Abstract

Electrochemical properties of oxide-covered polycrystalline Ag electrodes were studied in a 0.1 M KOH aqueous electrolyte. The oxide layers formed by a constant potential oxidation at 420 mV vs. Hg|HgO are composed of oxygen-deficient Ag2O as follows from the XPS and Auger experiments. Steady-state conditions required for collection of valid impedance spectra were obtained at a potential range of 345–365 mV. The components of the equivalent circuit used for the impedance spectra analysis are analysed as a function of the Ag2O layer thickness. The value of the coefficient of the constant phase element (CPE) attributed to the oxide layer is Ag2O thickness dependent. On the other hand, the components of the CPE describing the double-layer capacitance of the oxide-covered Ag electrode are independent on the oxide thickness and their values are comparable to those obtained for the oxide-free metal. This indicates that the double-layer capacitances of oxide-covered and oxide-free Ag electrodes are similar.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Measurements of the double-layer capacitance, C dl, are amongst the most important ways to study electrolyte-electrode interfaces in electrochemical systems. Analysis of the capacitance data is relatively simple for metallic electrodes but becomes complicated when the electrode is covered with a layer of an oxide/hydroxide. This is due to the fact that the most of the metal oxides and hydroxides exhibit non-metallic, i.e. semiconducting or insulating, properties [1, 2]. The capacitance of a semiconducting oxide/hydroxide layer, C ox, contributes to the total measured interfacial capacitance of the electrolyte-electrode interface, C tot, according to Eq. 1 [3,4,5]:

where C dlox stands for the double-layer capacitance of an oxide/hydroxide-covered electrode. The separate determination of C dlox and C ox values can be difficult, and it is often assumed that the C dlox has the same value as C dl of the oxide-free metallic surfaces, C dlm [6]. However, a strong deviation of experimentally determined C dlox values from the typical range of C dlm is often reported [e.g. 7, 8].

Silver is one of the metals with reported significant differences between C dlm and C dlox [8,9,10]. The double-layer capacitance of various types of Ag electrodes was studied in aqueous electrolytes at potentials where the surface is metallic [e.g. 11–17] and oxide-covered [8,9,10, 13, 15, 16, 18,19,20]. Silver oxidation in an alkaline electrolyte starts at ca. 10 mV vs. Hg|HgO; the usually reported oxidation products are Ag2O and AgO, depending on the oxidation potential [21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38]. AgO is described as a mixture of Ag(I) and Ag(III) species [11, 39, 40]. Ag oxides exhibit non-metallic properties, and this factor undoubtedly complicates determination of C dlox (Eq. 2). Most of the authors point out to n-type semiconducting properties of the electrochemically formed Ag2O [1, 21, 41,42,43,44] although a p-type semiconductivity is also reported [21, 45, 46].

Hepel and Tomkiewicz [9] studied oxidised layers generated on Ag electrodes in 1 M KOHaq at potentials where Ag2O and AgO are formed. The oxides were formed during constant potential anodic oxidation of Ag while the interfacial capacitance was calculated on the basis of the high-frequency imaginary part of the impedance and was analysed as a function of the charge passed during formation of the oxide layer, q ox. The latter value was assumed to be a direct indicator of the oxide layer thickness, l ox. The analysis was based on a parallel plate capacitor approach (Eq. 2) [9]:

where A, ε r and ε 0 stand for the surface area and the relative permittivity of the oxidised layer and dielectric permittivity of the vacuum, respectively. C dlox values, which were obtained from a combination of Eqs. (1) and (2), were in the range of 0.1 μF cm−2 [9] being substantially lower than tens of μF cm−2 typically reported for C dlm. It follows from data reported in [9] that for such low values of C dlox, the condition of C ox ≪ C dlox holds only for very thick oxide layers (oxidation charge of at least few hundred mC cm−2).

In [8], the C dlox of Ag electrodes oxidised in 1–10 M KOH was determined by means of extrapolation of a single-frequency capacitance to the infinite-frequency limit. Such determined C dlox was dependent on the Ag2O layer thickness: for a monolayer film, its value was equal to ca. 50% of reported C dlm (~27 μF cm−2) while for a multilayer Ag2O, the C dlox was ca. order of magnitude smaller than C dlm (100 μF cm−2 range) [8]. In [10], several equivalent circuits were used in an analysis of the impedance data recorded for Ag oxidised in KOHaq at various potentials. The interfacial capacitance, identified as the double-layer capacitance of the oxide-electrolyte interface, was found to decrease upon the surface oxidation, even by two orders of magnitude to the 100–10−1 μF cm−2 range [10]. The contribution from C ox to the measured impedance was, however, not discussed. A decrease of the interfacial capacitance of Ag upon oxidation in 0.1 M NaOH was shown also in [15]. Measurements carried out at pH of 4.5 show that the overall capacitance measured with 370 Hz decreases with the polarisation time at potentials of phase oxide formation and oxygen chemisorption [16]. At such low-frequency values, however, the contribution from pseudocapacitances can be significant [16].

An equivalent circuit containing two connected in series subcircuits, each of them composed with a parallel combination of a resistance and a capacitance (C ox or C dlox), was used for fitting impedance spectra for Ag oxides formed in 1 M NaOH in [41] and in 1 M KOH in [47]. Fast Fourier transform impedance spectroscopy [48] was applied in both these works; in [41], the spectra were recorded during a negative potential scan. The validity of the spectra recorded in [41] was evaluated by means of an analysis of the relation between power spectra of the perturbation signal and the recorded current [41]. The following C ox values were obtained at potentials of Ag2O formation: ca. 0.6–9.7 μF cm−2 at ca. 330–600 mV vs. Hg|HgO in [47] and ca. 0.16–1.6 μF at 100–290 mV vs. SCE in [41] (the values of the double-layer capacitance were not reported). Considering the electrode diameter of 0.7 cm reported in [41], one may recalculate C ox values from [41] into the specific capacitance range of ca. 0.4–4 μF cm−2 (in respect to the geometric area). When these C ox values from [41, 47] are compared with very low values of C dlox reported for Ag2O-covered silver by other authors (100–10−1 μF cm−2 range [9, 10]), one may conclude that the requirement of C dlox ≫ C ox may not be met here, similarly as for data from [9]. Consequently, classical Mott-Schottky analysis of semiconducting electrodes which is based on the abovementioned relation between C dlox and C ox [3,4,5, 49,50,51] may be not applicable here. Clearly, the values of C ox, C dlox and C dlm need to be unequivocally determined and the relation between them has to be clarified if they are to be applied in a further analysis of the capacitance data.

This manuscript presents results of the studies on properties of Ag oxides formed electrochemically at the surface of a polycrystalline Ag in an alkaline electrolyte during constant potential oxidation at 420 mV vs. Hg|HgO. Chemical composition of the oxidised layers was analysed by means of X-ray photoelectron spectroscopy (XPS) while electrochemical impedance measurements were applied to evaluate electrochemical properties of the interface between the electrolyte and the oxides studied. The impedance data are analysed as a function of the amount of generated Ag oxide, and the conclusions about the double-layer capacitance of the oxide-covered silver electrode are drawn.

