Abstract

Jamming/un-jamming, the transition between solid- and fluid-like behavior in granular matter, is an ubiquitous phenomenon in need of a sound understanding. As argued here, in addition to the usual un-jamming by vanishing pressure due to a decrease of density, there is also yield (plastic rearrangements and un-jamming that occur) if, e.g., for given pressure, the shear stress becomes too large. Similar to the van der Waals transition between vapor and water, or the critical current in superconductors, we believe that one mechanism causing yield is by the loss of the energy’s convexity (causing irreversible re-arrangements of the micro-structure, either locally or globally). We focus on this mechanism in the context of granular solid hydrodynamics (GSH), generalized for very soft materials, i.e., large elastic deformations, employing it in an over-simplified (bottom-up) fashion by setting as many parameters as possible to constant. Also, we complemented/completed GSH by using various insights/observations from particle simulations and calibrating some of the theoretical parameters—both continuum and particle points of view are reviewed in the context of the research developments during the last few years. Any other energy-based elastic-plastic theory that is properly calibrated (top-down), by experimental or numerical data, would describe granular solids. But only if it would cover granular gas, fluid, and solid states simultaneously (as GSH does) could it follow the system transitions and evolution through all states into un-jammed, possibly dynamic/collisional states—and back to elastically stable ones. We show how the un-jamming dynamics starts off, unfolds, develops, and ends. We follow the system through various deformation modes: transitions, yielding, un-jamming and jamming, both analytically and numerically and bring together the material point continuum model with particle simulations, quantitatively.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The macroscopic Navier-Stokes equations allow one to describe Newtonian fluids with constant transport coefficients (e.g., viscosity). In many non-Newtonian systems, complex fluids [1], colloidal suspensions, review [2,3,4], and especially granular matter [5] in its flowing state [6], the transport coefficients depend on various state-variables such as the density and the granular temperature [7]. This interdependence and the presence of energy dissipation is at the origin of many interesting phenomena: clustering [8], shear-band formation [9], jamming/un-jamming [10], dilatancy [11], shear-thickening [3, 4, 12, 13] or shear-jamming [10, 14], plastic deformations [15,16,17,18,19,20,21], related also to creep/relaxation [11, 22,23,24,25], and many others. The research on granular matter in the last decades—to a good fraction inspired by works of Bob Behringer and co-workers—will be briefly reviewed next.

1.1 A brief history of granular research

In order to describe solid-like granular matter on the macroscopic scale, concepts from elasto- and visco-plastic theories were used [15, 16, 21, 26,27,28,29,30,31,32,33,34,35] including instabilities, yield and failure [29, 36,37,38,39,40,41,42,43,44,45]. Recently, statistical mechanics/physics concepts [19, 46], helped to better understand the probabilities for plastic deformations [17,18,19,20,21, 34, 47,48,49], force network change/growth [50, 51], stress-based meso ensembles [52], or stress-relaxation [11, 22,23,24]. A traditional subject of research are stress-fluctuations [53,54,55,56], and the quest for the “effective temperature” [47, 48, 57, 58] of thermal or a-thermal granular packings [48, 52, 59]. Most recently, universal scaling laws [60] were reported, and compression and shear in particularly small systems [61] could be understood. Considering granular solids, their stiffness, and the elastic moduli [31, 62, 63] have to be considered in the presence of non-affine deformations [63]. For this, over-compression [45, 49] and shear [49, 60, 62, 64,65,66] cyclic loading [66, 67] or even thermal cyclic loading [68] were applied. When sheared granular matter starts to flow and (for large enough strain) reaches a steady state, or critical state [69,70,71], the nowadays widely accepted “classical” \(\mu (I)\)-rheology [72] holds. It was recently extended to include friction, softness and cohesion [2, 12, 13, 69, 70, 73,74,75], but it does not have a fully tensorial form [76, 77], and doubts about its well-posed-ness are still discussed [78,79,80]. Modern experimental techniques [25, 71, 81, 82], also with focus on low confining stress [83], shed new light on classical works on the response to local perturbations [84], jamming and un-jamming [23, 84,85,86,87], in particular by shear [10, 49, 60, 65, 88,89,90], and transient fabric/micro-structure evolution [31, 49, 55, 91,92,93,94]. One of the classical experimental techniques involves photoelastic materials that allow to visualize stress [95,96,97], as complemented by a huge amount of particle simulations, e.g., see Ref. [9], or for a most recent example, see Ref. [98] and references therein. One important success of granular research was to bring solid-like and flowing behavior of granular matter together, e.g., in a continuum theory with fluidity [18, 47, 48, 99], and to understand anisotropy [70, 91, 93, 94], also shape induced [100, 101], as well as involving the rotational degrees of freedom and micro-polar models [2, 102,103,104,105,106], not to forget wet particle systems [3, 4], for which a thermodynamically consistent theory [21, 107] and numerical solutions [108] were recently proposed.

1.2 Open challenges

Some open questions are: How can we understand phenomena that originate from the particle- or meso-scale, which is intermediate between atoms and the macroscopic, hydrodynamic scale? And how can we formulate a theoretical framework that takes the place of the Navier-Stokes equations?

A universal theory must involve all states granular matter can take, i.e., granular gases, fluids, and solids, as well as the transitions between those states. What are the state-variables needed for such a theory? And what are the parameters (that we call transport coefficients) and how do they depend on the state-variables?

Main goal of this paper is to propose a minimalist candidate for such an universal theory, able to capture granular solid, fluid, and gas, as well as various modes of transitions between these states. The model, remarkably, involves only four state-variables, density, momentum density (vector), elastic strain (tensor), and granular temperature. It is a boiled down, simplified case of the more complete theory GSH [47, 48, 109,110,111,112], complemented by insights based on DEM, see Ref. [49] and references therein, modified such that it works below, above and during transitions. For the sake of transparency and treatability, whenever possible, we reduce most transport coefficients and parameters to constants—without loss of generality.

Each transport coefficient is related to the propagation or evolution of one (or more) of the state-variables that encompass the present state of the system. For simple fluids [1, 113], it is possible to bridge between the (macroscopic) hydrodynamic and the (microscopic) atomistic scales; as an example, the diffusion coefficient quantifies mass-transport mediated by microscopic fluctuations.

In the case of low density gases, the macroscopic equations and the transport coefficients can be obtained using the Boltzmann kinetic equation as a starting point. For moderate densities, the Enskog equations provide a good, quite accurate description of dense gases (or fluids) of hard atoms [1], or of particles including the effects of dissipation, which results in what is nowadays referred to as standard kinetic theory (SKT) [7, 114]. Beyond SKT one can only reach out (empirically) towards realistic systems [8, 115, 116], and beyond, see, e.g., [4, 12]. The limit of granular fluids is where transport coefficients, like the viscosity, deviate from SKT. This involves a divergence [12, 117, 118] when the granular fluid becomes denser [8, 116, 118], approaching the jamming density from well below, i.e., the state that we could call a granular solid, as described by classical solid mechanics [120]. Recent research also considers soft particles [74, 118, 121] for which jamming changes from a sharp to a rather smooth transition. One objective of this paper is to bring together fundamental theoretical concepts of continuum mechanics [21, 32, 35, 48, 107, 122, 123] with observations made from particle simulations for simple granular systems in the gas, fluid, and solid states, including also the transitions between those states [8, 49, 116, 118, 124,125,126].

1.3 About states of granular matter

When exposed to external stresses, grains are elastically deformed at their contacts. In static situations, there is only elastic energy; in flowing states, some of the elastic energy is transferred to kinetic energy and backFootnote 1, as sketched in Fig. 1 for the example of slow isotropic jamming, and—after an overcompression cycle—eventually un-jamming. Note that the jamming transition at small (yet finite) compression rate appears smooth/continuous, whereas the un-jamming transition is rather sharp/discontinuous [127].

Grains yield differently for vanishing or finite \(T_g\). In motion, for \(T_g\not =0\), yield is a continuous phenomenon, i.e., state-variables vary continuously. If the grains are at rest initially, \(T_g=0\), yield is discontinuous—as evidenced by a layer of grains on a tilted plane. Discontinuity is mainly in the equilibrium value of the elastic stress. It is finite in the convex region and zero in the concave one, as it always relaxes away there. Any discontinuity of a phase transition is always in the equilibrium values of some quantities.

