Abstract

Camalexin is the key phytoalexin in Arabidopsis thaliana and crops such as Camelina sativa. It is typically quantified by liquid chromatographic methods using camalexin dilutions as external standards. Alternatively, 6-fluoroindole-3-carboxaldehyde (6-FICA) is used as an internal standard with the advantage that identical conditions can be used for the analyte and standard, but two detectors are needed (ideally fluorescence for camalexin; UV for 6-FICA). We established an easy method to use readily available, cheap thiabendazole as a novel internal standard, facilitating the use of a fluorescence detector for standard and analyte for fast, reliable camalexin quantification in samples of diverse biological origin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Phytoalexins are ubiquitous, specialized plant metabolites of low molecular weight, derived from various metabolic pathways and accumulate in response to pathogen infections, having defensive antioxidative and antimicrobial activities against various pathogens (e.g., Ahuja et al. 2012; Großkinsky et al. 2012b; Jeandet 2018). The indole derivative camalexin [IUPAC: 2-(1 H-indol-3-yl)-1,3-thiazole] was originally identified as a phytoalexin in the crop Camelina sativa (Browne et al. 1991) and is now well-established as the key phytoalexin in Arabidopsis thaliana (Glawischnig 2007; Tsuji et al. 1992). Camalexin has been studied as an important part of inducible defence in response to infections with pathogens, such as Pseudomonas syringae, Alternaria alternata, Botrytis cinerea, or Hyaloperonospora parasitica (e.g., Kliebenstein et al. 2005; Mert-Türk et al. 2003; Nguyen et al. 2022a; Schuhegger et al. 2007; Tsuji et al. 1992) and of induced systemic resistance mediated by beneficial microbes (Li et al. 2024; Nguyen et al. 2022a, b), revealing antimicrobial activities to control pathogen spread (Chassot et al. 2008; Liao et al. 2022; Rogers et al. 1996). Components of the biosynthetic pathway of camalexin and related regulatory elements have been identified in A. thaliana (e.g., Glawischnig 2007; Li et al. 2022; Rawat et al. 2023; Schuhegger et al. 2006; Zook 1998). Furthermore, camalexin has been studied in relation to phytoalexin detoxification mechanisms in certain pathogens (Pedras and Khan 2000; Stefanato et al. 2009). In addition to their functions in specific plant–pathogen interactions, the potential use of phytoalexins including camalexin for increasing plant resistance to pathogens is being studied, e.g., by optimizing their activities or introducing phytoalexins into other plant species to expand their pathogen resistance (Ahmed and Kovinich 2021; Großkinsky et al. 2012b). Interestingly, the cytotoxicity of camalexin is not limited to only microbial cells; it can also restrict cancer cell proliferation (Sierosławska and Rymuszka 2023; Smith et al. 2013) and may thus have medical applications (Ahmed and Kovinich 2021). Therefore, the biological functions of camalexin, its regulation and biosynthesis are important research areas, which require reliable procedures for extracting and quantifying camalexin in numerous samples needed to compare treatments and/or different genotypes. However, no common method for determining camalexin has been used (Beets and Dubery 2011), and methods are often based on external standardization (Bréard et al. 2022; Kopriva et al. 2023). Hence, methods for the robust extraction and reliable determination of camalexin are desirable.

Analytical methods can benefit from the use of internal standards in comparison to sole external quantification (McNally et al. 2015) because both analyte and standard are processed identically during extraction and analyzed using the same chromatographic conditions (e.g., matrix effects). Nevertheless, only a few methods have used external standards for camalexin determination because of the challenge of finding an appropriate internal standard. Indolepropionic acid [IUPAC: 3-(1 H-indol-3-yl)propanoic acid] has been used for GC-MS analyses (Mishina and Zeier 2006) and 6-fluoroindole-3-carboxyaldehyde (6-FICA; IUPAC: 6-fluoro-1 H-indole-3-carbaldehyde) for HPLC analysis (Großkinsky et al. 2014; Kottb et al. 2015; Loeffler et al. 2005; Raacke et al. 2006; Saga et al. 2012), which are primarily deployed for camalexin determination (Beets and Dubery 2011). Although 6-FICA appears to be a suitable internal standard, it requires a UV detector, whereas camalexin is ideally detected via fluorescence.

