Abstract

The chemistry and limnology of the Berkeley Pit lake, located in Butte, Montana, have substantially changed during the past 15 years. These changes are due to: (1) a large-scale Cu recovery project in which deep water was pumped to a Cu precipitation plant and returned to the surface of the lake; and (2) in-pit disposal of lime-treatment sludge. As a consequence, the lake has shifted from a meromictic to a holomictic state, over 99% of the dissolved Fe has precipitated as schwertmannite and other ferric solids, the total acidity of the water column has dropped by roughly 35%, and the pH has risen from about 2.5 to near 4.1. Whereas most of the lake was anoxic prior to 2013, the water column now contains > 6 mg/L dissolved oxygen from the lake surface to the deepest levels sampled (> 150 m). Concentrations of several other solutes, including As, P, Cr, and V, have fallen sharply due to adsorption or co-precipitation with Fe, while other species, such as Al, Mg, and Mn, have increased due to dissolution of solids in the sludge. Although the Cu recovery circuit was discontinued in 2013, in-pit disposal of sludge is expected to continue. The pit water is now close to saturation with basaluminite, and the pH should remain poised in the range of 4.1–4.5 for many years as Al precipitates out of the water column. Pumping and treating of pit water is set to commence in 2019, and will continue for the foreseeable future. Continued in-pit disposal of sludge should translate into long term water-quality improvement and a decrease in annual lime-consumption costs. Although the Berkeley Pit still has a long ways to go before it will meet water quality standards, it is heartening to mine-water specialists that the pit lake may not be a problem that is “too big to fix”.

Zusammenfassung

Im Berkeley Restlochsee im Bergbaurevier von Butte, Montana (USA) erfolgten über die vergangenen 15 Jahre maßgebliche Änderungen in der Chemie und Limnologie. Diese Veränderungen sind zurückzuführen auf: 1) Ein großangelegtes Kupferrückgewinnungsprojekt im Zuge dessen Tiefenwasser in eine Kupferfällungsanlage gepumpt und anschließend oberflächennah zurückgeführt wurde, und 2) Entsorgung von Schlamm aus der kalkbasierten Wasserbehandlung im Restloch. Als Folge dieser beiden Prozesse änderte sich der See von einem meromiktischen zu einem holomiktischen Gewässer, über 99% des gelösten Eisens wurde als Schwertmannit und anderen Eisenmineralen ausgefällt, die Gesamtazidität des Sees verringerte sich um rund 35% und der pH-Wert stieg von rund 2,5 auf Werte um 4,1. Während vor 2013 ein Großteil des Sees anoxisch war, enthält die Wassersäule mittlerweile über 6 mg/L gelösten Sauerstoff von der Oberfläche bis zum tiefsten gemessenen Punkt (> 150 m). Die Konzentrationen weiterer gelöster Stoffe wie As, P, Cr und V sind durch Co-Präzipitation mit Eisen stark abgesunken, wohingegen andere Spezies wie Al, Mg and Mn infolge der Auflösung von Mineralen aus dem ins Seewasser gemischten Schlamms angestiegen sind. Das Wasser im Restlochsee ist mittlerweile nahe dem Sättigungslevel mit Basaluminit und es wird erwartet, dass der pH-Wert im Bereich 4,1 bis 4,5 verbleibt, während Aluminium ausfällt. Abpumpen und Aufbereitung von Wasser aus dem Restlochsee soll in 2019 beginnen und für die absehbare Zukunft andauern. Die Fortsetzung der Schlammentsorgung im Restlochsee sollte eine langfristige Verbesserung der Wasserqualität bewirken und die jährlichen Verbrauchskosten für Kalk verringern. Obgleich der Berkeley Restlochsee noch weit davon entfernt ist, typische Wasserqualitätsstandards einzuhalten, sollte die grundsätzliche Botschaft, dass die Bemühungen trotz des Ausmaßes der Bergbaufolgen nicht zum Scheitern verurteilt sind, für mit dem Thema Grubenwasser befasste Experten ermutigend sein.

铜回收和污泥处置对柏克莱矿坑湖酸性水质的改善

在过去的15年里,美国蒙大拿州Butte采矿中心伯克利矿坑湖(Berkeley Pit lake)的化学和湖沼学特性已经发生明显变化。这是由于:1) 大型铜回收项目将深层湖水泵到铜沉淀处理厂后,再循环返回到湖水表层;2)湖内石灰法污泥处理。这两个过程已经使矿坑湖水从半对流状态演化为全对流状态,99%的溶解态铁已沉淀为施氏矿和其它固态铁(三价),水柱总酸度下降约35%,pH值从2.5升至约4.1。相对于2013年之前大部分湖泊处于缺氧状态,目前湖水表层到最深点(> 150米)取样水柱的溶解氧 > 6 mg/L。As、P、Cr和V等溶质已经因吸附或与Fe共沉淀而浓度急剧降低;Al、Mg和Mn则由于汇入污泥的固体成分溶解而浓度增加。虽然铜回收水循环已在2013年停止,但是矿坑湖内污泥处理仍有望持续进行。目前,矿坑湖水已经接近羟铝矾(basaluminite)饱和状态;随着铝沉淀析出,未来多年湖水pH值将稳定于4.1到4.5之间。2019年将再次抽取并处理矿坑湖水,直到实现预期目标。湖内污泥处理也应升级为长期的用以改善水质和降低年石灰消耗成本的技术措施。尽管伯克利矿坑水达到水质标准之路仍很漫长,对于矿井水文专家来说,不再视矿坑湖“太大而无法修复”的态度也令人鼓舞。

