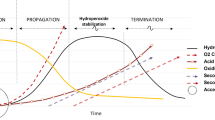

Forced Degradation Studies

To determine the degradant peaks, stressed blank (stress agent without drug), stressed sample (stress agent with drug), and unstressed sample (plain drug) were injected into the HPLC. A study was started with a shorter duration of exposure (in case of acidic, basic, and oxidative stress), but the drug did not exhibit much deterioration; therefore, the duration of the exposure was extended to produce a significant level of degradation. Here, comparatively more degradation 96.765 ± 0.155% was observed under alkaline conditions (0.01 N NaOH, 24 h) due to hydrolysis of the drug. The previous reports have shown stability-indicating nature and degradation products of paclitaxel, i.e., for alkali-induced degradation viz. N-benzoyl-(2R,3S)-phenylisoserine methyl ester of the paclitaxel side chain (Fig. 3B: Peak 1, Mol. wt. 285, C16H15NO4), Baccatin III (Fig. 3B: Peak 2, Mol. wt. 586, C31H38O11) 10-Desacetyl Paclitaxel (Fig. 3B: Peak 3, Mol. wt. 811, C45H49NO13), 7-Epipaclitaxel (Fig. 3B: Peak 4, Mol. wt. 854, C47H51NO14) [27, 28]. Under long-wavelength UV exposure (photolysis 24 h) and moist heat at 80 °C (thermal degradation 24 h), the drug has shown less degradation 25.92 ± 0.139% and 26.53 ± 1.25% respectively. The stability-indicating nature and degradation products of UV and moist heat exposure were also reported previously, i.e., Paclitaxel-C3-C11 bridge isomer (Fig. 3D: Peak 1, Mol wt. 854, C47H51NO14) and 7-Epipaclitaxel (Fig. 3E: Peak 1, Mol wt. 854, C47H51NO14) respectively [27, 28]. However, a very less degradation 4.81 ± 0.144% with oxidative stress conditions 3%H2O2 (24 h), and 2.07 ± 0.33% degradation with acidic stress conditions 0.1 N HCl (24 h), 80 °C (24 h) were noted and no peak of degradation products was observed for these stressed samples (Fig. 3A, and C). The reported degradation products of paclitaxel and their stability-indicating nature are given in Table 3. Our approach has shown better quantification of the PTX in different stress conditions due to the improved peak shape and absence of interference at the Rt of the PTX, as shown in Fig. 3 when compared with the stressed PTX samples with their respective stressed blanks. PTX showed minimum degradation in all stress conditions except with alkali-induced hydrolysis.

Method Validation

The results of the validation study performed according to the ICH guidelines are shown in Table 4.

System Suitability

The RSD of the peak areas and Rt of six replicates of standard PTX solution were found to be 0.00241% (< 2%) and 7.68 min respectively. The average NTPs were 6403 (> 2000) and the average Tf10% was 1.13 (< 2%) for the PTX peak. All the response parameters were well within the acceptance criteria and hence suggested that the system for testing the PTX was suitable for the intended application.

Specificity

Overlay chromatograms of diluent, placebo, PTX (10 µg/mL standard), and cationic liposomes are shown in Fig. 4. There was no interference at the Rt of PTX either by blank (diluent; Fig. 4a), by placebo cationic liposomes (Fig. 4b), or by cationic liposomes loaded with PTX (Fig. 4d). In addition, the PTX peak was well separated from its degradant peaks as observed in the case of force degradation studies. All these results demonstrate that the developed method is specific for estimating PTX content.

Linearity

The developed method was linear between a range of concentrations (2.5–100 µg/mL) and the R2 (coefficient of determination) was found to be 0.9999.

Precision and Accuracy

Percent RSD was < 2% for both inter-day and intra-day precision and mean recovery was between 96 and 101% (Table 4). The method was precise and accurate with LOD and LOQ values of 0.062 and 0.188 µg/mL, respectively.

Robustness

Box–Behnken Design approach was followed to evaluate the robustness of the method. The effect of deliberate variations in factors (i.e., A: Buffer pH, B: Flow rate, C: MeOH: AAB content, and injection volume) on the individual method responses was evaluated by applying a Box–Behnken design (BBD) at three distinct levels, i.e., low (− 1), medium (0) and high (+ 1) levels (Table 1). Retention time (Rt), area under the peak, tailing factor (Tf10%), and theoretical plates (NTP) were the method responses. The significant factors impacting each response were identified using perturbation plots (Fig. 5) and 3-D graphs (Fig. 6). The analysis of variance (ANOVA) test was applied to acquire the p value, R2, and the equations for each response by including only significant terms. The results are shown in Table 5.

