Abstract

The electrochemistry nowadays has many faces and challenges. Although the focus has shifted from fundamental electrochemistry to applied electrochemistry, one needs to acknowledge that it is impossible to develop and design novel green energy transition devices without a comprehensive understanding of the electrochemical processes at the electrode and electrolyte interface that define the performance mechanisms. The review gives an overview of the systematic research in the field of electrochemistry in Estonia which reflects on the excellent collaboration between fundamental and applied electrochemistry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The chemical composition and crystallographic structure of electrodes, as well as the chemical composition and dielectric characteristics of electrolytes, have a remarkable influence on the electrical double layer (EDL) characteristics, adsorption kinetics of organic compounds and ions, faradaic processes of electroreduction of oxygen, complex cations and anions, and on the fuel oxidation kinetics. The latter has been systematically studied at the University of Tartu since 1990 [1,2,3,4,5,6,7,8,9,10,11,12,13,14]. Detailed theoretical analyses and experimental results have been discussed based on previously published models [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34].

The current results of the Tartu electrochemistry working group are based on the fundamental studies at solid drop bismuth electrodes (started in 1965) [35] and at single-crystal Bi(hkl) facets (started in 1974) [36, 37]. Therefore, the pioneering ideas of Grahame, Frumking, and Trasatti have been all applied for the development of fundamental electrochemistry at the University of Tartu [1,2,3,4,5,6,7,8,9,10,11,12, 20,21,22,23,24,25,26,27,28, 36, 37]. The role of the potential drop in the electrode surface layer, obtained by the electronic characteristics of metal or carbon electrodes, has been discussed in [11, 12, 33, 38,39,40,41,42,43]. Systematic analysis of experimental data indicates that the electronic characteristics of the sp-metals and carbon electrodes (effective mass and concentration of effective charge carriers, dielectric constant, Fermi energy levels work function dependence of crystallographic structure and orientation, etc.) [1, 2, 9, 11, 38,39,40,41,42,43] can have a more significant role on the EDL structure (including interfacial capacitance values) and Gibbs adsorption and Gibbs free energy values than the solvent (dielectric constant, dipole moment, etc.) or anion solvation/adsorption characteristics [5,6,7,8, 13]. Additionally, the EDL structure has been simulated by density functional theory (DFT) and molecular dynamics (MD) methods [44,45,46,47,48,49,50,51,52].

The influence of surface roughness on the EDL characteristics [53, 54] has been analysed based on models developed by Daikin et al. [55,56,57]. It was demonstrated that the surface roughness values established from electrochemical impedance spectroscopy (EIS) data depend on the electrode potential (surface charge density), electrolyte concentration (Debye screening length), and temperature. In addition, the surface roughness depends on the electrode’s crystallographic and electronic structure (Fermi energy differences), and the difference in work function values for different crystallographic planes exposed on the rough polycrystalline surface [1, 2, 53,54,55,56,57].

EDL and adsorption studies have been conducted on Bi(hkl), Sb(hkl), Cd(hklf), and C(0001) single-crystal electrodes [2, 9,10,11,12, 44, 45, 53, 54, 58,59,60,61,62,63,64,65,66], as well as on porous carbon electrodes [7, 44, 45, 53, 54, 67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85]. Gibbs adsorption and Frumkin molecular interaction coefficient values depend remarkably on the crystallographic structure of the electrode, the chemical nature of electrode metal and electronic parameters, solvent chemical composition, and organic molecule characteristics. This was explained by the different solvation energies of the metal surface, organic molecules and solvent polarisability, and electrode potential, i.e., surface charge density applied. Therefore, the electrode metallic characteristics and crystallographic structure play a critical role in the density and geometrical structure of the adsorbed molecular layers formed, i.e., calculated Gibbs adsorption values.

A detailed comparison of specific adsorption at metal Bi(hkl), Sb(hkl), and Cd(0001) electrodes, glassy carbon, highly oriented pyrolytic graphite basal plane C(0001), graphene electrodes, and micro-mesoporous (MMP) carbons with high surface area will be given [25,26,27,28,29,30,31,32]. It was found that the influence of the solvent properties on the adsorption kinetics of iodide, bromide, and chloride and Gibbs energy of adsorption can most clearly be established using simple single-crystal plane | surface-active electrolyte systems, including 1-ethyl-3-methylimidazolium tetrafluoroborate (EMImBF4) with additions of 1-ethyl-3-methylimidazolium chloride (EMImCl), 1-ethyl-3-methylimidazolium bromide (EMImBr), and 1-ethyl-3-methylimidazolium iodide (EMImI). It should be noted that surface pre-treatment processes hugely influence the EDL, adsorption kinetics, and faradaic reaction kinetics.

The fundamental knowledge collected has been applied for the development of very high energy and power density electrical double layer capacitors (EDLCs) [7, 68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89] prepared by applying the sol–gel method for syntheses of very mesoporous carbons [81, 90, 91], hybrid superacpacitors (HSCs), and Li+- and Na+-ion batteries (LIBs and SIBs) [92,93,94,95,96,97,98]. It should be stressed that the porous structure (hierarchical porosity) of metal and complex oxide electrodes, but especially of the carbon electrodes, has a large influence on the limiting series capacitance (Cs), characteristic adsorption time constant (tchar), Gibbs adsorption and adsorption free energy, and on the power density (P) values. In order to widen the ideal polarisability region, ionic liquids (ILs) with variable chemical compositions have been studied [60,61,62,63,64,65, 99,100,101,102,103,104,105,106,107,108,109,110]. Systematic EIS studies of electrodes in aqueous and non-aqueous electrolytes, ILs and IL mixtures containing surface-inactive ions and surface-active anions and cations, and some additions of organic solvents [60, 62,63,64,65, 99,100,101,102,103,104,105,106,107,108,109] demonstrate a high correlation with electrolytes based on non-aqueous solvents with additions of specifically adsorbing, so-called surface-active, anions and physically adsorbing organic compounds. The role of electrode potential on the region of ideal polarisability has been demonstrated by in situ Fourier transform infrared (FTIR), Raman, EIS, and synchrotron beam–based X-ray photoelectron spectroscopy (XPS) studies [5, 65, 101, 107,108,109,110,111,112,113,114,115]. Electrochemical blocking of electrodes under high overpotentials due to the electropolymerisation of active organic compounds has been demonstrated, and patents have been received [116]. This effect is significant in avoiding overcharging EDLC, HSC, LIBs, and SIBs.

The influence of the polymer membrane characteristics on EDLCs, HSCs, LIBs, and SIBs has been studied by Tõnurist (Liivand) et al. [99, 117, 118]. It was demonstrated that the power density, as well as energy density of EDLCs completed with various self-made polyvinylidene membranes using the electrospinning method [119,120,121,122,123], depends very strongly on the electrolyte membrane characteristics (on the meso-macroporosity, thickness, pore size distribution, etc.), especially in solvents with high viscosity (including ILs).

The carbide-derived carbons (CDCs), such as Mo2C-derived hierarchically porous carbon with an optimal ratio of micro- and mesopore volumes, have been used for the fabrication of artificial switches/muscles [124,125,126]. The quickest relaxation times have been established for highly mesoporous carbon–based switches [124,125,126,127]. The carbon materials synthesised have been studied by novel in situ methods, including small angle neutron scattering (SANS), quasielastic (QENS), and inelastic (INS) neutron scattering methods, wide-angle X-ray diffraction, and other synchrotron beam based and traditional gas adsorption methods [8, 128,129,130,131,132,133,134]. It was found that for hydrogen storage, very microporous carbon materials can be applied. The same tendency is valid for CH4 storage [133,134,135,136].

The Faradaic processes at MMP carbon electrodes activated with Pt, Pt-Ru, Pt-Ir, Pt-CeO2, Pt-Pr6O11, and d-metal = nitrogen nanoclusters (Fe = N2, Co = N2, FeCo = N2) activated catalysts depend exceptionally strongly on the carbon support specific surface area, mesopore volume ratio to micropore volume, and pore size distribution function of carbon support and to surprisingly large extent on the electrical conductivity of powder under application [4, 5, 137,138,139,140,141,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165,166,167,168,169,170].

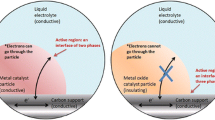

Solid oxide materials for solid oxide fuel cells (SOFC) and electrolysers [66, 171,172,173,174,175,176,177,178,179,180], including complex perovskite oxides, Ni–cermet anodes, and fluoride-type electrolytes, have been synthesised and tested for solid oxide fuel cells and electrolysers by Nurk, Kivi, Lillmaa, Korjus, Maide, and Heinsaar since 2001 [181,182,183,184,185,186,187,188,189,190,191,192,193,194,195,196,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212,213]. Different complex oxide electrode synthesis methods have been applied, starting from the solid oxide high-temperature sintering method.

