Abstract

We develop a novel coarse-grained contact model for Discrete Element Method simulations of \(\hbox {TiO}_2\) nanoparticle films subjected to mechanical stress. All model elements and parameters are derived in a self-consistent and physically sound way from all-atom Molecular Dynamics simulations of interacting particles and surfaces. In particular, the nature of atomic-scale friction and dissipation effects is taken into account by explicit modelling of the surface features and water adsorbate layers that strongly mediate the particle-particle interactions. The quantitative accuracy of the coarse-grained model is validated against all-atom simulations of \(\hbox {TiO}_2\) nanoparticle agglomerates under tensile stress. Moreover, its predictive power is demonstrated with calculations of force-displacement curves of entire nanoparticle films probed with force spectroscopy. The simulation results are compared with Atomic Force Microscopy and Transmission Electron Microscopy experiments.

Similar content being viewed by others

References

Zhu, H.P., Zhou, Z.Y., Yang, R.Y., Yu, A.B.: Discrete particle simulation of particulate systems: a review of major applications and findings. Chem. Eng. Sci. 63(23), 5728–5770 (2008)

Min, Y., Akbulut, M., Kristiansen, K., Golan, Y., Israelachvili, J.: The role of interparticle and external forces in nanoparticle assembly. Nat. Mater. 7(7), 527–538 (2008)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Zhu, H.P., Zhou, Z.Y., Yang, R.Y., Yu, A.B.: Discrete particle simulation of particulate systems: theoretical developments. Chem. Eng. Sci. 62(13), 3378–3396 (2007)

Schilde, C., Burmeister, C.-F., Kwade, A.: Measurement and simulation of micromechanical properties of nanostructured aggregates via nanoindentation and DEM-simulation. Powder Technol. 259, 1–13 (2014)

Chandler, M.Q., Peters, J.F., Pelessone, D.: Discrete element modeling of calcium-silicate-hydrate. Model. Simul. Mater. Sci. 21(5), 055010 (2013)

Boltachev, G.S., Lukyashin, K.E., Shitov, V.A., Volkov, N.B.: Three-dimensional simulations of nanopowder compaction processes by granular dynamics method. Phys. Rev. E 88(1), 012209 (2013)

Moreno-Atanasio, R., Antony, S.J., Williams, R.A.: Influence of interparticle interactions on the kinetics of self-assembly and mechanical strength of nanoparticulate aggregates. Particuology 7(2), 106–113 (2009)

Luding, S.: Cohesive, frictional powders: contact models for tension. Granul. Matter 10(4), 235–246 (2008)

Laube, J., Salameh, S., Kappl, M., Mädler, L., Colombi Ciacchi, L.: Contact forces between \(\text{ TiO }_2\) nanoparticles governed by an interplay of adsorbed water layers and roughness. Langmuir 31, 11288–11295 (2015)

Laube, J., Dörmann, M., Schmid, H.-J., Mädler, L., Colombi Ciacchi, L.: Dependencies of the adhesion forces between \(\text{ TiO }_2\) nanoparticles on size and ambient humidity. J. Phys. Chem. C 121, 15294–15303 (2017)

Salameh, S., Schneider, J., Laube, J., Alessandrini, A., Facci, P., Seo, J.W., Colombi Ciacchi, L., Mädler, L.: Adhesion mechanisms of the contact interface of \(\text{ TiO }_2\) nanoparticles in films and aggregates. Langmuir 28(31), 11457–11464 (2012)

Mädler, L., Kammler, H.K., Mueller, R., Pratsinis, S.E.: Controlled synthesis of nanostructured particles by flame spray pyrolysis. J. Aerosol Sci. 33, 369–389 (2002)

Salameh, S., Scholz, R., Seo, J.W., Mädler, L.: Contact behavior of size fractionated \(\text{ TiO }_2\) nanoparticle agglomerates and aggregates. Powder Technol. 256, 345–351 (2014)

Fabre, A., Salameh, S., Colombi Ciacchi, L., Kreutzier, M., Ommen, J.R.: Contact mechanics of highly porous oxide nanoparticle agglomerates. J. Nanopart. Res. 18, 200 (2016)

