Abstract

Stainless steel ISO 5832–9 type is often used to perform implants which operate in protein-containing physiological environments. The interaction between proteins and surface of the implant may affect its corrosive properties. The aim of this work was to study the effect of selected serum proteins (albumin and γ-globulins) on the corrosion of ISO 5832–9 alloy (trade name M30NW) which surface was modified by titania coatings. These coatings were obtained by sol–gel method and heated at temperatures of 400 and 800 °C. To evaluate the effect of the proteins, the corrosion tests were performed with and without the addition of proteins with concentration of 1 g L−1 to the physiological saline solution (0.9 % NaCl, pH 7.4) at 37 °C. The tests were carried out within 7 days. The following electrochemical methods were used: open circuit potential, linear polarization resistance, and electrochemical impedance spectroscopy. In addition, surface analysis by optical microscopy and X-ray photoelectron spectroscopy (XPS) method was done at the end of weekly corrosion tests. The results of corrosion tests showed that M30NW alloy both uncoated and modified with titania coatings exhibits a very good corrosion resistance during weekly exposition to corrosion medium. The best corrosion resistance in 0.9 % NaCl solution is shown by alloy samples modified by titania coating annealed at 400 °C. The serum proteins have no significant effect onto corrosion of investigated biomedical steel. The XPS results confirmed the presence of proteins on the alloy surface after 7 days of immersion in protein-containing solutions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The term “biomaterial” was defined by Williams (1987) as any substance (other than a drug) or combination of substances, synthetic or natural in origin, which can be used for any period of time as a whole or as a part of a system which treats, augments, or replaces any tissue, organ, or function of the body [1]. Metals, polymers, ceramics, and composites may be used as biomaterials. Each type of these materials has specific properties which are needed in a specific application field. Metallic biomaterials find an application as prostheses and implants in many medical disciplines, e.g., in orthopedics, cardiology, and dentistry. All of the requirements set out for metallic biomaterials are detailed in International Standard ISO 5832. This standard contains several parts concerned with titanium-based materials, cobalt-based materials, and stainless steels. Part 9 of the standard describes the chemical composition and physicochemical properties of wrought high nitrogen stainless steel dedicated for orthopedic implants [2]. The main alloying elements of this group of steel are as follows (wt%): iron (base), chromium (19.5–22.0), nickel (9.0–11.0), manganese (2.0–4.45), molybdenum (2.0–3.0), and nitrogen (0.25–0.5).

An ideal metallic biomaterial is expected to exhibit a very high biocompatibility, good corrosion resistance, and good mechanical properties. It is very difficult to combine all these properties in only one material. Improvement of mechanical properties, corrosion resistance, and biocompatibility of biomedical steels for implantology may be achieved through surface modification, for example by surface coating. A very popular material for biomedical coating is titanium dioxide (titania, TiO2) due to its excellent corrosion, mechanical, and biological properties [3, 4]. Many methods are used to prepare biomedical coatings. One of them is sol–gel method [4–7].

Orthopedic implants, made of stainless steel ISO 5832–9 type, operate in protein-containing physiological environments. Blood plasma contains three types of dissolved proteins—albumin, globulins, and fibrinogen. Following the implantation of a biomaterial, the first event to occur at the tissue-material interface is protein adsorption [8, 9]. The layer of adsorbed proteins is formed immediately after metal immersion in human plasma [10]. The interaction between proteins and surface of the implant may affect its corrosive properties. Conclusions concerning the influence of proteins are not clear. Some authors [11, 12] report that bovine serum albumin (BSA) diminishes the corrosion rate of stainless steels and titanium alloys, while other authors [13, 14] report that BSA promotes the dissolution of these alloys by forming stable complexes with the metallic components of the alloys. Literature data show that the effect depends on the type of biomaterial [15] and its surface finish [16], as well as on the concentration of protein [15] and pH of the solution [17].