Electrical double layer structure at single-crystal metal and carbon electrodes

The electrical double layer structure at different electrodes has been studied in various electrolytes such as H2O, acetonitrile (ACN), ethanol, methanol, propylene carbonate (PC), gamma butyrolactone (GBL), ethylene carbonate (EC), and dimethyl carbonate (DMC) [36, 59, 214,215,216,217,218,219,220]. For that purpose, various methods such as cyclic voltammetry (CV), EIS, in situ scanning tunnelling microscopy (STM) and atomic force microscopy (AFM), in situ FTIR and Raman as well as operando synchrotron radiation beam–based photoelectron (SR-XPS), and SANS have been applied. Typically, the CV method is employed first when studying the systems mentioned above to determine their ideal polarisability range. It was found that the region of ideal polarisability is narrow for Cd(hklf) and very wide for C(0001) and graphene electrodes. The series capacitance, electrode potential curves (C vs E curves) calculated from Nyquist complex plane (− Z”, Z′) plots, given in Fig. 1, show that the interfacial properties of electrode | H2O and electrode | non-aqueous electrolyte solution depend on the metal electronic characteristics and used solvent chemical composition. The series capacitance can be divided into the inner layer (Ci) and outer layer (Cd) capacitances, connected in series:

In 1980–1990s [1, 2, 11, 12, 21, 38,39,40,41,42,43, 58, 59], it was demonstrated that Ci can be represented as:

where Cm is the capacitance of the metal or thin surface film, Cdip is the solvent layer capacitance, and CH is the Helmholtz capacitance.

The influence of electrode material on the interfacial capacitance has been demonstrated by Oll et al. [62]. In the given study, very low Cs values have been measured for ionic liquid–based systems (Fig. 2), increasing from C(0001) (non-metallic electrode) towards Au, known as an ideal electronic conductor. For a semi-metallic Bi, the moderate Cs values, similar to Pb, have been calculated. It should be stressed that for Bi, Pb, Pt, and Au, the high-vacuum electromagnetic deposition method of electrode materials has been used to avoid any chemical contamination of surfaces during the chemical or electrochemical polishing steps. Furthermore, it can be seen how the crystallographic structure of the carbon electrode influences the Cs values. A very sharp capacitance minimum can be seen for a very high-quality graphene electrode and C(0001). This capacitance minimum is mainly caused by the potential drop inside the graphene and C(0001) surface layer due to the very low concentration of charge carriers in the electrode surface layer [2, 58, 222], which results in low Cm. Oll et al. also showed that there is no hysteresis of Cs vs E curves that is visible in the case of amorphous carbon electrodes. It is very interesting that the potential of capacitance minimum somewhat depends on the carbon electrode under study, but overlapping Emin values can be seen for graphene and partially graphitised porous carbon synthesised from TiC using chlorination method and further cleaned during high-temperature (800 °C for 4 h) hydrogen reduction step. Surprisingly, there is no capacitance minimum in the Cs vs E curve for amorphous carbon electrode, explained by the non-ideal metal phase structure and slow kinetics of formation of EDL at the micro-mesoporous surface.

C vs E dependences for different electrode materials measured in EMImBF4 [62]

In addition to experimental investigations, numerous computational studies have been conducted to study the electrode | ionic liquid EDL structure and its properties [46,47,48,49,50,51,52, 223,224,225,226]. Followingly, these studies have allowed investigation of the adsorption of ionic liquid ions on the electrode’s surface, which is experimentally challenging, as well as the influence of the electrode’s potential on the EDL structure. For instance, in the case of Bi(111) | ionic liquid interface, the DFT calculations allowed to reason the difference between the measured capacitance of EMImBF4 and 1-butyl-4-methylpyridinium tetrafluoroborate (BMPyBF4) by estimating the optimal distance between the electrode’s surface and ionic liquid ions, which are related to the CH [227]. Under intensive scrutiny has been the computational estimation of C vs E dependence, as it can be determined both experimentally using EIS and computationally. Numerous aspects of C vs E dependence and capacitance-structure dependence at the metal | ionic liquid interface have been investigated by Ivaništšev et al. [46, 47, 223,224,225,226]. Using constant field MD simulations, the occurrence of aforementioned capacitance hysteresis has been reasoned with the formation of different ionic liquids interfacial structures, which need overpotential to transition from one structure to another [50]. The impact of the surface charge plane position at Au(hkl) | ionic liquid interfaces has been highlighted by Voroshylova et al. by showing that a simple correction of computational data significantly improves the agreement with the experimental results [48]. Furthermore, a recent study showed that the peaks in a C vs E curve arise due to the restructuring of the ionic liquid near the electrode’s surface [51]. The effect of temperature and quantum capacitance (i.e., Cm) on the C vs E dependence of graphene | ionic liquid interface has been studied by Ers et al. [49, 52], showing that the quantum capacitance has a significant impact on the overall interfacial capacitance. In contrast, the temperature has a minor effect on the interfacial capacitance near the potential of zero charge (pzc) when the quantum capacitance is very low, as shown in Fig. 3b.

Adsorption of organic compounds from H2O and IL electrolytes

The adsorption of organic compounds at Bi(hkl), Sb(hkl), Cd(hklf), and C(0001) electrodes has been studied mainly by EIS and in situ STM and AFM methods [228,229,230,231,232,233,234,235,236,237,238,239,240,241,242]. The data collected for the adsorption of aliphatic alcohols, cyclohexanol, cyclohexanone, and cyclohexane carboxylic acid at Bi(hkl), Sb(111), and Cd(0001) facets have been discussed in detail in Lust et al. [13]. It was concluded that the Gibbs adsorption energy increases from Bi(111) to Bi(011) facet and from Bi(111) to Sb(111). The small positive calculated formal charge transfer coefficient values (from 0 to 0.09) characterise the substitution of water clusters, consisting of two or three molecules and a small dipole contribution of the functional group of adsorbate, which is directed towards the solution. Additionally, it was found that the organic compound adsorption activity is lowest at Cd(0001) and highest at Sb(111) facet [13, 228,229,230,231,232, 240,241,242]. Thus, the H2O adsorption activity decreases from Cd(0001) to Sb(111) [1, 2].

The adsorption behaviour of 2,2′-bipyridine (2,2′-BP) and 4,4′-bipyridine (4,4′-BP) molecules has been investigated by in situ STM method [237,238,239,240,241]. For 2,2′-BP and 4,4′-BP, the compact adsorption layer forms, which has been visualised. The in situ STM data, given in Fig. 4, show the highly organised molecular rows of 4,4′-BP at various electrodes together with the models of formed layers. Interestingly, these rows’ configurations depend on the electrode’s crystal structure and metallic properties.

It should be stressed that the atomic level adsorption layer structure of 4,4′-BP depends on the concentration of surface-inactive electrolyte [239]. With the increase of ionic strength, the Gibbs adsorption of 4,4′-BP increases in agreement with data for other organic molecules’ adsorption at metal electrodes [13]. Interestingly, recently, Pikma et al. showed that in an ionic liquid environment, the adsorption of 4,4′-BP takes place in two distinctive self-assembled layers, one on top of the other, not just in a monolayer [241].

Additionally, the adsorption of camphor and thiourea was investigated on the Bi(111) surface. Similarly to 4,4′-BP, camphor forms a highly regular adsorbed layer at Bi(111) (Gibbs adsorption 2.3·10−10 mol·cm−2) [238]. It is fascinating that, in contrast, the thiourea, exhibiting weak specific chemisorption behaviour at Bi(111), does not form a regular adsorption layer. Surprisingly, there are no adsorbed thiourea molecules at ideally flat monocrystal areas. Instead, the adsorbed molecules can be observed at defect surface areas, i.e., on the step edges of the characteristic triangular steps [234], illustrated in Fig. 5.

In situ STM image and model highlighting the adsorption of thiourea at the defect surface areas of Bi(111) surface [234]

EIS, Raman, and infrared spectroscopy methods have been used to study the chemical interaction between Bi(hkl) and other sulphur-containing organic compounds [243]. It was identified that the interaction is very strong, and due to chemisorption, a bismuth-thiolate layer forms at the Bi(111) surface.

Adsorption of halide anions at single-crystal Bi(hkl), Sb(111), and Cd(0001)

Specific adsorption of ions from H2O, non-aqueous, and IL mixture electrolytes at metal and carbon electrodes has been a focus of intensive studies and discussions since the 1960s [1, 2, 5, 20, 22, 24, 25, 33, 60, 62,63,64,65, 99,100,101, 112,113,114, 215,216,217,218, 220, 221, 244,245,246,247,248,249,250,251,252,253,254,255]. Various models (Hurwitz-Parsons [244,245,246], Kolotyrkin et al. [256], Damaskin [257], Palm and Damaskin [258], etc.) and modified isotherms and models [38, 259,260,261,262,263,264,265], including the conception of partial charge transfer, have been developed and tested. It was found that the Frumkin adsorption isotherm can be used for the interpretation of specific adsorption data calculated at fixed potentials [215,216,217,218, 220, 221, 247,248,249,250,251,252,253, 255, 257, 258]. The specific adsorption of halides has been studied by CV, EIS, SR-XPS, and subtractively normalised interfacial Fourier transform infrared spectroscopy (SNIFTIRS), in situ Raman, and in situ STM/AFM methods. It was found that the adsorption of halide anions depends on the single-crystal plane structure, solvent characteristics, and on the anion or cation chemical composition. The anion surface activity increases from Cd(0001) to Sb(hkl) and from F− to I−. The halide adsorption is nearly reversible up to C vs E curves peak potentials in agreement with in situ STM data. As for the Bi(111) interface, very stable adsorption superstructures have been observed for I− and Br− containing electrolytes. The contact adsorption of Cl− is more questionable at the Bi(111) interface as only a weak Moire structure of an adlayer has been observed. It is interesting that within a very wide potential region (even over 1 V), the Br− and I− superstructure is stable and drastic reorganisation processes of the electrode surface structure have been observed only at very high negative (desorption of anions) and at very positive potentials, where dissolution/oxidation of Bi(hkl) surface started [5].

