Abstract

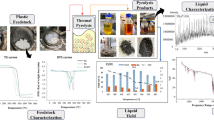

Five of the most prevalent plastics in the Chinese market (polypropylene (PP), polyvinyl chloride (PVC), high-density polyethylene (PE), acrylonitrile–butadiene–styrene (ABS) copolymer, and polystyrene (PS)) were mixed to form waste plastic samples, which were then converted into renewable fuels via stepwise pyrolysis conducted up to a temperature of 500 °C. The pyrolysis behavior and product distribution were elucidated at different temperature intervals. The pyrolysis products tended to be highly variable among different temperature intervals. The carbon chain width of plastic-derived oil (PDO) increased significantly from 450 to 500 °C, and C12 became more dominant than C8 with increasing temperature. The oil derived from the pyrolysis of waste plastic samples containing PVC was dechlorinated at 460 °C. Products with carbon chain lengths from C1 to C3 were widely distributed in the non-condensable gas, and alkylation trends were observed for PP/PVC/PE/ABS/PS blends as the temperature interval increased.

Similar content being viewed by others

References

Gu F, Wang J, Guo J, Fan Y (2020) Dynamic linkages between international oil price, plastic stock index and recycle plastic markets in China. Int Rev Econ Financ 68:167–179

Siddiqui MN, Redhwi HH (2009) Pyrolysis of mixed plastics for the recovery of useful products. Fuel Process Technol 90(4):545–552

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel: a suitable method for plastic waste management and manufacture of value added products—a world prospective. Renew Sustain Energy Rev 14(1):233–248

Melendi-Espina S, Alvarez R, Diez MA, Casal MD (2015) Coal and plastic waste co-pyrolysis by thermal analysis–mass spectrometry. Fuel Process Technol 137:351–358

Zhou N, Dai L, Lv Y, Li H, Deng W, Guo F, Ruan R (2021) Catalytic pyrolysis of plastic wastes in a continuous microwave assisted pyrolysis system for fuel production. Chem Eng J 418:129412

Paraschiv M, Kuncser R, Tazerout M, Prisecaru T (2015) New energy value chain through pyrolysis of hospital plastic waste. Appl Therm Eng 87:424–433

Marcilla A, Gómez-Siurana A, Valdés F (2007) Catalytic pyrolysis of LDPE over H-beta and HZSM-5 zeolites in dynamic conditions: study of the evolution of the process. J Anal Appl Pyrol 79(1–2):433–442

Olazar M, Lopez G, Amutio M, Elordi G, Aguado R, Bilbao J (2009) Influence of FCC catalyst steaming on HDPE pyrolysis product distribution. J Anal Appl Pyrol 85(1–2):359–365

Demetrious A, Crossin E (2019) Life cycle assessment of paper and plastic packaging waste in landfill, incineration, and gasification-pyrolysis. J Mater Cycles Waste Manage 21(4):850–860

Williams PT, Slaney E (2007) Analysis of products from the pyrolysis and liquefaction of single plastics and waste plastic mixtures. Resour Conserv Recycl 51(4):754–769

Das P, Tiwari P (2018) The effect of slow pyrolysis on the conversion of packaging waste plastics (PE and PP) into fuel. Waste Manage 79:615–624

Zhang Y, Fu Z, Wang W, Ji G, Zhao M, Li A (2021) Kinetics, product evolution, and mechanism for the pyrolysis of typical plastic waste. ACS Sustain Chem Eng

Jaafar Y, Abdelouahed L, El Hage R, El Samrani A, Taouk B (2022) Pyrolysis of common plastics and their mixtures to produce valuable petroleum-like products. Polym Degrad Stab 195:109770

Singh G, Varma AK, Almas S, Jana A, Mondal P, Seay J (2019) Pyrolysis kinetic study of waste milk packets using thermogravimetric analysis and product characterization. J Mater Cycles Waste Manage 21(6):1350–1360

Abbas-Abadi MS, Haghighi MN, Yeganeh H, McDonald AG (2014) Evaluation of pyrolysis process parameters on polypropylene degradation products. J Anal Appl Pyrol 109:272–277