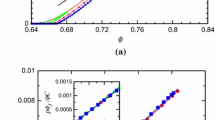

Sketch of isotropic jamming and un-jamming, with dimensionless compression rate \(I_v < I_v(\phi _J^{0}=0.6608)={\dot{\varepsilon }}_v d_p/\sqrt{P_{\mathrm{sim}}\rho _p}=1.2\times 10^{-5}\), of frictionless, polydisperse particles, from simulations in Ref. [49], with reversal at maximal density \(\phi _{\mathrm{max}}=0.9\), so that unjamming occurs at \(\phi _J^{1}=0.666\). Displayed from particle simulations are the coordination number Z (green, scaled as \(Z/4-1\)) that defines dynamic initial jamming at \(Z(\phi _J^{0})=Z_0\,=\,6\), the dimensionless elastic pressure \(P_{\mathrm{sim}} d_p/k_n\) (blue, scaled by a factor of 3000), with magnitude \(4\times 10^{-5}\) at \(\phi _J^{0}\), and the fraction of kinetic energy \(K/(1+K)\) (red), as discussed in footnote 1: For initial jamming, the yellow area designates the dense collisional flow state (\(K\sim 1\)), while the cyan area designates the quasi-static (isotropic) state (\(K\ll 1\)). The thin magenta line is a fit to Eq. (11) in Ref. [49] of all solid-like high-pressure data (using \(K<5\times 10^{-4}\), i.e., \(\phi \ge 0.665\)), on the initial compression branch (data out of this plot, well above the rather unstable cyan area, up to much larger \(\phi _{\mathrm{max}}\)), yielding an extrapolated jamming density of \(\phi _J^{P}=0.66125\) (around which the cyan area is centered), and a dimensionless modulus \(p_0 = 0.06272\) (note that \(p_0 \rightarrow p_0/\phi _J^{P}\) in Ref. [49]), and the nonlinear coefficient \(\gamma _p=0.179\) that accounts for the large overlaps of particles in the simulation, for more details see Ref. [49]. Note that this full-range fitting perfectly collapses with the unloading branch (not visible), agrees with the loading branch for \(P>0.001\) (out of range), but is fundamentally different from the calibrated comparison between simulation and model solution, as presented in Sect. 6

Particle systems, compressed and decompressed with different rates, are discussed in Ref. [127]. Here, a rather slow rate is chosen and the system response is plotted in Fig. 1. Even such little dynamics allows for a rich phenomenology below and above jamming, where the yellow area corresponds to a dense fluid with solid features—just below jamming, while the cyan area corresponds to a solid with fluid features—jammed, but strongly unstable (see the steps and wiggles in pressure and coordination number) [88].

The capability of granular solids to remain quiescent, in mechanical equilibrium, under a given finite stress is precarious. For small perturbations they will return to their original state. If pressure or shear stress become too large, the grains will, suddenly, start moving—either locally or globally [17, 127]—with a decaying elastic stress. This qualitative change in behavior is an unambiguous phase transition. We shall refer to the region capable of maintaining the global, overall equilibrium of static grains as elastic, and its boundary (in the space spanned by the state-variables) as the yield surface. For local loss of elasticity we rather use the term plastic, irreversible events, see Refs. [19, 61].

Granular systems will also un-jam for vanishing pressure and a continuous reduction of density, though we reserve the term yield for the (sudden) loss of elastic stability: Grains un-jam in either case, they yield only when the elastic stress, in particular the pressure, is finite.

Starting from the elastic region, decompression (tension) reduces the density and the elastic deformations of the grains—until the latter vanish and the system un-jams. Decompressing further just reduces the density accordingly. The system is now un-jammed in the sense that one can change the density without any restoring force, i.e., the elastic energy remains zero. In reverse, compression only increases the density, as long as it is smaller than the jamming density. At jamming both the elastic deformations and the associated energy start to increase with density. In contrast, there is a discontinuity leaving the elastic regime at finite values of elastic stress. It is a sudden transition from quiescent, enduringly deformed grains, to moving ones oscillatorily deformed due to “jiggling” particle motions. This transition needs to be explained, to have a model for. And it is clear that the transition must be encoded in the elastic energy—the only quantity characterizing the quiescent state—not in the dynamic/fluctuating contributions to energy.

In the elastic region, grains appear solid when at rest, but they will flow if subject to an imposed finite shear rate, and appear liquid. Such a continuous change in appearance is well accounted for by any competent dynamic theory or rheology, it is not a transitionFootnote 2 . Moreover, flowing grains in the elastic region do feature a macroscopic elastic shear stress, with an associated elastic energy (even though granular contacts switch continually), something no Newtonian liquid is capable of. Also, the shear stress remains finite when the grains stop flowing, which is not the case in Newtonian fluids.

So there are two different flowing states, either with finite elastic stress/strain, or with vanishing ones, which includes granular gases, as accounted for by the kinetic theory, see Refs. [8, 116] and references therein. There is also a transition between them, as possibly related to (dry) liquefaction [37], but not to be confused with liquefaction due to a fluid between the particles, which is completely disregarded in this study of dry granular matter (even though the fluid stress can be considerable in wet system). We take both transitions, either leaving the quiescent state, or the flowing one, as the same transition, with the same underlying physics. In fact, encoding the transition in the elastic energy certainly affects the flowing state as well. The mechanism for yield is here related to elastic energy (irrespective whether the pressure or the shear stress is too large, or the density too small), as traditionally encompassed by concepts like plastic potentials, yield functions, or flow rules [21, 30, 32, 34, 106, 122], see Fig. 2 and textbooks like Ref. [122].

1.4 Relation to other systems in physics

We do not think that the transition is due to spontaneously broken translational symmetry—the usual mechanism giving rise to static shear stresses, as in any fluid-solid transition. The quick argument is: Consisting of solid, grains already break translational symmetry. More importantly, the loss of equilibrium and granular statics is caused by the shear stress or pressure being too strong.

This is an indication of an over-tightening phenomenon, of which the (pair-breaking) critical current is a prime example. If a superconductor conducts electricity without dissipation, it is in a current-carrying equilibrium state. If, however, the imposed current exceeds a maximal value, the system leaves equilibrium and enters a dissipative, resistive state. The superfluid velocity, \(v_{sf}\sim \nabla \varPsi _q\), given by the gradient of a quantum mechanical phase, \(\varPsi _q\), is the analogue of the strain. The dissipationless current, \(j_{sf}=\partial w/\partial v_{sf}\), given by the derivative of the energy with respect to \(v_{sf}\), is the analogue of the elastic stress. The over-tightening transition in superconductivity is well accounted for by an inflection point, at which the energy turns from stably convex to concave, see the classic paper by Bardeen [130]. The close analogy between the two systems is a good reason to employ the same approach here, to postulate that the surface of the cone in Fig 2 can be related to an inflection surface of the elastic energy.

1.5 About elastic granular matter

The granular solid state is contingent on granular matter capable of being elastic, for which there is ample evidence, see e.g. Refs. [6, 52, 84, 95, 125, 131,132,133,134] and references therein. In addition to the material stiffness, many other material properties (including cohesion, friction, surface-roughness, particle-shape) determine the elastic response of granular matter. For soft and stiff materials the deformations are, respectively, considerable and slight, but never zero. Because of their Hertz-like non-linear contacts, grains are infinitely soft in the limit of vanishing contact area (deformation). Therefore, at any given finite force, deformations are always sufficiently large to display the full spectrum of elastic behavior, including a considerable static shear stress (enabling a tilted surface), and elastic waves. Even the simplest model material, consisting of perfectly smooth spheres of isotropic, linearly elastic material, displays non-linearity due to their Hertz-type contacts, on-top of the contact network (fabric) and its re-structuring. Only in computer simulations is it possible to remove the first and focus on the second, see e.g. Ref. [49].

Elastic waves propagate in granular media, displaying various non-linear features, including anisotropy, dispersion and rotations, see e.g. Refs. [104,105,106, 135,136,137,138,139,140] and references therein. The discreteness and disorder of granular media add various phenomena—already for tiny amplitudes—such as dispersion, low-pass filtering and attenuation [104, 140,141,142]. With increasing amplitudes, a wide spectrum of further phenomena is unleashed, among which the beginning of irreversibility and plasticity, see Ref. [20] in this topical issue, and references therein, and the loss of mechanical stability [143], what we call “yield” in the following.

1.6 Yield: About the limits of elasticity

To envision the yield surface, we consider the space spanned by three parameters: pressure P, shear stress \(\sigma _s\), and void ratio \(e=(1-\phi )/\phi \) (where \(\rho =\rho _p \phi \), with material density \(\rho _p\) and volume fraction \(\phi \)), ignoring the granular temperature (i.e., fluctuations of kinetic and potential energy), as discussed in Ref. [144] and so many papers following. Based on the observation of the Coulomb yield and the virgin consolidation line, we assume that the yield surface is as rendered in Fig. 2. Elastic, jammed states, maintained by deformed grains, are stable and static only inside itFootnote 3.

Granular yield surface, or the jamming phase diagram, for \(T_g=0\), as a function of the pressure P, shear stress \(\sigma _s\), and void ratio e, as rendered by an energy expression in [112]. Panel c is the 3D combination of a and b; with b depicting how the straight Coulomb yield line bends over, depending on the void ratio e—a behavior usually accounted for by cap models in elasto-plastic theories; while a depicts the maximal void ratio \(e=1/\phi -1\) (equivalent to the inverse density) plotted against pressure P, or the so-called virgin consolidation line (VCL). In panel (a), the dotted line is an empirical relation, \(e=e_1-e_2 \log (P/P_0)\), with \(P_0=0.5\) MPa, \(e_1=0.679\) and \(e_2=0.097\), approximating the VCL, but not valid for \(P \rightarrow 0\). The thick solid line cuts the e-axis at \(e_0\), with the intersection being the lowest possible, random loosest packing value, see Ref. [112] for details, where also the thin solid line is discussed. Thus \(e_0\) also defines the lowest possible jamming volume fraction, \(\phi _{J0}=1/(1+e_0)\), see Ref. [49], with static, elastic states possible only below the VCL, as will be shown in Sect. 5 and 6

The Coulomb yield line, see Fig. 2b, can be reached by increasing the shear stress at given confining pressure. When the shear stress exceeds a certain level, the system yields, un-jams and becomes dynamic. No static, stable elastic state exists above the Coulomb yield line, as evidenced by a sand pile’s steepest slope.

