Abstract

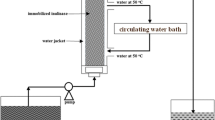

A 23.5-fold purified exoinulinase with a specific activity of 413 IU/mg and covalently immobilized on Duolite A568 has been used for the development of a continuous flow immobilized enzyme reactor for the hydrolysis of inulin. In a packed bed reactor containing 72 IU of exoinulinase from Kluyveromyces marxianus YS-1, inulin solution (5%, pH 5.5) with a flow rate of 4 mL/h was completely hydrolyzed at 55 °C. The reactor was run continuously for 75 days and its experimental half-life was 72 days under the optimized operational conditions. The volumetric productivity and fructose yield of the reactor were 44.5 g reducing sugars/L/h and 53.3 g/L, respectively. The hydrolyzed product was a mixture of fructose (95.8%) and glucose (4.2%) having an average fructose/glucose ratio of 24. An attempt has also been made to substitute pure inulin with raw Asparagus racemosus inulin to determine the operational stability of the developed reactor. The system remained operational only for 11 days, where 85.9% hydrolysis of raw inulin was achieved.

Similar content being viewed by others

References

Bajpai P, Margaritis A (1985) Immobilization of K. marxianus cells containing activity in open pore gelatin matrix: application for high fructose syrup production. Enzyme Microb Technol 7:459–461

Bajpai P, Margaritis A (1987) Characterization of molecular-sieve bound inulinase. J Ferment Technol 65:239–242

Catana R, Eloy M, Rocha JR, Ferreira BS, Cabral JMS, Fernandes P (2007) Stability evaluation of an immobilized enzyme system for inulin hydrolysis. Food Chem 101:260–266

Ettalibi M, Baratti JC (1992) Immobilization of Aspergillus ficuum inulinases on porous glass. Biocatalyst 5:175–182

Gill PK, Manhas RK, Singh P (2006) Hydrolysis of inulin by immobilized thermostable extracellular exoinulinase from Aspergillus fumigatus. J Food Eng 76:369–375

Kaur N, Gupta AK (2002) Applications of inulin and oligofructose in health and nutrition. J Biosci 27:703–713

Kim CH, Rhee SK (1989) Fructose production from Jerusalem artichoke by inulinase immobilized in chitin. Biotechnol Lett 11:201–206

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Nakamura T, Ogata Y, Shitara A, Nakamura A, Ohta K (1995) Continuous production of fructose syrups from inulin by immobilized inulinase from Aspergillus niger mutant 817. J Ferment Bioeng 80:164–169

Parekh S, Margaritis A (1986) Continuous hydrolysis of fructans in Jerusalem artichoke extracts using immobilized nonviable cells of Kluyveromyces marxianus. J Food Sci 51:854–855

Rocha JR, Catana R, Ferreira BS, Cabral JMS, Fenandes P (2006) Design and characterization of an enzyme system for inulin hydrolysis. Food Chem 95:77–82

Singh P, Gill PK (2006) Production of inulinases: recent advances. Food Technol Biotechnol 44:151–162

Singh RS, Dhaliwal R, Puri M (2006) Production of inulinase from Kluyveromyces marxianus YS-1 using root extract of Asparagus racemosus. Process Biochem 41:1703–1707

Singh RS, Dhaliwal R, Puri M (2007) Partial purification and characterization of exoinulinase from Kluyveromyces marxianus YS-1 for preparation of high fructose syrup. J Microbiol Biotechnol 17:733–738

Singh RS, Dhaliwal R, Puri M (2007) Production of high fructose syrup from Asparagus inulin using immobilized exoinulinase from Kluyveromyces marxianus YS-1. J Ind Microbiol Biotechnol 34:649–655

Singh RS, Sooch BS, Puri M (2005) An improved process for inulinase production. Indian Patent Application No. 962/DEL/2005

Wenling W, Huiying WWL, Shiyuan W (1999) Continuous preparation of fructose syrups from Jerusalem artichoke tubers using immobilized intracellular inulinase from Kluyveromyces sp. Y-85. Process Biochem 34:643–646

Acknowledgments

The authors are grateful to the Department of Biotechnology, Punjabi University, Patiala for providing necessary laboratory facilities to undertake this work. The financial assistance received under FIST programme of Department of Science and Technology, Government of India, New Delhi is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, R.S., Dhaliwal, R. & Puri, M. Development of a stable continuous flow immobilized enzyme reactor for the hydrolysis of inulin. J Ind Microbiol Biotechnol 35, 777–782 (2008). https://doi.org/10.1007/s10295-008-0348-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0348-3