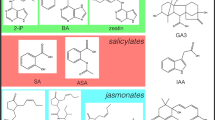

Considering known procedures, we aimed to facilitate camalexin determination via HPLC by implementing a novel internal standard with similar structural properties (Fig. 1), namely, thiabendazole [TBZ; IUPAC: 4-(1 H-1,3-benzodiazol-2-yl)-1,3-thiazole], allowing the use of a fluorescence detector for both internal standard and analyte. Furthermore, TBZ is readily available and relatively cheap compared to authentic camalexin used for external standardization and to 6-FICA for internal standardization. The TBZ-based method was developed for one HPLC system using plants of A. thaliana inoculated with a bacterial pathogen. To verify the method, we used an independent HPLC system to analyze C. sativa treated with silver nitrate. Here we present an easy and robust extraction method for camalexin and subsequent HPLC determination using TBZ as a novel internal standard.

Chemical structure of camalexin, the novel internal standard thiabendazole (TBZ) and previously used standard 6-fluoroindole-3-carboxyaldehyde (6-FICA). Chemical structures were drawn with the MolView application (https://molview.org/)

Materials and methods

Plant materials and treatments

Arabidopsis thaliana ecotype Col-0 was grown in growth chambers at 18 °C to 22 °C, 8 h day/16 h night for 6 to 8 weeks (Großkinsky et al. 2012a). Then, fully expanded leaves were inoculated with 106 cfu/ml Pseudomonas syringae pv. tomato DC3000 (PtoDC3000) by injection with a needleless syringe to induce camalexin production and incubated in the growth chamber. Leaves of a minimum of 10 replicate plants were harvested at 0 h post inoculation (0 hpi; non-inoculated control) and at 24 and 48 hpi, snap-frozen in liquid nitrogen and stored at − 80 °C until used for extractions.

Camelina sativa cv. Celine was grown in a greenhouse at 20 °C to 25 °C, 12 h day/12 h night for 4 weeks, then sprayed with 5 mM AgNO3 with 0.05% v/v Tween 20 as described for inducing camalexin biosynthesis in A. thaliana (Böttcher et al. 2009). Plants were incubated for 2 days more in the greenhouse. Leaves were sampled from untreated plants and 24 h and 48 h after AgNO3 treatment, snap-frozen in liquid nitrogen and stored at − 80 °C until used for extractions. Each sample consisted of three biological replicates.

Camalexin extraction

Leaf material was ground in liquid nitrogen. After we reviewed published procedures (Beets and Dubery 2011; Großkinsky et al. 2014), we modified the method of Großkinsky et al. 2014 for the extraction protocol. Camalexin was extracted using 80% v/v methanol, then up to 500 mg of ground material was combined with 250 µl 6-FICA (200 µg/ml in 80% methanol; Loeffler et al. 2005) and/or 50 µl TBZ (20 µg/ml in 80% methanol); 80% methanol was added to the sample for a final volume of 1.25 ml. Samples were vortexed, then incubated for 30 min at 4 °C, and centrifuged (30 min, 4 °C, 20,000 × g). If any debris remains in the supernatant after centrifugation, extracts can be passed through regenerated cellulose filters to remove the debris. Supernatants were then used for HPLC analysis. 6-FICA (98% purity) and camalexin (≥ 98% purity, HPLC) were purchased from Sigma-Aldrich and methanol (gradient grade for LC) from Merck.

HPLC analyses

Two independent HPLC systems were tested using the same conditions. The first system tested was an UltiMate 3000 (Dionex, Sunnyvale, CA, USA) including a tempered autosampler unit (8 °C). Camalexin (excitation at 318 nm, emission at 370 nm) and TBZ (excitation at 300 nm, emission at 350 nm) were detected via a fluorescence detector, 6-FICA (absorption at 280 nm) with a UV detector. The standard curve (linear fitting) was generated using 10 µl of standard dilutions of authentic camalexin (0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.5, 1, 2, and 5 µg/ml) and samples containing 0.8 µg/ml TBZ and/or 40 µg/ml 6-FICA as internal standards were loaded onto a Dionex Acclaim 120 C-18 reversed-phase column (5 μm, 4.6 × 250 mm) set to 30 °C, and eluted at a flow rate of 1 ml/min with mobile phase A consisting of methanol–water–acetic acid (50:49.9:0.1) and mobile phase B consisting of methanol–acetic acid (99.9:0.1) for chromatographic separation. The elution consisted of a linear gradient from 0 to 100% of mobile phase B in 15 min, with 100% mobile phase B maintained for 5 min. The column was then equilibrated with 100% mobile phase A for 9 min before each analytical run. Under these conditions, the retention times were 11.07 min for camalexin, 5.34 min for TBZ, and 7.25 min for 6-FICA. Peak areas were quantified using Dionex Chromeleon software (version 6.80). An extended standard curve and exemplary chromatograms of standards and samples are shown in Supplementary Fig. 1.