Application of the Method

PTX-loaded cationic liposomes were prepared by thin-film hydration technique and quantified for drug content. The chromatograms of placebo and drug-loaded formulation (Fig. 4) indicated that there was no interference of the excipients used in cationic liposomes at the Rt of the drug. PTX-loaded cationic liposomes had an overall particle size of 219.25 ± 7.566 nm and a zeta potential of 57.15 ± 12.374 mV. The polydispersity index was found to be 0.807 ± 0.1958. The %RSD and recovery were found to be < 2% and 99–101%, respectively (Table 6). The percent entrapment of PTX was found to be 59 ± 1.414%. The method was precise and accurate in quantifying PTX from cationic liposomes as indicated by the recovery and %RSD results. Hence, this method can be successfully adopted to estimate PTX content from bulk as well as from cationic liposomes.

Conclusion

The developed analytical method was statistically validated using a BBD approach, and the data were analyzed using DesignExpert® software. The ANOVA test was performed to assess the significant effect of varied chromatographic factors on the individual responses and the data were reported in the form of 3D plots and perturbation plots. The performance data of all the tested parameters were acceptable which demonstrated the compliance of the method as per ICH guidelines. The optimized analytical method showed a broad linearity range with optimum retention time, baseline resolution, and sensitivity. Forced degradation studies revealed the stability of PTX under all stress conditions, except alkaline conditions. Estimation of PTX in its cationic liposomes showed good recovery, indicating the successful adaptability of this method to quantify PTX in bulk as well as in cationic liposomes. The method has been successfully applied for the quantification of the PTX entrapped and percent recovery in cationic liposomes and can be utilized for the estimation of the PTX in any other formulations as well.

References

Sze DM, Miller K, Neilan B (2008) Development of Taxol and other endophyte produced anti-cancer agents. Recent Pat Anticancer Drug Discov 3(1):14–19. https://doi.org/10.2174/157489208783478685

Success Story: Taxol (2021) https://dtp.cancer.gov/timeline/flash/success_stories/s2_taxol.htm. Accessed 01 Nov 2021

Ghadi R, Dand N (2017) BCS class IV drugs: Highly notorious candidates for formulation development”. J Control Release 248:71–95. https://doi.org/10.1016/J.JCONREL.2017.01.014

Weaver BA (2014) How Taxol/paclitaxel kills cancer cells. Mol Biol Cell 25(18):2677. https://doi.org/10.1091/MBC.E14-04-0916

Paclitaxel (Intravenous Route) Side Effects-Mayo Clinic (2021). https://www.mayoclinic.org/drugs-supplements/paclitaxel-intravenous-route/side-effects/drg-20065247. Accessed 01 Nov 2021

Chou P-L, Huang Y-P, Cheng M-H, Rau K-M, Fang Y-P (2020) Improvement of paclitaxel-associated adverse reactions (ADRs) via the use of nano-based drug delivery systems: a systematic review and network meta-analysis. Int J Nanomed 15:1731. https://doi.org/10.2147/IJN.S231407

Aboul-Enein HY, Ali I, Gübitz G, Simons C, Nicholls PJ (2000) HPLC enantiomeric resolution of novel aromatase inhibitors on cellulose- and amylose-based chiral stationary phases under reversed phase mode. Chirality 12(10):727–733

Ali I, Al-Othman ZA, Hussain A, Saleem K, Aboul-Enein HY (2011) Chiral separation of β-adrenergic blockers in human plasma by SPE-HPLC. Chromatographia 73(3–4):251–256. https://doi.org/10.1007/S10337-010-1891-4/TABLES/4

Gómez-Caravaca AM, Verardo V, Berardinelli A, Marconi E, Caboni MF (2014) A chemometric approach to determine the phenolic compounds in different barley samples by two different stationary phases: a comparison between C18 and pentafluorophenyl core shell columns. J Chromatogr A 1355:134–142. https://doi.org/10.1016/J.CHROMA.2014.06.007

Al-Othman ZA, Al-Warthan A, Ali I (2014) Advances in enantiomeric resolution on monolithic chiral stationary phases in liquid chromatography and electrochromatography. J Sep Sci 37(9–10):1033–1057. https://doi.org/10.1002/JSSC.201301326

Ali I, Al-Othman ZA, Al-Warthan A, Asnin L, Chudinov A (2014) Advances in chiral separations of small peptides by capillary electrophoresis and chromatography. J Sep Sci 37(18):2447–2466. https://doi.org/10.1002/JSSC.201400587

Saadat E, Ravar F, Dehghankelishadi P, Dorkoosh FA (2015) Development and validation of rapid RP-HPLC-DAD analysis method for simultaneous quantitation of paclitaxel and lapatinib in polymeric micelle formulation. Sci Pharm 84:333–345. https://doi.org/10.3797/SCIPHARM.1507-03

Noorbasha K, Shaik AR (2021) Determination of residual solvents in paclitaxel by headspace gas chromatography. Future J Pharm Sci 7(1):1–17. https://doi.org/10.1186/S43094-021-00186-7

Bernabeu E et al (2014) Development and validation of a highly sensitive HPLC method for determination of paclitaxel in pharmaceutical dosage forms and biological samples. Curr Pharm Anal 10(3):185–192. https://doi.org/10.2174/1573412910666140409002944