Experimental

A silver wire or foil (4N, Mint of Poland) was used as a working electrode while a high surface area Au foil or Pt gauze wire and a Hg|HgO (0.1 M KOH) electrode served as counter and reference electrodes, respectively. Before the experiments, the silver electrode was cleaned by mechanical polishing with a diamond paste (MetaDi, Buehler, 1 μm). The electrolyte solutions were prepared with water purified in a Millipore system (18.2 MΩ cm) and analytical-grade reagents (POCh, Poland). The electrolyte solutions were deoxygenated with N2 (5N, Air Products); during the measurements, the N2 stream was directed above the electrolyte level. All the experiments were carried out at room temperature.

A CHI660D potentiostat (CH Instruments) was used in the experiments. Both single-frequency and multiple-frequency impedance measurements were carried out. In the single-frequency measurements, a high-frequency (1465 Hz, 5-mV amplitude) AC signal was superimposed on a DC potential scan with 20- or 50-mV steps. In the constant potential impedance spectroscopy (electrochemical impedance spectroscopy (EIS)), the frequency range of 10.01 kHz–46.4 mHz with 5-mV amplitude was usually applied. The EIS spectra were fitted using the Equivcrt software [52] while for Kramers-Kronig tests, the FRA (EcoChemie) software that allows introduction of greater number of circuit components was used.

A 150-W Xe lamp with a ZXE power supply unit (both Optel, Poland) were used for photocurrent measurements. XPS measurements were carried out in the Institute of Physical Chemistry of Polish Academy of Sciences, Warsaw, with an ESCALAB-210 (VG Scientific) apparatus using an Al X-ray gun, and an Ar ion gun was used for depth profiling. The rate of sputtering with Ar ions varied from 0.31 to 12.7 nm min−1 (ion energy from 250 eV to 2 keV) at various stages of the sputtering process and was calculated in respect to SiO2/Si standards (Reference Material No. 564 from the Institute for Reference Materials and Measurements, European Commission-Joint Research Centre). The XPS spectra were fitted using the XPSPeak software [53].

The real surface area of the polycrystalline Ag electrodes was calculated on the basis of the double-layer capacitance determined from EIS measurements at potentials of hydrogen evolution region (HER) (−1100 to −1300 mV), where the electrode surface is oxide-free. At higher potentials, the C dlm measurements may be complicated by adsorption of anions [15, 35, 54, 55] or pre-monolayer surface oxidation, suggested in [56]. Further on, the C dlm varies with the electrode potential between the onsets of the surface oxidation and HER [19, 57]. The C dlm measured in HER region was also used as a reference value for comparison with the capacitance of the oxide-covered surfaces.

The EIS spectra were recorded for freshly prepared electrodes not subjected to a previous oxidation and after 90–120 s of polarisation at potentials of HER. The spectra (not shown) were fitted with an equivalent circuit shown in Fig. S1 in Supplementary Material. The circuit contains a parasitic capacitance, C p (nF range), connected in parallel with a branch which contains a series combination of an ohmic resistance (R ohm) and a subcircuit describing the electrolyte-electrolyte interface. The latter subcircuit is composed with two components connected in parallel: a charge transfer resistance (R ct) and a constant phase element (CPE), which represents the double-layer capacitance. The CPE impedance is defined as follows [58,59,60] (3):

where i is the imaginary unit, Q is the CPE coefficient, and α is the exponential factor (α = 1 for pure capacitance). There is a long discussion in the literature about origins of CPE-type behaviour of the double layer and whether the Q value can be identified as a pure capacitance. In general, the lower is the α value, the higher is the departure from the ideal capacitive behaviour. The reasons of such behaviour include surface roughness, surface non-homogeneity, contribution of various basal planes, adsorption processes, etc. [58,59,60,61]. It has been also recommended that Q cannot be considered equal to the pure capacitance unless α is equal to unity [58, 62]. The Z CPE can be recalculated into the capacitance units according to [59, 61] (4):

There was no need to include a pseudocapacitance due to hydrogen adsorption, presumably due to a potential independent surface coverage with adsorbed hydrogen at such high overpotentials [63]. It was found that the double-layer capacitance reaches the lowest values and was practically potential independent in −1100 to −1300-mV range with α and Q value ranges of 0.944–0.961 and (2.80–3.25) · 10−5 F sα−1 for cm−2 of the real surface area, respectively. The surface roughness factor of the freshly prepared electrodes was in the range of 3.3 ± 0.3 and was calculated with assumed specific double-layer capacitance of 20 μF cm−2, which is the lowest capacitance value in HER region measured for Ag single crystal electrodes in neutral and acidic electrolytes [64,65,66]. It is assumed that the real surface area is determined most accurately for single crystals, and for these electrodes, the most reliable values of the specific double-layer capacitance are expected. The higher values of specific C dl in HER region are also reported for Ag electrodes (e.g. 25–30 μF cm−2 range in HER region [16, 17]), but it should be stressed that selection of the value of the specific double-layer capacitance used for the real surface area determination has no influence on the comparison of C dlm and C dlox values discussed later in the text. Therefore, presented conclusions about relation between C dlm and C dlox values are valid regardless of the selected specific C dl value.

Ag oxidation and dissolution may lead to the surface roughening, as already pointed out in [8, 21, 22, 29, 30, 67]. Comparative measurements carried out after completing the Ag oxidation experiments described later in the text showed an increase in C dlm in HER region by 2.0 ± 0.5 times (α = 0.919–0.942 and Q = (7.34–6.17) · 10−5 F sα−1 cm−2 in respect to the real surface area determined before the oxidation or (2.90–3.45) · 10−5 F sα−1 cm−2 in respect to the real surface calculated after the oxidation experiments) pointing out to an increase in the electrode real surface area. This conclusion is valid when the previously formed Ag2O is completely reduced such that the electrode is oxide free at potentials of HER [22, 74]. A decrease in α with the surface area increase suggests that the surface roughness is the main factor responsible for lowering the α values. It is important to note that an increase in the surface roughness detected at potentials more negative than Ag oxidation, e.g. in HER region, might be caused not only by the electrode dissolution during anodic Ag oxidation. Other processes which may contribute to changes in the surface roughness include surface rearrangement during reduction of Ag2O [8, 68, 69] and possible re-deposition of dissolved Ag species. Data reported in this manuscript are expressed in respect to the real surface area determined for the electrode not subjected to the anodic oxidation, unless stated otherwise. It should be bearing in mind, however, that a dissolution-induced increase in the surface roughness is expected during the anodic Ag oxidation.