It is imperative to realize that (what we call) the Coulomb yield line is conceptually different from the peak shear stress achieved during the approach to the critical state at much larger strains. Coulomb yield is the collapse of static states—such as when one slowly tilts a plate carrying grains until they start to flow (max. angle of stability). Its behavior is necessarily encoded in the system’s energy, because this phenomenon does not at all involve the system’s dynamics. The critical state, including the peak shear stress—though referred to as “quasi-static”—is a fully dynamic and irreversible effect. It is accounted for by the stationary solution at given strain rates in GSH. The angle of repose (always smaller than the max. angle of stability) is in GSH given by the critical friction angle [47, 48].

In the absence of shear stresses, the maximally sustainable pressure depends on the void ratio, e, as rendered in Fig. 2a. Starting from a given e, slowly increasing P, the grain-structure will collapse and yield at this pressure, to a smaller value of e, such that the final state is stable, static, and below the curve of Fig. 2a. This is because when applying a slowly increasing pressure, the point of collapse is (ever so) slightly above the curve; and the end point below it is typically also close. This evolution resembles a stair-case, with the granular medium increasing its density by hugging this curve, which frequently referred to as the virgin/primary consolidation line, or simply the pressure yield line. The line cuts the e-axis at the random loosest void ratio, \(e_0\), above which no elastic stable states exists.

Because of the pressure yield line, the Coulomb yield curve cannot persist for arbitrarily large P at given e. Rather, it bends over to form a “cap”, as rendered in Fig. 2b, since an additional shear stress close to the pressure yield line will also cause the packing to collapse. (The shape of the cap depends on the interplay of isotropic and deviatoric deformations as well as the probability for irreversible, possibly large-scale re-structuring events of the micro-structure, i.e., the contact network, including also the sliding of contacts, but also breakage of particles, which is, however, excluded from this study. Whether the picture sketched here is sound without breakage remains an open question [21].)

Merging Figs. 2a and 2b yields the elastic region below the yield surface, as given in Fig. 2c. Although the e-axis, for \(P,\sigma _s=0\), is also referred to as the loci of (isotropic) un-jamming, the elastic stress goes continuously to zero here, because the grains are successively less deformed. There is, as already discussed above in Sect. 1.3, no discontinuous phase transition or yield here, except for the coordination number, see Fig. 1. Point is, concerning only this one point of the plot, if the elastic stresses vanish, both in the convex and concave region, nothing much resembling a discontinuous transition happens there. Isotropic jamming and un-jamming, as well as the discontinuity in the coordination number on the isotropic e-axis is discussed in detail at various spots in this paper, see Sects. 1.3, 3.2.3, and 4.1.1.

Next, all different symbols and nomenclatures are summarised.

1.7 Notation and symbols

This paper is a cooperation of co-authors, whose notational baggage from past publications clash with one another. In the dire need to compromise, we ask the readers to suffer—with us—using varying symbols and notations. Our state-variables are: density, \(\rho \), momentum density, \(\rho v_i\), granular temperature, \(T_g\), and the elastic (true) strain, as summarized here.

-

1.

The bulk density, \(\rho \), is related to the volume fraction, \(\phi =\rho /\rho _p\) (with \(\rho _p\) the particles’ material density), the porosity \(1-\phi \), and the void ratio \(e=(1-\phi )/\phi \). (Later, we shall choose units such that \(\rho _p=1\), so that volume fraction and bulk density are identicalFootnote 4.)

-

2.

The conserved momentum density defines the velocity \(v_i=( \rho v_i ) / \rho \). The symmetric part of the velocity gradient is

$$\begin{aligned} v_{ij}:=v_{(i,j)} = -{\dot{\varepsilon }}_{ij} = D_{ij} = \textstyle \frac{1}{2}(\nabla _iv_{j}+\nabla _jv_{i}) \,, \end{aligned}$$where differences between finite and linear strain theory are detailed, e.g., in Refs. [145,146,147]. Eigenvalues of the total strain rate \({\dot{\varepsilon }}_{ij}\) are positive for compression and negative for tension.

The symbol \(v_{ij}\) is usual in condensed matter physics [113, 120, 145, 148]; it is also the one employed in most previous GSH-publications. The notation \({D_{ij}}\) is common in theoretical mechanics [32, 107, 146], while \({\dot{\varepsilon }}_{ij}\), or \({\dot{\gamma }}\), are used, e.g., in soil mechanics and related literature [106, 122].

-

3.

Subscripts, such as i,j,k,l, refer to components of tensors in the usual index notation, with double-indices implying summation, the comma indicating a partial derivative, as in \(v_{(i,j)}\); the superscript \(^{*}\) denotes the respective traceless (deviatoric) tensor. Using the summation convention, the volumetric strain rate is abbreviated as: \({\dot{\varepsilon }}_v={\dot{\varepsilon }}_{ll}=-v_{ll}=-D_{ll}=-\mathrm{tr}{} \mathbf{D}\), where the last term is in symbolic tensor notation. The deviatoric strain rate is thus \({\dot{\varepsilon }}_{ij}^{*}=-v^{*}_{ij}=-D_{ij}^{*}\), with the norm \(v_s:=\sqrt{v^{*}_{ij}v^{*}_{ij}} =D_s={(2 J^{D}_2)^{1/2}}\), where \(J^{D}_2\) is the second deviatoric invariant, insensitive to the sign convention.

-

4.

The elastic (true) strain, \(\varepsilon ^{e}_{ij} \equiv - u_{ij} \), as properly defined in theoretical mechanics, e.g., see Refs. [145, 147], even for large deformations (implying the logarithmic definition due to its additivity, reversibility, and split-ability into isotropic and deviatoric contributions), is the tensorial state-variable on which the elastic (potential) energy depends. It is always well-defined and unique, in contrast to the total or plastic strains, which are not, and thus will not be used as state-variables for (constitutive) modeling. The respective strain rates, however, are well-defined and thus are used. The strain rate was already given (see item 2.), \({\dot{\varepsilon }}_{ij}=-v_{ij}\), so that the plastic strain rate is defined as: \(\textstyle {\dot{\varepsilon }}^{p}_{ij} ={\dot{\varepsilon }}_{ij}-\frac{d}{dt}\varepsilon ^{e}_{ij}\) (see also item 7.).

-

5.

The isotropic elastic strain

$$\begin{aligned} \varDelta := -u_{ll} = \varepsilon ^{e}_{ll} = \varepsilon ^{e}_v = \log \left( \rho /\rho _J\right) \end{aligned}$$is positive for compressionFootnote 5. It may be seen as the true (finite) strain relative to a stress-free reference configuration—for finite \(\varDelta > 0\). Arriving at \(\varDelta =0\), the system un-jams at \(\rho _J^{u}=\rho \) and the jamming density remains the actual one.Footnote 6

-

6.

The norm of the deviatoric elastic strain is, in accordance to the general scheme, \(u_s=\sqrt{u_{ij}^*u_{ij}^*}=(2 J^{u}_2)^{1/2}\).

-

7.

In general, we take \(\frac{\partial }{\partial t}\) as the partial time derivative, and \(\frac{d}{dt}\) as the total one, including all convective terms. Hence, with the vorticity tensor given as \(\varOmega _{ij} \equiv v_{[i,j]} \equiv \textstyle \frac{1}{2}(\nabla _iv_j-\nabla _jv_i)\), one has (as example) the total time derivative of the elastic strain

$$\begin{aligned} \textstyle { \frac{d}{dt} }\varepsilon _{ij}^e=\left( \textstyle { \frac{\partial }{\partial t}}+v_k \nabla _k\right) \varepsilon ^e_{ij}+\varOmega _{ik}\varepsilon ^e_{kj} -\varepsilon ^e_{ik}\varOmega _{kj} ~. \end{aligned}$$(1)Being off the focus here, the convective and vorticity terms are neglected, so that \(\textstyle {\frac{d}{dt} \equiv \frac{\partial }{\partial t}}\). The dots in \({\dot{\varepsilon }}^p_{ij}\) and \({\dot{\varepsilon }}_{ij}\) are only a (convention preserving) indication of rates, but do not represent the mathematical operation above.

-

8.

The total stress is not an independent state-variable, but rather given by the energy density and entropy production, as discussed in the classical GSH literature. In the simplified version, it may be written as \(\sigma _{ij}=\pi _{ij}+P_T\delta _{ij}+\sigma _{ij}^{\mathrm{visc.}}\), with elastic, kinetic/granular temperature and viscous contributions. The isotropic stress is referred to as pressure, \(P=\frac{1}{3}\sigma _{kk}\), the elastic pressure is \(P_\varDelta =\frac{1}{3}\pi _{kk}\), for three dimensions \({{\mathcal{D}}}=3\), and the deviatoric elastic stress is denoted as \(\pi ^*_{ij}=\sigma ^{e*}_{ij}\), with norm \(\pi _s = \sqrt{\pi ^*_{ij}\pi ^*_{ij}} = \sqrt{2 J_2^\pi }\).

Note that there are alternative definitions for shear/deviatoric stressFootnote 7.

-

9.