The robustness of the method was verified using an Agilent 1100 HPLC (Agilent Technologies, Santa Clara, CA, USA) with an Agilent ZORBAX Eclipse Plus C-18 column (5 μm, 4.6 × 150 mm) using the same conditions and chromatographic settings as for the first HPLC. Retention times were 8.49 min for camalexin and 2.99 min for TBZ. The obtained chromatograms and relevant peak areas were analyzed using the Chem Station HPLC software (Agilent Technologies). The standard curve and exemplary chromatograms of standards and samples are shown in Supplementary Fig. 2.

Results

Quantification of camalexin levels

To prove the suitability of TBZ as an internal standard, we first aimed to detect and quantify camalexin induced in response to the infection of A. thaliana with PtoDC3000. In untreated leaves, levels of camalexin in A. thaliana were always below the detection limit. At 24 hpi, approximately 0.1 µg/g FW of camalexin was quantified, indicating that camalexin biosynthesis had been induced. By 48 hpi, camalexin had increased greatly (1.8 µg/g FW, Fig. 2a). No significant differences between the two standards in quantifying camalexin levels were found for any analyzed time, verifying the suitability of TBZ as an internal standard to determine camalexin levels. Furthermore, quantifications with both internal standards were comparable to previously reported camalexin levels (Mishina and Zeier 2006; Simon et al. 2010), indicating that the quantified levels of camalexin were physiologically reasonable.

Mean (± SD) camalexin levels in Arabidopsis thaliana leaves at various hours post inoculation (hpi) with Pseudomonas syringae pv. tomato DC3000 based on two internal standards using (a) 6-FICA and TBZ as internal standard and (b) at 48 hpi using FICA and TBZ together or separately as internal standards. Means are for four independent extractions

To test the potential influence of the varying addition of the internal standards to different extracts, we compared the results of 48-hpi samples supplemented with TBZ or 6-FICA alone or with both standards (four replicates each). No significant differences were detected in relation to the addition of one or both internal standards and with respect to the internal standard used for quantification (Fig. 2b). Thus, the results obtained from quantifications with TBZ as the internal standard for camalexin determination can be considered reasonable and reliable.

Reproducibility of camalexin extraction and recovery rates

The reproducibility of the extraction method using TBZ as an internal standard was tested using 10 leaf samples (250 mg FW each) from A. thaliana at 48 hpi with PtoDC3000 that were extracted in parallel. Camalexin levels in these samples appeared highly reproducible (Supplementary Table 1) with an average of 1.75 µg/g FW camalexin and relative standard error of 1.18%. The stability of the method was further supported by the recovery of authentic camalexin that was added to the samples before extraction. For mimicking physiological camalexin levels at 24 and 48 hpi with PtoDC3000 (Fig. 2a), 9–160 µl of authentic standard (2.8 µg/ml) were added to non-inoculated samples (0 hpi), which corresponded respectively to 0.0252 µg and 0.448 µg camalexin per extract. The average recovery based on four replicates was 85.77% with a relative standard error of 0.01% for the lower concentration and 101.24% with a relative standard error of 0.01% for the higher concentration. Differences between the theoretical and recovered camalexin amounts for the lower concentration may be the result of higher relative losses during extraction and higher variations due to pipetting smaller volumes. Nevertheless, the quantity extracted was reproducible with high recovery rates.