Results and discussion

General electrochemical characterisation and XPS results

Figure 1 shows a cyclic voltammetry (CV) curve recorded for a polycrystalline Ag electrode in 0.1 M KOH in potential range 486–914 mV. The curve reveals complex oxidation currents (A) composed with several overlapped anodic peaks with the onset at ca. 10 mV and a corresponding reduction peak (C) seen at potentials more negative than 100 mV (the exact location depends on the amount of Ag compounds subjected to the reduction [37, 69]). Detailed discussion of the processes related to the anodic currents (A) can be found elsewhere [21,22,23,24,25,26,27,28,29, 70,71,72,73,74,75]. Various products of Ag oxidation at potentials up to ca. 540 mV are reported in the literature, including soluble Ag ions, surface AgOH species and solid Ag2O film. Formation of a solid oxide layer at the electrode surface at potentials of peaks (A) was confirmed by e.g. electrochemical quartz crystal microbalance [22, 23], XPS [15] and ellipsometric [76,77,78] measurements.

The silver oxidation in an alkaline environment can be accompanied by a dissolution of the electrode [22, 23, 38, 67, 72, 77,78,79], and Ag2O itself may undergo a dissolution as well [22, 79]. Thus, apart from the reduction of the solid oxide [22], the charge of peak (C) may also contain a contribution from reduction of soluble Ag species formed during the electrode oxidation [24, 70,71,72, 77]. Therefore, the oxide thickness calculated directly on the basis of the oxidation or reduction charge without correction for Ag dissolution should be treated as an upper limit of the oxide thickness, which may be formed under applied experimental conditions rather than the exact thickness value. It should be pointed out that although quantification of the exact thickness of the oxide layer can be difficult, an analysis of the influence of the oxidation or reduction charge on the impedance data still delivers qualitative information on the electrochemical properties of the system studied. Regarding the potential range investigated in these studies, the experiments with a rotating ring-disk electrode reported in [79] show that for solid Ag electrodes in 0.1 M KOHaq and q ox as high as ca. 1 mC cm−2, the dissolution contributes to the overall oxidation current by no more than 3% at 355–365 mV vs. Hg|HgO. For q ox lower than 1 mC cm−2, this contribution was not quantified, but it is expected that at early stages of the oxidation process, when the surface is not completely passivated or the oxide layer is very thin, the dissolution plays a more important role [44].

Figure 2 shows examples of XPS spectra for Ag subjected to oxidation in 0.1 M KOH at 420 mV and recorded at various stages of the Ar+ sputtering. The Ag(0)3d5/2 peak was fitted with an asymmetric Gaussian-Lorentzian function [39] with a tail extension of 90 and a asymmetry factor of 0.1 [53, 80]. The spectra recorded for the fully oxidised surface before the sputtering reveal Ag3d5/2 and 3d3/2 peaks at 367.8 ± 0.1 and 373.8 ± 0.1 eV, respectively (Fig. 2a). These binding energy (BE) values point out to Ag(I) in Ag2O [11, 81,82,83,84,85]. For Ag(I), both 3d5/2 and 3d3/2 peaks are located at lower BE values as compared to the fully metallic surface, in agreement with [84, 86, 87]. The location of Ag M4VV Auger peak (Fig. 2b) at kinetic energies (KE) of 356.3 eV also confirms the presence of Ag2O [81, 87]. Removal of the Ag(I) layer during Ar+ sputtering (Fig. 2b–d) is indicated by a gradual decrease of Ag(I) signal accompanied by a growth of Ag(0) peaks: a 3d5/2 peak at 368.2 ± 0.1 eV and a 3d3/2 peak at 374.2 ± 0.1 eV. Both Ag(0) peaks are accompanied by poorly developed satellites at ca. 372.0 and 378.1 eV, respectively [88]. It should be noted that a reduction of Ag2O during Ar+ bombardment [89] may also contribute to the development of the Ag(0) signal. Addition of Ag(III)3d5/2 peak, usually reported at ca. 367.4 eV [39, 81, 84], has no influence on the fit quality indicating absence of detectable amounts of AgO.

Ag3d XPS and Auger spectra for the electrode oxidised in 0.1 M KOH at 420 mV for various stages of the Ar+ sputtering: a 3d5/2 and 3d3/2 XPS signals before and after completing (metallic surface) the sputtering, b Auger M4VV signals before the sputtering and c–e deconvoluted 3d5/2 XPS signals recorded before sputtering and after 5 and 16 sputtering cycles, respectively. The sputtering rates were 0.31 nm min−1 (cycles 1–20) and 1.52 nm min−1 (from 21st cycle), 1 cycle = 2 min of sputtering. Red lines: experimental data, black lines: fit

The O1s signal recorded for the oxide-covered sample before the sputtering can be deconvoluted into two components (Fig. 3a–d). The main peak at 528.9 ± 0.4 eV is attributed to O2− in a solid oxide phase [11, 87, 90], and its binding energy is very close to the value reported for oxygen in Ag2O in [84]. Interpretation of the second O1s peak at 530.9 ± 0.4 eV, which is observed for the first as well as the subsequent sputtering cycles, is more complicated. In the case of spectrum recorded before the sputtering (Fig. 3a), this signal can be linked with surface-adsorbed species: oxygen [11, 87], water or OH [91, 92] or other contaminations. In the case of advanced stages of the sputtering process (Fig. 3b–d) several identifications of this signal may be proposed: it may be attributed to OH− incorporated into the oxide (XPS experiments presented in [15] indicate possibility of incorporation of the double-layer species into the Ag2O film) or other forms of the oxygen dissolved in the bulk of the oxide [86]. It should be noted that Ag(I) hydroxide is unstable at room temperature and decomposes to Ag2O and water [27, 93]. Although formation of AgOH during anodic Ag oxidation was proposed in [41, 42, 71, 79, 94,95,96,97], the existence of silver-hydroxyl ion species under UHV conditions seems to be highly unlikely.

O1s XPS spectra for the same electrode as in Fig. 2 for various stages of the sputtering process: a before the sputtering and b–d recorded after 5, 16 and 42 sputtering cycles, respectively. Red lines: experimental data, black lines: fit. e Ag(I)3d5/2 to O1s (528.9 eV) XPS peak area ratio as a function of the Ar+ sputtering cycle. The sputtering conditions were the same as for Fig. 2

Assuming that O1s peak at 528.9 eV is the only structural constituent of the Ag2O lattice and other O1s signals are related to incorporated interstitial species, one may evaluate stoichiometry of the film by means of an analysis of the areas of the respective XPS peaks (Fig. 3e). The ratio between areas of Ag(I)3d5/2 and O1s (528.9 eV) peaks, measured for the surface subjected to the ion etching and corrected for the respective sensitivity factors [98], is greater than 2 and is practically independent on the number of sputtering cycles, indicating that the oxide composition can be considered unchanged across the oxide thickness. It follows then that the electrochemically generated Ag2O is oxygen deficient, the effect confirmed by an analysis of semiconducting properties of the film discussed later in the text. Such oxygen deficiency of Ag2O film is in line with data reported in [11] for the Ag(I) oxide formed in more concentrated alkali solution (1 M KOH) at more positive potential of ca. 535 mV. Therefore, the O1s signal at 530.9 eV is most likely linked with oxygen species incorporated in the interstitial sites which do not form bond with Ag. These species may neutralise charge of oxygen-deficient Ag2O, and their presence may alter lattice parameters of Ag2O, as discussed in [77] for hydrous oxides. When the sum of both O1s peaks is considered, the ratio between areas of Ag(I)3d5/2 peak and the total oxygen signal varies between 1.3 and 2 for the sample subjected to the ion sputtering.