The aim of this work was to study the effect of selected serum proteins (albumin and γ-globulins) added to the physiological saline solution (0.9 % NaCl, pH 7.4) on the corrosion of ISO 5832–9 alloy (trade name M30NW) which surface was modified by titania coatings.

Experimental

Materials

The biomedical alloy M30NW (Aubert & Duval, France) was used as a metallic substrate. Its chemical composition is as follows (wt%): Cr (20.62), Ni (9.53), Mn (4.13), Mo (2.12), N (0.40), Nb (0.31), C (0.032), and Fe (rest). M30NW alloy samples were discs with a diameter of 22 mm and a thickness of about 3 mm. Every sample was ground on SiC abrasive paper (80–1,500 grits), polished with Al2O3 suspension (0.3 μm), chemically etched in a mixture of 2 % HF, 10 % HNO3, and 88 % H2O, passivated in boiling water (10 min), rinsed with ethanol, and dried with argon. Samples prepared in such a way were ready for TiO2 coating. The precursor for TiO2 coating was titanium (IV) isopropoxide (Ti[OCH(CH3)2]4, 97 %, Aldrich) [7]. Titania coating (as a single layer) was applied onto alloy surface by dip-coating technique using a dip-coater DCMono 75 (NIMA Technology). The final annealing of applied coating was carried out in a muffle furnace at temperatures of 400 and 800 °C for 1 h.

All the chemical reagents used in the experiment were of analytical grade and were applied without further purification.

Corrosion medium

The corrosion medium was composed of sodium chloride (NaCl, pure p.a., POCH S.A.), bovine serum albumin (BSA, >96 %, Sigma), γ-globulins from bovine blood (≥97 %, Sigma), and distilled water. The starting composition in 1,000 mL of each solution and their codes are listed in Table 1. All solutions were buffered by phosphate buffer (KH2PO4/Na2HPO4 × 12H2O) and adjusted to pH 7.4 using hydrochloric acid (HCl, pure p.a., POCH S.A.).

Electrochemical measurement

During the weekly corrosion tests, all samples immersed in corrosion medium were stored at constant temperature of 37 °C. On selected days (0, 1, 3, 7), non-destructive corrosion tests were performed using potentiostat/galvanostat PGSTAT 128 with FRA2 module (EcoChemie Autolab). The corrosion measurements were carried out in three-electrode electrolytic cell with a sample as a working electrode, platinum foil with an area of 60 cm2 as a counter electrode, and saturated calomel electrode (SCE, E° = 0.241 V vs SHE) as a reference electrode. All potentials reported in this paper are given versus SHE electrode. Exposed area of each sample was approximately 0.64 cm2.

Some basic corrosion parameters such as corrosion potential, polarization resistance, and electrochemical impedance, were determined versus immersion time. The corrosion potential (E cor) as open circuit potential was measured for 2,000 s. The polarization resistance (R p) of the specimen in the test solution was measured using linear polarization method. The measurements were done in a scanning range of ±20 mV versus E cor potential with a scan rate of 0.3 mV s−1. Electrochemical impedance characteristics were registered at E cor potential by applying a sinusoidal signal of ±10 mV within the frequency range from 0.01 to 10 kHz. Each measurement was maintained at 37 °C. Three specimens were tested for each corrosion test and results presented in this paper are averaged values.

Surface characterization

The specimens were removed from the solutions after immersion for 7 days and rinsed with distilled water. Next, their surfaces were examined by optical microscopy and X-ray photoelectron spectroscopy (XPS). The optical images were obtained using metallographic microscope MMT 800BT (Mikrolab, Poland). All XPS spectra were recorded with a PHI 5000 VersaProbe scanning spectrometer (ULVAC-PHI, Japan/USA). The X-ray source used was monochromatic Al-Kα radiation (1486.6 eV) with an input power of 25 W. X-ray beam was focused to a diameter of 100 μm; measured area was defined as 1,000 μm × 1,000 μm. The electron energy analyzer was operated at a pass energy of 117.4 eV (energy step 0.4 eV) for fast survey scan, and 23.5 eV (energy step 0.1 eV) for all high-resolution spectra. All measurements were conducted with the use of a charge neutralizer system. The angle between sample surface and electron energy analyzer was 45°. The binding energy scale was normalized to the C1s peak (285.0 eV).

