Abstract

Wind energy plays a significant role in renewable energies. The increasing demand for wind energy has caused wind turbines (WT) to grow steadily larger, which means that the control objectives are no longer solely to maximize the energy produced but to control mechanical loads, among other objectives actively. Model-based WT control, particularly model predictive control (MPC), has been the focus of research for the last decades. Nevertheless, only a few practical investigations of MPC for WTs in field tests exist.

This paper highlights some key challenges and pitfalls when applying MPC for WTs. We render these critical points based on the experience of a recently conducted field test and discuss possible solutions for these challenges. In doing so, we highlight the following three critical areas: Firstly, we show how the design and practical operation of an MPC system can take into account the nonlinear properties of the WT. In particular, we address the highly varying sensitivity to the pitch angle and the dynamic responses of the rotor speed and mechanical loads to the actuator commands over the partial and full load ranges. Secondly, we discuss the problem of having limited computational capacities on real-time platforms, restricting the possible complexity of the MPC algorithm. Lastly, we show how some safety aspects decisively influence the design and operation of the control algorithm.

Zusammenfassung

Die Windenergie spielt bei den erneuerbaren Energien eine bedeutende Rolle. Die steigende Nachfrage nach Windenergie hat dazu geführt, dass die Windenergieanlagen (WEA) immer größer werden, was bedeutet, dass die Regelungsziele nicht mehr nur darin bestehen, die produzierte Energie zu maximieren, sondern unter anderem auch die mechanischen Lasten aktiv zu regeln. Die modellbasierte WEA-Regelung, insbesondere die Modellprädiktive Regelung (MPC), ist seit Jahrzehnten ein Schwerpunkt der Forschung. Dennoch gibt es nur wenige praktische Untersuchungen von MPC für WEA in Feldversuchen.

In diesem Beitrag werden einige zentrale Herausforderungen und Problemfelder bei der Umsetzung von MPC für WEA aufgezeigt. Wir stellen wesentliche Punkte anhand der Erfahrungen aus einem kürzlich durchgeführten Feldversuch dar und diskutieren mögliche Lösungen für diese Herausforderungen. Dabei heben wir die folgenden drei kritischen Bereiche hervor: Erstens zeigen wir, wie das Design und der praktische Betrieb eines MPC-Systems die nichtlinearen Eigenschaften der WEA berücksichtigen kann. Insbesondere gehen wir auf die stark variierende Sensitivität auf den Pitchwinkel und die dynamischen Reaktionen der Rotordrehzahl und der mechanischen Lasten auf die Aktuatorbefehle über den Teil- und Volllastbereich ein. Zweitens diskutieren wir das Problem der begrenzten Rechenkapazitäten auf Echtzeitplattformen, die die mögliche Komplexität des MPC-Algorithmus einschränken. Schließlich zeigen wir, wie einige Sicherheitsaspekte den Entwurf und den Betrieb des Regelungsalgorithmus entscheidend beeinflussen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Model predictive control (MPC) for wind turbines (WT) has been investigated for at least the past two decades. Therefore, different MPC formulations have been investigated and proven their benefits against conventional control and other advanced control methods [1,2,3,4]. Nevertheless, only a few attempts to investigate MPC for commercial WTs in the field have been published so far (e.g. [5, 6]). In [6] the authors evaluate trailing edge flaps with active load reduction using a frequency-weighted MPC for a 225 kW WT, whereas [6] shows the results of a proof of concept of a weight-scheduled MPC with active load reduction for a 3 MW WT. To the authors’ best knowledge, no further field test results with a full-scale WT in the multi-megawatt range using MPC are published so far.

The authors of [7,8,9,10] show standardized procedures for applying model-based control in practical applications. Virtual commissioning in different situations comparable to Software-in-the-Loop (SiL)- and Hardware-in-the-Loop (HiL)-tests are essential to reduce the commissioning time and effort and significantly help reduce the risk of costly damages to real machines. Albo and Falkman [7] highlight the importance of digital twins of the controlled system and standardized commissioning procedures. Commissioning software can be expensive if this process has to be performed once for each application.