Salameh, S., Veen, M.A., Kappl, M., Ommen, J.R.: Contact forces between single metal oxide nanoparticles in gas-phase applications and processes. Langmuir 33, 2477–2484 (2017)

Krylov, S.Y., Frenken, J.W.M.: The physics of atomic-scale friction: basic considerations and open questions. Phys. Status Solidi B 251(4), 711–736 (2014)

Dong, Y., Perez, D., Voter, A.F., Martini, A.: The roles of statics and dynamics in determining transitions between atomic friction regimes. Tribol. Lett. 42(1), 99–107 (2011)

Gao, J., Luedtke, W.D., Gourdon, D., Ruths, M., Israelachvili, J.N., Landman, U.: Frictional forces and amontons’ law: from the molecular to the macroscopic scale. J. Phys. Chem. B 108(11), 3410–3425 (2004)

Park, J.Y., Salmeron, M.: Fundamental aspects of energy dissipation in friction. Chem. Rev. 114(1), 677–711 (2014)

Szlufarska, I., Chandross, M., Carpick, R.W.: Recent advances in single-asperity nanotribology. J. Phys. D 41(12), 123001 (2008)

Mo, Y., Turner, K.T., Szlufarska, I.: Friction laws at the nanoscale. Nature 457(7233), 1116–1119 (2009)

Luan, B., Robbins, M.O.: The breakdown of continuum models for mechanical contacts. Nature 435(7044), 929–932 (2005)

Jinesh, K., Frenken, J.: Experimental evidence for ice formation at room temperature. Phys. Rev. Lett. 101(3), 036101 (2008)

Israelachvili, J.N.: Intermolecular and Surface Forces. Elsevier, Oxford (2011)

Hertz, H.: Über die Berührung fester elastischer Körper. J. für die reine und Angew. Math. 92, 156–171 (1882)

Isaak, D.G., Carnes, J.D., Anderson, O.L., Cynn, H., Hake, E.: Elasticity of \(\text{ TiO }_2\) rutile to 1800 k. Phys. Chem. Miner. 26(1), 31–43 (1998)

Feistel, R.: A new equation of state for \(\text{ H }_2\text{ O }\) ice \(\text{ I }_{\rm h}\). J. Phys. Chem. Ref. Data 35(2), 1021 (2006)

Prandtl, L.: Ein Gedankenmodell zur kinetischen Theorie der festen Körper. Z. Angew. Math. Mech. 8(2), 85–106 (1928)

Li, Q., Dong, Y., Perez, D., Martini, A., Carpick, R.W.: Speed dependence of atomic stick-slip friction in optimally matched experiments and molecular dynamics simulations. Phys. Rev. Lett. 106(12), 126101 (2011)

Sang, Y., Dubé, M., Grant, M.: Dependence of friction on roughness, velocity, and temperature. Phys. Rev. E 77(3), 036123 (2008)

Chandross, M., Webb, E., Stevens, M., Grest, G., Garofalini, S.: Systematic study of the effect of disorder on nanotribology of self-assembled monolayers. Phys. Rev. Lett. 93(16), 166103 (2004)

Carpick, R.W., Agraït, N., Ogletree, D.F., Salmeron, M.: Variation of the interfacial shear strength and adhesion of a nanometer-sized contact. Langmuir 12(13), 3334–3340 (1996)

Socoliuc, A., Bennewitz, R., Gnecco, E., Meyer, E.: Transition from stick-slip to continuous sliding in atomic friction: entering a new regime of ultralow friction. Phys. Rev. Lett. 92(13), 134301 (2004)

Glosli, J., McClelland, G.: Molecular dynamics study of sliding friction of ordered organic monolayers. Phys. Rev. Lett. 70(13), 1960–1963 (1993)

Friddle, R.W., Noy, A., De Yoreo, J.J.: Interpreting the widespread nonlinear force spectra of intermolecular bonds. Proc. Natl. Acad. Sci. 109(34), 13573–13578 (2012)

Wenning, L., Müser, M.H.: Friction laws for elastic nanoscale contacts. Europhys. Lett. 54(5), 693–699 (2001)

Carpick, R.W., Ogletree, D.F., Salmeron, M.: Lateral stiffness: a new nanomechanical measurement for the determination of shear strengths with friction force microscopy. Appl. Phys. Lett. 70(12), 1548 (1997)