Results

Electrochemical measurements

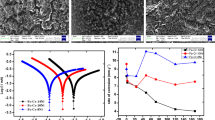

Figure 1 presents the results of corrosion potential E cor versus immersion time. For uncoated samples (Fig. 1a) in solution without proteins, the E cor value is rising close to 0.23 VSHE at the 7th day. The positive potential evolution indicates the formation of a protecting passivation layer on the M30NW alloy. Such evolution of E cor values is not observed in the protein-containing solutions. In case of samples modified by titania coatings (Fig. 1b, c) a regression with time of the E cor is observed. This regression is similar in solutions both with and without proteins.

The values of polarization resistance were determined from the slope of the linear polarization characteristics using CorrView software (Scribner Associates Inc.). Figure 2 presents the polarization resistance-immersion time dependence for all investigated samples. It can be seen that the longer the immersion time, the higher the value of R p in case of both uncoated samples (Fig. 2a) and samples coated with TiO2 annealed at 800 °C (Fig. 2c). In case of samples with titania coating annealed at 400 °C (Fig. 2b), the R p values are relatively stable during the immersion time.

Collected values of polarization resistance were used for determination one of the most important corrosion parameters—corrosion rate. The values of corrosion rate CR were calculated from the Eq. (1) according to procedure described by ASTM Standard G 102–89 [18], which assumes that at E cor potential, only uniform type of corrosion is occurring:

where CR is the corrosion rate (mm year−1), K 1 = 3.27 103 mm g (μA cm year)−1, i cor is the corrosion current density (μA cm−2) calculated on the basis of linear polarization characteristics, ρ is the density of investigated alloy which is 7.90 g cm−3, and EW is the equivalent weight which for M30NW alloy equals to 19.18 in the experimental set used in this study.

To calculate the CR value, it was assumed that at corrosion potential, only the substrate, M30NW alloy, corrodes. No other corrosion processes associated with the formed and annealed TiO2 coatings were taken into account in this calculation. According to the ASTM standard [18], only elements above one mass percent in the alloy were included in EW calculation.

Table 1 presents the values of corrosion rate at 0 and 7th day of immersion. In case of uncoated samples and samples coated with TiO2 annealed at 800 °C, a decrease in corrosion rate can be observed in all solutions while immersion time increases, but this behavior is more pronounced in the protein-containing solutions. The values of corrosion rate of samples coated with TiO2 annealed at 400 °C are very low and they are independent on the presence of serum proteins.

Impedance spectra for all investigated samples recorded at the beginning and the end of immersion tests are presented in Fig. 3. Impedance spectra for uncoated alloy (Fig. 3a) show an increase of impedance during 7 days of immersion. This increase seems to be greater in case of protein-containing solutions. In case of alloy samples with TiO2 coating annealed at 400 °C (Fig. 3b), their impedance do not depend on immersion time and solution chemistry—the impedance spectra are almost identical at day 0 and at day 7 for all solutions. The samples with titania coating heat-treated at 800 °C (Fig. 3c) have different impedance characteristics—the Bode plots show three time constants in all corrosion solutions.

All obtained impedance data were fitted by the equivalent electrical circuits using Zview2 software. The quality of the fitting was judged by the χ2 value that was lower than 4 × 10−4. Instead of pure capacitors, constant phase elements (CPE) were introduced in the fitting procedure to obtain good agreement between the experimental and simulated data. The impedance of CPE is defined by the Eq. (2):

where Q (Ω−1 sn cm−2) is the combination of properties related to both the surface and the electroactive species independent on frequency, n is related to a slope of the logZ versus logf (Bode plot), and ω is the angular frequency.