During testing and commissioning, simulation models of the process are needed. So, the accuracy of the models is essential not only for the control performance but also for the commissioning of model-based controllers [8]. Therefore, complex models should be divided into dynamic submodels, which can be identified separately. The models can afterward be used to test the control hardware in a HiL-structure. The control hardware is connected to a virtual machine running on a real-time computer using the same interfaces (Fieldbusus) as in the field [8]. Through this procedure, the simulations against the virtual machine can be transferred very well to the real process.

In [9], Forbes et al. describe MPC’s challenges in the field of production industries. They point out that in an environment with MPC, the main challenges lie in maintaining and adapting the control algorithms, which were commissioned some time ago rather than improving the algorithms. The once-developed algorithms perform well, but usually, changing the settings requires expertise. Thus, they propose standardization of the commissioning process.

Schramp et al. [10] highlight the savings of commissioning time using virtual commissioning, similar to the HiL- and SiL-tests. They propose a dynamical 3D-Model of the controlled system, in which the control algorithms can be tested systematically in different use cases. In the wind energy industry, this is already standard, but it highlights the vital role of accurate models and simulation environments for applying these model-based algorithms.

Nevertheless, only some contributions are found in academia and industry about the occurring challenges when transferring a complex model-based controller for WTs from simulation to actual application at full experimental scale. Ossmann et al. [11] conducted a field test of a model-based individual blade pitch controller (IPC) on a utility-scale research WT. They mention the practical hurdle, that model-based control potentially requires WTs to be equipped with new sensors and explain the importance of checking the consistency of the measurements. They also present an iterative procedure of the controller design starting with a continuous time control algorithm over its discretization to automated code generation using MathWorks® MATLAB® and SIMULINK® (Simulink).

The open research question is: Which obstacles arise in the development of MPC for WTs when these algorithms are to be evaluated in field tests? This contribution shows some key challenges that arise on the path to applying MPC in the field. Knowledge about these challenges is vital in the planning process to assess the resources needed for conducting field tests of MPC. After the conducted field test with its results described in detail in [6], we address the above-mentioned open research question with the key design decisions and their influence on the results.

The contribution is structured as follows. In Sect. 2, we explain the dynamic model of a WT, the control system, and its interactions with the environment. Section 3 presents the requirements for the control system under practical investigation in the field, which arise from the WT, including a description of the field test. Section 4 shows opportunities to overcome the challenges and points out possible adaptions of the MPC algorithm. In Sect. 5, we show particular challenges that arise when the MPC algorithm is executed on a Programmable Logic Controller (PLC) and embedded in the overall operational control. Here we especially point out the limitations to MPC arising from the real-time hardware.

2 System description

Model-based control schemes require dynamic models, which represent all relevant dominant dynamics. Concerning MPC, the model’s complexity must be simple enough to be used in real-time optimization. Therefore, these models need to be as simple as possible and as dynamically complex and accurate as necessary. The model’s complexity is one of the first design decisions for MPC. The following WT description is a possible solution and has been adapted from the publications [3] and [12]. Different descriptions can be found in [13].

2.1 Dynamic model and state estimation

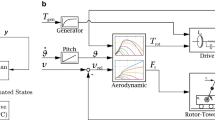

The structure of the WT’s dynamic model is shown in Fig. 1: The model consists of two linear dynamic models for the rotational dynamics of the drive train and the fore-aft dynamics. For simplicity, the aerodynamics are modeled as a static map of thrust- and power coefficients, resulting in the thrust force Ft and the aerodynamic torque Trot acting on the rotor blades. The WT’s actuator dynamics are modeled as an integrator for the pitch angle ϑ and as a PT1 for the generator torque Tgen. The measured outputs are the rotor speed ωrot and the generator speed ωgen, as well as the translational tower top acceleration \(\ddot{x}_{t}\). The relative wind speed vrel acting onto the WT is calculated by the absolute rotor effective wind speed v, which is the last model input, and the tower top motion \(\dot{x}_{t}\). Measuring the exact rotor effective wind speed is tricky. Using simple methods of measuring behind the rotor result in high disturbances, because of the rotor blades and the reduction of the cross-section of the airflow around the nacelle. More complex methods of Light Imaging, Detection and Ranging (Lidar) systems can measure the wind speed ahead of the WT. However, these systems are expensive and not available in every system. Hence, the exact wind speed is considered as unknown input and thus as a disturbance variable.