The symbols B and G are used in the definitions of, respectively, isotropic and deviatoric (shear) elastic energy density, \(w_e = w - w_T\), defined as the total minus the thermal energy density. In previous GSH-papers [47, 48, 112], the symbol A was used instead of G, but since A is here referred to as anisotropy, see Ref. [49], we stick to GFootnote 8.

-

10.

The granular temperature used in GSH is \(T_g \propto \sqrt{w_T}\), encompassing both kinetic and potential fluctuating energy contributions. The granular temperature used in kinetic theory and DEM is different, denoted as \(T_G = T_K = 2E_{\mathrm{kin}}/M{{\mathcal{D}}}\), with total mass of all particles, M, in dimension \({{\mathcal{D}}}\), ignoring the potential part. Comparing GSH-formulas in the gas limit to those of kinetic theory [7, 8, 114, 116, 119], one should remember

$$\begin{aligned} T_g^2\sim T_G ~. \end{aligned}$$(2)In the following, we will use \(T_{g}\)Footnote 9, with units of velocity, i.e., if scaled by the particle diameter, that of an inverse time, or a rate, very similar to the fluidity, g, studied and discussed in Ref. [18], and references thereinFootnote 10, Footnote 11.

1.8 Overview

In what follows, we shall, in Sect. 2, consider the significance of an inflection surface, of a convex-concave transition in the energy, as relevant for classical systems, transiently elastic systems and granular matter. We then present a review of GSH and new constitutive relations based on particle simulations, as well as a minimalist version, in Sect. 3, allowing for analytic solutions in Sect. 4, and numeric calculations to catch some transitions in Sect. 5. A quantitative comparison and calibration with particle simulations is carried out in Sect. 6, before we conclude in Sect. 7.

2 Equilibrium conditions and dissipative terms

In this section, we first revisit the reason for thermodynamic energy’s convexity, and derive the equilibrium conditions for three systems: elastic, transiently elastic and granular media. There is one equilibrium condition for each state-variable, that maximizes its contribution to entropy or, equivalently, minimizes its contribution to energy. Examples for equilibrium conditions are uniform temperatures and stress gradients proportional to density. As these conditions represent extremal points, the energy needs to be convex to be minimal, for the system to be stable.

Then we make the general point that every equilibrium condition, if not satisfied, is a dissipative channel that gives rise to a negative/dissipative term in the evolution equation of the associated state variable. As a result, the state-variable relaxes, towards satisfying the condition. In a closed system, all variables will eventually satisfy all their respective conditions, which is the state we called equilibrium.

If the energy is concave, equilibrium conditions represent maxima of the energy with respect to variation of a state-variable Footnote 12. The dissipative terms can thus drive the system away from equilibrium, producing, e.g., non-uniformity in temperature and non-equilibrium stress fields. When this happens, what micro-mechanical mechanisms it originates from, is necessarily more specific. How the dynamics further evolves depends on the system one considers. In the classical van der Waals theory of the gas-liquid transition, droplet formation is the basic mechanism. In granular media, we propose the following mechanism.

In the stable region, within the cone of Fig 2, the dissipative term in the equation for the elastic strain serves to maintain stress equilibrium. It remains inconspicuous as long as one studies the evolution of stresses close to equilibrium.

Outside the cone, beyond stability, it can force the system to leave equilibrium. Non-equilibrium stresses accelerate grains in varying directions, producing jiggling and thus granular temperature which, in turn, allows the stress to relax, pushing the system back into the convex region.

This is what we believe happens in grains at yield and beyond the transition. Setting up a dynamical model for following the system through the transition to different states is the main purpose of this paper.

2.1 Classical view on equilibrium states

Consider a system characterized by the state-variables density, \(\rho \), entropy density, s, and elastic strain,

with elastic displacement vector (field) \(U_i\), relative to the stress-free reference configuration, and a thermodynamic energy density that is a function of all state-variables, \(w=w(\rho ,s,u_{ij}) \) [113, 120].

Note that, for convenience, we spell out only the small-strain approximation in Eq. (3) [145,146,147], however, throughout, we work with the (logarithmic) Hencky finite (true) strain definition, due to its more favorable properties: additivity, reversibility, split-ability into isotropic and deviatoric parts, which allows the interpretation of \(\rho _J\) as the stress-free reference density, and thus allows us to work not only with hard but also with very soft materials.

A textbook proof of energy convexity considers only the entropy as a variable, and involves that the system is connected to a heat bath. A temperature fluctuation (associated to entropy fluctuations) vanishes only if the energy is larger with it than without, which is shown to imply convexity [149].

In a more general consideration, we start with the assumption that the system is stable and has an equilibrium for given values of \(\rho \), s and \(u_{ij}\). Since the elastic stress, \(\pi _{ij}\equiv -\partial w/\partial u_{ij}\) is symmetric, \(\pi _{ij}=\pi _{ji}\), we may write the total differential of the energy density as:

with gravitational potential \(\varPhi \), chemical potential \(\mu =\partial (w-\rho \varPhi )/\partial \rho \)Footnote 13, and temperature \(T=\partial w/\partial s\).

Varying this energy by

- (i):

-

keeping \(\int s\,\mathrm{d}V=const.\), or \(\delta \int \left( w-T_Ls\right) \,\mathrm{d}V = 0\), with Lagrange parameter \(T_L=const.\);

- (ii):

-

keeping \(\int \rho \,\mathrm{d}V=const.\), or \(\delta \int \left( w-\mu _L \rho \right) \,\mathrm{d}V = 0\), with Lagrange parameter \(\mu _L=const.\);

- (iii):

-

forbidding external work, i.e., assuming a closed system: \(\oint {\pi _{ij}}\delta U_i\,\mathrm{d}A _j=0\); and

- (iv):

-

using Gauss’ theoremFootnote 14, yields

$$\begin{aligned} 0 =&\int \left[ {T}\delta s -\pi _{ij}\delta \nabla _jU_i + (\mu +\varPhi ) \delta \rho - T_L\delta s - \mu _L \delta \rho \right] \,\mathrm{d}V \nonumber \\ =&\int \left[ \left( {T}-T_L\right) \delta s + {(} \nabla _j{\pi _{ij}} {)} \delta U_i + \left( {\mu }+\varPhi -\mu _L\right) \delta \rho \right] \,\mathrm{d}V \, , \end{aligned}$$(5)

with either \(\delta \rho \), \(\delta s\) or \(\delta U_i\) varying independently, while keeping the others constant. The split-up equilibrium (extremal) conditions may now be written as:

with the total equilibrium stress \(\sigma ^{eq}_{ij}\)Footnote 15. They represent an energy minimum—and stable equilibrium—only if deviations from them yield an energy increase.

2.2 The limit of solid elasticity

Elasticity (reversibility) corresponds to the unique dependence between density and isotropic elastic strain increment, \(\delta u_{ii} = - \delta \rho / \rho \), or, integrated, \(\varDelta = - u_{ii} = \log (\rho /\rho _0)\), the logarithmic (true) isotropic elastic strain, where \(\rho _0\) is the density of the stress free reference configurationFootnote 16. This allows to rewriteFootnote 17 the integral

which now implies, in conjunction with Eq. (5):

(or \(\nabla _j\pi _{ij} = \rho g_i\), for \(P_T=0\)), with the thermal contribution to stress, \(P_T = - \partial ((w-w_e)/\rho ) / \partial (1/\rho )\), using volume, i.e., inverse density \(1/\rho \propto V\), as state-variable, as discussed in more detail in Sect. 3.1.1.

Next, inserting \(T=T^{eq}+\delta T\), \(\pi _{ij}=\pi _{ij}^{eq}+\delta \pi _{ij}\), with \(\nabla _iT^{eq}=0\) and \(\nabla _j\pi _{ij}^{eq}= {\rho g_i}\), we require

Assuming first \(\delta u_{ij}\equiv 0\), we may write \(\delta ^2 w=\delta T\delta s=({\partial T}/{\partial s})(\delta s)^2>0\), implying

or that the energy w is a convex function of s. As a result, temperature fluctuations will diminish, and the state characterized by a uniform temperature is a stable equilibrium. Conversely, if the energy is concave, \(\partial ^2 w/\partial s^2<0\), the condition \(\nabla _iT=0\) represents a maximum of energy, and the system is unstable. Any fluctuations in entropy will move it away from uniform temperature. In the case of the van der Waals transition between gas and liquid, a uniform single-phase system is moved to the coexistence of two phases, with different entropy densities, but the same temperature.

Next, assuming \(\delta s\equiv 0\), as used explicitly below, in Sect. 3.2.2 and 3.2.3, we order the six components of \(\pi _{ij}\) and \(u_{ij}\) each as a 6-tuple vector, denoted by Greek letters, and require

This implies that the \(6\times 6\) Hessian matrix

implying that the elastic energy \(w_e\) is a convex function of the elastic strain \(u_{ij}\). If there is at least one negative eigenvalue, the condition \(\nabla _j\pi _{ij}= {\rho g_i}\) no longer represents a stable state, because along the associated eigenvector, the energy is a maximum. The system can and will depart from its previously stable elastic state, initially by violating \(\nabla _j\pi _{ij}= {\rho g_i}\), typically rendering the stress in non-equilibrium.

To obtain stable, static elastic solutions, one has to solve \(\nabla _j\pi _{ij}= {\rho g_i}\) for given boundary conditions. This is equivalent to looking for minima of the elastic energy. The solutions are stable if the elastic energy is convex and unstable otherwise.