Reproducibility of HPLC measurements

For validating the reproducibility of HPLC measurements, three subsamples from each of three extracts, each from a 250 mg FW sample of leaves from A. thaliana at 48 hpi with PtoDC3000, were analyzed with the HPLC. For the three measurements of the three extracts, an average of 1.82, 1.71, and 1.66 µg/g FW of camalexin was detected with relative standard errors of 0.68%, 0.85%, and 0.51%, respectively. Furthermore, for all samples, the average retention time for TBZ was 5.29 min with a maximum relative standard error of 0.0004% and 10.98 min for camalexin with a maximum relative standard error of 0.0001%, indicating stability of the HPLC run with a high grade of reproducibility.

Sample stability

Since the determination of camalexin should also facilitate the analysis of big sample sets, extracts must be stable during the handling and storage time in the autosampler. Thus, we compared camalexin levels in four extracts (48 hpi PtoDC3000) directly after extraction and after 48 h at 8 °C (autosampler temperature). The average camalexin level at both time points was 1.76 µg/g FW with a relative standard error of around 2%. This result indicates good sample stability facilitating the screening of a high number of samples.

Extraction robustness and response linearity

To determine the linear range in which the extract of fresh leaves of A. thaliana is proportional to the amount of camalexin detected, we extracted camalexin from samples with six different masses from 20 to 500 mg (four replicates per mass) using a consistent extraction volume of 1.25 ml of 80% methanol containing the internal standard. For the whole range of sample masses, a linear correlation was found (R2 = 0.9985; Fig. 3a), which also confirms that 250 mg FW is appropriate for testing other variables. Also when the ratio of the quantified camalexin to the recovered TBZ was plotted against the different sample amounts extracted, a linear relation was obtained over the whole range of sample quantities (R2 = 0.9957; Fig. 3b). Based on these linear correlations, a wide range of sample amounts can reliably be analyzed without adjusting the volume of extraction agent, thus facilitating camalexin quantification within a reasonable detection range.

Response linearity of camalexin and camalexin/TBZ ratio for extracts from 20–500 mg of Arabidopsis thaliana leaves at 48 h post inoculation with Pseudomonas syringae pv. tomato DC3000 with an extraction volume of 1.25 ml and quantified using HPLC. (a), Linear range of camalexin quantification. (b), Camalexin/TBZ ratio vs. sample mass

Verification of TBZ-based camalexin quantification of leaves of C. sativa using the second HPLC system

The usability and robustness of the new method to quantify camalexin using TBZ as a novel internal standard was then verified using a second HPLC system and leaves of C. sativa 24 and 48 h after treatment with AgNO3 or untreated (0 h) and mock-treated (24 h and 48 h). None of the controls contained camalexin, and camalexin levels were higher at 24 h and even higher at 48 h after the treatment (Fig. 4). The test of the reproducibility of the extraction and the run stability of the second HPLC device using 10 leaf samples of C. sativa at 48 h post AgNO3 treatment that were extracted in parallel showed that camalexin quantification was also highly reproducible (mean 2.70 µg/g FW with a relative standard error of 1.48%; Supplementary Table 2) and in a reasonable physiological range (Purnamasari et al. 2015; Sigareva and Earle 1999).

Discussion

Our data demonstrated that the new HPLC-based method to quantify camalexin using a highly sensitive and selective fluorescence detector and TBZ as a novel internal standard yielded robust camalexin data within the known physiological range in A. thaliana (Mishina and Zeier 2006; Simon et al. 2010) and C. sativa (Purnamasari et al. 2015; Sigareva and Earle 1999). Since it enables the detection of TBZ and camalexin with the same detector, this method facilitates the direct determination of camalexin, benefitting from the advantages of internal standardization (McNally et al. 2015). After proper correlation with external standards, this new method facilitates compensation for sample variation (matrix effects, extraction efficiency, deviations in processing) and internal control for large sample sets (instead of repeated/additional runs of external standards). Hence, it can complement camalexin quantification based on external standards, while costs and laborious technical steps such as the use of a second detector (as for 6-FICA) or external quantification with an expensive authentic standard can be minimized. In addition, TBZ may also be used as an internal standard for more complex extractions needed for more difficult plant material. Summarized, the developed TBZ-based camalexin quantification method combines a robust extraction procedure, which allows for a wide range of sample amounts, with good HPLC run and extract stabilities. Hence, it represents a reliable method to screen large sample sets for camalexin, which can easily be deployed on different HPLC systems.