In the ideal case when the exponential factor n = 1, the CPE acts as a pure capacitor. In practice, n deviates from 1 so the fitting results are given as both the parameter Q and the exponent “n.” It should be noted that for simplicity, Q is often considered as a capacitance [19].

For uncoated alloy and alloy with TiO2 coating annealed at 400 °C, the best data-fitting equivalent circuit (Fig. 4a) is characterized by parallel combination term (R, CPE) in series with the resistor R s. The values of the parameters obtained with the fitting procedure versus immersion time are reported in Table 2. Resistor R s determines uncompensated electrolyte resistance and it is about 40 Ω cm2 for all types of corrosion medium. Constant phase element CPE dl is equivalent to double layer capacity (since the factor n has a value in the range of 0.92–0.96, CPE can be said to behave similarly to a pure capacitor). Resistor R ct reaches a value in the order of 107 Ω cm2 and it is related to charge transfer resistance of corrosion processes. It is in agreement with R p value obtained from linear polarization characteristics.

In case of alloy samples coated by TiO2 layer annealed at 800 °C, the simple equivalent circuit (Fig. 4a) was inadequate; therefore, a more complex circuit (Fig. 4b) has been used. This circuit contains three parallel combination terms (R, CPE) since three time constants are present on the Bode plots. The differences result from entirely different surface properties of TiO2 coating depending on applied annealing temperature. In previous paper [7], we have reported that TiO2 sol–gel coating heat-treated at 800 °C is a porous, diffusive layer which contains new TiO2-based phases instead of pure TiO2 crystal structures. Therefore, in addition to solution resistance R s, double layer capacitance CPE dl, and charge transfer resistance R ct, the electrical equivalent circuit contains elements associated with pores and coating properties. The values of the parameters obtained with the fitting procedure versus immersion time are reported in Table 2. Constant phase element CPE pore and resistor R pore describe porosity of coating layer. These elements are related with time constant visible in high frequency range in Bode plots (Fig. 3c). Low R pore values (in the order of hundreds of Ω cm2) are to be expected since they correspond to the low electrolyte resistance inside the pores [19]. Constant phase element CPE coat and resistor R coat characterize surface properties of TiO2 layer. These elements are related with time constant visible in medium frequency range in Bode plots (Fig. 3c). The low n values obtained for CPE elements are typical for rough surface of the coating [20]. The rough surface is a result of dislocations, grain boundaries, and precipitations. CPE element is a practical way to describe the above interfacial characteristics [21].

Surface analysis after 7 days of immersion

At the end of the corrosion tests, the alloy samples were observed by optical microscope in order to analyze the changes in surface morphology. Optical microscope results did not reveal any local corrosion damage on the investigated samples. This fact indicate that during weekly corrosion tests, only general corrosion occurred. Additionally, for all samples immersed in solutions with proteins, some sediment on the surface was observed. The representative microscope images obtained for alloy samples with TiO2 coating annealed at 400 °C are presented in Fig. 5.