The charge consumed for the oxide formation or reduction can be recalculated into the number of the oxide layers providing that the oxidation charge passed during formation of a single monolayer of Ag2O (single plane containing Ag and O ions), q ox(ml), is known. The number of the monolayers can be further recalculated into the thickness units, required for Eq. (2), when the thickness of a single atomic or molecular layer of the oxide is known. Two approaches of determination of q ox(ml) are reported in the literature. The first one assumes that the first monolayer of the oxide is described as a chessboard-like structure containing atomic layers with alternatively mixed metal cations and oxygen anions with the overall crystallographic structure and q ox(ml) the same as for the metal subjected to the oxidation [99]. Alternatively, it may be assumed that the anodically formed oxide has the same structure, lattice constant and q ox(ml) as the respective bulk oxide obtained by e.g. chemical synthesis [e.g. 7]. It is likely that the crystallographic structure, and consequently q ox(ml), changes with the oxide thickness due to a possible transition between two abovementioned scenarios of the oxide formation. Therefore, for relatively thin oxide films, such as these studied in this work, it is helpful to find an average value of q ox(ml), which can be considered representative for the whole oxidised layer. Based on the respective lattice parameters of Ag (fcc structure with the lattice constant of 4.09 Å [100]) and Ag2O (fcc sublattice of Ag ions with lattice constant of 4.74 Å in cubic cuprite-type structure of Ag2O [101,102,103]), one obtains q ox(ml) values equal to 192 and 143 μC cm−2 for complete one electron oxidation of a single layer of surface atoms of Ag metal [99] and for formation of a single molecular layer of bulk Ag2O, respectively (for formation of a complete monolayer of closed packed AgOH, the value of 400 μC cm−2 was assumed in [94, 104]). The average q ox(ml) is then equal to 168 μC cm−2, and this gives the maximum thickness of the oxidised layers studied in this work equal to ca. 106 monolayers (when the surface roughness changes are disregarded and without corrections for Ag dissolution).

Single-frequency impedance measurements

The single-frequency impedance measurements with 1465 Hz were carried out for the oxide-covered Ag electrodes at 365 mV. For such high-frequency value, the contribution from the parallel parasitic capacitance described in the “Experimental” section is meaningless, and when the parallel charge transfer resistance is sufficiently high, the condition confirmed by results of EIS spectra analysis shown in Fig. 7 further in the text, the Z″−1 can be recalculated into C tot when a series resistance-capacitance (RC) circuit is assumed. The C tot measured at a constant potential value decreases with the increase in q ox (left bottom inset in Fig. 4) in agreement with the relation between and C ox and l ox from Eq. 2 and C tot and C ox from Eq. 1 and in line with data reported in [9]. Quantitative analysis of this relationship, such as determination of C dlox or ε r, is, however, more complicated. Firstly, contribution from Ag dissolution to q ox must be known: although for q ox range presented in Fig. 4, this contribution is expected to be practically meaningless and q ox independent [79], the earlier stages of the oxidation process might be much stronger affected by the dissolution processes. Secondly, the exact value of the crystallographic cell dimensions must be known: it was reported [77] that the electrochemically formed hydrous oxides may possess ca. 2.5 times greater cell parameters as compared to the anhydrous form [77]. Finally, the contribution of other capacitive elements, such as the surface state capacitance discussed in the next chapter, to the imaginary impedance component, must be also considered.

Main panel: reciprocal of |Z″| (left axis) and corresponding series capacitance C tot (right axis) for 1465 Hz as a function of the electrode potential for Ag oxidised in 0.1 M KOH at 420 mV (q ox = 20.3 mC cm−2). Shown are the first negative (backward, open points) and subsequent positive (forward, closed points) potential scans. Potential ranges: circles: 235–385 mV, triangles: 375–315 and 305–365 mV for negative and positive scans, respectively. Left lower inset: C tot −1 measured with 1465 Hz at 365 mV as a function of q ox. Right upper inset: photocurrents recorded at 420 mV for the oxide-covered Ag (q ox = 21.5 mC cm−2)

The main panel in Fig. 4 shows how the C tot of Ag2O-covered electrode is influenced by the electrode potential when the impedance is measured at various potential values. Measurements under such conditions are complicated by limited stability of such layers, as discussed in [41]. The oxidised layers, especially the thin ones, may undergo further thickening or partial reduction during the impedance data collection, depending on the applied potential range. The stability of the oxidised layers may be evaluated on the basis of the degree of overlapping of subsequently recorded curves for forward and backward potential scans [105, 106]. It follows that stability of Ag2O-covered electrodes depends on the potential range where the impedance was acquired (main panel in Fig. 4). Thus, for a very narrow potential window of ca. 305–375 mV, the Z″−1 (or C tot) vs. E curves for negative and positive potential scans practically overlap. An increase of the capacitance with the potential decrease is noted below ca. 345 mV, but the very narrow potential range where this effect is observed does not allow drawing definitive conclusions about electronic properties of the Ag2O film.

An opposite effect is observed when the negative potential limit is extended to 235 mV, which is the value located ca. 30 mV before the apparent potential of the onset of the oxide reduction deduced from the respective voltammetric curves (main panel in Fig. 4). In this case, the capacitance is lower for the subsequent positive potential scan and the curves recorded for both scan directions do not overlap, most likely due to a partial reduction of Ag2O: it is likely that deduction of the reduction onset from the voltammetric curves (potential of zero current) gives only a rough estimation of its value. It should be also stressed the Mott-Schottky equation cannot be applied here because the oxide layers are most likely too thin and the measurements were carried out at conditions too close to the full depletion of the semiconductor (C tot −2 vs. E plots (not shown) are non-linear) [1, 107]. Therefore, although a decrease of C tot with increasing potential suggests behaviour of an n-type semiconductor [1, 41,42,43, 47], the unequivocal proof of such type of properties comes from photocurrent measurements showing formation of positive photocurrents (top right inset in Fig. 4). This type of the photocurrent is observed only for sufficiently thick Ag2O layer (at least 10 mC cm−2), which confirms its assignment to the semiconducting properties of the film. The n-type semiconducting properties are also in agreement with XPS data discussed in the previous chapter and indicating oxygen deficiency of Ag2O [108]. The transient shape of the photocurrents points out to existence of surface states [109]. Such a confirmation of the semiconductor type is important because semiconducting properties of electrochemically formed Ag2O may vary depending on formation conditions [21].