References

Ahmed S, Kovinich N (2021) Regulation of phytoalexin biosynthesis for agriculture and human health. Phytochem Rev 20:483–505. https://doi.org/10.1007/s11101-020-09691-8

Ahuja I, Kissen R, Bones AM (2012) Phytoalexins in defense against pathogens. Trends Plant Sci 17:73–90. https://doi.org/10.1016/j.tplants.2011.11.002

Beets C, Dubery I (2011) Quantification of camalexin, a phytoalexin from Arabidopsis thaliana: a comparison of five analytical methods. Anal Biochem 419:260–265. https://doi.org/10.1016/j.ab.2011.08.031

Böttcher C, Westphal L, Schmotz C, Prade E, Scheel D, Glawischnig E (2009) The multifunctional enzyme CYP71B15 (PHYTOALEXIN DEFICIENT3) converts cysteine-indole-3-acetonitrile to camalexin in the indole-3-acetonitrile metabolic network of Arabidopsis thaliana. Plant Cell 21:1830–1845. https://doi.org/10.1105/tpc.109.066670

Bréard D, Barrit T, Sochard D, Aligon S, Planchet E, Teulat B, Le Corff J, Campion C, Guilet D (2022) Development of a quantification method for routine analysis of glucosinolates and camalexin in brassicaceous small-sized samples by simultaneous extraction prior to liquid chromatography determination. J Chrom B 1205:123348. https://doi.org/10.1016/j.jchromb.2022.123348

Browne LM, Conn KL, Ayert WA, Tewari JP (1991) The camalexins: New Phytoalexins produced in the leaves of camelina sativa (cruciferae). Tetrahedron 47:3909–3914. https://doi.org/10.1016/S0040-4020(01)86431-0

Chassot C, Buchala A, Schoonbeek H-J, Métraux J-P, Lamotte O (2008) Wounding of Arabidopsis leaves causes a powerful but transient protection against Botrytis infection. Plant J 55:555–567. https://doi.org/10.1111/j.1365-313X.2008.03540.x

Glawischnig E (2007) Camalexin Phytochemistry 68:401–406. https://doi.org/10.1016/j.phytochem.2006.12.005

Großkinsky DK, Koffler BE, Roitsch T, Maier R, Zechmann B (2012a) Compartment-specific antioxidative defense in Arabidopsis against virulent and avirulent Pseudomonas syringae. Phytopathology 102:662–673. https://doi.org/10.1094/PHYTO-02-12-0022-R

Großkinsky DK, van der Graaff E, Roitsch T (2012b) Phytoalexin transgenics in crop protection – fairy tale with a happy end? Plant Sci 195:54–70. https://doi.org/10.1016/j.plantsci.2012.06.008

Großkinsky DK, Albacete A, Jammer A, Krbez P, van der Graaff E, Pfeifhofer H, Roitsch T (2014) A rapid phytohormone and phytoalexin screening method for physiological phenotyping. Mol Plant 7:1053-1056. https://doi.org/10.1093/mp/ssu015

Jeandet P (2018) Structure, chemical analysis, biosynthesis, metabolism, molecular engineering, and biological functions of phytoalexins. Molecules 23:61. https://doi.org/10.3390/molecules23010061

Kliebenstein DJ, Rowe HC, Denby KJ (2005) Secondary metabolites influence Arabidopsis/Botrytis interactions: variation in host production and pathogen sensitivity. Plant J 44:25–36. https://doi.org/10.1111/j.1365-313X.2005.02508.x

Kopriva A, Schwier M, Volz V, Kopriva S (2023) Shoot–root interaction in control of camalexin exudation in Arabidopsis. J Exp Bot 74:2667–2679. https://doi.org/10.1093/jxb/erad031

Kottb M, Gigolashvili T, Großkinsky DK, Piechulla B (2015) Trichoderma volatiles effecting Arabidopsis: from inhibition to protection against phytopathogenic fungi. Front Microbiol 6:995. https://doi.org/10.3389/fmicb.2015.00995

Li Y, Liu K, Tong G, Xi C, Liu J, Zhao H, Wang Y, Ren D, Han S (2022) MPK3/MPK6-mediated phosphorylation of ERF72 positively regulates resistance to Botrytis Cinerea through directly and indirectly activating the transcription of camalexin biosynthesis enzymes. J Exp Bot 73:413–428. https://doi.org/10.1093/jxb/erab415