Enachescu, M., Oetelaar, R.J.A., Carpick, R.W., Ogletree, D.F., Flipse, C.F.J., Salmeron, M.: Atomic force microscopy study of an ideally hard contact: the diamond(111)/tungsten carbide interface. Phys. Rev. Lett. 81(9), 1877–1880 (1998)

Ecke, S., Butt, H.-J.: Friction between individual microcontacts. J. Colloid Interf. Sci. 244(2), 432–435 (2001)

Mindlin, R.D., Deresiewicz, H.: Elastic spheres in contact under varying oblique forces. J. Appl. Mech. Trans. ASME 20(3), 327–344 (1953)

Zhou, Y.C., Wright, B.D., Yang, R.Y., Xu, B.H., Yu, A.B.: Rolling friction in the dynamic simulation of sandpile formation. Physica A 269(2–4), 536–553 (1999)

Ai, J., Chen, J.-F., Rotter, J.M., Ooi, J.Y.: Assessment of rolling resistance models in discrete element simulations. Powder Technol. 206(3), 269–282 (2011)

O’ Sullivan, C., Bray, J.D.: Selecting a suitable time step for discrete element simulations that use the central difference time integration scheme. Eng. Comput. 21(2/3/4), 278–303 (2004)

Meißner, R.H., Wei, G., Colombi Ciacchi, L.: Estimation of the free energy of adsorption of a polypeptide on amorphous \(\text{ SiO }_2\) from molecular dynamics simulations and force spectroscopy experiments. Soft Matter 11, 6254–6265 (2015)

Melnikov, K., Mani, R., Wittel, F.K., Thielmann, M., Herrmann, H.J.: Models, algorithms and validation for opensource DEM and CFD–DEM. Phys. Rev. E 92, 022206 (2015)

Mädler, L., Lall, A.A., Friedlander, S.K.: One-step aerosol synthesis of nanoparticle agglomerate films: simulation of film porosity and thickness. Nanotechnology 17(19), 4783–4795 (2006)

Mädler, L., Roessler, A., Pratsinis, S.E., Sahm, T., Gurlo, A., Barsan, N., Weimar, U.: Direct formation of highly porous gas-sensing films by in situ thermophoretic deposition of flame-made Pt/SnO\(_2\) nanoparticles. Sensors Actuators B Chem. 114(1), 283–295 (2006)

Eggersdorfer, M.L., Gröhn, A.J., Sorensen, C.M., McMurry, P.H., Pratsinis, S.E.: Mass-mobility characterization of flame-made \(\text{ ZrO }_2\) aerosols: primary particle diameter and extent of aggregation. J. Colloid Interface Sci. 387(1), 12–23 (2012)

Weber, A.P., Friedlander, S.K.: In situ determination of the activation energy for restructuring of nanometer aerosol agglomerates. J. Aerosol Sci. 28(2), 179–192 (1997)

Mandzy, N., Grulke, E., Druffel, T.: Breakage of \(\text{ TiO }_2\) agglomerates in electrostatically stabilized aqueous dispersions. Powder Technol. 160(2), 121–126 (2005)

Buesser, B., Gröhn, A.J., Pratsinis, S.E.: Sintering rate and mechanism of \(\text{ TiO }_2\) nanoparticles by molecular dynamics. J. Phys. Chem. C 115(22), 11030–11035 (2011)

Schneider, J., Colombi Ciacchi, L.: First principles and classical modeling of the oxidized titanium (0001) surface. Surf. Sci. 604(13–14), 1105–1115 (2010)

Schneider, J., Colombi Ciacchi, L.: A classical potential to model the adsorption of biological molecules on oxidized titanium surfaces. J. Chem. Theory Comput. 7(2), 473–484 (2011)

Schopf, S.O., Salameh, S., Mädler, L.: Transfer of highly porous nanoparticle layers to various substrates through mechanical compression. Nanoscale 5, 3764–3772 (2013)

Thakur, S.C., Morrissey, J.P., Sun, J., Chen, J.F., Ooi, J.Y.: Micromechanical analysis of cohesive granular materials using the discrete element method with an adhesive elasto-plastic contact model. Granul. Matter 16, 383–400 (2014)

