Abstract

The effective disposal of plastic waste has been a key global research issue. In this regard, the pyrolysis of plastic wastes seems to be an effective technique as this process is capable of producing fuel-grade oils. In the present work, the thermal decomposition of polyethylene (PE), polystyrene (PS), and their mixture (PS/PE) was investigated with an aim to enhance yields of liquid fractions with fuel-grade quality. The effect of operating parameters on the end products was studied. The obtained maximum liquid yields for polyethylene (PE) and polystyrene (PS) samples were 96.3 wt.% at 380 °C and 88.1 wt.% at 415 °C, respectively. For the PS/PE (50/50%) sample, the maximum conversion was 93.2 wt.% at 420 °C. Char yield was observed negligible (1–3 wt.%) at low reaction temperatures (350–420 °C). PE samples showcased a sharp initial decrease from 1.8 wt.% at 350 °C to 0.7 wt.% at 415 °C. PS also presented a similar trend; whereas, PS/PE sample was observed with 3.1 wt.% char at 350 °C that decreased to 1.4 wt.% at 420 °C. PE oil samples showed the presence of 1-alkenes and n-alkanes compounds in abundance, with carbon numbers in the range of C7 to C28. PS oil fractions comprised of toluene, ethylbenzene, and styrene in higher proportions of around 42%. On the other hand, PS/PE oil fractions mostly constituted the aliphatic hydrocarbons embracing both alkanes and alkenes with carbon numbers C12 to C22. Comparative assessment reveals that for PE oil fractions from the autoclave reactor are 44.4% and 90.2% higher than the same with fluidized bed and microwave-assisted reactors, whereas for PS oil fractions the values were marginally higher.

Graphical abstract

Similar content being viewed by others

Data availability

All data of the findings and analysis of the present study is included in the article.

Abbreviations

- PE:

-

Low-density polyethylene

- PS:

-

Polystyrene

- TGA:

-

Thermogravimetric analysis

- GC–MS:

-

Gas chromatography and mass spectrometry

- FTIR:

-

Fourier-transform infrared spectroscopy

- NMR:

-

Nuclear magnetic resonance

References

Aguado J, Serrano DP, Miguel GS et al (2007) Feedstock recycling of polyethylene in a two-step thermo-catalytic reaction system. J Anal Appl Pyrol 79:415–423. https://doi.org/10.1016/j.jaap.2006.11.008

Al-Salem SM (2019) Thermal pyrolysis of high density polyethylene (HDPE) in a novel fixed bed reactor system for the production of high value gasoline range hydrocarbons (HC). Process Saf Environ Prot 127:171–179. https://doi.org/10.1016/j.psep.2019.05.008

Bartoli M, Rosi L, Frediani M et al (2015) Depolymerization of polystyrene at reduced pressure through a microwave assisted pyrolysis. J Anal Appl Pyrol 113:281–287. https://doi.org/10.1016/j.jaap.2015.01.026

Brown LJ, Collard F, Görgens J (2019) Fast pyrolysis of fibre waste contaminated with plastic for use as fuel products. J Anal Appl Pyrol 138:261–269. https://doi.org/10.1016/j.jaap.2019.01.007

Budsaereechai S, Hunt AJ, Ngernyen Y (2019) Catalytic pyrolysis of plastic waste for the production of liquid fuels for engines. RSC Adv 9:5844–5857. https://doi.org/10.1039/c8ra10058f

Chen Z, Zhang X, Che L, Peng H, Zhu S, Yang F, Zhang X (2020) Effect of volatile reactions on oil production and composition in thermal and catalytic pyrolysis of polyethylene. Fuel 271:1–8. https://doi.org/10.1016/j.fuel.2020.117308

Colantonio S, Cafiero L, De AD, Ippolito Nicolo M, Tuffi R, Ciprioti SV (2020) Thermal and catalytic pyrolysis of a synthetic mixture representative of packaging plastics residue. Front Chem Sci Eng 14:288–303. https://doi.org/10.1007/s11705-019-1875-3

Faisal F, Rasul MG, Ahmed A, Schaller D, Jahirul MI (2023) Uncovering the differences: a comparison of properties of crude plastic pyrolytic oil and distilled and hydrotreated plastic diesel produced from waste and virgin plastics as automobile fuels. Fuel 350:128743. https://doi.org/10.1016/j.fuel.2023.128743