Reduced order WT model with the submodels for the actors, the drive train, the fore-oft motion, and the aerodynamics [14]

Apart from the aerodynamics, all the dynamics can be modeled with linear time-invariant models, because inaccuracies resulting e.g. from varying natural frequencies in the operational region were found smaller than the estimation uncertainties [14]. The model dimensions were chosen based on proper simulation results, presented in [3, 12, 15].

We here want to focus on the calculation of the aerodynamic torque Trot for the challenges of MPC for WTs, ignoring dynamic inflow, which can be approximated by adopted power coefficients cP.

The aerodynamic torque can be derived by the aerodynamic power Paero divided by the rotor speed ωrot. Both are calculated using the air density ϱ, the radius R of the rotor and the so-called power coefficient cP, which depends on the rotor speed ωrot, the wind speed vwind, and the pitch angle ϑ. The values of the power coefficient above \(c_{P} > -0.1\) are shown in Fig. 2. The tip-speed-ratio (TSR) λ is given as the ratio of the tip speed of the rotor blades ωrotR to the wind speed vwind.

Despite the wind speed, many more states like the tower top position or the tension of the gearbox are not measured directly, but estimated. We propose an Extended Kalman Filter, described in [12, 15] that uses the dynamic model and the measurements to estimate the dynamic states used by the MPC. The accuracy of the estimation has an important impact on the controller performance and thus its tuning is crucial.

2.2 Operating strategy

As shown in Fig. 1, the drive train is freely spinning. Under normal operating conditions, it is accelerated by the aerodynamic torque Taero and decelerated by the generator torque Tgen. As described in [13], most WTs have three operational regions, depending on the wind speed as shown in Fig. 3, which all needs to be considered when commissioning a WT control scheme in the field.

Steady power (normalized to nominal power Pnom) and pitch angle curve (normalized to maximum pitch angle ϑmax) over wind speed (normalized to rated wind speed vrated): On the primary axis, there are the electrical (el) power output, the aerodynamic (aero) power input without mechanical losses and theoretically (theor) achievable power without losses for optimal tip speed ratio. On the secondary axis, we depict the pitch angle

In region I, for low wind speed above the cut-in wind speed, the aim is to extract as much energy from the wind as possible. From Eq. 1 follows, that the aerodynamic power Paero is maximized for the maximum power coefficient cP. This is derived by operating the WT with optimal TSR and pitch angle. In this point, the gradient of cP towards the pitch angle is zero (Fig. 2). Consequently, the sensitivity of the aerodynamic torque toward the pitch angle is zero. Thus, that the aerodynamic power hardly varies for small variations in the pitch angle.

In region I.5, the nominal rotor speed is reached, but the aerodynamic power is still below the rated power Pnom. Thus, the TSR must be reduced as the wind speed increases further. As the aerodynamic power Paero is still below the rated power Pnom, the maximum aerodynamic power for the allowed TSR is attempted to be used. Here, the pitch angle must vary slightly, the sensitivity of the aerodynamic power Paero towards the pitch angle ϑ is still zero.

When the wind speeds further increases, region II is reached. Here the WT can produce nominal electrical power Pnom, and the pitch angle needs to reduce the aerodynamic power Paero to stay within the operating limits of the turbine. In this region II, the pitch sensitivity increases steadily with increasing wind speed.

In general, the wind conditions are not steady. To ensure, that the WT operates at approximately optimal operating points, the WT must be operated by feedback control.

2.3 Baseline MPC

The basic idea of MPC is to quantify the requirements as control objectives and to optimize the manipulated variables to meet these requirements in the best possible way. Figure 4 shows the components of a reference MPC and their interconnection for the closed-loop system. These components are:

-

1.