The adsorption of halide anion starts at a very negatively charged electrode surface, in agreement with in situ STM and SR-XPS data, and this phenomenon is known as the specific adsorption of anions as it takes place against the electrostatic repulsion forces. Data in Fig. 6 and in Table 1 indicate that the Gibbs adsorption energy is influenced by the solvent chemical composition, and the strongest adsorption of I− takes place from ACN (where the solvation energy of anions is lowest).

Cs vs E curves for Bi(111) electrode in 0.1 M LiI in different solvents [5]

Surprisingly, it was found that the simple virial isotherm can be applied for the analysis of specific adsorption data from ACN, ethanol (EtOH), methanol (MeOH), PC, and ethyl methyl carbonate (EMC) mixed binary electrolyte solutions with moderate constant ionic strength [12, 59, 215,216,217,218, 220, 221, 247,248,249,250,251,252,253, 255, 258]. According to the Hurwitz–Dutkiewicz-Parsons method [244, 245], charges for specifically adsorbed ions σ1° can be calculated at constant surface charge density σ or at constant electrode potentials E, according to formulas:

where ζ is the Parsons’ function ζ = γ + σE and Δζ = ζ0 − ζ at constant σ, γ is the specific surface work value, Δγ = γ0 − γ at constant E, and the parameters with index 0 corresponding to these values in the supporting electrolyte. The most important adsorption characteristic, the Gibbs energy of adsorption − ΔGA, was obtained by fitting the σ1 values to the semi-empirical simple virial isotherm [12, 20,21,22, 33, 59, 215,216,217,218, 220, 221, 244,245,246,247,248,249,250,251,252,253, 255].

or to the corrected virial isotherm

with

where z is the charge number of the adsorbed anion (− 1 in the case of I−, Br−, and Cl− anions), c is the total concentration of electrolyte solution (0.1 M), and Beff is the second virial coefficient, characterising the mutual repulsion (and size) of the adsorbed ions. Using a simple virial isotherm, the Beff is an effective parameter because we have neglected the dependence of the diffuse layer potential drop (ψ0 from σ1) in isotherm (3) and calculations. However, the Beff values can be used for very preliminary analysis of the mutual interaction of adsorbed ions from various solvent systems [12, 59, 215,216,217,218, 220, 221, 247,248,249,250,251,252,253, 255, 258], especially at Emin potential (pzc), where the ψ0 potential drop value is zero and Beff can have some (comparative) physical meaning. The coinciding σ1 value, calculated both ways, gives evidence of the self-consistency and correctness of the obtained data. Similar to non-aqueous mixed electrolytes, Damaskin and Palm introduced additional corrections for isotherms [257, 258], but surprisingly deviation of the corrected experimental isotherm from linear correlation increases further. This approximation has been criticised by Vorotyntsev [266], but no final theory has not been developed yet.

The slope of a virial isotherm depends on the electrode metal studied, and for Bi(hkl), not shown for shortness, the slope values are higher if compared with Cd(0001) plane. Thus, Beff values calculated using uncorrected isotherm can be used only for qualitative analysis of data, assuming that in the same solvent, the ψ0 effects are comparable for different Bi(hkl) planes.

Systematic analysis of experimental data for Bi and Sb electrodes demonstrates that the ψ0 potential drop corrections in diffuse layer applied for corrected isotherm (4) are usually strongly overestimated [12, 26, 27, 30, 59, 215,216,217,218, 220, 221, 247,248,249,250,251,252,253, 255, 258]. Only for water-based binary electrolyte systems with constant ionic strength electrolyte systems the diffuse layer potential drop (ψ0 potential drop) corrections for quantitative analysis of data at Bi(hkl) electrodes can be used [12, 59, 247, 258]. The same effect, i.e., overestimated ψ0 value, has been observed for analyses of faradic charge transfer processes at Bi(hkl) and Cd(0001) electrodes [267,268,269,270,271,272,273,274,275,276] if the Frumkin slow charge transfer theory [21, 26,27,28, 30, 66, 277,278,279,280,281,282,283], including ψ0 potential correction, has been applied. Thus, the role of diffuse layer seems to be insignificant for specifically adsorbing anions from non-aqueous electrolytes and nearly contact adsorption of Cl−, Br−, I−, and SCN− anions at single-crystal planes from non-aqueous electrolytes [12, 59, 215,216,217,218, 220, 221, 247,248,249,250,251,252,253, 255, 258], including from ILs and IL mixtures as well as IL with addition of solvent [5, 63,64,65, 101, 107,108,109, 112,113,114], demonstrated using in situ STM [5, 100, 114, 284], infrared spectroscopy [60], and in situ synchrotron beam–based XPS measurements data [109, 110].

This is in agreement with the very weak influence of solvent characteristics (dipole moment, dielectric permittivity, donor–acceptor number, etc.) on the Gibbs adsorption energy, but specifically on the values of formal charge transfer coefficient (so-called electrosorption valency) and effective dipole moment [38, 216,217,218, 220, 247,248,249,250,251,252,253, 259, 262,263,264,265], created at metal | electrolyte interface, being 10 times lower for Bi, Sb, and Cd electrodes, than the dipole moment values calculated for ideal conductor | anion at vacuum interface [12, 26, 27, 30, 59, 215,216,217,218, 220, 221, 247,248,249,250,251,252,253, 255, 258]. Due to the partial charge transfer process being reversible within the moderate potential region at non-ideal metals (Bi, Sb), the adsorption of halide ions is a complicated process, and new systematic studies and detailed comparison of experimental data from various aprotic and technologically important solvents (ACN, EC, PC, EMC, DMC, diethyl carbonate (DEC), GBL) and IL mixtures, potentially applicable in modern energy storage and conversion devices like batteries and EDLCs [215,216,217,218, 250], have a more straightforward direction of studies.

The Gibbs adsorption energy values, given in Table 1, indicate that there are noticeable differences between Cd, Bi(hkl), and Sb(hkl) electrodes with the increasing adsorption activity in the presented order of metals. The most active adsorption for Bi(hkl) has been observed for most reticular density plane Bi(011) plane and very lyophilic C(0001). Adsorption of I− anions (like Br− and Cl− anions) increases in the order of solvents; H2O < MeOH < EtOH < EC < PC < GBL < ACN, demonstrating that with the decrease of solvation energy of anions, the Gibbs adsorption energy increases.

Data in Fig. 7a show that the Cs depends extremely strongly on the chemical composition of IL under study. Very low capacitance values have been calculated for big anions with high molar volume. The surface structure of Bi(111) and Bi(01 \(\overline{1 }\)) has shown to be very stable within a wide potential region [114, 285]. Only at moderately negatively charged electrode surface (E = − 1.6 V vs Fc/Fc+ reference electrode) the Moire superstructure has been observed, dependent on the electrode crystallographic structure, surface electrochemical activity, and electrode potential.

The capacitance values are very sensitive for water additions in IL. For extremely well-dried 1-ethyl-3-methylimidazolium trifluoromethanesulfonate (EMImOtf), very low capacitance values have been calculated, demonstrated in Fig. 7b. In very well-dried IL, the capacitance values are higher for the Bi(01 \(\overline{1 }\)) plane and lower for Bi(001), like for H2O electrolytes. The capacitance values increase noticeably when the H2O concentration increases. Detailed analysis of EIS data demonstrates that the adsorption of anions is quicker than cations (nearly 1.5 orders), but the series capacitance values are very low for big fluorinated anions (OTf−) within all adsorption regions demonstrating slow adsorption kinetics similar for big cations. Nearly ideal capacitive behaviour has been observed from − 1.7 to − 0.6 V vs Fc/Fc+.

The specific adsorption of Cl−, Br−, and I− anions from surface-inactive IL EMImBF4 mixture has been analysed (Fig. 8). Very similar behaviour as already discussed for H2O [12, 59], non-aqueous surface-active electrolytes [218, 220, 221, 247,248,249,250,251,252,253, 255] has been established for halide ions + IL electrolytes for Bi(hkl), Sb(111), Cd(0001), and C(0001) planes by Siinor and Siimenson et al. [63, 65, 286, 287]. STM images in Fig. 8 show the well-organised adsorbed layers of I−, Br− from EMImBF4. With the increase of halide anion concentration in surface-inactive electrolyte, the differential capacitance curve shifts towards more negative potentials, but the maximal capacitance values (Cs(max) = 58 μF·cm−2) are independent of Br− (or I−) additions in surface-inactive IL. The back-integration method of Cs vs E curves has been used to calculate surface charge density values in [5]. Using the given method, very high surface charge densities have been calculated, indicating the high surface activity of halide anions at Bi(hkl) and Sb(111) surface from IL. Therefore, the higher charges for non-aqueous solutions containing specifically adsorbed I− ions have been calculated.