Fan L, Chen P, Zhang Y, Liu S, Liu Y, Wang Y, Dai L, Ruan R (2017a) Fast microwave-assisted catalytic co-pyrolysis of lignin and low-density polyethylene with HZSM-5 and MgO for improved bio-oil yield and quality. Biores Technol 225:199–205. https://doi.org/10.1016/j.biortech.2016.11.072

Fan L, Zhang Y, Liu S, Zhou N, Chen P, Liu Y, Wang Y, Peng P, Cheng Y, Addy M, Lei H, Ruan R (2017b) Ex-situ catalytic upgrading of vapors from microwave-assisted pyrolysis of low-density polyethylene with MgO. Energy Convers Manag 149:432–441. https://doi.org/10.1016/j.enconman.2017.07.039

Fan S, Zhang Y, Cui L, Maqsood T, Nizetic S (2023) Cleaner production of aviation oil from microwave-assisted pyrolysis of plastic wastes. J Clean Prod 390:136102. https://doi.org/10.1016/j.jclepro.2023.136102

Ghassemi H, Baek SW, Khan QS (2006) Experimental study on evaporation of kerosene droplets at elevated pressures and temperatures. Combust Sci Technol 178:1669–1684. https://doi.org/10.1080/00102200600582392

Hammond PG, Jones C (2008) Inventory of Carbon & Energy (ICE). University of Bath, UK

Handawy MK, Snegirev AY, Stepanov VV, Talalov VA (2021) Energy recovery strategies as a sustainable solutions for municipal solid waste in Egypt. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/1100/1/012052

Heydariaraghi M, Ghorbanian S, Hallajisani A, Salehpour A (2016) Fuel properties of the oils produced from the pyrolysis of commonly-used polymers: effect of fractionating column. J Anal Appl Pyrol 121:307–317. https://doi.org/10.1016/j.jaap.2016.08.010

Imani Moqadam S, Mirdrikvand M, Roozbehani B, Kharaghani A, Shishehsaz MR (2015) Polystyrene pyrolysis using silica-alumina catalyst in fluidized bed reactor. Clean Technol Environ Policy 17:1847–1860. https://doi.org/10.1007/s10098-015-0899-8

Jung S, Cho M, Kang B, Kim J (2010) Pyrolysis of a fraction of waste polypropylene and polyethylene for the recovery of BTX aromatics using a fluidized bed reactor. Fuel Process Technol 91:277–284. https://doi.org/10.1016/j.fuproc.2009.10.009

Kassargy C, Awad S, Burnens G, Kahine K, Tazerout M (2017) Experimental study of catalytic pyrolysis of polyethylene and polypropylene over USY zeolite and separation to gasoline and diesel-like fuels. J Anal Appl Pyrol 127:31–37. https://doi.org/10.1016/j.jaap.2017.09.005

Kassargy C, Awad S, Burnens G, Kahine K, Tazerout M (2018) Gasoline and diesel-like fuel production by continuous catalytic pyrolysis of waste polyethylene and polypropylene mixtures over USY zeolite. Fuel 224:764–773. https://doi.org/10.1016/j.fuel.2018.03.113

Leng L, Huang H (2018) An overview of the effect of pyrolysis process parameters on biochar stability. Biores Technol 270:627–642. https://doi.org/10.1016/j.biortech.2018.09.030

Lerici LC, Renzini MS, Pierella LB (2015) Chemical catalyzed recycling of polymers: catalytic conversion of PE, PP and PS into fuels and chemicals over H-Y. Procedia Mater Sci 8:297–303. https://doi.org/10.1016/j.mspro.2015.04.076

Li C, Sun Y, Li Q, Zhang L, Zhang S, Wang H, Hu G, Hu X (2022a) Effects of volatiles on properties of char during sequential pyrolysis of PET and cellulose. Renew Energy 189:139–151. https://doi.org/10.1016/j.renene.2022.02.091

Li P, Pan H, Wan K, Zhou S, Zhang Z, Hong D, Zhang Y (2022b) Jet fuel-range hydrocarbon production from catalytic pyrolysis of low-density polyethylene by metal-loaded activated carbon. Sustain Energy Fuels 6:2289–2305. https://doi.org/10.1039/d2se00129b

Liu Y, Qian J, Wang J (2000) Pyrolysis of polystyrene waste in a fluidized-bed reactor to obtain styrene monomer and gasoline fraction. Fuel Process Technol 63:45–55. https://doi.org/10.1016/S0378-3820(99)00066-1