Hutter, J.L., Bechhoefer, J.: Calibration of atomic-force microscope tips. Rev. Sci. Instrum. 64(11), 1868–1873 (1993)

Jorgensen, W.L., Chandrasekhar, J., Madura, J.D., Impey, R.W., Klein, M.L.: Comparison of simple potential functions for simulating liquid water. J. Chem. Phys. 79(2), 926 (1983)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117(1), 1–19 (1995)

Filippov, A.V., Zurita, M., Rosner, D.E.: Fractal-like aggregates: relation between morphology and physical properties. J. Colloid Interface Sci. 229(1), 261–273 (2000)

Friedlander, S.K.: Smoke, Dust and Haze: Fundamentals of Aerosol Behavior. Wiley, New York (1977)

Ommen, J.R., Valverde, J.M., Pfeffer, R.: Fluidization of nanopowders: a review. J. Nanopart. Res. 3, 1–29 (2012)

Eggersdorfer, M.L., Pratsinis, S.E.: The structure of agglomerates consisting of polydisperse particles. Aerosol Sci. Technol. 3, 347–353 (2012)

Zhang, C., Thajudeen, T., Larriba, C., Schwartzentruber, T.E., Hogan, C.J.: Determination of the scalar friction factor for nonspherical particles and aggregates across the entire knudsen number range by direct simulation Monte Carlo (DSMC). Aerosol Sci. Technol. 46(10), 1065–1078 (2012)

Mansfield, M.L., Douglas, J.F., Garboczi, E.J.: Intrinsic viscosity and the electrical polarizability of arbitrarily shaped objects. Phys. Rev. E 64(6), 061401 (2001)

Kloss, C., Goniva, C., Hager, A., Amberger, S., Pirker, S.: Models, algorithms and validation for opensource DEM and CFD–DEM. Prog. Comput. Fluid Dyn. 12(2/3), 140 (2012)

Acknowledgements

We acknowledge fruitful discussion with S. Luding (University of Twente, The Netherlands) and M. Kappl (MPI for Polymer Research Mainz, Germany). The AFM/TEM investigations have been performed by S. Salameh during a research stay in the group of J.W. Seo (KU Leuven, Belgium). This work has been funded by the DFG within the SPP 1486 “Partikel im Kontakt” (Grants CO 1043/3 and MA 3333/3). Computational time has been provided by the HLRN supercomputing centre at Hannover and Berlin, Germany.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 2 (avi 42288 KB)

Appendix

Appendix

In this Appendix we summarise the experimental as well as all computational and methodological details concerning the performed MD and DEM simulations.

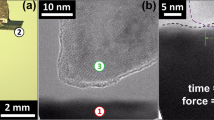

1.1 AFM experiments

Highly porous \(\hbox {TiO}_2\) nanoparticle films on mica substrates are produced using a flame spray reactor as described in detail in our previous works [13, 14]. Force-displacement curves for the detachment of single agglomerates from the film are measured with an Atomic Force Microscope (Nanowizard 3 from JPK) under ambient conditions (relative humidity about 50%, temperature about 21 \(^\circ \hbox {C}\)), using \(\hbox {Si}_3\hbox {N}_4\) cantilever (DNPS from Bruker) with a spring constant of approximately 0.16 N/m, as determined from the thermal noise method [57]. The AFM is placed on a vibration isolation table (i4 from Accurion) inside an acoustic hood. To account for statistical significance, several force curves with a cantilever speed of 2 \(\upmu \hbox {m/s}\) and a setpoint of 2.5 nN are collected by force mapping with 64 measurement points in an area of 2 \(\upmu \hbox {m}^2\). The dynamical agglomerate behaviour under strain is imaged using a combined AFM/TEM set-up with an \(\hbox {Si}_3\hbox {N}_4\) cantilever of spring constant 5.3 N/m. These in-situ investigations are performed inside a Phillips CM 200 FG transmission electron microscope equipped with an AFM/TEM holder (Nanofactory Instruments AB) and with a column vacuum of approximately \(10^{-6}\) mbar.