The more general consideration, including both \(\delta s\) and \(\delta u_{ij}\), leads to a \(7\times 7\) matrix that, for stable equilibria, must possess seven positive eigenvalues.

A complete consideration for elasticity requires also the inclusion of density, \(\rho \), and momentum density \(\rho v_i\) (conjugate to \(v_i\)) as the energy’s variables. This, being somewhat more lengthy, would distract from the present concern. The associated equilibrium conditions, with the chemical potential, \(\mu =\partial w/\partial \rho \) (conjugate to \(\rho \), see Refs. [123, 150]), are:

All three equations, together, express minimal energy, or maximal entropy.

If any of the equilibrium conditionsFootnote 18 are not satisfied, dissipative currents appear to counteract: heat diffusion \(\sim \nabla _iT\) in the evolution equation for s, viscous stress \(\sim v_{ij}\) in the evolution equation for \(\rho v_i\), and a term \(\sim {\nabla _k\pi _{ik}-\rho g_i = \nabla _k\pi _{ik}-\rho \nabla _i \mu } \), in the equation for the “dissipative displacement rate”:

Analogous to heat-conductivity, \(\beta \) quantifies the strength of the dissipation, carrying units of time divided by density, a mere abbreviation; taking it as a scalar is a simplification. All these terms serve the sole purpose of restoring the respective equilibrium conditions: \( {\nabla _iT=0, ~v_{ij}=0, ~\nabla _k\pi _{ik}=\rho g_i}\).

The dissipative displacement rate, as a necessary result of thermodynamics, has been first recognized in the classical 1972-paper: “The unified hydrodynamic theory for crystals, liquid crystals, and normal fluids”, by Martin et al. [148]. It drives the system, boundary conditions permitting, towards a constant stress gradient, \(\nabla _k\pi _{ik}=\rho g_i\). If on top of this equilibrium state, the stress varies, such as in elastic waves, the dissipative displacement rate, contributes to wave damping. If one concentrates on the evolution of stresses in equilibrium, this term vanishes and is irrelevant. However, if the energy is concave, this term can drive the system away from equilibrium and even can result in instabilities (numerical as well as physical). Writing the elastic stress gradient in the notation of the \(6\times 6\) matrix, see Eq. (11), as:

since \(\partial \mu /\partial u_\beta = \partial \varPhi /\partial u_\beta = 0\), we see that, if the matrix, \(\partial \pi _{\alpha }/\partial u_{\beta }\), has a negative eigenvalue, the corresponding term will flip its sign. Instead of keeping maintaining stress equilibrium, it can drive the stress away from equilibrium. This, in turn, accelerates mass points, possibly leading to non-uniform velocities, \(v_i\), and thus finite strain rates, \(v_{ij}\equiv -{\dot{\varepsilon }}_{ij}\). Initially, the stress perturbation will grow along the direction associated with the negative eigenvalue, but for finite times, this is by no means true, as the system will try to move towards a new stable equilibrium state, whatever that is. See the next Sect. 4 and 5 about what happens in granular matter without gradients. Discussing the possibility of a relation to gradient plasticity is beyond the scope of this paper.

Inserting Eq. (15) in the definition of the elastic strain, Eq. (3), reads

which seems to suggest that the “dissipative current”, \(\psi _{ij}\), is simply the plastic strain rate, \(\psi _{ij} ={\dot{\varepsilon }}^p_{ij}\), which apparently exists even in classical solids if the stress is not in equilibrium. This could be confusing, as it is not related to typical plasticity formulations, and neither is it connected to concepts of plastic potentials or flow functions (see Refs. [32, 34, 122]). The term plastic strain rate is more appropriate for the other dissipative contributions discussed in the next two sections, on transient elasticity and granular media.

Note that heat diffusion and viscous stress exist in any system, in which entropy and momentum are state-variables: liquids, solids, granular media, irrespective of the microscopic interaction. Same holds for the dissipative term \(\psi _{ij}\), which exists in any system in which the elastic strain is a variable. This is the reason it also exists in granular media. Generally speaking, every dissipative term strives to satisfy its equilibrium condition by changing the value or distribution of the associated state-variable. Equilibrium is achieved if all equilibrium conditions are satisfied, as entropy is then maximal.

2.3 Transient elasticity and plasticity

There are many transiently elastic systems in nature. If quickly deformed, they are elastic and capable of restoring their original shape. But this does not happen if the deformation is kept longer; then the deformation is irreversible, plastic. One example are polymeric melts that consist of entangled elastic strands, which elastically deform, but disentangle if given enough time. This leads to a reduction, and eventually vanishing, of the elastic stress. For such systems, the equilibrium condition is:

Consequently, Eq. (17) takes the form:

with the plastic strain rate now a relaxation term, with a positive coefficient \(\lambda _e\). Employing essentially this equation, including the convective terms of Eq. (1), a wide range of polymer behavior including shear thinning/thickening and the Weissenberg or rod-climbing effect were reproduced [151, 152].

It is noteworthy that the plastic strain rate in the form \({\dot{\varepsilon }}^p_{ij} = -\lambda _e u_{ij}\) is a diagonal Onsager term, quantify dissipative currents that drive the system towards the respective equilibrium, in this case of the elastic strain. Hence, off-diagonal ones such as

are also permitted (in this case strain-rate causes dissipative currents that drive elastic strain to equilibrium). They will turn out to be useful in granular physics, see below, Eq. (26), and the discussion below it.

The close link, even identity, between transient elasticity and strain relaxation on one hand, and plastic behavior of irreversible shape change on the other, is a useful insight. Similarly useful is the understanding of the difference between elasticity and transient elasticity. For the latter to be in equilibrium, the elastic stress has to vanish, while a constant stress suffices for the former. For verbal clarity, we denote

where “plastic equilibrium” is short for “transiently elastic, long-term equilibrium”.

There is a further subtlety that we must address here. If the polymer energy depends on both the density and the elastic strain, there are two contributions in the stress: the pressure as given by Eq. (14) and the elastic stress. Then the system may possess an equilibrium pressure even when Eq. (21) holds. However, if the density is not an independent state-variable, implying \(P\equiv 0\), an equilibrium pressure needs a finite \(\varDelta \equiv -u_{ll}\) to be sustained, and \(u_{ij}=0\) cannot be the equilibrium condition. Rather, it is given as

the vanishing of the deviatoric part, while the trace \(\varDelta \), not independent from the density, simply follows the dynamics of the density. It does not relax.

Note that the relaxation time of \(\varDelta \) and \(u_s\) need not be the same. If that of \(\varDelta \) is especially long, it may be neglected for certain phenomena, for which the dynamics is governed by \({\dot{\varepsilon }}^p_{ij} =-\lambda _e u_{ij}^*\) alone.

When the system is crossing an inflection surface, the term \(-\lambda _e u_{ij}\), in Eq. (19) is not affected, and continues to push the elastic strain towards \(u_{ij}=0\).

2.4 Granular matter

GSH was set up in compliance with thermodynamics and conservation laws. Here, we discuss its structural part, necessary if one is to be consistent with the general principles of physics. In Sect. 3, a reduced complete version of GSH is presented, including a few, as simple as possible constitutive choices, which will be employed later to study the jamming and un-jamming dynamics.

Two basic pieces of physics characterize granular media: (1) They have two entropies: \(s_g\) for the granular degrees of freedom and s for the much more numerous microscopic ones. (2) Depending on circumstances, granular media may be elastic or transiently elastic. Both elastic and plastic equilibria of Eqs. (21) are therefore relevant. However, note that the equilibrium (limit) state is not necessarily ever reached, neither under permanent deformation, nor under free relaxation. In the former case, the system is permanently pulled away from the equilibrium (steady state is not equal to equilibrium), while in the latter, if \(T_g\) relaxes fast enough, the equilibrium cannot be realized by the other state-variables either.

Including \(s_g\) as an extra state-variable, with \(T_g \equiv \partial w/\partial s_g\), the equilibrium condition is \(T=T_g\), obtained by maximizing \(\int (s+s_g)\mathrm{d}V\approx \int s\,\mathrm{d}V\), where \(s_g \ll s\) may be ignored. The equilibrium condition implies that all degrees of freedom, microscopic as well as granular ones, will eventually equilibrate with one another. Furthermore, since for particles of grain size well above molecular size, already for tiny velocity fluctuations (jiggling), one typically has \(T_g \gg T\) by many orders of magnitude, \(\sim 10^{10}\), see item 10. in Sect. 1.7, we may set the equilibrium granular temperature to zero,

In analogy to the relaxation terms discussed above, the evolution equation for \(s_g\) must therefore possess a relaxation term \(\sim T_g\), pushing \(s_g\) towards \(s_g \propto T_g=0\). This dissipation/relaxation takes place due to collisions, with rate \(\sim T_g\), in the collisional gas- and fluid-like regime. In addition, analogous to the viscous heating term in the hydrodynamic theory of Newtonian fluids, which transfers kinetic energy into heat, via \(\eta v_{ij}^*v_{ij}^*\equiv \eta v_s^2 \rightarrow T \textstyle {\frac{\partial }{\partial t}} s\), there is a term that transfers kinetic energy into “granular heat”, \(\eta _gv_s^2\rightarrow T_g\textstyle {\frac{\partial }{\partial t}} s_g\). Therefore, assuming \(\nabla _i T_g=0\), and ignoring other gradients, the evolution equation for granular energy reads

with coefficient \(\gamma =\gamma (T_g)\) dependent on \(T_g\), and the compressional viscosity neglected, like convective and diffusive terms, for the sake of brevity. To be used in the following, after division by \(T_g\) and some re-writing, the evolution equation for granular temperature reads:

The effective rate of dissipation \(T_g^* = T_g + T_e\) is discussed in more detailFootnote 19 below in Sects. 3.1 and 4.