Electrochemical impedance spectroscopy

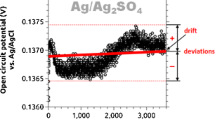

A two-step potential program was applied in EIS measurements for Ag2O-covered electrodes with a relatively fast oxide formation at E ox = 420 mV and subsequent EIS data collection at E m = 365 or 345 mV where the rate of faradaic reactions is significantly smaller. Selection of such type of the procedure was driven by two factors. Firstly, it allows significant reduction of time of the experiment as compared to formation of Ag2O layers at E m as low as 345–365 mV. Secondly, it was found that stability of the system during the spectra acquisition at E ox as high as 420 mV was doubtful for the q ox range studied (details of the stability tests are presented in the next paragraphs). This procedure did not include reduction of the Ag2O layer; i.e. after completing the spectra acquisition at E m, the potential was stepped back to E ox without the oxide reduction and the procedure of the oxide formation at E ox followed by the impedance measurements at E m was repeated. The conditions of continuous oxide growth and its accumulation were maintained, and the q ox used in data analysis was a sum of the charges passed during all previous steps of the oxide formation. The cumulative oxidation time at 420 mV was up to 400 s.

The validity of EIS data acquired after long-time polarisation was analysed by means of a Kramers-Kronig-type test. The impedance spectra were fitted with a Voigt-type circuit composed with a network of connected in series subcircuits, each of them containing a resistance and a capacitance connected in series (RC) [110,111,112]. Two examples are shown in Fig. 5. Figure 5a shows an example of the residual distribution for the spectrum which passed the test, i.e. for the sufficiently thick oxide layer. The number of RC subcircuits (usually 12) used in this equivalent circuit was smaller than the number of the experimental points resulting in a sinusoidal shape of some sections of the residual trace. However, the lack of continuous and consequent departure of the residual trace from the zero line with the residuals distributed below and above the zero line confirms correctness of the acquired EIS data. This indicates very low rate of observed reactions or attainment of steady-state conditions. If a steady state is attained, the related processes might be interpreted in terms of e.g. point defect model [7].

Examples of distribution of residuals from Kramers-Kronig (KK)-type tests for EIS spectra recorded at 365 mV for Ag oxidised at 420 mV for q ox = 14.0 (a) and 9.5 mC cm−2 (b). Spectra were fitted with a Voigt-type equivalent circuit with 12 RC subcircuits. The residuals are defined as ΔZ′ = 100 · (Z′(experiment) − Z′(KK))/|Z(experiment)| and ΔZ″ = 100·(Z″(experiment) − Z″(KK))/|Z(experiment)|

An opposite example is presented in Fig. 5b where a clear departure from random distribution of the residuals is noticed with most of the residuals located above the zero line and with the average departure from the zero line greater than for Fig. 5a. This EIS spectrum was recorded at the early stages of the oxidation procedure when the Ag2O layer was relatively thin, and it follows from Fig. 5b that its stability was doubtful. In general, the stability required for EIS measurements under conditions of potentiostatic polarisation is observed for q ox of at least 14 mC cm−2, for a potential window located between ca. 345 and ca. 365 mV and long enough polarisation at E m, usually from 240 to 180 s. It should be noted that for sufficiently long polarisation times, the subsequently recorded spectra reveal very small differences indicating very low rate of faradaic processes at E m. The abovementioned potential window of the system stability under conditions of EIS measurements is significantly narrower than the one for the single-frequency impedance measurements from Fig. 4 indicating more challenging stability conditions for acquisition of EIS spectra with a long-time polarisation.

Examples of EIS data recorded at 365 mV for various q ox values are shown in Fig. 6a (Nyquist plots) and 6b (Bode plots). In all cases, a semicircle is observed on Nyquist plots (Fig. 6a), indicating that the electrode does not behave as an ideally polarisable one even for the thickest oxide layers studied (up to ca. 20 mC cm−2). Similar shapes of the Nyquist plots with a semicircle distorted to a various degree were shown in [9, 41, 47] for Ag oxidised in alkaline electrolytes in a potential range similar to that investigated in this work. Figure 6a indicates that the radius of the apparent semicircle of the Nyquist plots increases when q ox increases, indicating that the rate of the faradaic reactions decreases when the oxide layer becomes thicker.

EIS data recorded in 0.1 M KOH at 365 mV for an Ag electrode oxidised at 420 mV for various q ox values indicated in the plot: a Nyquist and b Bode plots. Points: experimental data, lines: fits to the equivalent circuit shown in the inset in a. The circuit components are explained in the text. Vertical arrows in b indicate evolution of the plots with increasing q ox; for clarity, b shows spectra for only three q ox values

Several factors were considered in selection of the best equivalent circuit used for EIS data fitting; the most important one was the fit quality which was evaluated on the basis of χ 2 values (usually 1 · 10−4–5 · 10−5 range), residual distribution and values of the relative errors of the individual circuit components [105]. The number of the circuit components was optimal so that introduction of additional components had no significant influence on the results of the fitting and only a single set of the fitting parameters gave the best fit.

The equivalent circuit used in the analysis of EIS data is depicted in the inset in Fig. 6a; for the sake of clarity not shown is the parallel parasitic capacitance (C p) described in the “Experimental” section and depicted in Fig. S1 in the supplementary material. The two subcircuits of the equivalent circuit from Fig. 6a represent both sides of the electrode-electrolyte interface between Ag2O and 0.1 M KOHaq. It is assumed that the oxide layers studied are so thick that the electrolyte cannot penetrate them to the metallic surface and the latter effect is disregarded. On the electrolyte side of the interface, the double-layer capacitance is represented as CPE (CPEdlox) with R dl as the parallel charge transfer resistance describing the rate of a red-ox reaction at the electrode/electrolyte interface with an electron transfer through it (e.g. [7]). The oxide side contains the capacitance of the Ag2O film, represented as another one CPE (CPEox), and two parallel branches: the one containing the resistance R 1 related to faradaic processes of Ag oxidation and another one branch, which describes surface states with the respective capacitance (C ss) and the resistance (R ss). Existence of the surface states is indicated by the shape of the photocurrents recorded for the oxidised Ag electrode (Fig. 4), and addition of C ss and R ss to the equivalent circuit significantly improves quality of the fit (χ 2 decreases by a factor of up to 8). Two main differences between the circuit from Fig. 6a and the one used in [9] are the lack of another one RC branch parallel to CPEox, which introduction did not affect quality of the fitting, and the presence of the additional subcircuit (CPEdlox-R dl) that represents the double-layer side of the electrode/electrolyte interface. The spectra also do not reveal the Warburg element reported in [10, 47]; its introduction to the equivalent circuit does not improve the fit significantly and leads to unacceptable errors of some of the fitting parameters (up to hundreds of %). On the other hand, replacement of C ss with the Warburg impedance deteriorates quality of the fit. Presumably, the layers studied in this work are thinner than those analysed in [10, 47] and this may explain discussed differences. The differences between the circuit from Fig. 6a and the one used in [41, 47] include the presence of an additional branch describing surface states (R ss and C ss) and replacement of the capacitances with CPEs. Further on, the frequency range used in this work was extended towards lower values as compared [41, 47].