1.2 All-atom MD simulations

All-atom \(\hbox {TiO}_2\) nanoparticle models of different sizes, shapes and with surface-adsorbed water corresponding to a relative humidity of 50% are created as described in detail in refs. [10,11,12]. This results in nanoparticles preserving the \(\hbox {TiO}_2\) stoichiometry, but terminated with OH groups as a consequence of a thought-process of dissociative water adsorption, which saturates under-coordinated Ti and O sites with OH and H, respectively. An extended \(\hbox {TiO}_2\) surface slab model with nanometer-scale roughness and size of \(16 \times 14\) \(\hbox {nm}^2\) is created via cleavage of an infinite \(\hbox {TiO}_2\) single rutile crystal in the \(\langle 213 \rangle \) lattice direction, subsequent surface relaxation, annealing and hydroxylation, similarly as for the particle models. The choice of the \(\langle 213 \rangle \) direction is arbitrary; any combination of relatively large Miller indices would be suitable, as long as it leads, after annealing and termination with OH and H, to a non-periodic series of asperities and grooves on the size-scale of 0.1 to 1 nm. The Ti-O interactions are described by a modified Matsui/Akaogi force field [53], water molecules are described by the TIP3P model [58], and the interactions between water and \(\hbox {TiO}_2\) by the force field of Schneider et al. [54]. All MD simulations are performed using LAMMPS [59] within the NVT ensemble at 300 K, using a Berendsen Thermostat, a timestep of 1 fs, a force cutoff of 12 Å for the van-der-Waals interactions and a particle-particle particle-mesh long-range solver for the Coulomb interactions.

In the MD simulations of single particles dragged tangentially over the \(\hbox {TiO}_2\) surface, the particle/surface systems are first relaxed for 1 ns, then a harmonic constraint with a spring-stiffness of 160 N/m is applied to their centres of mass and moved at constant speed (0.1 to 1 m/s in different simulations) over a distance of 5 nm, while the atom positions of the slab are kept fixed, except for the terminal OH atoms and the adsorbed water molecules, which are free to move. The dragging force is recorded every \(10^{-6}\) nm and averaged over \(10^4\) datapoints, giving a single force value every 0.01 nm. The angular momentum acting on the particle is set to zero at every time step in the sliding simulations, while it is unconstrained in the rolling simulations. The largest local maxima of the force-displacement curves obtained in these simulations are selected as in other works [30, 33]. Namely, first the as-recorded curve is smoothed using a low-pass smoothing function with a cut-off frequency of \(f_{cut}\) = 2.8 \(\hbox {nm}^{-1}\). The peak forces and peak positions of the smoothed function are then determined analytically. Finally, the maxima of the pristine curve nearest to the positions of the maxima of the smoothed forces are located. Averaging the force peak values and the spacings between the peaks leads the mean values of \(F_{t,max}^S\) and \(F_{t,max}^R\), as well as the period \(\lambda _t\).

In the all-atom MD simulations of the nanoparticle agglomerate, 14 particles of different sizes are placed in contact and relaxed within 2 ns, keeping fixed the positions of the four outermost particles. The particles are created as (irregular) hollow spheres with a shell thickness of 1 nm, which considerably decreases the computational effort with no effect on the interparticle contact forces. The pulling force is exerted via a harmonic constraint with a spring-stiffness of 160 N/m moving at the constant speed of 5 m/s, recorded at every time step and averaged over \(10^4\) steps before plotting the force-displacement curves.