Huang WC, Huang MS, Huang CF, Chen CC, Ou KL (2010) Thermochemical conversion of polymer wastes into hydrocarbon fuels over various fluidizing cracking catalysts. Fuel 89(9):2305–2316

Kaminsky W, Zorriqueta IJN (2007) Catalytical and thermal pyrolysis of polyolefins. J Anal Appl Pyrol 79(1–2):368–374

Aisien ET, Otuya IC, Aisien FA (2021) Thermal and catalytic pyrolysis of waste polypropylene plastic using spent FCC catalyst. Environ Technol Innov 22:101455

Čolnik M, Kotnik P, Knez Ž, Škerget M (2021) Hydrothermal decomposition of polyethylene waste to hydrocarbons rich oil. J Supercrit Fluids 169:105136

Fan L, Zhang Y, Liu S, Zhou N, Chen P, Liu Y, Ruan R (2017) Ex-situ catalytic upgrading of vapors from microwave-assisted pyrolysis of low-density polyethylene with MgO. Energy Convers Manage 149:432–441

Miandad R, Barakat MA, Aburiazaiza AS, Rehan M, Ismail IMI, Nizami AS (2017) Effect of plastic waste types on pyrolysis liquid oil. Int Biodeterior Biodegrad 119:239–252

Miandad R, Nizami AS, Rehan M, Barakat MA, Khan MI, Mustafa A, Murphy JD (2016) Influence of temperature and reaction time on the conversion of polystyrene waste to pyrolysis liquid oil. Waste Manage 58:250–259

Sogancioglu M, Ahmetli G, Yel E (2017) A comparative study on waste plastics pyrolysis liquid products quantity and energy recovery potential. Energy Procedia 118:221–226

Çit İ, Sınağ A, Yumak T, Uçar S, Mısırlıoğlu Z, Canel M (2010) Comparative pyrolysis of polyolefins (PP and LDPE) and PET. Polym Bull 64(8):817–834

Akoueson F, Chbib C, Monchy S, Paul-Pont I, Doyen P, Dehaut A, Duflos G (2021) Identification and quantification of plastic additives using pyrolysis-GC/MS: a review. Sci Total Environ 773:145073

Adrados A, De Marco I, Caballero BM, López A, Laresgoiti MF, Torres A (2012) Pyrolysis of plastic packaging waste: a comparison of plastic residuals from material recovery facilities with simulated plastic waste. Waste Manage 32(5):826–832

López A, De Marco I, Caballero BM, Laresgoiti MF, Adrados A (2011) Influence of time and temperature on pyrolysis of plastic wastes in a semi-batch reactor. Chem Eng J 173(1):62–71

Win MM, Asari M, Hayakawa R, Hosoda H, Yano J, Sakai SI (2020) Gas and tar generation behavior during flash pyrolysis of wood pellet and plastic. J Mater Cycles Waste Manage 22(2):547–555

Soliman A, Farag HA, Nassef E, Amer A, ElTaweel Y (2020) Pyrolysis of low-density polyethylene waste plastics using mixtures of catalysts. J Mater Cycles Waste Manage 22(5):1399–1406

Nunome Y, Suzuki T, Nedjalkov I, Ueki Y, Yoshiie R, Naruse I (2019) Generation behavior of tar from ABS, PC, and PE during pyrolysis and steam gasification by mass spectrometry. J Mater Cycles Waste Manage 21(6):1300–1310

Lei J, Yuan G, Weerachanchai P, Lee SW, Li K, Wang JY, Yang Y (2018) Investigation on thermal dechlorination and catalytic pyrolysis in a continuous process for liquid fuel recovery from mixed plastic wastes. J Mater Cycles Waste Manage 20(1):137–146

Bhagat SP, Gera P, Bhavanam A (2018) Catalytic co-pyrolysis of Pterospermum acerifolium and plastic waste. J Mater Cycles Waste Manage 20(4):1923–1933

Premalatha N, Prathiba R, Miranda MA, Miranda LR (2021) Pyrolysis of polypropylene waste using sulfonated carbon catalyst synthesized from sugarcane bagasse. J Mater Cycles Waste Manage 23(3):1002–1014

Das P, Tiwari P (2018) Valorization of packaging plastic waste by slow pyrolysis. Resour Conserv Recycl 128:69–77

Ma ZF, Jiang WJ, Yang S (2019) China Plastics Processing Industry (2018). China Plastics 33(06): 27–131+146.

