Abstract

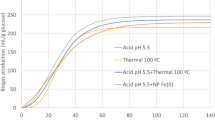

Decades have passed, facing the energy crisis and environmental pollution and researching various possible solutions to tackle them. The use of renewable sources and sustainable development processes is continuously under study to substitute conventional fossil fuels for environmental benefit. Amongst these, hydrogen is thought to be an ideal energy source with almost no hydrocarbon and carbon dioxide emissions and high energy output. Among the hydrogen production techniques, dark fermentation (DF) is a promising option for hydrogen production as it is less costly and has more energy recovery potential. The current study was designed to test the ability of kitchen waste, like potato peels, which is a common waste coming out of kitchens worldwide. The experiment demonstrates that the acidic pH of 4.5 at 40 °C yields maximum hydrogen in the bench-scale batch reactor. Hydrogen production from potato waste feedstock using sewage sludge inoculum has not been reported at this scale before. The actual results and their significance analysis by ANOVA also confirmed that fermentative hydrogen production from waste potato peels using sewage sludge inoculum is possible at a mesophilic temperature in a bench-scale batch fermenter.

Similar content being viewed by others

References

Antonopoulou G, Gavala HN, Skiadas IV et al (2008) Biofuels generation from sweet sorghum: Fermentative hydrogen production and anaerobic digestion of the remaining biomass. Biores Technol 99:110–119

Bharathiraja B, Sudharsanaa T, Bharghavi A et al (2016) Biohydrogen and Biogas – An overview on feedstocks and enhancement process. Fuel 185:810–828

Bhurat KS, Banerjee T, Pandey JK, Belapurkar P (2020) Fermentative bio-hydrogen production using lignocellulosic waste biomass: a review Waste Disposal & Sustainable Energy 2:249-264 doi:https://doi.org/10.1007/s42768-020-00054-9

Bhurat SS, Pandey S, Chintala V (2021) Combined effect of external mixture formation and cooled exhaust gas recirculation on engine performance and emissions characteristics of partially pre-mixed charged compression ignition engine. Environm Progress Sustain Energy 40:e13470

Bothi KL (2007) Characterization of biogas from anaerobically digested dairy waste for energy use. https://hdl.handle.net/1813/5329

Cappai G, De Gioannis G, Muntoni A et al. (2015) Effect of inoculum to substrate ratio (ISR) on hydrogen production through dark fermentation of food waste. In: Proceedings of the Fifteenth International Waste Management and Landfill Symposium. CISA Publisher, Italy, S. Margherita di Pula, Cagliari, Italy, pp 5–9

Cappai G, De Gioannis G, Muntoni A et al (2018) Biohydrogen production from food waste: Influence of the inoculum-to-substrate ratio. Sustainability 10:4506

Cheng J, Lin R, Ding L et al (2015) Fermentative hydrogen and methane cogeneration from cassava residues: effect of pretreatment on structural characterization and fermentation performance. Biores Technol 179:407–413

Cheng J, Su H, Zhou J et al (2011) Hydrogen production by mixed bacteria through dark and photo fermentation. Int J Hydrogen Energy 36:450–457

Diamantis VI, Kapagiannidis AG, Ntougias S et al (2014) Two-stage CSTR–UASB digestion enables superior and alkali addition-free cheese whey treatment. Biochem Eng J 84:45–52

Dyundi S, Matolia S, Singla A et al (2019) Review on biodiesel production and emission characteristic of non-edible vegetable oil. IOP conference series. Mater Sci Eng 691:012024

Fang HH, Liu H (2002) Effect of pH on hydrogen production from glucose by a mixed culture. Biores Technol 82:87–93

Gebrechristos HY, Chen W (2018) Utilization of potato peel as eco-friendly products: A review. Food Sci Nutr 6:1352–1356

Ghimire A, Frunzo L, Pirozzi F et al (2015) A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products. Appl Energy 144:73–95

Ghosh D, Hallenbeck PC (2010) Response surface methodology for process parameter optimization of hydrogen yield by the metabolically engineered strain Escherichia coli DJT135. Biores Technol 101:1820–1825

Girotto F, Lavagnolo MC, Acar G et al (2021) Bio-methane production from tomato pomace: preliminary evaluation of process intensification through ultrasound pre-treatment. J Mater Cycles Waste Manage 23:416–422

Gómez-Montoya J-P, Cacua-Madero K-P, Iral-Galeano L et al (2013) Effect of biogas enriched with hydrogen on the operation and performance ofadiesel-biogas dualengine. CT&F-Ciencia, Tecnología y Futuro 5:61–71

Gomez-Romero J, Gonzalez-Garcia R, Chairez I et al (2016) Continuous two-staged co-digestion process for biohydrogen production from agro-industrial wastes. Int J Energy Res 40:257–272

Han W, Yan Y, Shi Y et al (2016) Biohydrogen production from enzymatic hydrolysis of food waste in batch and continuous systems. Sci Rep 6:38395

Hassan GK, Hemdan BA, El-Gohary FA (2020) Utilization of food waste for bio-hydrogen and bio-methane production: influences of temperature, OLR, and in situ aeration. J Mater Cycles Waste Manag 2:1218–1226

Júnior ADNF, Wenzel J, Etchebehere C et al (2014) Effect of organic loading rate on hydrogen production from sugarcane vinasse in thermophilic acidogenic packed bed reactors. Int J Hydrogen Energy 39:16852–16862