Resumen

En los últimos 15 años se han producido cambios sustanciales en la química y la limnología del lago de hoyo de mina Berkeley en el centro minero de Butte, Montana, EE. UU. Estos cambios se deben a: 1) un proyecto de recuperación de cobre a gran escala en el que se bombeó agua profunda a una planta de precipitación de cobre y luego se devolvió a la superficie del lago; 2) disposición de un tratamiento con cal de los lodos directamente en el hoyo. Como consecuencia de estos dos procesos el lago ha cambiado de un estado meromíctico a holomíctico; más del 99% del Fe disuelto ha precipitado como schwertmannita y otros sólidos férricos; la acidez total de la columna de agua ha caído aproximadamente un 35%, y el pH ha aumentado de aproximadamente 2,5 hasta valores cercanos a 4,1. Mientras que la mayor parte del lago era anóxico antes de 2013, la columna de agua ahora contiene más de 6 mg/L de oxígeno disuelto desde la superficie hasta los niveles más profundos muestreados (> 150 m). Las concentraciones de varios otros solutos, incluidos As, P, Cr y V, han disminuido bruscamente debido a la adsorción o coprecipitación con hierro, mientras que otras especies, como Al, Mg y Mn, han aumentado su concentración debido a la disolución de los sólidos del lodo mientras se mezclan en el lago. Aunque el circuito de recuperación de cobre se suspendió en 2013, se espera que la eliminación de lodos en el pozo continúe en el futuro previsible. El agua del pozo ahora está cerca de la saturación con basaluminita y el pH debería permanecer en el rango de 4,1 a 4,5 durante muchos años a medida que el aluminio precipita fuera de la columna de agua. El bombeo y el tratamiento del agua de pozo comenzarán en 2019 y continuarán en el futuro previsible. La eliminación continua de lodos en el pozo debería traducirse en una mejora a largo plazo de la calidad del agua y una disminución en los costos anuales de consumo de cal. Aunque el lago Berkeley todavía tiene un largo camino por recorrer antes de que pueda cumplir con los estándares de calidad del agua, puede ser alentador para los especialistas en minas considerar que el lago no es un problema “demasiado grande para solucionarlo”.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the field of mine-lake research, the Berkeley Pit lake in Butte, Montana, USA, is iconic, both from the point of view of its size (> 185 billion L) and the severity of its chemistry. Reviews of mining lakes worldwide (e.g. Blanchette and Lund 2016; Castendyk and Eary 2009; Castro and Moore 2000; Davis and Eary 1997; Gammons et al. 2009a, b; Geller et al. 2013; Miller et al. 1996; Soni et al. 2014) often consider the Berkeley Pit to be an end-member of poor water quality. The lake’s metal toxicity poses a threat to wildlife (two mass fatalities of migratory waterfowl have occurred on the lake, most recently in Dec., 2016, see Robbins 2016), and the lake’s location within the city limits of Butte adds to its high profile in the media. Pumping and lime treatment of the Berkeley Pit has commenced (May, 2019) and is projected to continue for the foreseeable future. At the time of this writing, no beneficial “end use” is foreseen for the pit, other than as a sump to collect acidic and metal-rich groundwater associated with the historic mining complex of Butte.

When first described (Davis and Ashenberg 1989; Sonderegger et al. 1987), the Berkeley Pit had a pH of 2.7–3.1 and thousands of mg/L of total dissolved metals, including Fe, Al, Zn, Mn, Cu, Cd, and As. In a more recent paper, Gammons and Duaime (2006) showed that the chemistry of the pit had changed relatively little since the 1980s. However, beginning in the mid-2000s, a massive-scale precipitation of dissolved Fe out of the water column was noticed (Tucci and Gammons 2015). This event was attributed to a copper recovery circuit which pumped water from the deep lake and returned it to the surface, allowing oxidation of ferrous to ferric iron. During the period 2013–2016, unstable mine walls forced a suspension in monitoring and lake-sampling efforts in the Berkeley Pit. When monitoring resumed in the summer of 2017 with the help of a specially designed remotely controlled (RC) boat, the pH of the lake had risen to > 3.0, and by 2018 to > 4.0 (GWIC 2019; Hill et al. 2018). Meanwhile, sometime before Dec., 2016, the color of the lake changed from deep red-brown to blue-green (Fig. 1a, b).

Photographs of the Berkeley Pit lake: a in May, 2009 (view to south); b in April, 2017 (view to north); c view of return flow from copper precipitation plant (“Cu”) and the sludge disposal flow (“sludge”) from lake level in May, 2009; d same as c, but viewed looking down from the east rim of the pit (August, 2006)

The purpose of this paper is to summarize the various changes in the chemistry of the Berkeley Pit that have taken place since the review of Gammons and Duaime (2006), and to present possible explanations for these changes. Readers are referred to the MWEN special issue on Butte, in which Gammons and Duaime (2006) appeared, for more background on the geology, mining history, and history of flooding of the Berkeley Pit and surrounding underground mine workings. Additional information can be found in other journal articles (Gammons et al. 2003, 2009a, b; Pellicori et al. 2005; Stierle and Stierle 2013), and publications of the Montana Bureau of Mines and Geology (MBMG) (e.g. Duaime et al. 1998, 2016, 2018, 2019). A chronology with detailed notes on field and analytical methods used by the MBMG for Berkeley Pit sampling between 1982 and 2017 is given in Duaime and McGrath (2019). All field and analytical data for samples of Berkeley Pit water collected since monitoring began in the 1990s are available on the internet (GWIC 2019).