A dynamical model of the system that the MPC controls Eq. 4: This model is used to predict the system’s dynamical behavior under different control actions. It contains the state vector \(\boldsymbol{x}_{k| k+i}\) predicted from time step k to \(k+i\), the measurement vector \(\boldsymbol{y}_{k| k+i}\), the command vector \(u_{k| k+i}\) containing the sum of changes of the command \(\Delta \boldsymbol{u}_{k| k+i}\). The dynamic behavior is defined by the state matrix \(A_{k}\in R^{13 \times 13}\), the input matrix \(B_{k}\in R^{13 \times 2}\), the output matrix \(C_{k}\in R^{3 \times 13}\) and the feed through matrix \(D_{k}\in R^{3 \times 2}\).

-

2.

The cost function J, that quantifies the control objectives Eq. 5. For a reference tracking MPC, J consists of three costs. The cost for the reference tracking error (yref−y), the absolute control variables u and its change Δu weighted with the diagonal weighting matrices Q, R, S respectively.

-

3.

In numerical optimization, either online or offline, an optimal trajectory of the manipulated variables \(\Updelta \boldsymbol{u}_{\mathrm{opt}{,}\cdot | k}\) is determined in such a way that the cost function J is minimized Eq. 6.

-

4.

The optimization Eq. 6 in general is subject to Constraints Eq. 7. Here the constraints are all linear and efined by the matrix Alin and the corresponding vector blin, which renders the quadratic optimization problem together with the cost function Eq. 5.

Structure of the model-based control loop consisting of an MPC, an extended Kalman filter (EKF) and the WT [12]

To predict the dynamic behavior with Eq. 4, the MPC needs information on the dynamic state of the WT at the current time step k. As usually some certain states cannot be measured completely, the control system needs a state estimator (see Fig. 4). The combined model in Fig. 1 is non-linear and the states can be estimated by an EKF described in [12, 15]. Other state estimators such as unscented Kalman filters (UKF) or moving horizon estimators (MHE) could also be used.

3 Practical challenges

After conducting a full-scale field test [5] of an MPC implementation reported in [3, 12, 15] in July 2020, there remain new underestimated challenges. In this field test, a Reference tracking MPC with the following basic configuration was investigated: The Reference is adapted to using the power curve and the estimated wind speed. To cope with the varying sensitivities, the MPC’s gains are scheduled over the operational region. The dynamic states including the wind speed are derived by an EKF. The MPC was tuned in simulations and tested in SiL and HiL tests and commissioned on a commercial PLC for the field test. The control system was embedded into the existing automation system. To ensure, that in cases of an unexpected error, the WT still operates, the MPC only bypasses the state-of-the-art controller (SAC) and the SAC can take over the control.

The following section gives a brief overview of the fundamental challenges.

3.1 System requirements

We focus on the requirements regarding the control system, i.e. requirements that the control system can take into account. The overall requirement of a WT is to gain profit. As already described in [16], electrical power output with low power fluctuations generates profit in the electrical market. On the other hand, downtime, and repairs are expensive and should be avoided. Translated into control objectives, power output must be high and uniform on the one hand and the WT’s operation points must be gentle on the material and minimize damaging stresses to reduce downtime and repair costs.

Additionally, the control system must meet requirements arising from the environment in which the WT is located. Here the fluctuating and uncertainly measurable wind speed challenges the control system. In addition, aging symptoms can reduce the power production capacity and slightly change the dynamic behaviour. The control system must be robust against all these uncertainties.

An implicit requirement is to keep the operation points within certain bounds arising from the design or legal regulations. These can be exemplary to keep the rotor speed, or electrical power below certain bounds, to ensure the generator is not damaged. Legal regulations can regard sound emissions or electrical power fluctuation. Safety critical essential intrinsic requirements are that the control algorithm is stable, and the control algorithm must always be executed in real time. Otherwise, delayed control commands could potentially lead to instability or performance degradation.

When deciding which control method to use, it must be analysed how the methods can face all the requirements. This process is not the focus of this contribution. However, how different model-based control methods can face specific requirements is reviewed in [1]. Here we recapture how MPC can especially face the requirements and which challenges arise when it comes to its practical investigations. We chose a reference tracking MPC algorithm with a linear-time-variant (LTV) model and adaptive weights [12], combined with an EKF to estimate the states and the wind speed.