At very negative potentials, there is no halide adsorption and only with the increase of electrode potential does the specific adsorption start. It is surprising that the I− and Br− adsorption is very intensive, and it takes place already at a highly negatively charged (− 12 or − 10 μC·cm−2, respectively) surface. It is to be stressed that the adsorption of halides is nearly reversible up to capacitance maximum potentials for Sb(hkl) and Bi(hkl) electrodes. Thus, halide specific adsorption–based pseudocapacitors can be developed for enhanced energy density storage. The in situ STM data show that there are ions at the Bi(111) electrode surface with a regular distance of 0.42 nm between the Br−-anion centres. The Cl− adsorption is weak, and only after long-lasting polarisation of Bi(111) at fixed potentials the Moier’s superstructure is formed at the electrode with constant ionic strength.

There is a significant influence of the single-crystal planes and carbon electrode surface crystallographic structure (C(0001), graphene, porous carbon) on the shape of complex plane EIS plots (− Z” vs Z′) and C vs E [7, 63, 65, 68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87, 89, 286,287,288,289,290]. Thus, the surface charge density vs potential curves (σ vs E), established using the back-integration method of C vs E curves, depend very remarkably on the electrode studied. For comprehensive analysis and development of supercapacitors, HSC, LIBs, and SIBs, systematic analysis of data, including analysis of the influence of solvent polarisability, dielectric constant, and viscosity, is inevitable. Specific adsorption of iodide and bromide from non-aqueous surface-inactive electrolyte (E4NBF4, E3MNBF4, and EM3NBF4 in ACN) and from IL systems (EMImBF4 + EMImI, EMImBF4 + EMImBr, and EMImBF4 + EMImCl) at carbon electrodes [63, 65, 284, 286, 287] has been applied for the enhancement of specific energy and power densities of HSC based on MMP carbon or carbon microsphere electrodes.

Electrochemical kinetics at single-crystal electrodes

Thomberg, Jäger, and Härk have studied the electroreduction of [H3O]+ [14, 273] and [S2O8]2− at Bi(111) [271] and Cd(0001) [268, 270, 274], as well as (Co[NH3]6)3+ [269, 272] and Eu3+ [275] at Bi(hkl) and Cd(0001) by CV, EIS, and chronoamperometry methods. [Fe(CN)6]3− anions at Cd(0001) electrode have been studied by Nerut et al. [276]. It was found that the reduction rate depends on the crystallographic structure of the electrode used, as well as on the chemical composition and electronic characteristics of the electrode material (Bi or Cd) studied.

The overvoltage of [H3O]+ electroreduction increases from Bi(111) to Bi(01 \(\overline{1 }\)) [14, 268,269,270,271, 273,274,275] in the same order as established for the increase of adsorption activity of anions and organic compounds, explained by weaker adsorption of water molecules at Bi(111) and Bi(hkl) as well as weaker chemical adsorption of [H3O]+ on Bi(111) plane compared with Bi(01 \(\overline{1 }\)). For more chemically active planes, i.e., Bi(01 \(\overline{1 }\)) and Bi(001), some deviation from Frumkin’s slow discharge theory [26, 277] has been observed. This deviation has been explained by the weak adsorption of reacting compounds at the electrode surface. The given knowledge collected has been used for the development of electrochemical waste water purification systems [291].

The same order of activities has been recognised for [S2O8]2− and [Co(NH3)6]3+ reduction at Bi(hkl). For more hydrophilic Cd(0001), a weaker deviation from Frumkin classical model has been observed. A more pronounced deviation of Bi(hkl) from the classical model [26, 277,278,279,280, 283, 291] can be explained by the semi-metallic character of Bi(hkl) compared with Cd(0001) and Au(hkl) surface planes [278,279,280, 283]. The electroreduction of Eu2(SO4)3 has been studied at Bi(01 \(\overline{1 }\)) electrode in acidic HClO4 and H2SO4 solutions (at similar pH = 3.0) with additions of LiClO4 and Na2SO4 electrolytes as surface-inactive electrolyte solutions. The kinetics of Eu3+ cations depends on the electrode potential applied and on the concentration of the supporting electrolyte.

The systematic analysis of the electroreduction data for Bi(hkl) indicates that similar to the specific adsorption of anions, the diffuse layer potential drop values are overestimated. Therefore, it seems that the centre for charge transfer for real systems is closer to the electrode than that assumed by the classical Frumkin slow discharge model, i.e., ψ0 potential values are overestimated [14, 268,269,270,271, 273,274,275,276]. The new model developed by Damaskin et al. [30] is in better agreement than the classical ψ0 correction model. Detailed analysis of EIS data indicates that within the moderate ac frequency region, the system is controlled by an adsorption step. Only mixed kinetic processes occur at very low ac frequencies, i.e., the adsorption and mass-transfer step processes are the rate-limiting steps at Bi(hkl) and Cd(0001) surfaces.

Development of electrical double layer and hybrid supercapacitors

Syntheses and characterisation of micro-mesoporous carbon powders from metal carbides

Carbon electrodes have been systematically studied since 1991 in order to establish the electrical double layer characteristics and pzc values for geometrically rough carbon and glassy carbon electrodes in ACN + (C2H5)4NBF4 solutions [1, 2]. Experimental EIS data measured at different ac frequencies demonstrated that the surface is geometrically rough, and the capacitance values depend on the glassy carbon and graphite electrode surface treatment methods, i.e., on the surface roughness values of electrodes. Also, the role of half-metal (semi-metallic) surface film properties of glassy carbon and graphite electrodes were analysed [86].

Since 1997, the binary (α-SiC, TiC, VC, B4C, WC, Mo2C, Al4C3, Cr3C2, etc.) [7, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85, 87] and ternary carbides (Ta4HfC5, WTiC2) [82] have been used for the preparation of MMP carbon electrode powders with hierarchical porous structure. The so-called high-temperature chlorination method has been used for the synthesis of corresponding MMP carbon powders, respectively. The carbon powders were purified by the high-temperature hydrogen treatment step (by applying 750–850 °C for 2–6 h). HCl, CO2, KOH, and ZnCl2 or a combined ZnCl2 + KOH mixture of activators were used for additional activation of C(α-SiC) and other carbon powders [83,84,85].

The carbon materials were analysed using X-ray diffraction spectroscopy (XRD), focused ion beam time-of-flight secondary ion mass spectrometry (FIB-TOF–SIMS), Raman spectroscopy, scanning electron microscopy with energy dispersive X-ray analysis (SEM–EDX), and high-resolution transmission electron microscopy (HR-TEM) combined with electron energy loss spectroscopy (EELS) and selected area electron diffraction spectroscopy (SAED) analysis methods [7, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85, 87]. The SEM–EDX data show that prepared carbon particles have complicated and variable shapes, containing wrinkled, blocked, and amorphous regions [84]. It is interesting that, for different CDCs, nearly graphitised blocks form between amorphous particles at sintering temperatures lower than 1200 °C. The HR-TEM-SAED-EELS data confirm this conclusion, demonstrating that the ordering of carbon takes place even at T ≥ 900 °C [78,79,80,81,82]. The Raman spectra (l = 514 nm) were fitted with a combination of two Lorentzian and two Gaussian functions for both first-order and second-order Raman scattering regions [8, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85, 128,129,130,131,132,133,134, 288, 289, 292]. Detailed analysis of spectra indicates that with the increase of the final treatment temperature, the 2D peak and other second-order excitation peaks increased, demonstrating that the graphitisation processes have already started at 900 °C.

The Brunauer–Emmett–Teller (BET) gas adsorption method and Hg intrusion porosimetry methods have been used for detailed porosity analysis [7, 8, 67, 68, 70,71,72,73,74,75,76,77,78,79,80,81,82,83, 85, 87, 128,129,130,131,132,133,134,135,136, 169, 293,294,295]. For BET analyses, N2, Ar, Kr, CO2, and H2 were used as test gases; various fitting methods (non-local density functional theory (NLDFT) and Saieus program integrating different fitting models); different pore models (cylindrical pore, heterogeneous surface, standard slit, and aspect ratio 6) have been used [8, 71, 128,129,130,131,132,133,134,135,136, 169, 293,294,295].

Based on the BET gas adsorption method, the carbon powder micro-mesoporosity characteristics (ratio of micropore (Vmicro) to mesopore volume (Vmeso), the ratio of micropore surface area (Smicro) to mesopore surface area (Smeso)) are influenced by binary and ternary carbide chemical composition, raw carbide crystallographic structure, and synthesis temperature (Table 2). The X-ray scattering and SANS data show that the nanostructure of C(Mo2C) prepared at different chlorination temperatures depends on applied T [130, 132]. The specific inner surface area for C(Mo2C), together with the volume fraction of the pores, increases with the chlorination temperature up to 900 °C, but at higher temperature values (T > 1000 °C), a significant decrease of both parameters takes place. Materials prepared at T = 600 °C or 700 °C are ultramicroporous, having a slit-like or cylindrical pore shape with an average size in the order of 0.6 nm. C(Mo2C) synthesised at T > 900 °C have pore widths around 1 to 3 nm. Using the wide-angle X-ray scattering (WAXS), it was demonstrated that the pore shape of different CDCs varies, C(α-SiC) (1000 °C) has sphere-like pores (d = 1 nm), C(TiC) (950 °C) has cylinder-like pores, and C(Mo2C) (1000 °C) has slit-like pores [129]. Thus, the raw CDC chemical composition and crystallographic structure have a significant influence on the geometrical shape of micropores formed. The pore surface roughness decreases with the chlorination temperature as well as with the increase of activation temperature used, established by SANS method results [8, 71, 128,129,130,131,132,133,134].