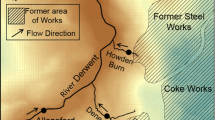

Mine Flooding and Pit Management 2003–2018

Table 1 presents a time-line summarizing significant events in the history of the Berkeley Pit. Extensive underground mining of high-grade, polymetallic (Cu–Zn–Ag–Pb–Mn) veins in the Butte District began in the 1870s and continued through the early 1970s. Open-pit mining of the Berkeley Pit took place between 1955 and 1982, after which the dewatering pumps were shut off and the main mining complex of Butte began to flood. Mining of a nearby deposit to the east named the Continental Pit began in 1980 and continues to this day. At the time of this writing, there appears to be little or no hydraulic connection between the flooded Berkeley Pit and the active Continental Pit (McGivern 2014).

Since the Berkeley Pit is part of the largest superfund site in the nation, the U.S. Environmental Protection Agency (EPA) and Montana Department of Environmental Quality (DEQ) require semi-annual sampling and profiling of the Berkeley Pit. Until 2013, this work was performed manually with a field crew using a boat to collect samples and data. Several landslides in late 2012 and early 2013 raised concerns for the safety of personnel on a boat during a landslide event. Due to these concerns, manual profiling and sampling of the Berkeley Pit ceased in 2013. In 2015, Montana Resources, Inc. funded Montana Tech to develop a remotely controlled (RC) boat to profile and sample the Berkeley Pit from 1 m to 200 m in depth (Fig. 2; Hill et al. 2018). The RC boat successfully collected profile data and samples in July 2017 and thereafter on a semi-annual schedule.

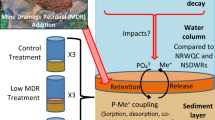

The Berkeley Pit is a terminal lake that is the lowest point in the water table for the entire Butte Summit Valley, with the exception of the bottom of the active Continental Pit (Duaime et al. 2019). The Berkeley Pit continues to fill from a combination of groundwater inputs and precipitation/runoff. In the past, the lake received additional diverted water from the mine complex. The most significant of these in terms of volume is the so-called “Horseshoe Bend springs” (HSB), a collection of acidic springs and seeps draining the active tailings impoundment and heap leach pads to the north and east of the Berkeley Pit (Fig. 3). During the period 2000–2003, the HSB flow was diverted (untreated) to the Berkeley Pit. Beginning in 2003 to the present day, the HSB flow has been treated with lime and reused by the active mine (Duaime et al. 2016). High-density sludge from the lime-treatment plant is discharged directly to the surface of the Berkeley Pit at a rate of ≈ 0.8–0.9 million L/day. This flow represents less than 8% of the total influx of water to the pit, but nonetheless has had a large impact on the lake chemistry, as discussed below. The lime-treatment plant discharges a combination of “Stage 1 sludge” and “Stage 2 sludge”. Information on the chemistry and mineralogy of representative sludge samples is provided as a Supplemental Information file.

Another process that has profoundly influenced the chemistry and limnology of the Berkeley Pit is Cu recovery (Duaime and McGrath 2019; Tucci and Gammons 2015). Between 1998 and 2000, and again from 2003 to 2013, the active mining company pumped tremendous volumes (averaging 50 million L/day) of deep-pit water to a Cu-precipitation plant where the acidic water interacted with scrap Fe to form elemental Cu. The reaction, sometimes referred to as cementation, is written:

Aside from the changes to the dissolved Cu and Fe concentrations, Reaction (1) had no discernable effect on the concentrations of other solutes, nor on the pH of the water (Gammons and Duaime 2006). The Cu-depleted and Fe(II)-enriched water was returned via a ditch to the rim of the Berkeley Pit where it cascaded down the pit wall to mix into the surface of the lake (Figs. 1c, d, 3). Pumping water from the deep lake, passing it through the Cu recovery plant, and returning it to the surface of the lake caused a steady decline in the elevation of the chemocline between the lower TDS mixolimnion from the higher TDS monimolimnion (Fig. 4). By the end of 2009, the chemocline was drawn down to the bottom of the pit and the lake ceased to be meromictic. In Feb., 2013, the Cu recovery circuit was discontinued due to damage to the pumps from one of the large landslides. In 10 years of operation between 2003 and 2013, the project circulated ≈ 1.5 pit volumes through the precipitation plant and recovered over 15 million kg of copper.

Changes to Chemistry

Figures 5 and 6 summarize changes in selected chemical attributes of the Berkeley Pit with time and depth, respectively. Prior to the suspension of conventional sampling in Nov., 2012, the pH of the pit water varied between 2.4 and 3.0, and there were no clear trends in pH with time or depth (Fig. 5a). When sampling resumed in 2016, the pH of the surface of the lake had risen to > 3.4 (Duaime et al. 2018), and by Nov., 2018 the pH of the lake was 4.1 ± 0.1 from top to bottom (Figs. 5a, 6a). Remarkably, between 2003 and 2018, the concentration of total dissolved Fe in the deep lake dropped from > 1000 to < 10 mg/L. The drop in ΣFe also decreased the total acidity of the pit lake (Fig. 5c); acidity values were calculated from published chemical analyses of pit-lake water samples (GWIC 2019), as follows:

Part of the scatter in the acidity graph is due to uncertainty in the relative concentrations of Fe(II) and Fe(III) for a given sampling date. For dates when no Fe speciation data were available, the valence of dissolved Fe was assumed to be 80% ferrous for the deep water, and 20% ferrous for the shallow water. These ratios are based on historical trends (Montana Resources Inc., unpublished data). Pellicori et al. (2005) provide a more detailed discussion of dissolved Fe speciation in the Berkeley Pit.