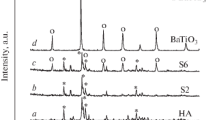

This sediment may be related to presence of proteins adsorbed on the sample surfaces. In order to clarify its origin, the surface analysis was performed using XPS method. X-ray spectra in a wide range of binding energy were collected for both uncoated samples and samples with titania coating after 7 days of immersion in corrosion medium. Figure 6 presents a representative XPS survey spectra taking each type of samples after immersion in BSA solution for example. Surface film composition of all alloy samples after 7 days exposure to the corrosion medium is presented in Table 3. The general features of the spectra are peaks of carbon (C1s) and oxygen (O1s) which are observed on all the samples. Carbon concentration is ranged from 16 to 57 at.%. The XPS results exhibit the presence of main alloying components (Fe, Cr, Ni, Mn, Mo) in case of uncoated samples. Some of the alloying elements (Fe, Cr, Mn) are also visible on the surface of alloy samples coated with TiO2 layer annealed at 800 °C. In case of samples modified with TiO2 coating annealed at 400 °C, only signals of Fe and Cr coming from the substrate were stated. Additionally, signals of Ti and O coming from the titania coating were stated for both modified alloy samples. The XPS results show also that nitrogen (N1s) is present on all the samples. In case of samples exposed to solution without addition of protein, the atomic concentration of N is lower than 3 %. Much higher percentage of nitrogen is observed for samples immersed in protein-containing solutions. Approximately two times as much nitrogen was found on the surface of samples after contact with a solution containing γ-globulins than for samples immersed in albumin-containing solution. It should be noticed that the higher the amount of nitrogen, the less the amount of iron and chromium found on the alloy’s surface. An example of high-resolution spectra for N1s region which were used for detection of nitrogen percentages is presented in Fig. 7. Percentages of N atoms on surfaces after immersion in protein-containing solutions obtained by XPS analysis are summarized in Fig. 8.

Discussion

The results of corrosion tests presented in this study confirm that titania sol–gel coatings improve the corrosion resistance of M30NW biomedical alloy in 0.9 % NaCl solution. This improvement is dependent on the annealing temperature used. In our previous paper [7], we characterized the structure and character of interactions between substrate and deposited TiO2 sol–gel layers in relation to different annealing temperatures. We have stated that the coating annealed at temperature of 400 °C has an adhesive character and it has an amorphous structure with anatase crystallites. Whereas, TiO2 coating annealed at 800 °C has a diffuse character and contains new phases (NiTiO3 and Fe2TiO4) due to the interaction with steel substrate. Such differences in crystalline structure and character of substrate layer interaction imply differences in anticorrosion properties of titania coatings [7].

The results presented in this paper indicate that M30NW alloy both uncoated and modified with titania coatings has a very good corrosion resistance also during weekly exposition to corrosion medium with and without addition of serum proteins. The results of corrosion potential versus immersion time show a very weak interaction of proteins with surfaces modified by titania coatings, while in case of unmodified alloy, it is significant. The polarization resistance of uncoated samples and samples with titania coating obtained at 800 °C increases, and corrosion rate decreases during exposure to all corrosion solutions. The samples with titania coating obtained at 400 °C show very good corrosion resistance in all solutions—polarization resistance is in the range of 30–50 MΩ cm2 not depending on the presence of proteins and immersion time. Results of impedance measurements did not show any significant effect of proteins onto weekly corrosion of investigated biomedical steel. However, they indicate the differences in phase boundary electrolyte solution/TiO2-coated alloy depending on annealing temperature.

The XPS results allowed to determine the changes in surface composition of analyzed samples after 7 days of exposure to the protein-containing solutions. Proteins (albumins and γ-globulins) as chemical molecules have carboxyl (−COOH), amino (−NH2), and amido (−CONH-) groups. Hence, the major elements of the proteins are oxygen, carbon, and nitrogen. Carbon contamination is unavoidable in XPS studies; therefore, carbon signal cannot acts as a protein indicator. We assumed that the nitrogen signal is indicative of the presence of a protein. This assumption is in accordance with Dupont-Gillain et al., Feng et al., and Karimi et al. [9, 22, 23]. The results of surface analysis obtained by X-ray photoelectron spectroscopy clearly showed that contact of samples with protein-containing solutions per 7 days causes increase in percentages of N atoms on their surfaces. This fact confirms the presence of proteins on the alloy surface after 7 days of immersion in protein-containing solutions.