López A, de Marco I, Caballero BM, Laresgoiti MF, Adrados A (2011) Influence of time and temperature on pyrolysis of plastic wastes in a semi-batch reactor. Chem Eng J 173:62–71. https://doi.org/10.1016/j.cej.2011.07.037

Lovás P, Hudec P, Jambor B, Hájeková E, Horn M (2017) Catalytic cracking of heavy fractions from the pyrolysis of waste HDPE and PP. Fuel 203:244–252. https://doi.org/10.1016/j.fuel.2017.04.128

Luo G, Suto T, Yasu S, Kato K (2000) Catalytic degradation of high density polyethylene and polypropylene into liquid fuel in a powder-particle fuidized bed. Polym Degrad Stab 70:97–102. https://doi.org/10.1016/S0141-3910(00)00095-1

Miandad R, Nizami AS, Rehan M, Barakat MA, Khan MI, Mustafa A, Ismail IMI, Murphy JD (2016) Influence of temperature and reaction time on the conversion of polystyrene waste to pyrolysis liquid oil. Waste Manag 58:250–259. https://doi.org/10.1016/j.wasman.2016.09.023

Miandad R, Barakat MA, Aburiazaiza AS, Rehan M, Ismail IMI, Nizami AS (2017) Effect of plastic waste types on pyrolysis liquid oil. Int Biodeterior Biodegradation 119:239–252. https://doi.org/10.1016/j.ibiod.2016.09.017

Navarro R, Marcilla A, Beltran MI (2009) Thermal and catalytic pyrolysis of polyethylene over HZSM5 and HUSY zeolites in a batch reactor under dynamic conditions. Appl Catal B 86(78–86):78–76. https://doi.org/10.1016/j.apcatb.2008.07.026

Nisar J, Ali G, Shah A, Iqbal M, Ali R, Anwar F, Ullah R, Salim M (2019) Fuel production from waste polystyrene via pyrolysis: kinetics and products distribution. Waste Manag 88:236–247. https://doi.org/10.1016/j.wasman.2019.03.035

Onwudili JA, Insura N, Williams PT (2009) Composition of products from the pyrolysis of polyethylene and polystyrene in a closed batch reactor: effects of temperature and residence time. J Anal Appl Pyrol 86:293–303. https://doi.org/10.1016/j.jaap.2009.07.008

Owusu PA, Banadda N, Kiggundu N (2018) Reverse engineering of plastic waste into useful fuel products. J Anal Appl Pyrol 130:285–293. https://doi.org/10.1016/j.jaap.2017.12.020

Özsin G, Pütün AE (2018) A comparative study on co-pyrolysis of lignocellulosic biomass with polyethylene terephthalate, polystyrene, and polyvinyl chloride: Synergistic effects and product characteristics. J Clean Prod 205:1127–1138. https://doi.org/10.1016/j.jclepro.2018.09.134

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel. A suitable method for plastic waste management and manufacture of value added products—a world prospective. Renew Sustain Energy Rev 14:233–248. https://doi.org/10.1016/j.rser.2009.07.005

Prathiba R, Shruthi M, Miranda LR (2018) Pyrolysis of polystyrene waste in the presence of activated carbon in conventional and microwave heating using modified thermocouple. Waste Manag 76:528–536. https://doi.org/10.1016/j.wasman.2018.03.029

Quesada L, Calero M, Martín-Lara MÁ, Pérez A, Blázquez G (2020) Production of an alternative fuel by pyrolysis of plastic wastes mixtures. Energy Fuels 34:1781–1790. https://doi.org/10.1021/acs.energyfuels.9b03350

Rafey A, Siddiqui FZ (2023) A review of plastic waste management in India—challenges and opportunities. Int J Environ Anal Chem 103:3971–3987. https://doi.org/10.1080/03067319.2021.1917560

Ren S, Xu X, Hu K, Tian W, Duan X, Yi J, Wang S (2022) Structure-oriented conversions of plastics to carbon nanomaterials. Carbon Res. https://doi.org/10.1007/s44246-022-00016-2

Saeaung K, Phusunti N, Phetwarotai W, Assabumrungrat S (2021) Catalytic pyrolysis of petroleum-based and biodegradable plastic waste to obtain high-value chemicals. Waste Manag 127:101–111. https://doi.org/10.1016/j.wasman.2021.04.024