3.2 Identified practical challenges

The following section shows the challenges arising from the chosen MPC structure.

Sensitivity to pitch

The manipulated variables are the pitch angle and the generator torque. As shown in Sect. 2, the sensitivity to the pitch is highly varying over the operation regions, but with the linear dynamic model, the MPC does not know that the actuation of the pitch will lead to a higher sensitivity along the prediction horizon. This challenge can be addressed using a nonlinear MPC algorithm as shown in [2]. However, the operation of a nonlinear MPC comes along with other challenges, because its complexity is increased, and preparing this algorithm for real-time operation in a PLC is challenging. In addition, nonlinear optimization problems are less accepted in the industry than quadratic problems (QP).

With a weight Rk for the pitch actuation in u in the cost function Eq. 5 and without a further reference in yref for the pitch angle in specific operation points the linear MPC would not actuate the pitch angle at all. We showed, that the operation of a linear MPC with the same weights over the whole operation range can lead to undesired behavior [12], and adaptive weights offer an increased number of tuning parameters, which suited for the field test.

References

In the present MPC, there are references needed. Here, the reference is determined to be the optimal steady operation point, depending on the actual wind speed. This reference neglects the unsteady trajectory towards this steady operation point. As the wind speed fluctuates, also the reference fluctuates. In the field test, the fluctuation of the reference was identified to influence the performance of the MPC.

Hardware capacity

To ensure that the convergence of the online optimization is guaranteed, the sampling time was chosen to be 0.1 s. HiL-tests with a PLCFootnote 1 have shown that this parameterization utilizes the PLC by about 30%. This sampling time restricts the model depth that can be used in the MPC in that the fastest possible dynamics that the MPC can respond to is in the range of less than 4 Hz. The dynamics observed in the field test suggest that this model depth is not sufficient and effects whose natural frequency is above 4 Hz should be considered as shown in [5].

To cope with an unexpected failure of the MPC algorithm, the existing basic control was bypassed [17]. Therefore, the measurements and command values were passed through the (SAC). The MPC commands were checked before being passed to the actors, which led to additional delay time. This delay, even more, reduces the maximum natural frequencies of the system, which can be covered by the MPC.

Model uncertainty

The lower-level actuator controller, especially the generator, was identified as a relevant model uncertainty. Until now, we assumed that the dynamics of the generator’s underlying controller were fast enough to be neglected in the MPC. Instead, this actuator controller showed dynamic behavior in the frequency range of the MPC. As it was not covered in the prediction model, this reduced the performance of the MPC, as shown in Fig. 5 and 6. Especially overshooting of the measured values of the generator torque was observed, resulting in the MPC trying to compensate for the measured deflections. In extreme cases, the steps of the measured generator torque exceeded the commands by up to 25% and their absolute values exceeded the commands by up to 5%. Figure 6 shows the frequencies for the commanded and measured generator torque and their difference together with the 6 modeled natural frequencies of the WT. The controller shows activities around 3.2 Hz, which are not modeled. Also for higher frequencies above 4 Hz, there are activities in the lower-level controller which cannot be addressed by the MPC. So the assumed PT1 behavior does not cover the generator dynamics precisely enough. It is important to identify all dynamics, which are relevant to the MPC’s prediction model. Since this can also include lower-level controllers, these must also be identified.

Additional uncertainty arises from differences in estimated and actual states. Here we exemplarily investigate the frequencies of the estimated wind speed in Fig. 7. Naturally, there are no peaks expected in the shown frequency range. The observed peaks result from dynamics, which are not modeled. The observer estimates those into the wind speed, which can be observed. The 3P periodical excitation as well as frequencies around 2.1 Hz, which arise from not modeled for-aft modes can be clearly seen in the estimated wind speed, but are unlikely part of the real wind speed. But even modeled frequencies as f1 the first tower fore-aft natural frequency is seen in the estimated wind speed. Improving the estimation requires more complex models.