Li Z-J, Tang S-Y, Gao H-S, Ren J-Y, Xu P-L, Dong W-P, Zheng Y, Yang W, Yu Y-Y, Guo J-H, Luo Y-M, Niu D-D, Jiang C-H (2024) Plant growth-promoting rhizobacterium Bacillus cereus AR156 induced systemic resistance against multiple pathogens by priming of camalexin synthesis. Plant Cell Environ 47:337–353. https://doi.org/10.1111/pce.14729

Liao A, Li L, Wang T, Lu A, Wang Z, Wang Q (2022) Discovery of phytoalexin camalexin and its derivatives as novel antiviral and antiphytopathogenic-fungus agents. J Agric Food Chem 70:2554–2563. https://doi.org/10.1021/acs.jafc.1c07805

Loeffler C, Berger S, Guy A, Durand T, Bringmann G, Dreyer M, von Rad U, Durner J, Mueller MJ (2005) B1-phytoprostanes trigger plant defense and detoxification responses. Plant Physiol 137:328–340. https://doi.org/10.1104/pp.104.051714

McNally MEP, Usher KM, Hansen SW, Amoo JS, Bernstein AP (2015) Precision of internal standard and external standard methods in high performance liquid chromatography. LCGC Supplements 33:40–46

Mert-Türk F, Bennett MH, Mansfield JW, Holub EB (2003) Camalexin accumulation in Arabidopsis thaliana following abiotic elicitation or inoculation with virulent or avirulent Hyaloperonospora Parasitica. Physiol Mol Plant Pathol 62:137–145. https://doi.org/10.1016/S0885-5765(03)00047-X

Mishina TE, Zeier J (2006) The Arabidopsis flavin-dependent monooxygenase FMO1 is an essential component of biologically induced systemic acquired resistance. Plant Physiol 141:1666–1675. https://doi.org/10.1104/pp.106.081257

Nguyen NH, Trotel-Aziz P, Clément C, Jeandet P, Baillieul F, Aziz A (2022a) Camalexin accumulation as a component of plant immunity during interactions with pathogens and beneficial microbes. Planta 255:116. https://doi.org/10.1007/s00425-022-03907-1

Nguyen NH, Trotel-Aziz P, Villaume S, Rabenoelina F, Clément C, Baillieul F, Aziz A (2022b) Priming of camalexin accumulation in induced systemic resistance by beneficial bacteria against Botrytis cinerea and Pseudomonas syringae pv. tomato DC3000. J Exp Bot 73:3743–3757. https://doi.org/10.1093/jxb/erac070

Pedras MSC, Khan AQ (2000) Biotransformation of the phytoalexin camalexin by the phytopathogen Rhizoctonia Solani. Phytochemistry 53:59–69. https://doi.org/10.1016/S0031-9422(99)00479-3

Purnamasari M, Cawthray GR, Barbetti MJ, Erskine W, Croser JS (2015) Camalexin production in Camelina sativa is independent of cotyledon resistance to Sclerotinia Sclerotiorum. Plant Dis 99:1544–1549. https://doi.org/10.1094/PDIS-12-14-1297-RE

Raacke IC, von Rad U, Mueller MJ, Berger S (2006) Yeast increases resistance in Arabidopsis against Pseudomonas syringae and Botrytis Cinerea by salicylic acid-dependent as well as -independent mechanisms. Mol Plant-Microbe Interact 19:1138–1146. https://doi.org/10.1094/MPMI-19-1138

Rawat AA, Hartmann M, Harzen A, Lugan R, Stolze SC, Forzani C, Abts L, Reißenweber S, Rayapuram N, Nakagami H, Zeier J, Hirt H (2023) OXIDATIVE SIGNAL-INDUCIBLE1 induces immunity by coordinating N-hydroxypipecolic acid, salicylic acid, and camalexin synthesis. New Phytol 237:1285–1301. https://doi.org/10.1111/nph.18592

Rogers EE, Glazebrook J, Ausubel FM (1996) Mode of action of the Arabidopsis thaliana phytoalexin camalexin and its role on Arabidopsis-pathogen interactions. Mol Plant-Microbe Interact 9:748–757. https://doi.org/10.1094/MPMI-9-0748