Sharuddin SDA, Abnisa F, Daud WMAW, Aroua MK (2016) A review on pyrolysis of plastic wastes. Energy Convers Manage 115:308–326

Al-Salem SM, Chandrasekaran SR, Dutta A, Sharma BK (2021) Study of the fuel properties of extracted oils obtained from low and linear low density polyethylene pyrolysis. Fuel 304:121396

Marcilla A, Beltrán MI, Navarro R (2009) Evolution of products during the degradation of polyethylene in a batch reactor. J Anal Appl Pyrol 86(1):14–21

Pan R, Martins MF, Debenest G (2021) Pyrolysis of waste polyethylene in a semi-batch reactor to produce liquid fuel: optimization of operating conditions. Energy Convers Manage 237:114114

Torres D, Jiang Y, Monsalve DS, Leeke GA (2021) Chlorine removal from the pyrolysis of urban polyolefinic waste in a semi-batch reactor. J Environ Chem Eng 9(1):104920

Wu Y, Zhu J, Wang Y, Yang H, Jin L, Hu H (2021) Insight into co-pyrolysis interactions of Pingshuo coal and high-density polyethylene via in-situ Py-TOF-MS and EPR. Fuel 303:121199

Wang Y, Wu K, Liu Q, Zhang H (2021) Low chlorine oil production through fast pyrolysis of mixed plastics combined with hydrothermal dechlorination pretreatment. Process Saf Environ Prot 149:105–114

Wang S, Kim H, Lee D, Lee YR, Won Y, Hwang BW, Lee KH (2021) Drop-in fuel production with plastic waste pyrolysis oil over catalytic separation. Fuel 305:121440

Ribeiro F, Okoffo ED, O’Brien JW, Fraissinet-Tachet S, O’Brien S, Gallen M, Thomas KV (2020) Quantitative analysis of selected plastics in high-commercial-value Australian seafood by pyrolysis gas chromatography mass spectrometry. Environ Sci Technol 54(15):9408–9417

Singh RK, Ruj B (2016) Time and temperature depended fuel gas generation from pyrolysis of real world municipal plastic waste. Fuel 174:164–171

Xue Y, Zhou S, Brown RC, Kelkar A, Bai X (2015) Fast pyrolysis of biomass and waste plastic in a fluidized bed reactor. Fuel 156:40–46

Jamradloedluk J, Lertsatitthanakorn C (2014) Characterization and utilization of char derived from fast pyrolysis of plastic wastes. Proc Eng 69:1437–1442

Singh E, Kumar A, Khapre A, Saikia P, Shukla SK, Kumar S (2020) Efficient removal of arsenic using plastic waste char: Prevailing mechanism and sorption performance. J Water Proc Eng 33:101095

Srinivasan S, Valsadwala AS, Begum SS, Samui AB (2021) Experimental investigation on the influence of novel catalyst in co-pyrolysis of polymeric waste: Characterization of oil and preparation of char reinforced composites. J Clean Prod 316:128225

Fan Y, Fowler GD, Zhao M (2020) The past, present and future of carbon black as a rubber reinforcing filler–A review. J Clean Prod 247:119115

Acknowledgements

This research was funded by the National Natural Science Foundation of China (No. 51875297 and 52173101).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chang, T., Li, C., Fan, F. et al. Effects of temperature zones on pyrolysis products of mixed plastic waste. J Mater Cycles Waste Manag 25, 430–440 (2023). https://doi.org/10.1007/s10163-022-01549-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01549-9