Some researchers have suggested that the electrostatic attraction between proteins and biomaterials is important [13, 24, 25]. The isoelectric point of BSA is in the range of 4.2–5.5 [13, 22, 26], and in case of γ-globulins, it is in the range of 6.5–7.0 [26] so both proteins are negatively charged in the solution at pH 7.4. The pH zero point of charge for Fe-oxide/hydroxide, which is the outer oxide layer on a stainless steel surface, is 8.5 [13]. Hence, at pH 7.4, the stainless steel surface at the E cor potential (Fig. 1a) has a net positive charge. This will facilitate the involvement of negatively charged carboxylate groups of the proteins as anchoring sites in the contact region between the proteins and the stainless steel surface [13]. However, for the interaction between proteins used in this study and TiO2 coating, the electrostatic effects should not be dominant factors since bovine serum albumin, γ-globulins, and TiO2 (isoelectric point in the range of 4.7–6.2 [20]) are negatively charged in the solution at pH 7.4. Therefore, in our experimental set, a chemical adsorption of both proteins onto alloy surface modified with titania coatings is more probable rather than a physisorption. The chemical adsorption of BSA onto titanium surfaces through the interaction of C and O groups with the surface hydroxyl groups was reported by Feng et al. [22].

Conclusions

The corrosion of ISO 5832–9 alloy (trade name M30NW) which surface was modified by titania sol–gel coatings was investigated in this study using 0.9 % NaCl solutions with addition of two serum proteins (albumin and γ-globulins). The experimental results have led us to the following conclusions:

-

M30NW alloy both uncoated and modified with titania coatings has a very good corrosion resistance during weekly exposition to corrosion medium. The best corrosion resistance in 0.9 % NaCl solution is shown by alloy samples modified by titania coating annealed at 400 °C.

-

The serum proteins used in this study have no significant effect onto corrosion of investigated biomedical steel.

-

The results of surface analysis by X-ray photoelectron spectroscopy clearly showed that contact of samples with protein-containing solutions per 7 days causes increase in percentages of N atoms on their surfaces. This fact confirms the presence of proteins on the alloy surface after 7 days of immersion in protein-containing solutions.

-

In case of uncoated alloy, a physisorption probably occurs, while in case of alloy modified with titania coatings, a chemical adsorption is more probable.

References

Ramakrishna S, Ramalingam M, Kumar TSS, Soboyejo WO (2010) Biomaterials: a nano approach. CRC Press

ISO 5832–9 (2007) Implants for surgery—metallic materials—Part 9: Wrought high nitrogen stainless steel

Jones FH (2001) Teeth and bones: applications of surface science to dental materials and related biomaterials. Surf Sci Rep 42:75–205

Velten D, Biehl V, Aubertin F, Valeske B, Possart W, Breme J (2002) Preparation of TiO2 layers on cp-Ti and Ti6Al4V by thermal and anodic oxidation and by sol–gel coating techniques and their characterization. J Biomed Mater Res 59:18–28

Galliano P, De Damborenea JJ, Pascual MJ, Duran A (1998) Sol–gel coatings on 316 L steel for clinical applications. J Sol–gel. Sci Technol 13:723–727

Wang D, Bierwagen GP (2009) Sol–gel coatings on metals for corrosion protection. Prog Org Coat 64:327–338

Burnat B, Dercz G, Blaszczyk T (2014) Structural analysis and corrosion studies on an ISO 5832–9 biomedical alloy with TiO2 sol–gel layers. J Mater Sci Mater Med 25:623–634

Collier TO, Jenney CR, DeFife KM, Anderson JM (1997) Protein adsorption on chemically modified surfaces. Biomed Sci Instrum 33:178–183

Dupont-Gillain CC, Mc Evoy KM, Henry M, Bertrand P (2010) Surface spectroscopy of adsorbed proteins: input of data treatment by principal component analysis. J Mater Sci Mater Med 21:955–961

Afonso MLCA, Villamil Jaimes RFV, Areas EPG, Capri MR, Oliveira E, Agostinho SML (2008) The influence of albumin on the anodic dissolution of chromium present in UNS S31254 stainless steel in chloride environment. Colloids Surf A 317:760–763