A more detailed study was conducted using the SANS method, where C(Mo2C) were synthesised at fixed Cl2 reaction temperatures of 700, 800, 900, and 1000 °C [130]. Results demonstrated that the shape of prevailing pores depends on the chlorination temperature applied, and there are structural geometry changes at the surface of the porous structure of materials studied. With increasing temperatures (from 700 to 1000 °C), microporous structures of materials change from mixed cylindrical/slit-like to purely slit-like. The observed changes in the geometries, expressed by the increase of the dimensionality parameter from 1.3 to 1.8, empirically correlate with the decrease of disorder between graphitic layers. Thus, the formation of the cylindrical pores can be explained by the curvature of graphitic carbon layers formed at T < 800 °C [130].

A combination of Raman spectroscopy and WAXS methods have been applied for detailed analysis of different CDC carbons synthesised from 6 different carbides at different temperatures (given after carbon powder in brackets) by chlorination and hydrogen cleaning methods from: Mo2C (600 °C, 700 °C, 800 °C, 900 °C, 1000 °C, 1100 °C), Ta4HfC5 (800 °C, 900 °C, 1000 °C, 1100 °C), WTiC2 (800 °C, 900 °C, 1000 °C, 1100 °C), WC (800 °C, 900 °C, 1000 °C, 1100 °C), TiC (800 °C, 900 °C, 1000 °C, 1100 °C), and VC (500 °C, 600 °C, 700 °C, 800 °C, 900 °C, 1000 °C, 1100 °C) [129]. The 5-peak fit of the Raman spectrum first-order scattering region, suggested by Sadezky et al. [297], obtained the most coherent results. Thus, the influence of the Tsyn on the peak shape, i.e., on the structural parameters of the collected results, showed the influence of the precursor carbide structural and chemical composition on the stage of graphitisation at equivalent temperatures at T = 1000 °C [129]. The graphitisation of C(Mo2C) and C(VC), both synthesised at 1000 °C, was evident from the considerable narrowing of the G-band and from the increase in average graphitic areas stacking size, LC, values obtained from WAXS data. The use of the ratio of Ad/Ag for the determination of the coherent domain length from Raman spectra based on the Ribeiro-Soares et al. method [298] yielded the most reliable results when compared to the La values calculated from WAXS data. The coherent domain length obtained from the Raman spectra was large (4.4 nm) than the average graphene layer extent value, La, obtained from WAXS. This discrepancy has been attributed to the number of defects and curvature in the graphene domains in the CDC-derived particles. Thus, this relates to the non-ideal structure of graphitic domains synthesised and formed into C(Mo2C) and C(VC) at T = 1000 °C. Detailed Raman and WAXS analysis data demonstrated that these methods are complementary to each other, and the simultaneous application of the mentioned methods is of high importance for the characterisation of disordered partially graphitic/non-graphitic carbon materials.

For the development of materials with more advanced mesoporous structures, the sol–gel method was used for the preparation of mesoporous TiC raw powders [90]. After the chlorination and hydrogen cleaning steps, the XRD, Raman, SEM–EDX, XPS, X-ray fluorescence (XRF), HR-TEM, combined SAED and EELS, and BET measurements were conducted. It was established that the mesoporosity of sol–gel prepared carbons is noticeably higher than the corresponding values for C(TiC) derived from industrial carbon powders (Fig. 9). Also, the experimental Nyquist plots show that the EDLCs based on the carbon materials prepared using the sol–gel method have a very wide region of ideal polarisability up to 3.4–3.6 V [41].

Pore size distribution for commercially available (C(TiC)) and sol–gel prepared TiC derived (C(SgTiC)) carbon electrodes, calculated from combined N2 and CO2 adsorption isotherms [90]

Micro-mesoporous carbon materials prepared from glucose, white sugar, and Estonian well-decomposed peat

Fascinating nanospherical carbon materials have been synthesised from glucose, white sugar solutions, and Estonian well-decomposed peat powder [97, 137, 149, 150, 157, 299,300,301,302,303,304], shown in Fig. 10. Highly homogeneous carbon material consisting of nano- and microspheres with diameters nearly 0.9–1.0 μm has been prepared from glucose (C(Glc)), with particle size and shape practically independent of synthesis T (800–1400 °C) [97, 149, 150, 299,300,301,302], different from white sugar–derived carbon (C(WS)) [301], where the diameter of carbon spheres varies from 1 to 4 μm. HR-TEM data show that the surface of C(Glc) is nicely graphitised. It is interesting that the diameter of these C(Glc) nanospheres is independent from the applied activation temperature. Only at very harsh activation conditions with KOH have the nanospheres been destroyed for open meso- and macropores.

Estonian well-decomposed peat has been used for the preparation of carbon powders (C(EP)) using high-temperature decomposition as well as hydrothermal carbonisation methods [137, 157]. Very well-oriented carbon graphitic areas can be seen in C(EP) material from with Raman spectroscopy, SEM–EDX, and HR-TEM data. For application in EDLCs, proton-exchange membrane fuel cells (PEMFCs), and gas adsorbing devices (mainly H2 and CH4), an additional carbon material treatment process at high activation temperatures using KOH or ZnCl2 has been conducted [305]. Depending on the activation temperature and activation reactant applied, the micro-mesoporous structure has been developed with a specific surface area from 540 up to 2150 m2·g−1. The Raman spectra indicate that some graphitisation (or crystallographic ordering) has started already at 900 °C, 1100 °C, and 1400 °C [3].

Electrochemical results for EDLC and hybrid supercapacitors based on non-aqueous electrolyte solutions

For electrochemical studies, both three-electrode and two-electrode electrochemical setups were applied. The electrodes have been assembled using carbon materials described earlier and the Teflon suspension in H2O as the binder [7, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85, 87, 90,91,92,93,94,95,96,97, 137, 149, 150, 157, 299, 300, 302,303,304, 306, 307]. The pastes of electrode materials were roll-pressed into thin carbon films with thicknesses from 60 to 400 μm. Generally, the Al current collectors were deposited onto one side of the roll-pressed film electrodes using the electromagnetic deposition method (in a high vacuum (10−8 bar)) for good electrical contact. Other times the electrospinning method of carbon layer deposition and followed by isostatic compression has been used for comparison. It should be noted that the influence of the electrode thickness on the energy and power densities is substantial [67]. This phenomenon will be discussed in more detail later, but in the referred works, electrodes with a thickness of 100 μm have been mainly used. The other aspect is that the electrolyte concentration has a significant influence on the electrochemical results. The complex impedance plane plot shape changes with the decrease of electrolyte concentration and the high-frequency series resistance Rs(hf) somewhat increases [86, 87]. Furthermore, the high-frequency polarisation charge transfer (Rch) resistance (i.e., the wideness of small high-frequency semicircle) and the mass-transfer limited processes resistance (RD) (wideness of linear area with 45° slope) increases, and the limiting capacitive (at very low ac frequencies) behaviour has been established only at very high series resistance values.

Various non-aqueous solvents (ACN, GBL, PC, DMC, EC, etc.) and mixtures of organic carbonates (EC:DMC; PC:EC; DMC:EC:PC, etc.), as well as ethylacetate, acetone (AC), solutions of Et4NBF4, but mainly TEMABF4 as electrolytes have been used, and the results are displayed in Fig. 11 [69]. It was found that the region of ideal polarisability is very wide for well-dried ACN + TEMABF4 solution (up to 3.2–3.4 V) for example C(VC) 900 °C [7, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85, 87, 89,90,91,92]. The electrolyte composition influence of fluorinated organic compounds addition to PC + 1 M Et3MeNBF4 mixture has been tested. It was found that the influence of fluoroethylene carbonate on the PC-based solution was weak in the system containing microporous titanium carbide–derived carbon (TiC-CDC) electrodes [307]. The EDLC cell characteristics based on TiC-CDC electrode and 1 M Et3MeNBF4 solutions in PC within a very wide temperature region from − 45 to 100 °C have been tested [308]. The results showed that the region of ideal polarisability decreases if T > 80 °C.

C vs E curves at a cell potential scan rate of 50 mV·s.−1 for the EDLCs in 1.0 M TEMABF4 in ACN, GBL, AC, and PC [69]

Almost simultaneously with the first publications from the Tartu University [67,68,69,70,71], Gogotsi et al. published a paper where CDC characteristics of micro-mesoporous carbon prepared from Ti3SiC2 were discussed [309]. Followingly, numerous papers were published, which investigated the parameters of CDCs, which were pepared from boron carbide [310] and ZrC [311, 312]. One of the first papers by Gogotsi et al. in cooperation with P. Simon was published in 2008 [313] that was pursued by a Nature Materials paper in the same year [314], which focused on the influence of carbon micro-mesoporosity onto gas adsorption characteristics. In 2016, Huang et al. [315] demonstrated that the CDC-based EDLCs can be integrated with silicon-based microelectronic devices. In papers [316, 317], more information analysing CDC characteristics in various conditions have been published. One of the shortcomings in the analysis of numerous papers is that the capacitance values have been calculated from the CVs, which are not corrected by ohmic drop. This results in overestimated capacitance and power density values.