Keskin T, Abubackar HN, Arslan K et al (2019) Biohydrogen production from solid wastes. In: Biohydrogen, vol 2. Elsevier, pp 321–346. https://doi.org/10.1016/B978-0-444-64203-5.00012-5

Kim DH, Kim SH, Jung KW et al (2011) Effect of initial pH independent of operational pH on hydrogen fermentation of food waste. Biores Technol 102:8646–8652

Kossmann W, Pönitz U (2011) Biogas digest: volume I-biogas basics. In:Information and advisory service on sppropriate technology, vol 1. pp 1-46

Kotay SM, Das D (2008) Biohydrogen as a renewable energy resource—prospects and potentials. Int J Hydrogen Energy 33:258–263

Lang CA (1958) Simple microdetermination of Kjeldahl nitrogen in biological materials. Anal Chem 30:1692–1694

Lee K-S, Lin P-J, Chang J-S (2006) Temperature effects on biohydrogen production in a granular sludge bed induced by activated carbon carriers. Int J Hydrogen Energy 31:465–472

Li C, Fang HH (2007) Fermentative hydrogen production from wastewater and solid wastes by mixed cultures. Crit Rev Environ Sci Technol 37:1–39

Liu D, Zeng RJ, Angelidaki I (2008) Effects of pH and hydraulic retention time on hydrogen production versus methanogenesis during anaerobic fermentation of organic household solid waste under extreme-thermophilic temperature (70° C). Biotechnol Bioeng 100:1108–1114

Lucas CKG (2014) Biogas production from potato peel waste. In: Licenciado em Ciências de Engenharia de Ambiente. Faculdade de Ciências e Tecnologia

Luo G, Karakashev D, Xie L et al (2011) Long-term effect of inoculum pretreatment on fermentative hydrogen production by repeated batch cultivations: Homoacetogenesis and methanogenesis as competitors to hydrogen production. Biotechnol Bioeng 108:1816–1827

Malaspina F, Cellamare CM, Stante L et al (1996) Anaerobic treatment of cheese whey with a downflow-upflow hybrid reactor. Biores Technol 55:131–139

Martinat S, Navratil J, Trojan J et al (2017) Interpreting regional and local diversities of the social acceptance of agricultural AD plants in the rural space of the Moravian-Silesian Region (Czech Republic). Rendiconti Lincei 28:535–548

Morra S, Valetti F, Gilardi G (2017) [FeFe]-hydrogenases as biocatalysts in bio-hydrogen production. Rendiconti Lincei 28:183–194

Mu Y, Zheng X-J, Yu H-Q et al (2006) Biological hydrogen production by anaerobic sludge at various temperatures. Int J Hydrogen Energy 31:780–785

Noblecourt A, Christophe G, Larroche C et al (2018) Hydrogen production by dark fermentation from pre-fermented depackaging food wastes. Biores Technol 247:864–870

Okamoto M, Miyahara T, Mizuno O et al (2000) Biological hydrogen potential of materials characteristic of the organic fraction of municipal solid wastes. Water Sci Technol 41:25–32

Remón J, García L, Arauzo J (2016) Cheese whey management by catalytic steam reforming and aqueous phase reforming. Fuel Process Technol 154:66–81

Rice EW, Baird RB, Eaton AD (1915) Standard methods for the examination of water and wastewater. American Public Health Association, American Water Works Association, Water Environment Federation

Singh A, Sevda S, Abu Reesh I et al (2015) Biohydrogen Production from Lignocellulosic Biomass: Technology and Sustainability. Energies 8:13062–13080

Vidal G, Carvalho A, Méndez R et al (2000) Influence of the content in fats and proteins on the anaerobic biodegradability of dairy wastewaters. Biores Technol 74:231–239

Wang J, Wan W (2008) Effect of temperature on fermentative hydrogen production by mixed cultures. Int J Hydrogen Energy 33:5392–5397

Wang X, Zhao Y-C (2009) A bench scale study of fermentative hydrogen and methane production from food waste in integrated two-stage process. Int J Hydrogen Energy 34:245–254

Wu D (2016) Recycle technology for potato peel waste processing: a review. Procedia Environ Sci 31:103–107

Yang G, Wang J (2018) Pretreatment of grass waste using combined ionizing radiation-acid treatment for enhancing fermentative hydrogen production. Biores Technol 255:7–15

Yu H-Q, Fang HHP (2002) Acidogenesis of dairy wastewater at various pH levels. Water Sci Technol 45:201–206

Zhen X, Zhang X, Li S et al (2020) Effect of micro-oxygen pretreatment on gas production characteristics of anaerobic digestion of kitchen waste. J Mater Cycles Waste Manage 22:1852–1858

Acknowledgements

The authors would like to thank the Devi Ahilya Vishwa Vidyalaya, Indore, and University of Petroleum and Energy Studies (UPES), Dehradun, for providing the support to carry out the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhurat, K.S., Banerjee, T., Pandey, J.K. et al. A lab fermenter level study on anaerobic hydrogen fermentation using potato peel waste: effect of pH, temperature, and substrate pre-treatment. J Mater Cycles Waste Manag 23, 1617–1625 (2021). https://doi.org/10.1007/s10163-021-01242-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01242-3