Santos BPS, Almeida D, MarquesHenriques MFVCA (2018) Petrochemical feedstock from pyrolysis of waste polyethylene and polypropylene using different catalysts. Fuel 215:515–521. https://doi.org/10.1016/j.fuel.2017.11.104

Shah J, Jan MR (2015) Effect of polyethylene terephthalate on the catalytic pyrolysis of polystyrene: investigation of the liquid products. J Taiwan Inst Chem Eng 000:1–7. https://doi.org/10.1016/j.jtice.2015.01.015

Sharma BK, Moser BR, Vermillion KE, Doll KM, Rajagopalan N (2014) Production, characterization and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process Technol 122:79–90. https://doi.org/10.1016/j.fuproc.2014.01.019

Singh MV (2018) Waste and virgin high-density poly (ethylene) into renewable hydrocarbons fuel by pyrolysis-catalytic cracking with a CoCO3 catalyst. J Anal Appl Pyrol 134:150–161. https://doi.org/10.1016/j.jaap.2018.06.003

Singh MV (2022) Deformation of waste tube-tyres into liquid green hydrocarbons (LGHs) through pyrolysis using the FeCO3. Mater Today: Proc 51:1669–1674. https://doi.org/10.1016/j.matpr.2020.08.689

Singh RK, Ruj B (2016) Time and temperature depended fuel gas generation from pyrolysis of real world municipal plastic waste. Fuel 174:164–171. https://doi.org/10.1016/j.fuel.2016.01.049

Tian X, Zeng Z, Liu Z, Dai L, Xu J, Yang X (2022) Conversion of low-density polyethylene into monocyclic aromatic hydrocarbons by catalytic pyrolysis: comparison of HZSM-5, H β, HY and MCM-41. J Clean Prod 358:131989. https://doi.org/10.1016/j.jclepro.2022.131989

Uddin A, Koizumi K, Murata K, Sakata Y (1997) Thermal and catalytic degradation of structurally different types of polyethylene into fuel oil. Polym Degrad Stab 56:37–44. https://doi.org/10.1016/S0141-3910(96)00191-7

Wang B, Li Y (2021) Plastic bag usage and the policies: a case study of China. Waste Manag 126:163–169. https://doi.org/10.1016/j.wasman.2021.03.010

Williams PT, Williams EA (1999) Interaction of plastics in mixed-plastics pyrolysis. Energy&fuels 13:188–196. https://doi.org/10.1021/ef980163x

Wong SL, Ngadi N, Abdullah TAT, Inuwa IM (2017) Conversion of low density polyethylene (LDPE) over ZSM-5 zeolite to liquid fuel. Fuel 192:71–82. https://doi.org/10.1016/j.fuel.2016.12.008

Zhang Y, Chen P, Liu S, Peng P, Min M, Cheng Y, Anderson E, Zhou N, Fan L, Liu C, Chen G, Liu Y, Lei H, Li B, Ruan R (2017) Effects of feedstock characteristics on microwave-assisted pyrolysis—a review. Biores Technol 230:143–151. https://doi.org/10.1016/j.biortech.2017.01.046

Zhou N, Dai L, Lyu Y, Li H, Deng W, Guo F, Chen P, Lei H, Ruan R (2021) Catalytic pyrolysis of plastic wastes in a continuous microwave assisted pyrolysis system for fuel production. Chem Eng J 418:129412. https://doi.org/10.1016/j.cej.2021.129412

Acknowledgements

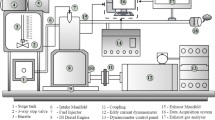

The author is thankful to the Engine Research laboratory, National Institute of Technology Silchar for the use of the autoclave pyrolysis unit and the physical characterization facilities. The authors also thank SAIC Iasst Guwahati for providing the GCMS & TG facility, SAIC Tezpur University for FTIR and CHNO facility, and SAIF IIT Bombay for the NMR facility.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Amarendra Deka performed conceptualization, methodology, experimentation and writing of the manuscript. Rahul Dev Misra conceptualized, supervised, reviewed, edited and provided experimental facilities for the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deka, A., Misra, R.D. Enhancement of fuel-grade oil yields from thermal pyrolysis of polyethylene and polystyrene through reflux condenser assisted autoclave reactor. Clean Techn Environ Policy (2024). https://doi.org/10.1007/s10098-024-02739-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10098-024-02739-9