The respective fits to the circuit from the inset in Fig. 6a are shown as solid lines in Fig. 6a, b. The values of the fitted components obtained for E m = 365 mV are shown in Fig. 7 as a function of the oxidation charge without correction for possible Ag dissolution. According to [79], the contribution from the Ag dissolution current for this q ox range reaches a few percent and is q ox independent. Thus, q ox changes seen in Fig. 7 directly mirror evolution of the Ag2O thickness although the exact value of the latter is unclear due to a possible extensive dissolution at the early stages of the oxidation (q ox < 1 mC cm−2) [79]. The q ox range from Fig. 7 without corrections for the dissolution covers the thickness range ca. 49–105 monolayers when the surface roughening during the oxidation is disregarded or ca. 23–50 monolayers when a surface increase deduced from a comparison of C dl measured in HER region before and after the oxidation is considered. Not shown is R dl which is independent on q ox with the average value of 11.5 kΩ cm2 and the average error of 22.3%.

Components of the equivalent circuit from Fig. 6 as a function of q ox. The average relative errors are (in %) 4.1 (Q(CPEox)), 0.5 (α(CPEox)), 21.1 (R ss), 16.5 (C ss), 5.1 (R 1), 9.8 (Q(CPEdlox)) and 4.2 (α(CPEdlox))

An analysis of Fig. 7 indicates that

-

α(CPEox) is the thickness independent, indicating that the physical/chemical properties of the oxide film do not change significantly with its thickness, in agreement with XPS data (Figs. 2 and 3) showing chemical homogeneity of the oxide layer. The relatively low values of α(CPEox) in the range of 0.781–0.759 can be attributed to a high defectiveness of the oxide layer. The XPS results (Fig. 3) show non-stoichiometry of the film, and one may expect the presence of local non-homogeneities of the film due to existence of randomly distributed domains with varying stoichiometries and oxygen content, which may differ also in respect to dielectric/electronic properties. These non-homogeneities are most likely randomly distributed along parallel and horizontal axis of the film, and due to their random distribution, their existence does not result in macroscopic homogeneities of the film, such as formation of layered sandwich-type structures possible to detect by XPS. It was proposed [59, 61] that the CPE-type behaviour of non-homogenous 3D films can be described as a normal or series combination of numerous RC subcircuits with different time constant values. Accordingly, the α value may mirror distribution of respective time constants inside the film volume [61, 113]: the lower the α value, the greater the difference between electric/dielectric properties of domains with different stoichiometry and oxygen content and/or the less sharp is their distribution.

-

For the thickness-independent α(CPEox), the Q(CPEox)−1 vs. q ox plot shown in Fig. 7 can be analysed in terms of the oxide thickness influence on Q(CPEox) and indicates that the latter parameter decreases from 9.96 · 10−6 to 7.53 · 10−6 F sα−1 cm−2 when the oxide thickness increases. Although the Q(CPEox)−1 vs. q ox plot can be approximated by a straight line, in apparent agreement with Eq. 2, it should be bearing in mind that for α values as low as 0.7–0.8, the Q(CPEox) cannot be identified as the pure capacitance.

-

As expected for the double layer, the Q(CPEdlox) ((3.94–4.39) · 10−5 F sα−1 cm−2 range), α(CPEdlox) (0.910–0.951 range) and R dl (not shown, 10.7–12.3 kΩ cm2 range) are thickness independent. Relatively low values of α(CPEdlox) are attributed to the rough surface of Ag2O [8, 22, 29, 30, 67, 77]; their independence on the oxide thickness may indicate that for the sufficiently thick oxide, the surface roughness becomes practically constant. It is likely that the surface roughening takes place mainly at the initial stages of the oxide formation, when significant sections of the metallic Ag surface are exposed to the electrolyte or the oxide is very thin. For sufficiently thick Ag2O layers, the surface becomes more stable and the dissolution, if takes place, does not change the surface roughness significantly although changes in the surface state capacitance are detected (see next point).

-

C ss (0.18–0.28 μF cm−2 range) and R ss (1.08–1.41 kΩ cm2 range) decrease and increase with q ox, respectively. This effect indicates some evolution of the oxide-electrolyte interface although without significant changes in the surface roughness, as discussed earlier. The values of both elements are within typically reported ranges [e.g. [114, 115].

-

R 1 (376–576 kΩ cm2 range) increases with the oxide thickness indicating that the related faradaic process becomes slower when the oxide thickness increases. These values of the charge transfer resistance are significantly greater than 101 Ω cm2 range reported for similar potential range in [10, 47].

A very narrow potential range where the EIS spectra were acquired complicates drawing unambiguous conclusions about the potential impact on the fitting parameters. A comparison of data from Fig. 7 with results of EIS measurements at 345 mV (results not shown) does not reveal a clear potential influence on any of the fitting parameters.

The CPE impedance components Q and α obtained for the double layer of the oxide-covered electrode (CPEdlox) can be compared with the respective values for the oxide-free silver measured at potentials of HER. In the case of the electrode from Fig. 7, the average Q and α values in the HER region were equal to, respectively, 2.86 · 10−5 F sα−1 cm−2 and 0.953 before the surface oxidation experiments and 7.14 · 10−5 Ω sα cm−2 and 0.929 after completing the oxidation experiments when the surface roughness is expected to increase (both Q values measured for HER region and Q for CPEdlox are expressed in respect to the real surface area measured before the oxidation experiments). A comparison of the above values with data from Fig. 7 indicates that the double-layer capacitance of the Ag2O-covered electrode does not differ significantly from that measured for the metallic surface: α is of the same range while Q(CPEdlox) lies between Q values measured in HER region before and after completing the oxidation experiments. Thus, an analysis of EIS data indicates that the difference between double-layer capacitances of Ag2O-covered and metallic Ag electrodes is not as high as an order of magnitude or more, as previously reported.

