Abstract

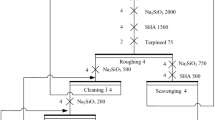

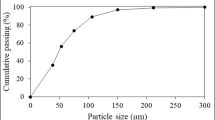

Recycling of materials is becoming progressively more significant for society due to the depletion of natural resources. Jewelry wastes are considered as secondary sources of raw material and contain a very high proportion of precious metals. Scraps and wastes from jewelry activities need to be pre-treated before refining to reduce costs and maximize the recovery of precious metals. In this paper, the recovery of gold (Au) and silver (Ag) from floor sweeping jewelry wastes (FSJW) of jewelry workshops using flotation followed by leaching process was studied. In flotation experiments, optimum pH value, particle size, type, and amount of reagent were the investigated parameters. Experimental results demonstrated that the flotation method was very successful in diminishing much of the waste fraction. A froth product, with more than 280 g/t Au and 2800 g/t Ag, was produced from a feed containing 174 g/t Au and 1834 g/t Ag with approximately 87% Au and 82% Ag recoveries. To investigate the dissolution behaviors of gold and silver, cyanide leaching tests were carried out directly on the feed and the froth product. 68% Au and 75% Ag in leach that were obtained with direct feed after 48 h of leaching in 12 g/L NaCN concentration at 40 °C and 1/5 solid/liquid ratio (w/w) were enhanced to 79% Au and 84% Ag when the froth sample was subjected to leaching under the same conditions.

Similar content being viewed by others

References

Ebin B, Petranikova M, Ekberg C (2018) Physical separation, mechanical enrichment and recycling-oriented characterization of spent NiMH batteries. J Mater Cycles Waste Manag 20:2018–2027

Mejame MPP, Kim YM, Lee DS, Lim SR (2018) Effect of technology development on potential environmental impacts from heavy metals in waste smartphones. J Mater Cycles Waste Manag 20:100–109

Burat F, Ozer M (2018) Physical separation route for printed circuit boards (PCBs). Physicochem Probl Mi 54:554–566

Prassad MS, Mensah Biner R, Pizarro RS (1991) Modern trends in gold processing—overview. Miner Eng 4:1257–1277

Loewen R (1989) Refining jeweler’s wastes. Proceedings, Santa Fe Symposium on Jewelry Manufacturing Technology 331

Yano J, Sakai S (2015) Waste prevention indicators and their implications from life cycle perspective: a review. J Mater Cycles Waste Manag 18:38–56

Yano J, Hirai Y, Okamoto K, Sakai S (2013) Dynamic flow analysis of current and future end-of-life vehicles generation and lead content in automobile shredder residue. J Mater Cycles Waste Manag 16:52–61

Arya S, Gupta A, Bhardwaj A (2018) Electronic waste management approaches—a pilot study in Northern Indian States. Int J Waste Resour 8:1–5

Sakai S, Yano J, Hirai Y, Asari M, Yanagawa R, Matsuda T, Yoshida H, Yamada T, Kajiwara N, Suzuki G, Kunisue T, Takahashi S, Tomoda K, Wuttke J, Mählitz P, Rotter VS, Grosso M, Astrup TF, Cleary J, Oh GJ, Liu L, Li J, Ma HW, Chi NG, Moore S (2017) Special feature: review, waste prevention for sustainable resource and waste management. J Mater Cycles Waste Manag 19:1295–1313

Canda L, Heput T, Ardelean E (2016) Methods for recovering precious metal from industrial waste. Mater Sci Eng, IOP Conf. Series, p 106

Corti CW (2002) Recovery and refining of gold jewellery scraps and wastes. The Santa Fe Symposium on Jewellery Manufacturing Technology 1–20. London

Delfini M, Manni A, Massacci P (2000) Gold recovery from jewellery waste. Miner Eng 13:663–666

Ferrini M, Manni A, Massacci P (1998a) Characterization and sampling of jewellery waste in Italy. In Proc. Second Biennial International Conference on chemical measurement and monitoring of the environment. Enviro Analysis 98, Ottawa, 529–534

Ferrini M, Manni A, Massacci P (1998b) Chemical analyses by ICP-AES of Jewellery waste in Italy. In Proc. second Biennial International Conference on chemical measurement and monitoring of the environment. Enviro Analysis 98, Ottawa, 501–506