Commissioning

In conventional control, a few parameters may be tuned online during the commissioning of the control system. Online tuning of the MPC is different because the tuning parameters of the MPC have different effects compared to those of conventional control. As shown by the different test stages in [17], intensive testing in simulations can reduce the effort of online tuning during commissioning, but the toolchains for this must exist, and the simulation environments must represent the physical WT precisely.

4 Adaption of the MPC algorithm

To overcome the identified challenges, we here present some solutions and further research topics to establish MPC for WTs in the field.

4.1 Process model

Section 3 shows that the process model is important for accurate prediction and optimization. Along with the data from field tests, even with data from SACs, it is possible to identify system dynamics.

Mechanics

The system dynamics need to be identified to cover the higher natural frequencies around 3.2 Hz in the rotational and around 2.1 Hz in the for-aft model and their influence for the controller performance. Therefore, not only the separate dynamical models but also their structure should be varied in the process of model identification. The dynamics of the flexible rotor blades and tower is modeled with fixed natural frequencies and modes. Especially the different flap-wise and edge-wise stiffness of the blades and their varying direction due to pitch action modifies the natural frequencies. In addition, coupled modes of fore-aft and rotational motions are not considered in the presented model and should be investigated. The coupled modes could even be introduced without additional model states.

Actuators

The actuators and their low-level controllers have already been identified as the source of uncertainties. To clarify the model for better predictions, we identify the dynamical actor responses to command values.

4.2 MPC-formulation

After defining the algorithm formally, we now discuss how the requirements and challenges can be met. The MPC algorithm has three key advantages when controlling a WT.

-

1.

Multiple objectives and controlled variables can be considered thoroughly in this formulation.

-

2.

The contrary objectives can be weighted against each other in the cost function.

-

3.

Constraints are handled inherently.

Besides these advantages, there are still challenges when it comes to applying MPC in the field.

Problem formulation

There are several problem formulations of MPC. The here used LTV MPC formulation with its linear prediction model, the quadratic cost function, and linear or affine constraints seemed sufficient. The main uncertainties arise from non-modeled dynamics, parameter uncertainties, and fluctuating wind speed. With a well-tuned linear MPC, this algorithm can be extended to a robust formulation. Especially tube-based and stochastic MPC allows the same number of optimization variables and slightly more constraints.

To investigate the influence of the knowledge, especially about the varying pitch sensitivity, the optimization problem could be extended to be a nonlinear MPC, including the nonlinear aerodynamic model, or in this formulation, even the cost function could easily be adopted to include an additional reference for the pitch angle.

The real-time capability on the available hardware must be guaranteed, when extending the algorithm. For this purpose, it should be considered, that the optimization effort grows differently. With the nonlinear MPC in general, several QPs have to be solved in a single time step, whereas the other presented MPC variants solve a single QP. In general, the number of optimization variables increases the optimization effort in order \(\mathcal{O}=3\). The effect of the constraints depends on the optimization algorithm used. With an increasing number of constraints, the online active set QP algorithm qpOASES [18] used for the online optimization, should be exchanged.

The cost function and reference

The challenge for the references lies predominantly in region I and I.5, because here, the nominal power cannot be produced and the optimal operation points depend on the present wind speed, which includes uncertainties. How to optimize the transition between different stationary points through the references, especially for the rotor speed and the electrical power depending on the actual wind condition, is part of the present investigations.

Uncertainties

The optimization strongly depends on the precise prediction of future states. The MPC achieves this only with precisely estimated states and an accurate dynamic model. As shown these models must be further adapted to the unmodeled but present natural frequencies. As original equipment Manufacturers (OEM) know the WT and its dynamics with very high accuracy, they can derive the needed dynamic model of the WT and its parameters, but the choice of the considered dynamics cannot be done only with simulations. The estimation of the present states using EKF is state-of-the-art, but estimating the effective wind speed is challenging and harbors the source of uncertainties. The reason why the wind speed can only be determined under uncertainties lies in the nature of wind and has been described further in [13]. The uncertain wind speed leads to an optimization result that is only optimal for a steady wind speed. Robust MPC formulations can deal with these uncertainties [19], but therefore either the number of optimization variables or the number of constraints must be increased significantly. The effect of the increased optimization problem is further discussed in Sect. 5.