Conclusions

Oxidation of polycrystalline solid Ag electrodes in 0.1 M KOHaq at 420 mV vs. Hg|HgO leads to formation of a homogenous anodic oxide layer containing Ag2O as follows from an XPS analysis. The electrochemical impedance experiments were applied to study the properties of the interface between the electrolyte and the Ag(I) oxide-covered electrode; the measurements were carried out under conditions of Ag2O film stability, i.e. in 305–375-mV range for single-frequency experiments (1465 Hz) and in 345–365-mV range for the EIS measurements (46.4 mHz–10.01 kHz). The overall interfacial capacitance of the electrode/electrolyte interface determined from the single-frequency measurements decreases with the progress in the surface oxidation process and weakly increases with the potential decrease pointing out to n-type semiconducting properties of the Ag2O layer, confirmed by means of photocurrent measurements. An analysis of the influence of the charge of the Ag2O formation on the impedance spectra allowed identification of components of the equivalent circuit used in EIS data analysis. The value of the coefficient of the constant phase element (CPE) describing the capacitance of the Ag2O layer depends on the oxide thickness while the components of the CPE attributed to the capacitance of the double layer of the oxide-covered electrode are Ag2O thickness independent. The latter CPE components were found to be comparable to those obtained for the oxide-free surface at potentials of the HER. This indicates that the double-layer capacitances of oxidised and oxide-free Ag electrode in an alkaline electrolyte are comparable.

References

Stimming U (1986) Electrochim Acta 31:415–429

Fierro JLG (2005) Metal oxides: chemistry and applications. CRC Press, Boca Raton

Gomes WP, Cardon F (1982) Prog Surf Sci 12:155–215

Albery WJ, O'Shea GJ, Smith AL (1996) J Chem Soc Faraday Trans 92:4083–4085

Bard AJ, Memming R, Miller B (1991) Pure Appl Chem 63:569–596

Trasatti S, Petrii OA (1991) Pure Appl Chem 63:711–734

Sun A, Franc J, MacDonald D (2006) J Electrochem Soc 153:B260–B277

Giles RD, Harrison JA, Thirsk HR (1969) J Electroanal Chem 22:375–388

Hepel M, Tomkiewicz M (1985) J Electrochem Soc 132:32–38

Pound BG, MacDonald DD (1982) Electrochim Acta 27:1489–1500

Lützenkirchen-Hecht D, Strehblow HH (2009) Surf Interface Anal 41:820–829

Łukomska A, Sobkowski J (2005) J Solid State Electrochem 9:277–283

Safonov VA, Choba MA, Seropegin YD (2003) J Electroanal Chem 552:153–162

Larkin D, Guyer KL, Hupp JT, Weaver MJ (1982) J Electroanal Chem 138:401–423

Lützenkirchen-Hecht D, Strehblow HH (1998) Electrochim Acta 43:2957–2968

Safonov VA, Krivenko AG, Choba MA (2008) Electrochim Acta 53:4859–4866

Rojhantalab HM, Richmond GL (1989) J Phys Chem 93:3269–3275

Trunov AM (1989) Sov Prog Chem 55:51–53

Perkins RS, Tilak BV, Conway BE, Kozlowska HA (1972) Electrochim Acta 17:1447–1469

Takehara Z, Namba Y, Yoshizawa S (1968) Electrochim Acta 13:1395–1403

Perkins RS, Tilak BV, Conway BE, Kozlowska HA (1972) Electrochim Acta 17:1471–1489

Chen SL, Wu BL, Cha CS (1996) J Electroanal Chem 416:53–59

Chen SL, Wu BL, Cha CS (1997) J Electroanal Chem 420:111–118

El Rehim SA, Hassan HH, Ibrahim MAM, Amin MA (1998) Monatsh Chem 129:1103–1117

Łukaszewski M, Klimek K, Czerwiński A (2009) J Electroanal Chem 637:13–20

Jović BM, Jović VD (2004) J Serb Chem Soc 69:153–166

Vvedenskii A, Grushevskaya S, Kudryashov D, Kuznetsova T (2007) Corr Sci 49:4523–4541

Hepel M, Tomkiewicz M (1984) J Electrochem Soc 131:1288–1294

Wan Y, Wang X, Liu S, Li Y, Sun H, Wang Q (2013) Int J Electrochem Sci 8:12837–12850

Kunze J, Strehblow HH, Staikov G (2004) Electrochem Commun 6:132–137

Hecht D, Frahm R, Strehblow HH (1996) J Phys Chem 100:10831–10833

Mikhlin YL, Vishnyakova EA, Romanchenko AS, Saikova SV, Likhatski MN, Larichev YV, Tuzikov FV, Zaikovskii VI, Zharkov SM (2014) Appl Surf Sci 297:75–83

Savinova ER, Zemlyanov D, Pettinger B, Scheybal A, Schlögl R, Doblhofer K (2000) Electrochim Acta 46:175–183

Dirkse TP (1990) Electrochim Acta 35:1445–1449

Horswell SL, Pinheiro ALN, Savinova ER, Pettinger B, Zei MS, Ertl G (2004) J Phys Chem B 108:18640–18649

Briggs GWD, Fleischmann M, Lax DJ, Thirsk HR (1968) Trans Faraday Soc 64:3120–3127

Lopez Teijelo M, Vilche JR, Arvía AJ (1982) J Electroanal Chem 131:331–339

Droog JMM, Alderliesten PT, Bootsma GA (1979) J Electroanal Chem 99:173–186

Ferraria AM, Carapeto AP, Botelho do Rego AM (2012) Vacuum 86:1988–1991

Grzelak A, Jaroń T, Mazej Z, Michałowski T, Szarek P, Grochala W (2015) J Electron Spectrosc Relat Phenom 202:38–45

Popkirov GS, Burmeister M, Schindler RN (1995) J Electroanal Chem 380:249–254

Kudryashov DA, Grushevskaya SN, Vvedenskii AV (2007) Protect Metals 43:591–599

Memming R, Möllers F, Neumann G (1970) J Electrochem Soc 117:451–457

Vvedenskii A, Grushevskaya S, Kudryashov D, Ganzha S (2010) J Solid State Electrochem 14:1401–1413

Jiang Z, Huang S, Qian B (1994) Electrochim Acta 39:2465–2470

Ross D, Roberts EFI (1976) Electrochim Acta 21:371–375

Naoi K, Nagase Y, Osaka T (1985) J Metal Finishing Soc Jap 36:404–408

Popkirov GS, Schindler RN (1992) Rev Sci Instr 63:5366–5372

König U, Schultze JW (1999) In: Wieckowski A (ed) Interfacial electrochemistry: theory, experiment, and applications. New York, Dekker

De Gryse R, Gomes WP, Cardon F, Vennik (1975) J Electrochem Soc 122:711–712

Nozik AJ, Memming R (1996) J Phys Chem 100:13061–13078

Boukamp BA (1986) Solid State lonics 20:31–44

Software manual (2016) The University of Warwick http://www2.warwick.ac.uk/fac/sci/physics/research/condensedmatt/surface/exp/xps/links/xpspeak_manual.doc. Accessed 5 Apr 2017

Iwasaki N, Sasaki Y, Nishina Y (1988) Surf Sci 198:524–540

Lucas CA, Thompson P, Gründer Y, Markovic NM (2011) Electrochem Commun 13:1205–1208