For given deviatoric (shear) strain rate, \(v_s=|v_{ij}^*|=|-{\dot{\varepsilon }}_{ij}^*|\), the steady state solution is given and discussed in Sect. 4.6 in the limit cases \(\gamma _0\ll \gamma _1T_g\) and \(T_e \ll T_g\):

a result known to hold in granular gasesFootnote 20, up to moderate densities [7, 8, 116]. In this case, the system is in the rate-independent elasto-plastic regime, where the granular temperature is proportional to the strain rate. For diminishing \(T_g \ll T_e\) and \(\gamma _0\gg \gamma _1T_g\), we have an exponential and much faster decay, \({\frac{\partial }{\partial t}}T_g \propto -T_g\), however, also here the steady state granular temperature persists and remains relevant, as \(T_g^{(e)} \approx (T_g^{(ss)})^2/T_e\), see Sect. 4.6.

Returning to the elastic strain \(u_{ij}\), we note that granular media are elastic for quiescent grains, \(T_g=0\), as slopes of sand-piles demonstrate. If the particles “jiggle”, \(T_g\not =0\), the elastic shear strain and stress will diminish, and eventually vanish: Tapping a vessel of grains (with a finite number) long (and strong) enough results in a flattened granular surface, like in transient elasticity. Combining both conditions of Eqs. (21), the evolution equation for the elastic strain contains different types of plastic strain rates, see also Ref. [21, 107] and Eqs. (17), and (20),

where the first term on the right, pushing \(u_{ij}\) towards the plastic minimum \(u_{ij}=0\), operates only for \(T_g\not =0\), representing the fluctuation driven plastic strain rate.

The second term represents strain-driven plastic deformations. Note that the probabilities \(p_{ijkl}\) occur well within the macroscopic, elastically stable regime—involving possibly local events, on the particle scale—and will be simplifiedFootnote 21 using only the respective purely isotropic and deviatoric (shear) plastic deformation probabilities, \(p_v\) and \(p_s\), see Sect. 4.1Footnote 22. The micro-mechanical origins of these probabilities, are not addressed here, rather see Refs. [14, 18,19,20, 28, 34, 49, 129] and many more references therein. There—among other considerations—it is shown that (finite) granular systems can remain elastic for tiny strain, then have localized plastic events at larger strain with probability increasing, before (global) yield takes place with particular probabilities as cast into a meso-scale, stochastic master-equation approach, in Refs. [50, 153, 154].

The third term, the dissipative current, \(\psi _{ij}\), depends on the equilibrium condition for the gradient of the elastic stress, see Refs. [47, 112], and thus vanishes for stress in equilibrium—or constant stress, for homogeneous/uniform systems in the absence of gravity—as relevant in the following sections. As discussed above, around Eq. (17), the dissipative current, \(\psi _{ij}\), pushes \(u_{ij}\) towards the elastic equilibrium in the energetically convex region, and away from it in the concave one, since it changes sign at the transition.

2.4.1 Dynamics at constant shear rate or stress

Equation (26), in addition to the dynamics of \(T_g\), Eq. (24), render granular behavior rather more complex than the superposition of behavior from polymers and elastic media. Imposing either a constant shear rate or a constant elastic stress in a polymer melt, Eq. (19), the steady state result is the same, \(v_s=\lambda _e u_s\), in either case.

This symmetry does not hold for granular media—not even for the simplest case with \(T_e=0\), and \(p=0\). A constant shear rate, \({\hat{v}}_s\), where the hat indicates the fact that this quantity is fixed/controlled, with the stationary solution \(T_g^{(s)}={\hat{v}}_s\sqrt{\eta _1/\gamma _1}\) inserted into Eq. (26), ignoring the p-terms on the r.h.s., leads to a rate-independent evolution equation for \(u_{ij}\) that possesses the hypoplastic structure [155], since \(T_g\) is taking a value proportional to the absolute value of the strain rate. The steady state elastic shear strain is thus: \(u_s^{(s)}=\sqrt{\gamma _1/\eta _1}/\lambda \). It accounts well for elasto-plastic motion [156], including the approach to the critical state and shear jamming [47, 48, 157, 158].

On the other hand, controlling the stress or, equivalently, holding the elastic strain, \({\hat{u}}_s\), constant and inserting the stationary limit of Eq. (26), \(v_s^{(u)}=\lambda T_g {\hat{u}}_s\), into Eq. (24), yields the relaxation rate: \(\gamma _c = ( \gamma _1 - \eta _1 \lambda ^2 u_s^2) = \gamma _1 [ 1 - (u_s/u_s^c)^2 ]\), negative if \({\hat{u}}_s < u_s^{c}=u_s^{(s)}=\sqrt{\gamma _1/\eta _1}/\lambda \), the case when we find \(T_g\) to relax to zero, pushing the system into a static state, \(v_s^{(u)} \rightarrow 0\).

The relaxation rate vanishes (i.e., the relaxation time diverges) as the stress (or elastic strain) approaches the critical value, \(u_s^c\). With a further increase of \(u_s\), the rate flips sign to positive above the critical value, see [47, 48], creating an ever increasing strain rate \(v_s^{(u)}\). Accordingly, switching from an imposed shear rate (say during an approach to the critical state) to an imposed sub-critical stress will render the system static due to the relaxation of \(T_g\), whereas a critical or super-critical stress will create \(T_g\) and thus accelerate the flow, since \(v_s \propto T_g\).

2.4.2 Dynamics in the concave region

Within the cone of Fig. 2, in the energetically convex region, as long as one considers only the evolution of stress close to equilibrium, the dissipative current, \(\psi _{ij}={\textstyle \frac{1}{2}} \left( \nabla _i[\beta (\nabla _k\pi _{jk} {-\rho g_j}) ]+\nabla _j[\beta (\nabla _k\pi _{ik} {-\rho g_j}) ] \right) ,\) remains close to zero, see also Eq. (26) and the discussion below it. Serving to maintain stress equilibrium, it may simply be neglected. Perturbing the system by a (local) stress, \(\delta \pi _{ij}\), from a static situation, in the convex, stable region, results in a relaxation of the elastic strain, due to the sign of \(\psi _{ij}\). In contrast, in the concave region, because of Eq. (16), the relaxation turns into an explosion, and can drive the stress towards further, stronger non-uniformity.

This accelerates the grains, locally, leading to non-uniform velocities \(v_i\) and finite strain rates, \(v_{ij}\equiv -{\dot{\varepsilon }}_{ij}\not =0\). The latter serve as a source for granular heat, see Eq. (24), and create considerable \(T_g\), which activates the first plastic term of Eq. (26), which relaxes the stress back into the stable, convex region. Hence, although the imposed perturbation creates a local stress response along the direction associated with the negative eigenvalue initially, it is the stress relaxation back to the convex region that dominates for finite times. If not strong/fast enough, the system will yield or un-jam dynamically. This is one way how GSH accounts for stability and un-jamming dynamics by instability, both mediated by the granular temperature

Unfortunately, including the elastic stress-gradient driven plastic strain rate renders Eq. (26) an unstable partial differential equation, the solution of which requires increased technical efforts. This is undesirable in a first, qualitative study, and an approximation scheme may prove useful. We suggest to go on neglecting the elastic dissipative terms, and to add a stress term to Eq. (24), such that \(T_g\) is directly produced by an elastic stress. The balance equations for \(s, s_g\), for the energetically convex region, are given as

The equally permissible alternative,

was not adopted, because any static \(\pi _{ij}\) would then produce \(T_g\), leading to its decay. This is not observed in static granular media that can sustain finite stresses indefinitely (see sand-piles)—if not perturbed externally. Yet the reasoning is not valid outside the cone, where static stresses are not stable. Hence we combine Eq. (27) with (30), noting

the elastically stable cone. The explicit forms for \(\beta _{ijkl}\) and \({\bar{\beta }}_{ijkl}\), which carry the units of inverse stress (compliance) rate, are constitutive choices that will be discussed in the next section in some detail for \(\beta _{ijkl}\), while a very simple model for \({\bar{\beta }}_{ijkl}\) will be presented in Sect. 4.9 and studied in Sect. 5.

2.5 Second law of thermodynamics

The second law of thermodynamics (the balance of thermal and granular entropy) from Eqs. (27) and (28) can be summarized as \(R>0\) and \(R_g+\gamma T_g^2>0\) (since both represent dissipative, irreversible processes), or combined:

noting that the dissipation of granular energy \(-\gamma T_g^2\) irreversibly enters the thermal energy, thus cancelling itself in \(R+R_g\). More general, the total production of entropy can be re-phrased [48, 107, 109, 110] as:

where the dissipative displacement rate, \(Y_i\), as defined above in Eq. (15), being proportional to \(\nabla _k \pi _{ik}- \rho g_i\) itself, renders the last term positive. Next, more complex expressions are needed for the evolution of the elastic strain, \(\varepsilon ^e_{ij}= {\dot{\varepsilon }}_{ij}- {\dot{\varepsilon }}^p_{ij}\), and the a-priori unknown viscous/dissipative stress, \(\sigma ^D_{ij}\), for both of which the isotropic and deviatoric parts can—and are assumed to—evolve independently from each other. As example, where the dissipative stress and the dissipative current are not shown for the sake of brevity, inserting the constitutive relation from Eq. (26), leads to the following split-up:

where the dots remind us of ignored terms (all \(\ge 0\)).