As would be expected, the precipitation of > 99% of the dissolved Fe out of the water column resulted in a decrease in specific conductance (Fig. 6b). Unexpectedly, the pit lake now contains elevated dissolved oxygen (DO) from top to bottom (Fig. 6c). Prior to 2012, concentrations of DO were below the practical quantification limit at all depths below the zone of wave mixing. Since 2017, DO concentrations have been poised at 6.2 ± 0.2 mg/L in the deep lake. It is not known if there is a drawdown in DO concentration during the stratified seasons of mid-summer or mid-winter, as sampling of the Berkeley Pit is typically conducted in late spring or late autumn when the lake is most likely to be vertically mixed.

Chemical Behavior of Individual Solutes

Table 2 provides a recent chemical analysis of the Berkeley Pit water for a sample collected at 67 m depth on 11/20/18. Figures 7 and 8 summarize changes in the concentrations of selected solutes (Fe, Cu, Zn, Al, Mg, Ca, SO4, As, and P) with depth and time in the Berkeley Pit; the following sections give a more detailed discussion of each solute. The discussion incorporates results of geochemical modeling using Visual Minteq, v. 3.0 (Gustafsson 2012), a recent variant of the original MINTEQA2 program developed by the U.S. EPA (Allison et al. 1991). More details on the methods and results of the geochemical modeling can be found in the Supplementary Information file.

Iron

In 2002, the deep Berkeley Pit contained roughly 1000 mg/L of dissolved Fe (Fig. 7a), most of which was Fe(II) (Pellicori et al. 2005). In contrast, samples collected in March 2018 contained < 5 mg/L of total dissolved Fe to a depth of 137 m. Thus, in 15 years, > 99% of the dissolved Fe in the pit lake precipitated out of the water column. Imhoff sediment samplers deployed in 2008 showed that most of the Fe-rich solid was schwertmannite, with lesser amounts of K-jarosite (Tucci and Gammons 2015). The mass of Fe precipitated out of the water column between 2002 and 2018 is estimated at roughly 2 × 108 kg Fe. Roughly 10% of this total came from Fe(II) generated at the precipitation plant by Reaction (1), with the remainder being equivalent to the total load of dissolved Fe in the water column in 2002. In addition, a considerable amount of Fe in the form of ferric hydroxide was added to the lake by disposal of lime-treatment sludge. Like the precipitates that formed in situ, any ferric solids in the sludge would have settled to the bottom of the lake.

Samples collected in Nov. 2017 and March 2018 were found to contain negligible dissolved Fe(II) at depths to 140 m (unpublished MBMG data), as might be expected from the presence of DO at all depths. Iron in samples collected in Nov 2018 was primarily Fe(III) at depths of 1 and 17 m, but switched to Fe(II) at 67 and 139 m. More frequent sampling at additional depths is needed to draw firm conclusions on the current redox behavior of the dissolved Fe.

Copper and Zinc

Concentrations of dissolved Zn have been remarkably constant (≈ 600 mg/L) over time since 2002 (Fig. 7d). In contrast, 10 years of pumping and Cu recovery between 2003 and 2013 lowered Cu concentrations from ≈ 160 to ≈ 60 mg/L (Fig. 7c), where they have remained to the present day. It is not obvious why Zn and Cu concentrations should be poised at 600 and 60 mg/L, respectively. Based on Visual Minteq modeling, there are no common Zn(II), Cu(II), or Cu(I) solid phases close to saturation in the pit water. Also, sorption reactions cannot be the primary control on dissolved Zn and Cu concentrations, for two reasons. First, until recently, the pH of the pit water has been too low to expect much sorption of Cu2+ or Zn2+. In the future, some sorption of Cu2+ onto schwertmannite could take place as pH values rise above 4.0 (Swedlund and Webster 2001). More importantly, if Cu and Zn were sorption-controlled, then their dissolved concentrations should have decreased as pH of the lake increased from 2.6 to > 4.0, bearing in mind the pH sensitivity of sorption of metal cations onto hydrous metal oxide surfaces (e.g., Dzombak and Morel 1990). It is more likely that the concentrations of Cu and Zn are source-controlled. That is, there is a more or less constant influx of Cu and Zn to the lake from influent groundwater, pit-wall runoff, and dissolution of soluble salts as the lake levels rise, but there is no chemical “sink” for these metals.

Aluminum and Magnesium

Concentrations of dissolved Al and Mg increased significantly between 2006 and 2017 (Figs. 7b, 8a), presumably due to dissolution of solids in lime-treatment sludge which contains > 2 wt % Al and > 3 wt % Mg (see supplementary information file). At ≈ 320 mg/L, the current concentration of dissolved Al is close to equilibrium with basaluminite (Al4(OH)10SO4) (S.I. = − 0.16, based on Visual Minteq modeling), and is supersaturated with respect to alunite (KAl3(SO4)2(OH)6, S.I. = 4.61), and kaolinite (Al2Si2O5(OH)4, S.I. = 2.67). Recent investigations of other AMD systems have shown that basaluminite (a poorly crystalline form of the mineral felsõbányaite) is the solid phase most likely to buffer dissolved Al concentrations and pH in the range of 4 to 5 (Carrero et al. 2017; Sánchez-España et al. 2011). Given that the Berkeley Pit waters are close to saturation with basaluminite now, it is unlikely that Al concentrations will continue to increase. In fact, as pH continues to rise due to sludge disposal, it is more likely that large quantities of basaluminite will precipitate out of the water column. The reaction of interest can be written as follows:

Considering the high concentration of dissolved Al (320 mg/L or 11.9 mmol/L), Reaction (3) is expected to buffer the pH of the lake for many years into the future.