The coworkes (A. Jänes, G. Nurk, P. Möller, E. Lust) and Ph.D students (M. Arulepp, L. Permann, M. Lätt) of the Univesrsity of Tartu were also engaged in Tartu Tehnoloogiad AS from 1997 to 2005. In this company, they established a laboratory and participated in the development of electrochemical background of EDLC studies, characterised the CDC materials in non-aqueous electrolytes, and measured the energy/power density characteristics of assembled supercapacitors. Based on the fundamental knowledge and technical information collected, common papers have been published [67,68,69,70,71,72,73,74,75] and many World and US patent applications have been completed and accepted. Unfortunately at these times, the supercapacitors were too expensive for wide areas technological application. Following the bankruptcy of Tartu Technologies AS at 2009, the supercapacitor development for commercial applications has carried on in Estonia. For example, one of the leading supercapacitor producers in EU, Skeleton Technologies OY has won 2018 SET Awards in “innovative mobility category.”

LiClO4, NaClO4, LiBF4, NaBF4, LiPF6, NaPF6, KBF4, KPF6, etc., were used to study the influence of electrolyte chemical composition on the electrical double layer parameters in non-aqueous solutions by analysing cation and anion chemical composition and geometric structure [7, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 86, 87, 92,93,94,95,96,97, 307, 308]. Very noticeable specific adsorption of Cs+ cations, as well as weak adsorption of K+ and Na+ ions, was observed from non-aqueous solutions using the constant current charging–discharging method [94,95,96,97, 307, 308].

For comparison, H2O-based supercapacitors containing Na2SO4, Li2SO4, Rb2SO4, and LiClO4, NaClO4, etc., have been studied [89]. Due to high hydrogen evolution overvoltage at carbon electrodes, the region of ideal polarisability in H2O is nearly up to 1.6 V for Na2SO4 + H2O. The ideal polarisation region is noticeably narrower for Rb2SO4 + H2O electrolyte due to weak solvation of Rb+ cations and specific adsorption of Rb+ at carbon electrodes. Some faradic processes started at higher cell potentials E > 1.6 V [89].

For analysis of experimental results, the complex plane plots have been measured and used for the calculation of series capacitance (Cs) and parallel capacitance (Cp) values. If the system is ideally polarisable, then the Cs and Cp are overlapping at low ac frequencies, where there is no dependence of Cp or Cs on f [29, 31]. Only these values have been used as the accurate capacitance values [7, 60,61,62,63,64,65, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85,86,87, 90,91,92,93,94,95,96,97, 105, 300, 306,307,308] corresponding to limiting Gibbs adsorption values. Collected data show that the Cs values highly depend on the electrode total and meso-microporosity, i.e., on the specific surface area (SBET) and on the DFT total pore volume values, calculated using the 2D-NLDFT-HS model [3]. The Cs values increase with the gas phase activation using CO2 up to 10 h, but at longer activations, the noticeable decrease of microporous surface area initiates the decrease of Cs and Cp values. The same tendency is valid for materials that were chemically activated with ZnCl2 and KOH. However, it should be noted that only optimal activation times for electrode materials increase the energy densities of EDLCs [305].

The characteristic relaxation times have been calculated using the complex power values (\(S\left(\omega \right)=P\left(\omega \right)+jQ(\omega )\)), where active and reactive power are equal to \(P\left(\omega \right)=\frac{\omega {C}^{\mathrm{^{\prime}}\mathrm{^{\prime}}}\left(\omega \right)\Delta {E}_{max}^{2}}{2}\) and \(Q\left(\omega \right)=-\frac{\omega {C}^{\mathrm{^{\prime}}}\left(\omega \right)\Delta {E}_{max}^{2}}{2}\), respectively [29, 31]. Data in Table 3 show that characteristic relaxation time depends on the electrolyte viscosity increasing from ACN to PC and further to IL. Very short relaxation times have been calculated for mesoporous carbon EDLCs prepared by the sol–gel syntheses method [90, 91, 306].

The energy density vs power density plots (Ragone plots) have been measured using the constant power method [7, 67, 68, 70, 72,73,74,75,76,77,78,79,80,81,82,83, 85, 87, 89,90,91, 306]. The energy density increases in a row of solvents PC < GBL < EC + PC < ACN (Fig. 12), from microporous materials to mesoporous and future to sol–gel derived very mesoporous carbon. The energy and power density depend on the cation’s chemical composition, and it increases in a row of cations: Li+ < Na+ < K+ < Rb+ < Cs+ [92,93,94,95, 97, 307, 308]. The dependence of energy density on anion composition is more complicated, and with the decrease of cation solvation energy, adsorption activity increases, but for Cs+, very slow specific adsorption started decreasing the physical adsorption of electrolyte cations due to the blocking effect of the electrode surface with the chemically bonded cations. This effect is heavily dependent on the solvent used.

Ragone plots for the EDLCs in 1.0 M TEMABF4 in ACN, GBL, AN, and PC, highlighting that higher energy and power density can be achieved with other organic solvents than commercially used PC [69]

EDLC in ionic liquids

For the analysis of the influence of IL composition on the region of ideal polarisability, the two-electrode systems have been completed based on various ILs (EMImBF4, 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide (EMImTFSI), 1-ethyl-3-methylimidazolium tetracyanoborate (EMImTCB), 1-ethyl-3-methylimidazolium tris(pentafluoroethyl)trifluorophosphate (EMImFAP), 1-ethyl-3-methylimidazolium thiocyanate (EMImSCN), 1-ethyl-3-methylimidazolium bis(fluorosulfonyl)imide (EMImFSI), etc.), as well as for ILs with the addition of ACN and other solvents [105, 318, 319]. Based on CV and EIS data, the widest region of ideal polarisability was measured for EMImTCB [254] (Fig. 13). It was found that the addition of ACN very slightly decreases (100–200 mV) the region of ideal polarisability compared to pure IL, especially for EMImTCB. EIS data show that in EMImBF4, nearly ideal capacitive behaviour was established up to 3.2 V and only at higher cell potentials a deviation of the ideal capacitive behaviour (phase angles higher than − 88°) takes place. However, the addition of ACN significantly decreases the characteristic time constant values (more than one order), thus increasing the power densities of EDLC remarkably.

Cyclic voltammograms for various microporous carbon cloth | IL-based EDLCs (noted in the figure) measured with scan rate 1 mV·s.−1 up to 3.2 V [254]

To analyse the effect of the carbon electrode, EDLCs based on hierarchical micro-mesoporous sol–gel TiC–derived carbon (SgTiC-CDC) electrodes and EMImBF4 and 1 M TEMABF4 + ACN as the electrolytes were tested to establish the electrochemical characteristics and region of ideal polarisability. A very wide region of ideal polarisability (up to 3.8 V) can be achieved if the cell potential limit has been shifted by small potential steps (∆E = 0.1 V) from 3.4 to 3.6 V and further to 3.8 V (Fig. 14) [91]. This effect has been explained by the dissolution of most active defect amorphous areas of carbon electrodes during the so-called surface passivation (defect and active surface area dissolution) step. Very high capacitance (energy values) values have been calculated for IL-based cells.

C vs E curves calculated from cyclic voltammograms at various potentials at a scan rate of 100 mV·s.−1 in EMImBF4 and TEMABF4 + ACN electrolytes (noted in the figure) [91]

The EIS revealed that the high-frequency series resistance depends on the electrolyte applied, and the R(hf) values are nearly one order higher for the EMImBF4-based systems. Additionally, for EMImBF4, the so-called micro-mesoporous mass-transfer area in the Nyquist plot is three times wider than that for TEMABF4 + ACN electrolyte-based EDLCs [91]. The Bode phase angle vs log f plots show (Fig. 15a) that the characteristic relaxation frequency is one order longer for IL-based EDLCs. The calculated series resistance values are higher than for ACN-based systems (Fig. 15b). Interestingly, the Cs values for ACN are practically independent of the electrode potential applied if the cell potential is around 3 V, indicating that the limiting Gibbs adsorption values have been established. EMImBF4-based EDLCs show that only at very high cell potentials (3.8 V) the limiting Gibbs adsorption (Cs independent of ac frequency) has been established.

a Phase angle (θ) vs ac frequency and b specific series capacitance (Cs) vs ac frequency dependencies for EDLCs completed with C(SgTiC) electrodes in EMImBF4 and TEMABF4 + ACN electrolytes (noted in the figure) [91]

Additionally, it has been shown that the micro-mesoporous structure, i.e., the ratio of Smicro/Smeso and Vmicro/Vmeso, has a remarkable influence on the limiting capacitance values, characteristic time constants, and real power and imaginary power values if the same electrolyte has been tested [91]. Very short characteristic time constant values have been established for two-electrode cells consisting of mainly mesoporous sol–gel method–derived carbon as a working electrode and TEMABF4 + ACN as an electrolyte. Very long characteristic charging/discharging times were calculated mainly for very microporous α-SiC-derived carbon-based systems. However, the latter systems exhibit high limiting capacitance values and very long characteristic relaxation times, especially in EMImBF4 [91].