Hoke CM (1982) Refining precious metal wastes: gold-silver-platinum metals: a handbook for the jeweler, Dentist and Small Refiner Metallurgical Publishing Company

Manni A, Saviano G, Massacci P (2001) Technical note: Characterization of gold particles in recoverable waste matrix. Miner Eng 14:1679–1684

Bellemans I, De Wilde E, Moelans N, Verbeken K (2018) Metal losses in pyrometallurgical operations—a review. Adv Colloid Interface Sci 255:47–63

Loewen R (1995) Small scale refining of jewellery wastes. Ronda R.Cordray Met-Chem. Research, Texas, pp 161–167

Embleton FT (1989) Refining of gold from jewellery scrap. Johnson Matthey Chemicals Ltd., England, pp 315–319

Ammen CW (1997) Recovery and refining of precious metals, 2nd edn. Chapman & Hall, New York

Corti CW (1997) Recovery and recycling in gold jewellery production. Gold Technol 21:11

Corti CW (1997) In-House gold refining: the options. Gold Technol 21:31

Mbaya RKK (2004) Recovery of noble metals from jewellery wastes, Doctorate Thesis, Tshwane University of Technology

Potgieter JH, Potgieter SS, Mbaya RKK, Teodorovic A (2004) Small-scale recovery of noble metals from jewellery wastes. J S Afr Inst Min Metall 104:563–572

Burat F, Baştürkcü H, Özer M (2019) Gold&silver recovery from jewelry waste with combination of physical and physicochemical methods. Waste Manag 89:10–20

Chmielewski AG, Urbanski TS, Migdal W (1997) Separation technologies for metals recovery from industrial wastes. Hydrometallurgy 45:333–344

Ashtari P, Pourghahramani P (2018) Hydrometallurgical recycling of cobalt from zinc plants residue. J Mater Cycles Waste Manag 20:155–166

Wang WY, Yen CH, Lin JL, Xu RB (2019) Recovery of high-purity metallic cobalt from lithium nickel manganese cobalt oxide (NMC)-type Li-ion battery. J Mater Cycles Waste Manag 21:300–307

Saca N, Dimache A, Radu LR, Iancu I (2017) Leaching behavior of some demolition wastes. J Mater Cycles Waste Manag 19:623–630

Habashi F (1997) Precious metals, refractory metals, scattered metals, radioactive metals, rare earth metals. In: Handbook of extractive metallurgy. Wiley, London, pp 1186–1279

Hoffmann JE (1992) Recovering precious metals from electronic scrap. JOM 44:43–48

Jha MK, Lee JC, Kumari A, Choubey PK, Kumar V, Jeong J (2011) Pressure leaching of metals from waste printed circuit boards using sulphuric acid. JOM 63:29–32

Menad N, Björkman B, Allain EG (1998) Combustion of plastics contained in electric and electronic scrap. Resour Conserv Recycl 24:65–85

Mallampati SR, Lee CH, Park MH, Lee BK (2018) Processing plastics from ASR/ESR waste: separation of poly vinyl chloride (PVC) by froth flotation after microwave-assisted surface modification. J Mater Cycles Waste Manag 20:91–99

Wills BA, Napier-Munn T (2006) Wills’ mineral processing technology, 7th edn. Butterworth-Heinemann, Oxford

Jeon S, Ito M, Tabelin CB, Pongsumrankul R, Kitajima N, Hiroyoshi N (2018) Gold recovery from shredder light fraction of e-waste recycling plant by flotation-ammonium thiosulfate leaching. Waste Manag 77:195–202

Logsdon M, Hagelstein K, Terry I (2001) The management of cyanide in gold extraction. ICME 1–40

Yüce E (1997) Gold mining with environmental impacts and trends (in Turkish), TMMOB Chamber of Mining Engineers Istanbul Branch Working Report

Klimpel R, Isherwood S (1993) Some new flotation products for the improved recovery of gold and platinum, Randol Gold Forum, Beaver Creek '93, 105–111

Acknowledgements

The present study is based on the results of the undergraduate theses conducted at the Istanbul Technical University. We would like to thank SAY Ramat Company for providing the sample and financial support of chemical analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Burat, F., Demirağ, A. & Şafak, M.C. Recovery of noble metals from floor sweeping jewelry waste by flotation-cyanide leaching. J Mater Cycles Waste Manag 22, 907–915 (2020). https://doi.org/10.1007/s10163-020-00982-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-00982-y