Calcium and Sulfate

Gypsum is a major constituent of sediment in the Berkeley Pit lake (Twidwell et al. 2006), and calculated S.I. values for this mineral have always been close to equilibrium (Davis and Ashenberg 1989; Pellicori et al. 2005; Tucci and Gammons 2015). Samples collected in Nov., 2017 yield gypsum S.I. values of +0.05 ± 0.01 (see Supplemental Information file). Gypsum is also a major component of the lime-treatment sludge. Gypsum precipitation probably accounts for most of the decrease in concentration of dissolved sulfate from ≈ 10,000 mg/L in 2002 to ≈ 7000 mg/L in 2017 (Fig. 8b). Some sulfate also would have precipitated as schwertmannite and jarosite. If all of the dissolved Fe in the pit precipitated as schwertmannite, then a stoichiometric decrease in the SO4 concentration of the water column of 2.8 mmol/L (≈ 270 mg/L SO4) would have occurred. This estimate is less than 10% of the observed decrease in SO4 concentration (≈ 31 mmol/L), which supports the ideas that gypsum is the main sink for dissolved sulfate in the Berkeley Pit.

To maintain equilibrium with gypsum, one might presume from the common ion effect that a proportional increase in Ca2+ concentration would have occurred as SO42− concentrations decreased. However, such an increase has not happened; concentrations of Ca were 440 ± 20 mg/L in 2002 compared to 445 ± 5 mg/L in 2017. The explanation is that much (approximately a third) of the dissolved SO4 in the 2002 pit lake was complexed with dissolved Fe(II) and Fe(III) in the form of FeSO4(aq) and FeSO4+ ion pairs. Thus, despite a 30% decrease in total dissolved SO4 concentration between 2002 and 2017, the concentration of “free” sulfate has remained about the same.

Phosphorus and Arsenic

The dominant forms of dissolved P and As in the Berkeley Pit lake are di-protonated phosphate (H2PO4−) and arsenate (H2AsO4−). Being anions, both of these species adsorb strongly onto schwertmannite and other hydrous ferric oxides that form at low pH (Dixit and Hering 2003; Manning and Goldberg 1996; Tucci and Gammons 2015). The massive precipitation of ferric precipitates between 2002 and 2017 resulted in almost complete removal of phosphate and arsenate from the water column (Fig. 8c, d). Concentrations of dissolved arsenic in March, 2018 were 10 ± 3 µg/L, essentially equivalent to the U.S. drinking water standard of 10 µg/L, and concentrations of dissolved phosphate were below the detection limit of 0.1 mg/L as P. It is possible that phosphate concentrations are also constrained by precipitation of strengite (FePO4∙2H2O), although this cannot be quantitatively evaluated without accurate data on P concentration and Fe(II)/Fe(III) speciation. The pit-lake water also has very low concentrations of nitrate (0.3 mg/L as N, measured in March 2018). Overall, the lake has very low nutrient levels to support growth of algae and other microorganisms.

Other Solutes

Two other trace elements that have experienced a sharp decrease in concentration during this time frame are vanadium and chromium. In Nov., 2007, V and Cr concentrations in the deep pit lake were 241 and 77 µg/L, respectively. By March 2018, V was below detection (< 1 µg/L) and Cr had dropped to ≈ 6 µg/L. At the current Eh and pH conditions of the Berkeley Pit, dissolved V most likely occurs as H2VO4− (Huang et al. 2015), while Cr could be either hexavalent (HCrO4−) or trivalent (Cr3+ or Cr(OH)2+). Similar to As and P, dissolved V and Cr were likely stripped out of the water column by adsorption onto secondary ferric precipitates. A smaller but significant decrease in concentration has occurred for uranium and the rare earth elements (REE). Gammons et al. (2003) reported concentrations of 820 to 880 µg/L U, 1050 to 1170 µg/L Ce and 480 to 500 µg/L Nd for pit-lake samples collected at different depths in July 1999, whereas samples collected in March 2018 contained 680 µg/L U, 707–737 µg/L Ce, and 300-314 µg/L Nd (GWIC 2019). Uranium adsorbs strongly onto hydrous ferric oxide at pH > 4 (Waite et al. 1994), and the lanthanides adsorb onto hydrous Fe or Al oxides at pH > 5 (Ayora et al. 2016; Verplanck et al. 2004). As the pH of the Berkeley Pit continues to rise, it is likely that REE and U will be completely stripped out of the water column by sorption processes. In contrast, concentrations of Cd, Co, and Ni have remained essentially unchanged in the past 20 years, averaging 2.0 ± 0.2, 1.7 ± 0.2, and 1.2 ± 0.2 mg/L, respectively. Dissolved Mn values have increased slightly, from about 240 mg/L in 2002 to about 280 mg/L in 2018 (GWIC 2019). Other solutes, such as Mo, Pb, Se, and W, have insufficient data to discern long-term trends.