It has been shown that the limiting series and parallel capacitance values are higher for ionic-liquid-based EDLC. Nevertheless, the characteristic time constant values are longer than that for ACN-based EDLCs. Thus, the solvent molecules adsorbed at the carbon surface decrease the Gibbs adsorption of ions from ACN-based electrolytes compared with IL data [91].

The constant power discharged method has been applied to analyse energy densities at fixed power density. Data in Fig. 16 show that the highest energy densities have been calculated with optimal porous structure, i.e., for systems with high microporosity and mesoporosity, prepared using the sol–gel method for syntheses of TiC compared to microporous carbon derived from commercially available TiC, D-glucose-derived carbon (C(Glc)-12 h), micro-mesoporous D-glucose-derived carbon (MMP C(Glc)), steam activated carbon derived from SiC (C(SteamSiC)), and carbon derived from granulated white sugar (C(WS)) [3, 91, 112, 300]. EDLCs with very high microporosity demonstrated moderate or even low power densities and cannot be used as peak power generating devices.

Gravimetric Ragone plots for different carbon materials (noted in the figure) measured within cell potential range 3.0 to 1.5 V in EMImBF4 electrolyte [91]

Electropolymerisation of ILs at carbon electrode surface

In order to identify the ideal polarisability region and processes limiting the ideal capacitive behaviour, the EMImBF4-based two-electrode system has been overpolarised [60, 109]. At negative potentials (E = − 2.4 V), the electroreduction of [EMIm]+ cations takes place, and a cyclic compound is formed, demonstrated in Fig. 17a, experimentally established by FTIR [60] as well as by synchrotron XPS studies [109]. At very positive potentials (E = 2.0 V) (three-electrode data), the oxidation (decomposition) of EMImBF4 to MImBF3, CH3CH2F, and B2F7 takes place, established by XPS studies [108, 320]. For ideal blocking of the carbon electrode surface, the oxidation of butyl methyl propyldicyanamide (BMPDA) to polydicyanamide (polyDCA) has been conducted and demonstrated at the carbon electrode (Fig. 17b) [106]. Very high energy density supercapacitors have been prepared if compared with ceramic, aluminium oxide, and tantalum oxide–based capacitors [106, 107], and this method has been patented in USA and UK [116, 321].

Influence of specifically adsorbing anions onto the EDLC characteristics

For the future increase of the capacitance and energy density of EDLCs, the mixtures of salt and ILs with the addition of surface-active anions (Cl−, Br−, and I−) have been investigated by Thomberg, Siinor, Siimenson, and Oll [60, 63,64,65, 100, 112, 113, 304]. Figure 18 demonstrates that the carbon surface is chemically stable and nearly ideally polarisable within cell potential region ΔE > 2.0 V. The given CVs show that the capacitance increases with the cycle number applied up to 1000 cycles, and the future increase of the cycle number does not improve the capacitance values. It is interesting that the charging and discharging cycle capacitance values are nearly the same, indicating the nearly reversible adsorption of I− at the MMP carbon electrode. However, cycling within a wide potential region indicates that at ΔE > 2.4 V, partial charge transfer takes place (in agreement with synchrotron XPS data at positively charged electrode), and the I3− or Br3− complex anion formation occurs (discussed by Rogers et al. [115]). In the discharging curve, the reduction current peak is formed; thus, the reduction of the surface compound takes place. It is important to mention that Epeak(red) is independent of the potential scanning rate indicating that the limiting step for the reoxidation process (I3− to I−) is the desorption/adsorption rate determined step from the electrode surface [112, 113, 115]. Impedance data indicate that with the increase of the specific adsorption of anions, the characteristic time constant increases, but only nearly 10%. Also, higher Emax values have been calculated for electrolytes with the addition of I− in IL mixture than the values calculated for surface-inactive EMImBF4.

Cycling voltammetry curves expressed as specific capacitance vs cell potential dependencies of electrical double layer capacitors based on microporous–mesoporous carbon electrodes in EMImBF4 + 5% EMImI mixture within different cell potential ranges at potential scan rate 10 mV·s−1 [112]

A noticeable increase in energy densities accumulated by the adsorption of halide anions has been demonstrated for two-electrode single cells at moderate power densities. Very high Emax values have been established at lower power density Ragone plot region, where the Emax is 20% higher than that for EMImBF4-based EDLC. However, a quicker decrease of Emax takes place at very high power densities compared with EDLCs based on surface-inactive electrolyte solutions [112, 113]. The energetic efficiency of supercapacitors containing specifically adsorbing anions is lower than for surface-inactive IL–based EDLCs due to the partial charge transfer between carbon surface and adsorbed anions.

Influence of membrane parameters on EDLC characteristics

The influence of separator characteristics on the two-electrode supercapacitor cells has been studied using standard (TF-4425 from Nippon Kodoshi, Japan; Cellgard Japan) and self-made polyvinylidene difluoride (PVDF) separators [99, 117, 118, 120,121,122,123]. PVDF was dissolved in dimethyl formamide, and used in the electrospinning method at different electric field strengths (10–40 kV·m−1), spinning rates, polymer pressing out rates, etc., have been used for the preparation of membranes with different thicknesses, densities, total porosity, etc. [99, 117, 118, 122, 123].

The influence of polymer membranes’ geometrical structure, thickness, and porosity values on EDLC parameters has been analysed by Thomberg et al. [99, 117, 118, 122, 123] using the EIS method for cells with various membranes. The characteristics of membranes have been established using the Hg intrusion porosimetry measurement method and BET gas adsorption methods [99, 117, 118, 122, 123]. The EIS data show that the very high-frequency series resistance value depends on the micro- and mesoporosity (hierarchical porosity parameters) of the membrane used. The characteristic relaxation frequency values, given in Table 4, noticeably depend on the membrane thickness selected for the completion of two-electrode cells. Therefore, the power density of a two-electrode supercapacitor cell depends strongly on the micro-meso-macroporosity of the membrane separating the positively and negatively charged electrodes. The low-frequency parameters are also influenced by high-frequency resistance Rs values, but this influence is moderate compared with that observed within the high-frequency (high power density) region. However, for extremely high power density supercapacitors, the optimisation of membrane porosity (ion–ion transfer resistance within the membrane) is extremely important. A more detailed discussion is given in [99, 117, 118, 122, 123].

For comparison, the same electrode systems have been completed using the EMImBF4 as an electrolyte and serial-produced membranes TF4425, etc. A comparison of data with standard separator TF4425 based cells shows that even higher power densities have been achieved for well-optimised membranes made in University of Tartu. Therefore, similarly to organic electrolyte–based systems, optimisation of membrane characteristics is very important for IL-based EDLCs, and as for EDLCs containing thick membranes (TUX 5), very low power densities were measured [99, 117, 118, 120,121,122,123].

Hydrogen and methane adsorption at carbon materials and thin-film complex metal hydrides

Hydrogen and methane adsorption in different CDCs: C(TiC) 950 °C, C(SiC) 1000 °C, C(Mo2C) 900 °C, with well-defined pores and different sizes and shapes, volumetric adsorption has been studied using in situ quasi-elastic neutron scattering methods by Härmas et al. [133], Koppel et al. [134], Palm et al. [135]. The predominant shape of pores for three of these carbons (spherical-C(SiC) 1000 °C, cylindrical C(TiC) 1000 °C, and slit-like C(Mo2C) 900 °C) has been established using the small angle neutron scattering method [128]. In addition to the strong effect of the presence of sub-nanometre pores, as in the case of C(TiC) 950 °C and C(SiC) 1000 °C, the effect of the pore shape on the diffusion coefficient of hydrogen has been observed and discussed. While the C(TiC) 950 °C and C(SiC) 1000 °C have the same, nearly similar pore size distributions, the prevalently shaped pores in C(SiC) 1000 °C restrict the diffusion of H2 to a large degree in comparison with C(TiC) 950 °C. In the case of low H2 loading pressure, no mobile H2 was detected in C(SiC) 1000 °C, but the H2 mobility has been demonstrated for C(TiC) 950 °C. It was found that the prevalently slit-shape and large pores for C(Mo2C) with flatter pore potential enabled a higher mass-transfer processes rate for confined hydrogen molecules and therefore exhibited weaker interaction between hydrogen molecule and adsorbing carbon surface. The observed molecular behaviour of hydrogen confined into micropores of C(SiC) 1000 °C, C(TiC) 950 °C, and in C(Mo2C) 900 °C allowed the explanation of differences in gas adsorption isotherms, given in Fig. 19, where it is visible that C(TiC) has a microporous structure and C(Mo2C) has a micro-mesoporous structure with well-expressed hysteresis in BET gas sorption curves [3]. The best fit of the experimental data for C(TiC) and C(Mo2C) has been established using the Aspect ratio 6 model or heterogeneous surface model [293,294,295].