Merrit K, Brown S (1988) Effect of proteins and pH on fretting corrosion and metal ion release. J Biomed Mater Res 22:111–120

Huang H (2003) Effect of fluoride and albumin concentration on the corrosion behavior of Ti–6Al–4 V alloy. Biomaterials 24:275–282

Omanovic S, Roscoe S (1999) Electrochemical studies of the adsorption behavior of bovine serum albumin on stainless steel. Langmuir 15:8315–8321

Williams RL, Brown SA, Merritt K (1988) Electrochemical studies on the influence of proteins on the corrosion of implant alloys. Biomaterials 9:181–186

Karimi S, Nickchi T, Alfantazi A (2011) Effects of bovine serum albumin on the corrosion behavior of AISI 316 L, Co-28Cr-6Mo, and Ti-6Al-4 V alloys in phosphate buffered saline solutions. Corros Sci 53:3262–3272

Hedberg YS, Killian MS, Blomberg E, Virtanen S, Schmuki P, Odnevall Wallinder I (2012) Interaction of bovine serum albumin and lysozyme with stainless steel studied by time-of-flight secondary ion mass spectrometry and X‑ray photoelectron spectroscopy. Langmuir 28:16306–16317

Sun D, Wharton JA, Wood RJK (2008) Effects of proteins and pH on tribocorrosion performance of cast CoCrMo—a combined electrochemical and tribological study. Tribology 2:150–160

ASTM G 102–89 (2004) Standard practice for calculation of corrosion rates and related information from electrochemical measurements

Rondelli G, Torricelli P, Fini M, Giardino R (2005) In vitro corrosion study by EIS of a nickel free stainless steel for orthopaedic applications. Biomaterials 26:739–744

Ahn SH, Choi YS, Kim JG, Han JG (2002) A study on corrosion resistance characteristics of PVD Cr-N coated steels by electrochemical method. Surf Coat Technol 150:319–326

Liu C, Bi Q, Leyland A, Matthews A (2003) An electrochemical impedance spectroscopy study of the corrosion behaviour of PVD coated steels in 0.5 N NaCl aqueous solution: Part I. Establishment of equivalent circuits for EIS data modelling. Corros Sci 45:1243–1256

Feng B, Weng J, Yang BC, Chen JY, Zhao JZ, He L, Qi SK, Zhang XD (2003) Surface characterization of titanium and adsorption of bovine serum albumin. Mater Charact 49:129–137

Karimi S, Nickchi T, Alfantazi AM (2012) Long-term corrosion investigation of AISI 316 L, Co–28Cr–6Mo, and Ti–6Al–4 V alloys in simulated body solutions. Appl Surf Sci 258:6087–6096

Ellingsen JE (1991) A study on the mechanism of protein adsorption to TiO2. Biomaterials 12:593–596

Kopac T, Bozgeyik K (2010) Effect of surface area enhancement on the adsorption of bovine serum albumin onto titanium dioxide. Colloids Surf B 76:265–271

Sakurai K, Nakajima K, Takahashi T (1993) Adsorption of bovine serum albumin and γ-globulin on chitosan membrane. http://repo.flib.ufukui.ac.jp/dspace/bitstream/10098/4195/1/AN00215401-041-02-010.pdf. Accessed 10 September 2013

Acknowledgments

The authors gratefully acknowledge Dr. Janusz Sobczak and Dr. hab. Wojciech Lisowski from Institute of Physical Chemistry of PAS for XPS surface analyses. The investigations were supported by the National Science Centre project No. N N507 501339.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Burnat, B., Blaszczyk, T. & Leniart, A. Effects of serum proteins on corrosion behavior of ISO 5832–9 alloy modified by titania coatings. J Solid State Electrochem 18, 3111–3119 (2014). https://doi.org/10.1007/s10008-014-2634-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2634-5