1.3 Generation of DEM particle film models

Nanoparticle aggregates are built from primary particles following a discretized log-normal distribution, as measured from TEM image analyses [14]. The primary particle diameter ranges from 3 to 23 nm, with a stepsize of 1 nm (median 9.0 nm, \(\sigma _G = 1.45\)). These primary particles are combined using a Sequential Algorithm (SA) combined with a Cluster-Cluster Aggregation (CCA) as presented in Ref. [60]. This procedure generates random aggregates that follow the fractal distribution \(N_p = k_f \cdot \left( \frac{d_g}{\bar{d}_s}\right) ^{D_f}\), which is frequently used to describe FSP-synthesized particles [49, 61,62,63]. Here, the amount of particles \(N_p\) in an aggregate is predicted using the diameter of gyration \(d_g\), the Sauter diameter \(\bar{d}_s\) (defined as \(\bar{d}_s = 6 V_{p,tot}/A_{p,tot}\), with \(V_{p,tot}\) the total particle volume and \(A_{p,tot}\) the total surface area), as well as the fractal prefactor \(k_f\) and the fractal dimension \(D_f\). \(k_f\) and \(D_f\) are 1.0 and 1.8, respectively, for FSP-synthesized particles [61]. The aggregate generation algorithm combines 6 particles to one cluster using the SA. Subsequently, these clusters are combined using the CCA. The number distribution of rigid particle aggregates is estimated from Disc Centrifuge experiments [14]. The equation \(N_p = k_{m} \cdot \left( \frac{d_m}{\bar{d}_s}\right) ^{D_{fm}}\) is used according to [49]. In this equation \(d_m\) describes the mobility diameter from Disc Centrifuge experiments and \(k_{m}\) and \(D_{fm}\) are the mass mobility prefactor and dimension, respectively, that are 1.0 and 2.15 for FSP-synthesized particles. The number distribution ranges from 1 to 128 primary particles with a median of 36 particles and an arithmetic standard deviation \(\sigma _s\) of 0.5. The rigid aggregates are deposited individually on the bottom surface of a tetragonal simulation box according to diffusion and a thermophoretic velocity as discribed elsewhere [47]. The contact of the aggregate with the bottom surface or a previously deposited aggregate marks it as deposited. A deposited aggregate remains static during the ongoing film formation. The coefficient of diffusion for polydispersed nanoparticle aggregates is calculated according to Zhang et al. [64]. The program zeno is used to determine the hydrodynamic radius [65] and 56 angles are used to calculate the mean projected area PA of the deposited agglomerates. The friction factor f follows:

with the fluid viscosity \(\mu \), mean free path \(\lambda \), the hydrodynamic radius \(R_H\) and the Cunningham slip correction \(C_C\). The application of a thermophoretic velocity of 0.1 m/s [48] results in a film with a porosity of 98 %, which matches very well the typical experimental value [47, 48]. The box presents a side length of 140 \(\bar{d}_s\), which corresponds to a box with geometric sizes of \(1.5814\times 1.5814 \times 3.3580~\upmu \hbox {m}^3\).

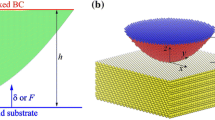

1.4 DEM simulations

All DEM simulations are performed using the LIGGGHTS package [66], in which we have implemented the here-developed contact model, using a timestep \(\varDelta t = 0.5\) ps. Capillary forces and solvation forces are implemented using a tabulated potential to reduce computational cost. Initial relaxation of each simulated system is performed using a viscosity term acting on all particles (viscosity of 10 \(\hbox {pN/}(\hbox {ms}^{-1})\)). The action of this ‘environmental viscosity’, together with the friction terms in the contact model, guarantees that the systems evolve quasi-statically, with sufficient dissipation of the kinetic energy that builds up as a consequence of the nanoparticle rearrangements under mechanical stress. The AFM tip with a side length of 0.8 \(\upmu \hbox {m}\), represented by non-interacting and rigid primary particles with 20 nm radius, is placed above the film without any initial contact to the film. The dynamical simulations are then carried out in the microcanonical ensemble, with the sole energy dissipation of the DEM contact model able to maintain the system under quasi-static conditions. The tip is moved with a constant velocityof −0.5 m/s along the z direction and the forces acting on the tip particles are averaged over periods of 10 ns, equaling a tip displacement of 5 nm. After reaching a repulsive force of 2 nN, the tip velocity is slowly decreased, reversed and then again increased to +0.5m/s within a period of 0.2 \(\upmu \hbox {s}\). Periodic boundary conditions are applied to the simulation box, with the bottom layer of aggregates kept fixed in order to mimic an underlying sample holder.

Rights and permissions

About this article

Cite this article

Laube, J., Baric, V., Salameh, S. et al. A new contact model for the discrete element method simulation of \(\hbox {TiO}_2\) nanoparticle films under mechanical load. Granular Matter 20, 28 (2018). https://doi.org/10.1007/s10035-018-0799-9

Received:

Published:

DOI: https://doi.org/10.1007/s10035-018-0799-9