When MPC is applied to the physical WT, a different source of uncertainties arises from internally controlled components of other manufacturers. In some cases these lower-level controllers may interfere with the MPC, leading to unexpected behaviour of the closed loop system.

Besides the challenges with the algorithm and its tuning, further challenges arise when the algorithm is executed on the physical controller hardware, which is used to operate the WT.

5 Hardware

The major constraining factor for the application of MPC algorithms is the capability of real-time calculations. For field tests, one would not want to change the whole automation system, so the used hardware to execute the MPC algorithm must be compatible with the existing automation system. To compile the MPC algorithm to the real-time hardware reliably, toolchains like HiL-setups must be established [17]. For many hardware, there are several restrictions regarding functionalities used for the MPC algorithm.

The computational capacity of real-time hardware like PLCs has increased in the last few years and parallel computing has found its way into PLCs so that more complex algorithms and real-time optimization of MPC algorithms can now be performed.

Even though the computational capacity of real-time has increased in the last few years, still, computational capacity is a limiting factor and the complexity of the MPC must be adapted to it. After benchmarking MPC performance by increasing sample rate, model depth, and complexity, those parameters usually must be reduced for real-time execution on commercial Hardware to still find satisfying tradeoffs. In the present case, the hardware is limited to be compatible with PLCs of Bachmann Electronics.

To include the MPC in the supervisory control of the OEM, adapting the supervisory control is also one key problem. The MPC is able to use measurements of the WT, which are usually ignored by the SAC. New interfaces must be implemented, and data traffic load must be considered in its extension. Within this data, transport delays must be investigated. Here MPC holds a major advantage because the delay can directly be considered in the prediction model.

During field tests safety against damage must be ensured. In [5] we showed how the use of a separate PLC can ensure safety requirements. For this purpose, the supervisory control decides which control command it uses. The MPC can handle the commands of different controllers because it has no internal states, and the optimization can easily be initialized with the commands of the SAC. In contrast, the SAC needs to be extended by reset routines to ensure a rapid switch from MPC in order to handle critical system states. Here the MPC and the SAC are connected in a row so that all commands and measurements pass the SAC before they are forwarded to the MPC. To adapt a structure between supervisory control and the MPC and to reduce the overall delay time, the two controllers could operate in parallel and the supervisory control handles this directly.

Also operating both the MPC and the SAC on the same PLC could decrease delays with the potential risk that flaws in the MPC could also influence the operation of the SAC.

All the different structures require intensive testing, to ensure safe operation during field tests. The safety of these structures can be investigated in HiL-tests, with the drawback, that these tests are time-consuming. They are performed on real-time hardware and therefore, they cannot be sped up.

6 Conclusion

To conduct field tests of MPC for a WT, the control algorithm must not only perform well in simulations, but real-time hardware must execute the algorithm. We showed major challenges of applying MPC for field tests and proposed some opportunities to improve the algorithm. The control algorithm must be a trade-off between a complex and robust MPC algorithm and a simple and real-time capable algorithm. As modern real-time hardware has become more powerful during the last few years, it now offers opportunities to apply MPC algorithms of increasing complexity. The accuracy of the model is crucial for the performance and especially for linear MPC, there are operation points around the region I.5, where a reference for the pitch angle is necessary even though it is a command value.

Essential steps must extend the design process of SiL- and HiL-testing and precise model identification, because online tuning is more difficult compared to SACs. This also allows fast commissioning and shrinks the risk of safety issues, as every critical scenario can be tested without the risk of damaging the WT.

In future work, we will optimize the reference trajectory to adjust to the operating point and the wind speed dynamically. Furthermore, we include the identified actuator dynamics of the generator and investigate how it is efficiently included in the MPC algorithm. To reduce overall delay times, for the next field test, we use a parallel structure of the SAC together with the MPC.

To conclude, applying MPC for WTs in the field is challenging but jet possible, and we expect further field tests of MPC in the near future.