Discussion

Combined Impacts of Copper Recovery and Sludge Disposal

In a recent paper, Tucci and Gammons (2015) attributed the massive-scale precipitation of ferric solids observed in the Berkeley Pit to the then-active copper recovery circuit, which moved much larger volumes of water (roughly 50 × 106 L/day) compared to the volume of sludge (roughly 0.8 × 106 L/day). Tucci and Gammons downplayed the importance of sludge disposal, which was an oversight, as discussed below. To be sure, copper recovery did play a key role in the precipitation of ferric solids by mixing deep water with surface water and allowing complete oxidation of dissolved Fe(II) to Fe(III) (e.g., as the FeSO4+ ion pair). After oxidation, most of the ferric iron precipitated as schwertmannite or jarosite, via the following reactions:

Precipitation of jarosite and schwertmannite resulted in a net decrease in total acidity of the water column (9 equivalents on the left side of Reaction 4 vs. 6 on the right; 24 equivalents of acidity on the left side of Reaction 5 vs. 21.5 on the right). Provided these solids do not revert to goethite, this mineral acidity would be stored indefinitely in the sediment at the bottom of the lake (Tucci and Gammons 2015). However, the fact that pH increased between 2013 and 2018 when the Cu recovery circuit was not active indicates that oxidation of Fe(II) and precipitation of ferric solids was not the only reason for the decrease in acidity. Some external source of alkalinity, i.e. the sludge, was needed to drive these reactions to completion and to raise the pH above 4.

The disposal of alkaline lime-treatment sludge from the Horseshoe Bend treatment plant into the Berkeley Pit has been continuous from 2003 to the present day. Although the rate of sludge inflow has been small compared to the total volume of the pit lake (> 1.6 × 1011 L), the effects of its disposal over 15 years have been dramatic. In 2015 alone, the lime-treatment plant consumed ≈ 22,000 tons (2.0 × 107 kg) of CaO, with the waste product being a two-stage, high density sludge. The first stage sludge is discharged at a pH in the range of 7 to 7.5, while the second stage is produced at a pH > 10.5 (Montana Resources, Inc., pers. commun.). Data on the chemical composition of each sludge are included in the Supplemental Information file, along with x-ray diffraction (XRD) data. Based on XRD, the dominant crystalline phase in the sludge is gypsum. The elements Al, Cu, Fe, Mg, Mn, and Zn are believed to be present as poorly crystalline hydroxides, possibly layered double hydroxides (Boclair and Braterman 1999) of the type M(II)(OH)2-xM(III)(OH)3(SO4)x/2 where M(II) is Cu2+, Fe2+, Mg2+, Mn2+, Zn2+, and M(III) is Al3+ or Fe3+. A laboratory titration of the combined Stage 1 and Stage 2 sludge with 0.2 N H2SO4 to a pH endpoint of 2.5 indicated an alkalinity of almost exactly 1 eq/kg, or 1.14 eq/L (the sludge has a measured density of 1.12 g/mL; MBMG, unpublished data). This agrees with mass balance calculations made by combining the known mass of lime added at the treatment plant (e.g. 4.74 × 106 kg in the first quarter of 2015) and the sludge volume discharged (1.63 × 108 L in the same time period).

At the pH endpoint of the lime treatment process (≈ 11), the contribution to total alkalinity from molecules that remain in solution, such as CO32− or OH−, is very small (about 3 meq/L, or 0.3% of the total alkalinity). Most of the alkalinity in the sludge is stored as precipitated metals (Fe, Al, Zn, Mn, Cu, Mg, etc.…) in the form of amorphous hydroxides or other poorly crystalline phases. After disposal into the acidic pit lake, some of the solids in the sludge redissolve, releasing their “mineral alkalinity” back to the waters:

where Me is any of the various metals in the sludge, and x is either 2 or 3. However, not all of the solid hydroxides would have redissolved into the pit lake. For example, at the present pH (≈ 4.1) of the Berkeley Pit, ferric hydroxide will remain insoluble, or will convert to another phase (e.g. jarosite or schwertmannite).

If we assume a constant rate of lime use over 15 years, the Horseshoe Bend plant consumed roughly 3 × 108 kg of lime, which equates to 1.1 × 1010 moles of alkalinity (2 mol of alkalinity per mole of CaO). Assuming a total lake volume of 1.6 × 1011 L and an average total acidity for the pre-2003 water column of 0.1 mol/L (Fig. 5c; see also Tucci and Gammons 2015), there would have been around 1.6 × 1010 mol of total acidity in the pit prior to interaction with the sludge. If all of the alkalinity in the lime wound up being stored as solid particles in sludge, and if these solids completely dissolved after disposal into the pit, then roughly two-thirds of the acidity of the pit lake could have been neutralized in 15 years. However, as stated above, some fraction of the sludge, in particular the ferric hydroxide, would not have reacted. Based on historical trends (Fig. 5c), the total acidity of the Berkeley Pit has actually dropped by roughly 35% to 40% in the period 2003 to 2018.

Because the flux of sludge into the pit has been more or less constant since 2003, the drop in acidity has been more or less linear (Fig. 5c). In contrast, the pH of the lake hardly changed between 2003 and 2013 (Fig. 5a). The constancy in pH is explained by the strong buffering effect of dissolved ferric iron precipitating as schwertmannite and jarosite (Reactions 4, 5; see also Nordstrom and Campbell 2014). Once most of the dissolved ferric iron was titrated out of the water column, the pH of the pit lake rose rapidly to > 4, and the lake shifted from being Fe-controlled to being Al-controlled (Reaction 3). Inconveniently, much of the rise in pH occurred between 2012 and 2017, when monitoring was suspended for safety reasons.

What Lies Ahead?

The long-term remedial plan for the Berkeley Pit is to pump and treat the water to maintain a water elevation (critical water level) below the lowest point in the local groundwater/surface water system to prevent the spread of contamination (EPA 2016). At the current filling rate of 10.8 million L/day, the critical water level will be reached in 2023. In anticipation of this, and to assess various treatment options, pumping and treating of Berkeley Pit water will begin in 2019. Water pumped from the Berkeley Pit will be treated at the lime-treatment plant currently treating Horseshoe Bend (HSB) water and the HSB water will be diverted to the active tailings pond. Because the current chemistry of the Berkeley Pit is different than the HSB chemistry, the sludge discharged to the pit will be different. The character of the sludge, and its potential impact on the future chemistry of Berkeley Pit, will depend on the treatment systems that are currently being assessed.