The first and second term in Eq. (34) represent entropy production by fluctuation driven relaxation and are always positive. In general, the isotropic term can have a different coefficient, \(\lambda _1 \ne \lambda \). In contrast, the third and fourth term are due to plastic (re-arrangements) driven by isotropic and deviatoric strain, respectively. They can be either positive or negative, dependent on the direction of the strain rateFootnote 23. The third term is negative for extension (\({\dot{\varepsilon }}_{v}<0\)), while the fourth term is negative, in particular, at strain reversal. If negative, these contributions must be compensated by positive production terms, as derived nextFootnote 24, or the probabilities could be set to zero, as will be discussed in more detail in Sect. 4.

The general approach to construct the viscous/dissipative stress from an inserted plastic strain rate is using the Onsager matrix (also to establish time-inversion symmetry, which is not discussed here), from the appendix in Ref. [107]. After ignoring gradients of temperature and thus heat fluxes, as well as all associated terms, one can transform all tensors into eigen-value formFootnote 25, which also implies a signed variable \(\alpha _s\)Footnote 26. This results in only two independent invariants per state-variable tensor, ignoring the third for the sake of simplicity, yielding a \(4 \times 4\) matrix form to determine plastic strains and dissipative stresses:

with 4-tuple vectors of the invariants of the state-variables or their conjugates (pressure \(P_\varDelta = {{\mathcal{B}}}_\varDelta \varDelta \) and shear stress norm \(\pi _s=\pm |\pi _{ij}| = \mathrm{sign}(\pi )|\pi _{ij}|={{\mathcal{G}}}_\varDelta \varepsilon ^e_s\)), with secant moduli assumed constant in the momentary configuration, above jamming (cases below jamming, \(\varDelta <0\), are briefly discussed at the end of this section).

One can interpret the diagonal (off-diagonal) terms as quantifying the dissipative currents that drive the system towards its equilibrium—of the respective (cross-coupled) state-variable. For example, \(e_{ss}\) quantifies the dissipative current caused by \(\varepsilon ^e_s\), driving itself to equilibrium, while \(e_{vs}\) quantifies the dissipative current caused by \(\varepsilon ^e_s\), driving the volumetric elastic strain, \(\varepsilon ^e_v\), to equilibrium.

Other terms, like \(\eta _{vv}\) (\(\eta _{ss}\)), quantify the volumetric (deviatoric) dissipative stresses, i.e., momentum current density, caused by isotropic (shear) strain, driving themselves to equilibrium, while cross-terms are ignored hereFootnote 27. The off-diagonal terms are non-symmetric, e.g., \(h_{vs}\) cross-couples plastic strain (dissipative current) caused by shear strain that drives volumetric elastic strain to equilibrium and, at the same time, cross-couples dissipative shear stress with isotropic elastic stress, involving the modulus \({{\mathcal{B}}}_\varDelta \)Footnote 28. The diagonal term \(-\gamma T_g\) driving granular temperature to equilibrium, represents a source term for temperature, T, and is not shown here, like all related off-diagonal terms (set to zero).

The plastic strain rates (placeholder for strain-rate minus elastic strain, which is the state-variable) are thus:

and

while the dissipative stresses are

and

where the probabilities \({p_v}\) and \({p_s}\) vanish if the strain-rate is zero, i.e., they represent strain-activated dissipative stresses, different from the strain-rate activated viscous stresses, as in the first terms.

For the sake of brevity, some of the above terms are not used further on, i.e., while the \(\alpha _1\)-term will be used, only a placeholder is given for \({\alpha _{sv}}=\alpha _s \varDelta {\dot{\varepsilon }}_v(1-{p_v})\); similarly, for the dissipative stresses, only the first terms are used in some (numerical) solutions (even though small), while the other terms are subject to ongoing studies. The only non-classical term used is the granular energy creation, active outside the elastically stable regime, abbreviated as \({f_g} = {\bar{\beta }}_{ijkl} \pi _{ij} \pi _{kl}\), defined in subsection 2.4.2, and used below in Sect. 4.

Inserting the above expressions into Eq. (33) results in an always positive total entropy production:

which is true by construction, since all terms are quadratic in either elastic strains (stresses) or strain rates. The first two terms are a simple constitutive choice for the more general forms in Eq. (32), with purely isotropic, \(\beta _v = \lambda _1 T_g / {{\mathcal{B}}}_\varDelta \), and deviatoric, \(\beta _s=\lambda T_g / {{\mathcal{G}}}_\varDelta \), compliance rates.

Below jamming, one has (per definition) no elastic stress with purely plastic deformations, with probabilities, \({p_v}={p_s}=1\), and thus only the viscous terms survive in Eq. (36). On the other hand, in the ideal elastic limit, above jamming, one has no plastic deformations, \({p_v}={p_s}=0\), so that the classical GSH shows up with only the \(\lambda \)-preceded relaxation terms surviving (and the \(\alpha \)-preceded terms in plastic strains and dissipative stresses cancelling each other).

The question how to split up R and \(R_g\), as well as related questions about the discrete nature of plastic (re-arrangement) events, and the principle of time-reversal symmetry are subject of ongoing research [21, 159].

3 Granular solid hydrodynamics (GSH)

As review, GSH is a continuum mechanical theory for granular media, set up in compliance with thermodynamics and conservation laws. GSH possesses the state-variables:

- (i):

-

density, \(\rho \), or volume fraction, \(\phi =\rho /\rho _p\),

- (ii):

-

momentum density, \(\rho v_i=0\), neglected here,

- (iii):

-

elastic isotropic strain \(\varDelta =-u_{ll}=\varepsilon ^e_v=\log \left( \rho /\rho _J \right) \),

- (iv):

-

elastic deviatoric (shear) strain \(u_s=\sqrt{2 J^{u}_2}\),

- (v):

-

granular temperature \(T_G \propto T_g^2\), and

- (vi):

-

temperature T, not used in the following, conventions/nomenclature are given in Sect. 1.7.

The GSH used here reduces to various different, more classical theories, in the respective limits—when set appropriately, as was shown in: Refs. [156] for hypoplasticity, [160] for the \(\mu (I)\)-rheology, and [47] for fluidity, etc. The question is now if it is possible to catch the complex phenomenology at yielding, jamming, un-jamming, elasticity and loss of elasticity with a simple model that only knows about four state-variables: \(\rho \), \(\varDelta \), \(u_s\), and \(T_g\).

For the sake of completeness, we first recollect the more complex, more complete classical GSH, as published in the previous years, in Sect. 3.1, before we reduce GSH to an over-simplified minimal model in Sect. 3.2, which will allow for a better understanding of the structure of GSH. Note that the nomenclature of classical GSH is applied in Sect. 3.1, whereas we switch to the positive compressive strain convention and nomenclature in Sect. 3.2.

3.1 About classical GSH

The complete equations of GSH may be found in Refs. [47, 112], a simplified version in Ref. [48], from which we boil down to a minimalistic version in Sect. 3.2, ignoring not only momentum density and gradients, but also the density dependence of most transport coefficients and parameters, since those represent top-down constitutive assumptions, rather than basic (qualitative, bottom-up) theory. First, we discuss a few complications in the classical GSH nomenclature, that are not necessary for our present focus, but will become important if a more quantitative model is the goal, so that we keep them as reference for the sake of completeness.

3.1.1 The classical GSH constitutive model

The energy density has a granular thermal and an elastic part:

This represents the first constitutive assumption at the core of classical GSH. In the following, we drop the explicit \(\rho \)-dependence of B and G for convenience, but keep in mind and used it whenever needed. (In previous GSH-publications, G was denoted as \({{\mathcal{A}}}\).). The elastic stresses are defined as the derivatives of w with respect to the elastic strain \(u_{ij}\):

with \(P_\varDelta \equiv \pi _{\ell \ell }/3,\) which represent no constitutive assumptions, but are just a consequence of Eq. (37). Like the elastic stress, being conjugate to the elastic strain, the granular temperature is conjugate to the granular entropy, which allows to define the thermal pressure, \(P_T\), as the derivative of the granular thermal free energy with respect to volume, at constant \(s_g\) or \(T_g\), as:

where we note that the granular entropy is not needed, replaced by the density dependent (positive) function \(b=b(\rho )\), decaying with density, \(\partial b/\partial \rho < 0\).

The elastic energy \(w_\varDelta \) has been tested for: (1) static stress distributions in silos, sand piles, point loads on a granular sheet [161]; (2) incremental stress-strain relations from varying static stresses [162]; (3) propagation of elastic waves at varying stresses [163].