Nagle LC, Ahern AJ, Burke LD (2002) J Solid State Electrochem 6:451–462

Giles RD, Harrison JA (1970) J Electroanal Chem 24:399–407

Sluyters-Rehbach M (1994) Pure Appl Chem 66:1831–1891

Brug GJ, Van Den Eeden ALG, Sluyters-Rehbach M, Sluyters JH (1984) J Electroanal Chem 176:275–295

Lasia A (1999) In: Conway BE (ed) Electrochemical impedance spectroscopy and its applications, vol 32. New York, Kluwer

Hirschorn B, Orazem ME, Tribollet B, Vivier V, Frateur I, Musiani M (2010) Electrochim Acta 55:6218–6227

Zoltowski P (1998) J Electroanal Chem 443:149–154

Jafarian M, Mahjani MG, Azizi O, Gobal F (2003) Ind J Chem 42:516–519

Smoliński S, Zelenay P, Sobkowski J (1998) J Electroanal Chem 442:41–47

Łukomska A, Sobkowski J (2006) Electrochim Acta 51:2247–2254

Hamelin A, Doubova L, Stoicoviciu L, Trasatti S (1988) J Electroanal Chem 244:133–145

Maurice V, Klein LH, Strehblow HH, Marcus P (2007) J Phys Chem C 111:16351–16361

Gómez Becerra J, Arvia AJ (1990) Electrochim Acta 35:595–604

Lopez Teijelo M, Vilche JR, Arvía AJ (1984) J Electroanal Chem 162:207–224

Hur TU, Chung WS (2005) J Electrochem Soc 152:A179–A185

Alonso C, Salvarezza RC, Vara JM, Arvia AJ (1990) Electrochim Acta 35:489–496

Ambrose J, Barradas RG (1974) Electrochim Acta 19:781–786

Sasaki H, Toshima S (1975) Electrochim Acta 20:201–207

Cheng Y, Yan M, Jiang Z (2007) Electrochem Solid-State Lett 10:F5–F8

Iwasaki N, Sasaki Y, Nishina Y (1988) J Electrochem Soc 135:2531–2534

López Teijelo M, Zerbino JO, Vilche JR, Arvía AJ (1984) Electrochim Acta 29:939–946

Zerbino J, Lopez Teijelo M, Vilche JR, Arvia AJ (1985) Electrochim Acta 30:1521–1525

Droog JMM (1980) J Electroanal Chem 115:225–233

Vvedenskii A, Grushevskaya S, Kudryashov D (2008) Corr Sci 50:583–590

Conny JM, Powell CJ (2000) Surf Interface Anal 29:856–872

Waterhouse GIN, Bowmaker GA, Metson JB (2001) Appl Surf Sci 183:191–204

Feng HL, Gao XY, Zhang ZY, Ma JM (2010) J Korean Phys Soc 56:1176–1179

Weaver JF, Hoflund GB (1994) J Phys Chem 98:8519–8524

Hoflund GB, Hazos ZF, Salaita GN (2000) Phys Rev B 62:11126–11133

Gao XY, Ma JM, Chen C, Zhao MK, Gu JH, Lu JX (2012) J Korean Phys Soc 60:807–811

Kaspar TC, Droubay T, Chambers SA, Bagus PS (2010) J Phys Chem C 114:21562–21571

Schön G (1973) Acta Chem Scandinav 27:2623–2633

Leiro J, Minni E, Suoninen E (1983) J Phys F: Met Phys 13:215–221

Kim KS, Baitinger WE, Amy W, Winograd N (1974) J Electron Spectr Related Phenom 5:35l–367

Lützenkirchen-Hecht D, Strehblow HH (2006) Surf Interface Anal 38:686–690

Kuch W, Schulze M, Schnurnberger W, Bolwin K (1993) Surf Sci 287-288:600–604

Yamamoto S, Bluhm H, Andersson K, Ketteler G, Ogasawara H, Salmeron M, Nilsson A (2008) J Phys Condens Matter 20:184025

Wei J, Lei Y, Jia H, Cheng J, Hou H, Zheng Z (2014) Dalton Trans 43:11333–11338

Gomez Becerra J, Salvarezza RC, Arvia AJ (1988) Electrochim Acta 33:1431–1437

Burstein GT, Newman RC (1980) Electrochim Acta 25:1009–1013

Dirkse TP, De Vries DB (1959) J Phys Chem 63:107–110

Jovic BM, Jovic VD, Stafford GR (1999) Electrochem Commun 1:247–251

Wagner CD, Riggs WM, Davis LE, Moulder JF, Muilenberg GE (1979) Handbook of X-ray photoelectron spectroscopy. Physical Electronics, Eden Prairie

Conway BE, Barnett B, Angerstein-Kozlowska H, Tilak BV (1990) J Chem Phys 93:8361–8373

Haynes WM (2012) CRC handbook of chemistry and physics. CRC Press, Boca Raton

Allen JA (1965) In: Friend JA, Gutmann F (eds) Proc First Australian Conf Electrochem. Pergamon, London

Werner A, Hochheimer HD (1982) Phys Rev B 25:5929–5934

Zarechina ES, Karzhavykh DS, Kravchenko NG, Nikolaeva EV, Poplavnoi AS (2015) Russ Phys J 58:574–582

Pound BG, Macdonald DD, Tomlinson JW (1980) Electrochim Acta 25:563–573

Grdeń M (2014) J Electroanal Chem 713:47–57

Barral G, Njanjo-Eyoke F, Maximovitch S (1995) Electrochim Acta 40:2815–2828

Bard AJ (1982) J Phys Chem 86:172–177

Seebauer EG, Kratzer MC (2009) Charged semiconductor defects: structure, thermodynamics and diffusion. Springer, London

Peter LM (1990) Chem Rev 90:753–769

Boukamp BA (1995) J Electrochem Soc 142:1885–1894

Boukamp BA, Macdonald JR (1994) Solid State Ionics 74:85–101

Agarwal P, Orazem ME, Garcia-Rubio LH (1992) J Electrochem Soc 139:1917–1927

Hirschorn B, Orazem ME, Tribollet B, Vivier V, Frateur I, Musiani M (2010) J Electrochem Soc 157:C452–C457

Bockris JO’M, Kham SUM (1993) Surface electrochemistry. A molecular level approach. Plenum Press, New York

Debiemme-Chouvy C, Cachet H (2008) J Phys Chem C 112:18183–18188

Acknowledgements

This work was financially supported by Ministry of Science and Higher Education grant No. N N204 125037 and by Faculty of Chemistry, University of Warsaw (BST). The author is greatly indebted to Dr. J. Sobczak and Dr. hab. W. Lisowski, Institute of Physical Chemistry, Polish Academy of Sciences, for XPS measurements.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOC 94 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Grdeń, M. Impedance study on the capacitance of silver electrode oxidised in alkaline electrolyte. J Solid State Electrochem 21, 3333–3344 (2017). https://doi.org/10.1007/s10008-017-3684-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3684-2