Although mine-water management of the Berkeley Pit has resulted in significant decreases in acidity, increases in pH, and decreases in dissolved arsenic, it is unlikely that concentrations of other toxic metals (e.g. Cd, Cu, Zn) will drop in the near future. The pH of the lake is presently buffered by precipitation of basaluminite (Reaction 3) or some other hydrous Al phase. It could take 10 years or more to titrate all of the dissolved Al out of the lake at current rates of sludge disposal. Once the Al is removed, pH is expected to rise to the next buffer, which could involve precipitation of Cu or Zn as hydroxide or mixed hydroxy-sulfate-carbonate minerals (e.g. brochantite, hydrozincite). For the foreseeable future, discouraging exposure of wildlife (e.g. migratory waterfowl) to the lake via hazing will remain a priority.

Conclusions

In the past 15 years, the total acidity of the Berkeley Pit has dropped by more than a third, the pH has increased from ≈ 2.5 to > 4.0, and the total dissolved Fe concentrations have plummeted from ≈ 1000 mg/L to < 5 mg/L. These changes were the result of two processes: (1) Cu recovery, which completely mixed the lake and allowed oxidation of Fe(II) to Fe(III); and (2) sludge disposal, which neutralized the “iron acidity” released by precipitation of schwertmannite and other ferric solids. With Fe removed, the pH of the lake quickly rose to values > 4.0 where it is presently buffered by precipitation of hydrous Al phases. Other solutes have experienced decreases in concentrations (e.g. As, P, V, Cr, SO4), increases in concentrations (e.g. Mg, Mn), or negligible change (e.g. Ca, Cd, Co, Ni, Zn). In the past 2 years of monitoring, DO concentrations have been poised near 6 mg/L at all depths. The lake is presently holomictic, with seasonal mixing driven by wind events.

To pit-lake researchers, it may be heartening to consider that the Berkeley Pit is not an entirely hopeless case. The chemistry of the pit has improved in the past 15 years and future changes in treatment processes and water management may result in yet more changes. Although pumping and lime treatment will continue for decades (if not centuries), the slow but steady drop in acidity due to sludge disposal should translate into gradual water-quality improvement and a decrease in annual lime-consumption costs. Whether or not the chemistry of the lake will ever improve to the point where treatment could be safely discontinued is not known at this time.

References

Allison JD, Brown DS, Novo-Gradac KJ (1991) MINTEQA2/PRODEFA2, a geochemical assessment model for environmental systems. US EPA/600/3-91/021

Ayora C, Macías F, Torres E, Lozano A, Carrero S, Nieto JM, Pérez-López R, Fernández-Martinez A, Castillo-Michel H (2016) Recovery of rare earth elements and yttrium from passive-remediation systems of acid mine drainage. Environ Sci Technol 50:8255–8262

Blanchette ML, Lund MA (2016) Pit lakes are a global legacy of mining: an integrated approach to achieving sustainable ecosystems and value for communities. Curr Opin Environ Sust 23:28–34

Boclair JW, Braterman PS (1999) Layered double hydroxide stability. 1. Relative stabilities of layered double hydroxides and their simple counterparts. Chem Mater 11:298–302

Carrero S, Fernandez-Martinez A, Pérez-López R, Nieto JM (2017) Basaluminite structure and its environmental implications. Procedia Earth Planet Sci 17:237–240

Castendyk DN, Eary LE (eds) (2009) Mine pit lakes: characteristics, predictive modeling, and sustainability. Soc for Mining, Metallurgy, and Exploration, Littleton

Castro JM, Moore JN (2000) Pit lakes: their characteristics and the potential for their remediation. Environ Geol 39:1254–1260

Davis A, Ashenberg D (1989) The aqueous geochemistry of the Berkeley Pit, Butte, Montana, USA. Appl Geochem 44:23–36

Davis A, Eary LE (1997) Pit lake water quality in the western United States: an analysis of chemogenetic trends. Min Eng 49:98–102

Dixit S, Hering JG (2003) Comparison of arsenic(V) and arsenic(III) sorption onto iron oxide minerals: implications for arsenic mobility. Environ Sci Technol 37:4182–4189

Duaime TE, McGrath SF (2019) Butte Montana: the Berkeley Pit, changes in water quality and water sampling methods, 1982–2017. Bull 138, Montana Bureau of Mines and Geology

Duaime TE, Metesh JJ, Kerschen MD, Dunstan CB (1998) The flooding of Butte mines and Berkeley Pit. Open-File Rept 376, Montana Bureau of Mines and Geology

Duaime TE, Icopini GA, McGrath SF, Thale PR (2016) Butte underground mines and Berkeley Pit, water-level monitoring and water-quality sampling, 2015 Consent Decree update, Butte, Montana, 1982–2015. Open-File Rept 676, Montana Bureau of Mines and Geology

Duaime TE, McGrath SF, Icopini GA, Thale PR (2018) Butte mine flooding operable unit, water-level monitoring and water-quality sampling 2016 consent decree update, Butte, Montana 1982–2016. Open-File Rept 700, Montana Bureau of Mines and Geology