The localisation and low mobility of H2 in sub-nanometre pores lead to higher gas adsorption (intake) at lower pressures. Higher pressure needs to be applied to confine H2 in pores with flatter surface potential and weaker interactions between adsorbate and adsorbent, i.e., mainly the influence of H2 pressure and the interaction of H2 with C(Mo2C) have been analysed. It is shown that the increase in H2 pressure and the amount of confined H2 molecules leads to the increase in cooperative molecular interactions. A similar effect has been observed for H2 adsorbing in zeolites, and the establishment of this effect for very weakly adsorbing H2 molecules suggests the universal character of the phenomenon discussed [136, 322].

A detailed analysis of the porosity and solid base geometrical structure of different CDCs (α-SiC, TiC, Mo2C) (Fig. 19b) and peat-derived carbons has been conducted for moderate temperature and pressure. It was found that the hydrogen adsorption in non-modified CDC carbons decreases in order: α-SiC, TiC, Mo2C and thus with the decrease of microporosity. For fixed Mo2C carbons as well as for α-SiC-derived materials, H2 adsorption decreases with the increase of carbon syntheses temperature, thus with the increase of mesoporosity, and decrease of microporosity.

SANS, QENS, and INS data indicate that the carbon surface roughness influences the specific interaction of hydrogen, porous structure, tortuosity, etc., which has been discussed in [129, 130, 132, 134]. The decisive influence of CDC crystallographic structure (cubic, tetrahedral, rhombic, and hexagonal) on the CDC carbon structure synthesised has been investigated.

It was demonstrated by SEM, HR-TEM, AFM, and FIB-TOF–SIMS methods that the ball-like shape of pores prevails on/in CDC prepared from α-SiC, cylindric from TiC, and slit-shape pores in carbon prepared from Mo2C. Additionally, they have very different characteristic relaxation times and power densities increasing from C(α-SIC) to C(Mo2C). The QENS and INS studies of molecular hydrogen adsorption verified complicated adsorption/desorption kinetics of materials with different porous structures of hydrogen at very low temperatures (− 253 °C) [133, 134, 136].

The adsorption of methane also depends on the structure of the porous carbon, increasing with the increase of microporosity from C(α-SiC) to C(TiC) and lastly to C(Mo2C). The effect of pore size and surface morphology of carbon materials on the adsorption of methane was studied using C(TiC) 950 °C and 1100 °C, and C(Mo2C) 1000 °C materials. Nitrogen adsorption, Raman spectroscopy, and XRD have been used for the characterisation of methane adsorption. All materials have a high specific surface area: C(TiC) 950 °C, 1450 m2·g−1; C(TiC) 1100 °C, 870 m2·g−1; and C(Mo2C) 1000 °C, 820 m2·g−1, but the pore size distribution depends strongly on the synthesis temperature and the applied activation method. C(TiC) 950 °C contains mainly micropores, C(TiC) 1100 °C, activated with HCl, contains micro- and mesopores with a pore size distribution maximum from 1.5 to 5 nm, and C(Mo2C) 1000 °C is mainly mesoporous from 2.4 to 10 nm. The methane adsorption increases from C(Mo2C) to C(TiC) 950 °C, being 165 cm3·g−1 and 295 cm3·g−1, respectively. Excess isotherms of methane adsorption were measured at different temperatures from − 100 to 40 °C and pressures from 0.35 to 1.35 MPa and modelled enthalpies and entropies of CH4 adsorption. It was found that the changes in entropy are the key factor determining the amount of CH4 adsorbed per unit surface area of CDC. It was established that up to 55% more methane can be adsorbed in C(TiC) 950 °C, compared with C(Mo2C) 1000 °C if the carbon structure is optimised [135].

For higher hydrogen adsorption values, the MMP carbon electrodes have been modified with thin films of NaAlH4 [323]. Differently from homogenous NaAlH4 solid particles (7.5 wt% of H2 per 1 g NaAlH4), the release of hydrogen started at moderate temperatures (60–80 °C) differently from monolithic materials where H2 evolution started only at 240–280 °C. It means that the thin-film hydrogen storage materials can be used for the release of hydrogen using the heat generated by the PEMFC stack when it generates electricity for ac motors. It is great to point out that the hydrogen adsorption capacity in thin-film NaAlH4 is nearly 3–3.5 times bigger than that for MMP carbons (up to 2.5–3.0 wt%). In addition, the gravimetric hydrogen capacity is 4–5 times bigger than that for compressed hydrogen up to 700 bar, as well as nearly two times larger than for liquefied hydrogen. It should be stressed that the adsorption/desorption of hydrogen into nanostructural NaAlH4 is an energy-efficient process compared with the liquefaction of hydrogen.

Development of carbon materials for Li+-ion and Na+-ion batteries

The carbon materials synthesised from different raw materials (from carbides (CDC), glucose (glucose-derived hard carbon, HC(Glc)), and Estonian well-decomposed peat (peat-derived hard carbon, HC(EP)) at different syntheses temperatures from 1200 to 1700 °C have been used as negatively charged electrodes for LIBs and SIBs, where Li metal and Na metal have been used as positively charged electrodes, respectively. Very open porous 3D structures (SBET up to 1100 m2·g−1 for HC(Glc) and 1050 m2·g−1 for HC(EP)) with a partially graphitised curved graphitic surface, established by Raman spectroscopy, have been prepared. The partial graphitisation of HC(Glc) and HC(EP) is very important, giving materials under study good electrical conductivity compared with amorphous non-graphitised carbons [92,93,94, 96, 97, 299,300,301,302,303].

Due to the low graphitisation level of CDC and not partially graphitised carbons like HC(Glc), white sugar–derived hard carbon (HC(WS)), or HC(EP) carbons, the adsorption capacity values for Li+ are only moderate and mentioned CDC could not be used for high energy density LIBs. Surprisingly high capacities have been observed for glucose, and peat-derived carbons, even up to 320–360 mAh·g−1, thus showing very promising high capacity values (Fig. 20). The limiting capacity values depend on the electrolyte (salt and solvent) used. The highest capacity values have been calculated for NaPF6 electrolyte solutions dissolved in EC + PC 1:1 mol/mol mixed solvent system at a 50 mAh·g−1 charging rate. An increase in the PC molar ratio in the mixed solvent system also decreases the limiting capacity of negatively charged electrodes. The exchange of NaClO4 to NaPF6 increases the capacity values notably [303]. It should be noted that for C(EP), there is no noticeable dependence of limiting capacity values on the chemical nature of the cation tested, i.e., for LiBF4 and NaBF4, as well as for LiClO4 and NaClO4; nearly comparable high capacity values (320–360 mAh·g−1) have been established.

Galvanostatic charge/discharge profiles measured at 50 mA·g−1 current density for half-cells based on Li+- and Na.+-ions in different electrolytes, marked in the figure [97]

These systems have been studied using different operando testing methods, including XPS, XRD, AFM, and FIB-TOF–SIMS. It is interesting that the 20% larger Na atoms compared with Li atoms adsorption onto HC(Glc) surface causes a 60% increase in in-plane bond lengths values, established by operando X-ray total scattering study of HC(Glc) in Li+-ions and Na+-ions containing solutions [8, 131]. Thus, the Na adsorption to the surface or intercalation between the HC(Glc) graphitic layers could affect the neighbouring π-electron graphitic electron systems. Sodiation causes an increase in interlayer distances in the charging curve sloping region, characterising the different intercalation/charge collection mechanisms for Li+- and Na+-based systems [131]. FIB-TOF–SIMS data show that the surface chemistry for Li+-ions containing electrolytes is more complicated than that for Na+-ions containing systems. Therefore, at the carbon electrode surface in Na+-ions containing electrolytes, there is no dense blocking SEI differently from Li+-ions containing solutions. It was observed that the Na adsorption capacity depends very strongly on the hard carbon syntheses temperature, and the highest capacity values have been established for HC(Glc) and HC(EP), synthesised at 1400–1500 °C.

The accumulation of Li+-ions (formation of Li) and Na+-ions (Na) into hard carbon materials is very slow, and maximal capacity (maximal faradic current density) values have been calculated only at a very slow potential scanning rate (0.1 mV·s−1). The cyclic stability (so-called cyclability) of HC(Glc) is good, and after 80 cycles, the capacity stabilises at 160 mAh·g−1 level (at a high charging rate of 50 mA·g−1 applied). The charging Coulombic efficiency after the preliminary 10 cycles increases up to 98%.

Thus, based on the results collected for the three-electrode cell, it was decided to complete the two-electrode cells with real positively charged electrodes. The two-electrode cell capacity, containing HC(Glc) or HC(EP) and Li+-ions or Na+-ions electrolytes, is limited by the capacity of positively charged electrodes, and future studies are inevitable for completing high power density SIBs. At the moment, Na+-ions–based electrolyte systems can be used for stationary electricity storage only, where the capacity values (stored energy per g of device) of devices are not critical, and the cheap prize of SIBs is more important than the high volumetric or gravimetric density of devices.

The development of Pt-metal-nanoclusters activated and d-metal-nitrogen active centres based electrocatalysts for PEMFC electrodes and PEM single cells