As already observed in Ref. [112], \(w_\varDelta \) is convex if:

For more details see Sect. 3.4. Because the macroscopic friction, or yield limit, \(\mu _0 \sim \sqrt{2G/{B}}\), is observed to be not (or only weakly) density dependent, in steady state, at least for cohesionless granular media, the next constitutive model assumption used is: \(G/{B}=const.\), and

where \({B}_0>0\) is a constant, and \({\bar{\rho }}\equiv \frac{1}{9}(20\rho _{\ell p}-11\rho _{cp})\), with \(\rho _{cp}-\rho _{\ell p}\approx \rho _{\ell p} -{\bar{\rho }}\). (\(\rho _{cp}\) is the random-close packing density, the highest one at which grains may remain uncompressed, \(\rho _{\ell p}\) is the random-loose packing density, the lowest one at which grains may stay static.) The expression for B was empirically constructed to account for three granular characteristics: (1) It provides concavity, for any density smaller than \(\rho < \rho _{\ell p}\), and convexity between \(\rho _{\ell p}\) and \(\rho _{cp}\), ensuring the stability of elastic solutions in this region. (2) The density dependence of sound velocities, c (as measured by Hardin and Richart [164]), is well approximated by \(c=\sqrt{{{\mathcal{B}}}/\rho } \approx \sqrt{B\varDelta ^{1/2}/\rho }\). (3) The slow divergence at \(\rho _{cp}\) mimics the fact that the system is much stiffer for \(\rho =\rho _{cp}\) than at loose packing \(B(\rho = \rho _{\ell p})\). Comparing these constitutive assumptions for G and B with particle simulations is subject of ongoing workFootnote 29.

Finally, in 3D, the function b was chosen [47] as:

with another small power law, \(a\approx 0.1\), such that \(P_T \approx w_T\) for \(\rho \rightarrow 0\), and \(P_T \approx w_T/(1-\rho /\rho _{cp})\) for \(\rho \rightarrow \rho _{cp}\), limits which reduce b to first or second term, respectively.

The thermal pressure, explicitly given as:

defines the (positive, dimensionless) abbreviation

for the term in brackets, as set to constant in the following sections, a good approximation only for low densities, where the ideal gas pressure, \(P_T=\textstyle {\frac{{\mathcal{D}}}{2}}\rho T_g^2\), with \(G_p \approx 1\), defines the coefficient \(b_1={{\mathcal{D}}} \rho _p\), so that \(b=b_1/(2\rho ) = {{\mathcal{D}}}/(2\phi )\) .

In the regime of standard kinetic theory being valid, and with \(T_g\) carrying units of diameter, d, and rate, i.e., inverse time, one has a different, analytically known \(G_{\mathrm{SKT}}=\left[ 1+({{\mathcal{D}}}-1) (1+r) \phi g_2(\phi ) \right] \), with restitution coefficient r and pair correlation at contact, \(g_2(\phi )\).Footnote 30 For more details, in particular for the other transport coefficients, see Refs. [8, 116, 118, 166].

Adding some speculative connection to other works, the function b is qualitatively similar to the density dependence, \(F=gd/\delta v\), of the scaled fluidity, g, as reported in Ref. [18]. However, note that the fluidity is based on shear stress and shear strain only, whereas the thermal stress, \(P_T/G_p = \rho T_g^2 = \rho (\delta v/d)^2 \sim \rho (g/F)^2\) is also defined for isotropic deformations, i.e., non-sheared systems. Whether g and \(F(\rho )\) are truly related with \(T_g\) and \(G_p(\rho )\), and how exactly, is subject of ongoing research and goes beyond the scope of this paper.

3.1.2 The evolution equations

For completeness, we specify the evolution equations in the classical GSH nomenclature, where we note the sign conventions \(\varDelta =\varepsilon ^e_v\), \(u_{ij}=-\varepsilon ^e_{ij}\) and \(v_{ij}=-{\dot{\varepsilon }}_{ij}\), see Sect. 1.7. For the elastic strain one has:

with \(\alpha _1\) as an off-diagonal Onsager coefficient, see Sect. 2.5, accounting for Reynolds dilatancy.

Mass and momentum conservation read:

with the total stress: \(\sigma _{ij}=\pi _{ij}+P_T\delta _{ij}-\eta _1T_g v^*_{ij}\), with viscosity, \(\eta _g=\eta _1 T_g\).

Finally, the evolution equation for \(T_g\), with b as given by Eq. (41) and \(T_g^*\equiv T_g+\gamma _0/\gamma _1=:T_g+T_e\), is given by Eq. (25).

The coefficients \(\alpha _1,\gamma _0,\gamma _1,\eta _1\), and \(\rho b\) are all functions of the state variables, especially the density, which would require many more constitutive assumptions, so that they are over-simplified and taken as constants in the following sections. Alternative energy densities are compared next.

3.2 Minimal GSH type model for a material point

At the core of GSH, assuming a homogeneous representative volume, without convection, \(\rho v_i = 0\) and gradients, \(\nabla _i (...) = 0\), one has a postulated energy density,

with an elastic and a dynamic, kinetic/granular contribution. The total stress is thus not an independent (state) variable, but can be abbreviated as

where the five terms represent isotropic and deviatoric elastic stresses, kinetic/granular stress (with an over-simplified \(G_p=1\), which should depend—at least—on density, see Eq. (46)), and isotropic (v=volumetric) and deviatoric (s=shear) viscous stresses, with viscosities \(\chi =\eta _v\) and \(\eta =\eta _1=\eta _s\), respectively, where the subscript 1 was used above. Additional dissipative stresses are derived and shown in Sect. 2.5, but are mostly ignored further on.

Now, a few versions of the energy density are discussed, before elastic energy stability is considered in the next Sect. 3.4.

3.2.1 The linear elastic energy

For completeness, in the (too) simple case of a linear elastic energy density:

and \(w_{lin}=0 ~\mathrm{if}~ \varDelta \le 0\), with \(u_s^2=\varepsilon ^{e*}_{ij}\varepsilon ^{e*}_{ij}\), one can easily derive the elastic stress \(\pi _{ij}=\partial w/\partial u_{ij}\). The parameters \(B_{lin}\), \(G_{lin}\) carry the units of stress, while their possible dependencies on other state-variables (like density) are ignored here.

The isotropic elastic pressure (defined in \({{\mathcal{D}}}\) dimensions) is:

and the deviatoric elastic stress is:

Further differentiation yields the (constant) moduli: \({{\mathcal{B}}}_{lin}=B_{lin}\), \({{\mathcal{G}}}_{lin}=2G_{lin}\), and no anisotropy \({{\mathcal{A}}}_{lin}=0\), which is surely too simple for granular matter.

The anisotropic linear elastic energy density:

if \(\varDelta >0\) with \({\hat{\varepsilon }}^e_{ij}=\varepsilon ^{e*}_{ij}/|\varepsilon ^{e*}_{ij}|\), as proposed in Refs. [91, 125, 167]. yields:

and the deviatoric elastic stress:

Further differentiation yields the (constant) moduli: \({{\mathcal{B}}}_{A}=B_{lin}\), \({{\mathcal{G}}}_{A}=2G_{lin}\), and anisotropy \({{\mathcal{A}}}_{A}=A_{lin} {\hat{\varepsilon }}^e_{ij}\), which is the simplest possible anisotropic elastic model, with cross-coupling between isotropic and deviatoric elastic strains and stresses, as compared to particle simulations and discussed in detail in Refs. [91, 125, 167]. However, the anisotropy modulus is not constant and thus requires an evolution or state equation by itself, e.g., \(A_{lin}/B_{lin}=F_{dev}\), with deviatoric fabric, \(F_{dev}\), as observed from 3D particle simulations in Refs. [31, 125].

3.2.2 The non-linear (Hertzian) elastic energy

One can derive the elastic stress \(\pi _{ij}=\partial w/\partial u_{ij}\), from the simplest (non-linear) elastic energy density:

and \(w_e=0 ~\mathrm{if}~ \varDelta \le 0\), with \(u_s^2=\varepsilon ^{e*}_{ij}\varepsilon ^{e*}_{ij}\), and \(B=B(\rho )\), \(G=G(\rho )\) carrying the units of stress, while their possible functional dependencies on other state-variables (like density) are not carried along in the rest of this study. Two choices (out of many more) of the density dependence of the energy density (and its coefficients) are discussed below, where appropriate, but in other cases the density dependence is avoided completely in order to learn what the effect of this simplifaction would be. The isotropic elastic pressure (defined in \({{\mathcal{D}}}\) dimensions) is:

and the deviatoric elastic stress is:

implicitly defining the (\(\varDelta \)-dependent) bulk and shear secant moduli \({{\mathcal{B}}}_\varDelta \) and \({{\mathcal{G}}}_\varDelta \), which mimic a linear \(\varDelta \)- or \(\varepsilon ^{e*}_{ij}\)-dependence of isotropic or deviatoric stress, respectively, not to be confused with the (true) tangent moduli:

\({{\mathcal{B}}}= B \varDelta ^{1/2} \left[ (3/2) - (1/4) (G/B) (u_s / \varDelta )^2 \right] \ne {{\mathcal{B}}}_\varDelta \),

\({{\mathcal{G}}}=2G\varDelta ^{1/2} = {{\mathcal{G}}}_\varDelta \), and \({{\mathcal{A}}}_{ij}=G\varDelta ^{1/2} (u_s/\varDelta ) {\hat{\varepsilon }}^e_{ij}\), where the tensor nature of \({{\mathcal{A}}}\) is often dropped.