Saga H, Ogawa T, Kai K, Suzuki H, Ogata Y, Sakurai N, Shibata D, Ohta D (2012) Identification and characterization of ANAC042, a transcription factor family gene involved in the regulation of camalexin biosynthesis in Arabidopsis. Mol Plant-Microbe Interact 25:684–696. https://doi.org/10.1094/MPMI-09-11-0244

Schuhegger R, Nafisi M, Mansourova M, Petersen BL, Olsen CE, Svatos A, Halkier BA, Glawischnig E (2006) CYP71B15 (PAD3) catalyzes the final step in camalexin biosynthesis. Plant Physiol 141:1248–1254. https://doi.org/10.1104/pp.106.082024

Schuhegger R, Rauhut T, Glawischnig E (2007) Regulatory variability of camalexin biosynthesis. J Plant Physiol 164:636–644. https://doi.org/10.1016/j.jplph.2006.04.012

Sierosławska A, Rymuszka A (2023) Combined effects of two phytoalexins, brassinin and camalexin, on the cells of colorectal origin. Toxicon 234:107283. https://doi.org/10.1016/j.toxicon.2023.107283

Sigareva MA, Earle ED (1999) Camalexin induction in intertribal somatic hybrids between Camelina sativa and rapid-cycling Brassica oleracea. Theor Appl Genet 98:164–170. https://doi.org/10.1007/s001220051053

Simon C, Langlois-Meurinne M, Bellvert F, Garmier M, Didierlaurent L, Massoud K, Chaouch S, Marie A, Bodo B, Kauffmann S, Noctor G, Saindrenan P (2010) The differential spatial distribution of secondary metabolites in Arabidopsis leaves reacting hypersensitively to Pseudomonas syringae Pv. Tomato is dependent on the oxidative burst. J Exp Bot 61:3355–3370. https://doi.org/10.1093/jxb/erq157

Smith BA, Neal CL, Chetram M, Vo BH, Mezencev R, Hinton C, Odero-Marah VA (2013) The phytoalexin camalexin mediates cytotoxicity towards aggressive prostate cancer cells via reactive oxygen species. J Nat Med 67:607–618. https://doi.org/10.1007/s11418-012-0722-3

Stefanato FL, Abou-Mansour E, Buchala A, Kretschmer M, Mosbach A, Hahn M, Bochet CG, Métraux J-P, Schoonbeek H-J (2009) The ABC transporter BcatrB from Botrytis Cinerea exports camalexin and is a virulence factor on Arabidopsis thaliana. Plant J 58:499–510. https://doi.org/10.1111/j.1365-313X.2009.03794.x

Tsuji J, Jackson EP, Gage DA, Hammerschmidt R, Somerville SC (1992) Phytoalexin accumulation in Arabidopsis thaliana during the hypersensitive reaction to Pseudomonas syringae Pv. Syringae. Plant Physiol 98:1304–1309. https://doi.org/10.1104/pp.98.4.1304

Zook M (1998) Biosynthesis of camalexin from tryptophan pathway intermediates in cell-suspension cultures of Arabidopsis. Plant Physiol 118:1389–1393. https://doi.org/10.1104/pp.118.4.1389

Acknowledgements

We thank Helga Hammer for support with plant cultivation and Klaus Remele and Peter Krbez for technical assistance.

Funding

Open access funding provided by AIT Austrian Institute of Technology GmbH.

Open access funding provided by AIT Austrian Institute of Technology GmbH

Author information

Authors and Affiliations

Contributions

DKG and HP conceived the study. DKG did biological experiments and developed the extraction procedure. SMP, TR, HP did all HPLC work and processed the primary data. DKG analyzed the data and drafted the manuscript with input from all authors. All authors revised the manuscript and approved it for publication.

Corresponding author

Ethics declarations

Human and animal rights

This article does not contain any studies with human participants or animals.

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Großkinsky, D.K., Primisser, S.M., Reichenauer, T. et al. Camalexin quantification using HPLC and the novel internal standard thiabendazole. J Gen Plant Pathol 90, 173–179 (2024). https://doi.org/10.1007/s10327-024-01175-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10327-024-01175-3