Notes

PLC unit from Bachman electronics GmbH, Model MH230.

References

Novaes Menezes EJ, Araújo AM, Bouchonneau da Silva NS (2018) A review on wind turbine control and its associated methods. J Clean Prod 174:945–953

Gros S, Schild A (2017) Real-time economic nonlinear model predictive control for wind turbine control. Int J Control 90(12):2799–2812

Jassmann U, Dickler S, Zierath J, Hakenberg M, Abel D (2016) Model predictive wind turbine control with move-blocking strategy for load alleviation and power leveling. J Phys Conf Ser 753(5):52021

Kong X, Ma L, Liu X, Abdelbaky MA, Wu Q (2020) Wind turbine control using nonlinear economic model predictive control over all operating regions. Energies 13(1):184

Castaignet D, Barlas T, Buhl T, Poulsen NK, Wedel-Heinen JJ, Olesen NA, Bak C, Kim T (2014) Full-scale test of trailing edge flaps on a vestas v27 wind turbine: active load reduction and system identification. Wind Energy 17(4):549–564

Dickler S, Wintermeyer-Kallen T, Zierath J, Bockhahn R, Machost D, Konrad T, Abel D (2021) Full-scale field test of a model predictive control system for a 3 MW wind turbine. Forsch Ingenieurwes 85(2):313–323

Albo A, Falkman P (2020) A standardization approach to virtual commissioning strategies in complex production environments. Procedia Manuf 51:1251–1258

Henke C, Michael J, Lankeit C, Trachtler A (2017) A holistic approach for virtual commissioning of intelligent systems: Model-based systems engineering for the development of a turn-milling center. In: 11th Annual IEEE International Systems Conference. IEEE, pp 1–6

Forbes MG, Patwardhan RS, Hamadah H, Gopaluni RB (2015) Model predictive control in industry: Challenges and opportunities. IFAC-PapersOnLine 48(8):531–538

Schamp M, Ginste L, Hoedt S, Claeys A, Aghezzaf E‑H, Cottyn J (2019) Virtual commissioning of industrial control systems—a 3d digital model approach. Procedia Manuf 39:66–73

Ossmann D, Seiler P, Milliren C, Danker A (2021) Field testing of multi-variable individual pitch control on a utility-scale wind turbine. Renew Energy 170:1245–1256

Wintermeyer-Kallen T, Dickler S, Zierath J, Konrad T, Abel D (2021) Weight-scheduling for linear time-variant model predictive wind turbine control toward field testing. Forsch Ingenieurwes 85(2):385–394

Burton T (2011) Wind energy handbook, 2nd edn. Wiley, Chichester

Jassmann U (2018) Hardware-in-the-loop wind turbine system test benches and their usage for controller validation. Universitätsbibliothek der RWTH Aachen, Aachen

Jassmann U, Zierath J, Dickler S, Abel D (2016) Model predictive wind turbine control for load alleviation and power leveling in extreme operation conditions. In: 2016 IEEE Conference on Control Applications (CCA). IEEE, pp 1368–1373

Howlader AM, Urasaki N, Yona A, Senjyu T, Saber AY (2013) A review of output power smoothing methods for wind energy conversion systems. Renew Sustain Energy Rev 26:135–146

Dickler S, Kallen T, Zierath J, Abel D (2020) Rapid control prototyping of model predictive wind turbine control toward field testing. J Phys Conf Ser 1618:22068

Ferreau HJ (2017) qpoases user’s manual. https://www.coin-or.org/qpOASES/doc/3.2/manual.pdf. Accessed 16 Dec 2022

Bemporad A, Morari M (1999) Robust model predictive control: A survey. In: Garulli A (ed) Robustness in identification and control. Lecture notes in control and information sciences, vol 245. Springer, London, pp 207–226

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wintermeyer-Kallen, T., Basler, M., Konrad, T. et al. Challenges of applying model-based predictive wind turbine control in the field. Forsch Ingenieurwes 87, 119–128 (2023). https://doi.org/10.1007/s10010-023-00634-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-023-00634-1