Furman C, Carpentier R, Barczyk A, Chavatte P, Betbeder D, Lipka E (2017) Development and validation of a reversed-phase HPLC method for the quantification of paclitaxel in different PLGA nanocarriers. Electrophoresis 38(19):2536–2541. https://doi.org/10.1002/ELPS.201600552

Xia XJ, Peng J, Zhang PX, Jin DJ, Liu YL (2013) Validated HPLC method for the determination of paclitaxel-related substances in an intravenous emulsion loaded with a paclitaxel-cholesterol complex. Indian J Pharm Sci 75(6):672

Posocco B et al (2018) A new high-performance liquid chromatography-tandem mass spectrometry method for the determination of paclitaxel and 6α-hydroxy-paclitaxel in human plasma: Development, validation and application in a clinical pharmacokinetic study. PLoS ONE 13(2):e0193500. https://doi.org/10.1371/JOURNAL.PONE.0193500

Lian H, Sun J, Zhang T (2013) A rapid and sensitive determination of paclitaxel in rat plasma by UPLC-MS/MS method: application to a pharmacokinetic study. Asian J Pharm Sci 8(3):199–205. https://doi.org/10.1016/J.AJPS.2013.07.026

Sathyamoorthy N, Rajendran V, Vsh N, Dasaratha Dhanaraju M (2014) An approach for validated RP-HPLC method for the analysis of paclitaxel in rat plasma. J Appl Pharm Sci 4(09):73–076. https://doi.org/10.7324/JAPS.2014.40913

Hubert C, Houari S, Rozet E, Lebrun P, Hubert P (2015) Towards a full integration of optimization and validation phases: an analytical-quality-by-design approach. J Chromatogr A 1395:88–98. https://doi.org/10.1016/J.CHROMA.2015.03.059

Mutalik SP, Mullick P, Pandey A, Kulkarni SS, Mutalik S (2021) Box–Behnken design aided optimization and validation of developed reverse phase HPLC analytical method for simultaneous quantification of dolutegravir sodium and lamivudine co-loaded in nano-liposomes. J Sep Sci 44(15):2917–2931. https://doi.org/10.1002/JSSC.202100152

Hegde AR, Managuli RS, Naha A, Koteshwara KB, Reddy MS, Mutalik S (2017) Full Factorial experimental design for development and validation of a RP-HPLC method for estimation of letrozole in nanoformulations. Curr Pharm Anal 14(3):320–330. https://doi.org/10.2174/1573412913666171006152604

Mangla B et al (2020) Systematic development and validation of RP-HPLC method for simultaneous estimation of tamoxifen and sulphoraphane with specific application for nanolipidic formulations. Arab J Chem 13(11):7909–7920. https://doi.org/10.1016/J.ARABJC.2020.09.022

Sandhu PS, Beg S, Katare OP, Singh B (2016) QbD-driven development and validation of a HPLC method for estimation of tamoxifen citrate with improved performance. J Chromatogr Sci 54(8):1373–1384. https://doi.org/10.1093/CHROMSCI/BMW090

Managuli RS et al (2016) Development and validation of a stability-indicating RP-HPLC method by a statistical optimization process for the quantification of asenapine maleate in lipidic nanoformulations. J Chromatogr Sci 54(8):1290–1300. https://doi.org/10.1093/CHROMSCI/BMW062

Bangham AD (1968) Membrane models with phospholipids. Prog Biophys Mol Biol. https://doi.org/10.1016/0079-6107(68)90019-9

Volk KJ, Hill SE, Kerns EH, Lee MS (1997) Profiling degradants of paclitaxel using liquid chromatography-mass spectrometry and liquid chromatography-tandem mass spectrometry substructural techniques. J Chromatogr B 696(1):99–115. https://doi.org/10.1016/S0378-4347(97)00208-9

Zhang CY, Li J, Gao JM, Zhang QM (2016) The impurity profiling of paclitaxel and its injection by UPLC-MS/MS. Yao Xue Xue Bao 56(6):965–971

Acknowledgements

The authors are thankful to the All India Council for Technical Education (AICTE), Government of India, New Delhi for awarding the National Doctoral Fellowship to Mr. Gautam Kumar and a research grant under the scheme RPS-NDF (Ref. No.: File No. 8-34/RIFD/RPS-NDF/Policy-1/2018-19). We are also grateful to Neon laboratories, Mumbai, India, and Lipoid Germany for providing a gift sample of Paclitaxel and Lipoid S-100 respectively, and Manipal Academy of Higher Education, Manipal, Karnataka, India for providing all other facilities for carrying out this research work.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal. This study was funded by the All India Council for Technical Education (AICTE), Government of India, New Delhi (Grant Ref. No.: File No. 8-34/RIFD/RPS-NDF/Policy-1/2018-19).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Authors declare no conflict of interest.

Ethical approval

NA.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kumar, G., Mullick, P., Nandakumar, K. et al. Box–Behnken Design-Based Development and Validation of a Reverse-Phase HPLC Analytical Method for the Estimation of Paclitaxel in Cationic Liposomes. Chromatographia 85, 629–642 (2022). https://doi.org/10.1007/s10337-022-04172-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-022-04172-w