Duaime TE, McGrath SF, Icopini GA, Thale PR (2019) Butte mine flooding operable unit water-level monitoring and water-quality sampling 2017 consent decree update, Butte, Montana, 1982–2017. Open-File Rept 709, Montana Bureau of Mines and Geology

Dzombak DA, Morel F (1990) Surface complexation modeling: hydrous ferric oxide. Wiley, New York City

EPA (2016) Fourth five-year review report for Silver Bow Creek/Butte area superfund site. 1551629-R8 SDMS, US Environmental Protection Agency. EPA, Washington

Gammons CH, Duaime TE (2006) Long-term changes in the geochemistry and limnology of the Berkeley pit-lake, Butte, Montana. Mine Water Environ 25:76–85

Gammons CH, Wood SA, Jonas JP, Madison JP (2003) Geochemistry of rare earth elements and uranium in the acidic Berkeley Pit lake, Butte, Montana. Chem Geol 198:269–288

Gammons CH, Harris LN, Castro JM, Cott PA, Hanna BW (2009a) Creating lakes from open pit mines: processes and considerations, with emphasis on northern environments. Canadian Technical Report of Fisheries and Aquatic Sciences 2826

Gammons CH, Snyder DM, Poulson SR, Petritz K (2009b) Geochemistry and stable isotopes of the flooded underground mine workings of Butte, Montana. Econ Geol 104:1213–1234

Geller W, Schultze M, Kleinmann R, Wolkersdorfer CE (eds) (2013) Acidic mining lakes: the legacy of coal and metal surface mines. Springer, Berlin

Gustafsson JP (2012) Visual MINTEQ, v. 3.0, KTH, Dept Land Water Resources Eng, Stockholm, Sweden. https://vminteq.lwr.kth.se/

GWIC (2019) Montana Bureau of Mines and Geology, Groundwater Information Center. http://mbmggwic.mtech.edu/

Hill B, Cote P, Leishman W, Alangari A, Erickson M, Holliday T, Ellertson C, Fricks T, Duaime TE, Icopini GA (2018) Unmanned partially autonomous boat for profiling and sampling the Berkeley Pit.In: Proceedings of the 11th International Conference for Remediation Chlorinated Recalcitrant Compounds, Palm Springs, CA

Huang JH, Huang F, Evans L, Glasauer S (2015) Vanadium: global (bio)geochemistry. Chem Geol 417:68–89

Manning BA, Goldberg S (1996) Modeling competitive adsorption of arsenate with phosphate and molybdate on oxide minerals. Soil Sci Soc Am J 60:121–131

McGivern A (2014) Geochemistry and stable isotopes of surface water and groundwater in the Continental Pit in Butte, Montana, USA. Montana Tech Graduate Theses and Non-theses: https://digitalcommons.mtech.edu/grad_rsch/3/

Miller GC, Lyons WB, Davis A (1996) Understanding the water quality of pit lakes. Environ Sci Technol 30:118A–123A

Nordstrom DK, Campbell KM (2014) Modeling low-temperature geochemical processes. In: Drever JI (ed) Surface and Ground Water, Weathering, and Soils, Treatise on Geochemistry. Elsevier, New York, pp 27–68

Pellicori DA, Gammons CH, Poulson SR (2005) Geochemistry and stable isotope composition of the Berkeley pit lake and surrounding mine waters, Butte, Montana. Appl Geochem 20:2116–2137

Robbins J (2016) Hordes of geese die on a toxic lake in Montana. New York Times https://www.nytimes.com/2016/12/12/science/snow-geese-deaths-montana.html Accessed 12 Dec 2016.

Sánchez-España J, Yista I, Diez-Ercilla M (2011) Schwertmannite and hydrobasaluminite: a re-evaluation of their solubility and control on the iron and aluminum concentration in acidic pit lakes. Appl Geochem 26:1752–1774

Sonderegger JL, Duaime TE, Noble RA, Ohguchi T (1987) Butte mine flooding and the Berkeley Pit. Open File 195, Montana Bureau of Mines and Geology

Soni A, Mishra B, Singh S (2014) Pit lakes as an end use of mining: a review. J Mining Environ 5:99–111

Stierle AA, Stierle DB (2013) Bioprospecting in the Berkeley Pit: the use of signal transduction enzyme inhibition assays to isolate bioactive secondary metabolites from the extremophilic fungi of an acid mine waste lake. Stud Natl Prod Chem 39:1–45

Swedlund PJ, Webster JG (2001) Cu and Zn ternary surface complex formation with SO4 on ferrihydrite and schwertmannite. Appl Geochem 16:503–511

Tucci NJ, Gammons CH (2015) Influence of copper recovery on the water quality of the acidic Berkeley Pit lake, Montana, USA. Environ Sci Technol 49:4081–4088

Twidwell L, Gammons CH, Young C, Berg R (2006) Deepwater sediment/pore water characterization of the metal-laden Berkeley pit lake in Butte, Montana. Mine Water Environ 25:86–92

Verplanck PL, Nordstrom DK, Taylor HE, Kimball BA (2004) Rare earth element partitioning between hydrous ferric oxides and acid mine water during iron oxidation. Appl Geochem 19:1339–1354

Waite TD, Davis JA, Payne TE, Waychunas GA, Xu N (1994) Uranium (VI) adsorption to ferrihydrite: application of a surface complexation model. Geochim Cosmochim Acta 58:5465–5478

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gammons, C.H., Icopini, G.A. Improvements to the Water Quality of the Acidic Berkeley Pit Lake due to Copper Recovery and Sludge Disposal. Mine Water Environ 39, 427–439 (2020). https://doi.org/10.1007/s10230-019-00648-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-019-00648-8