Abstract

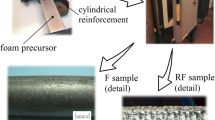

There is a significantly growing need for energy absorbing systems comprised of lightweight, low-cost and recyclable materials which can achieve high-capacity energy absorption with an ideal (near-constant) force response—these objectives are often only partially accomplished due to the many inherent engineering challenges. This study characterized a novel compounded energy dissipation system which could simultaneously exploit axial cutting, radial clamping, foam compression and extrusion/foam interactions or any desired combination of these mechanisms, for high-capacity energy absorption. Experiments were conducted for AA6061-T6 extrusions, with H-series PVC foam cores with relative densities between 0.09 and 0.18, subjected to 6-bladed cutting and 10-bladed cutting/clamping. The extrusion/foam interaction effects were newly observed, characterized by localized in-plane expansion of the foam cores and exhibited a transition from near-constant reaction forces to progressive quasi-linear increases. Introducing maximum density, H250 PVC foam consequently increased the average mean force and effectiveness (EAEF) by 33.8% with a marginal 12.3% CFE reduction. Numerical modeling was completed with a combined Lagrangian/Eulerian approach capable of predicting the experimental findings with an average validation metric of 0.92. An extended analytical modeling procedure was also developed with the ability to predict the entire force/displacement response with an average validation metric of 0.95. This modeling procedure was utilized in a parametric investigation which revealed a broad 10–200 kN steady-state load bearing capacity (86.0% average CFE) for the proposed, component-scale system since each deformation mechanism could theoretically be included or omitted as desired.

Similar content being viewed by others

Abbreviations

- B :

-

Half width of wedge/blade shoulder

- C :

-

Cumulative error

- CFE:

-

Compressive force efficiency

- D ss :

-

Distance between the plastic deformation tip and blade shoulder

- d o :

-

Outer diameter of extrusion

- d P :

-

Distance from extrusion axis to petalled sidewall centroid

- \(\dot{E}\) :

-

Energy dissipation rate

- E :

-

Elastic modulus

- F :

-

Total axial cutting (or cutting/clamping) resistance force

- F cfc :

-

Compounded cutting/foam crushing force

- F compact :

-

Foam compaction force

- F E :

-

Elastic indentation force

- F f,foam :

-

Force associated with extrusion/foam interface friction

- F m :

-

Mean reaction force

- F N,foam :

-

Normal (in-plane) foam core compressive force

- F p :

-

Axial cutting resistance force due to plastic deformation

- F ss :

-

Steady-state reaction force

- F T :

-

Total compounded reaction force

- F W :

-

Wedge penetration force

- G :

-

Shear modulus

- h c :

-

Cutting blade height

- h d :

-

Axial position of petal divergence

- h f :

-

Unconstrained/free axial position of petalled sidewall

- h FC :

-

Foam core height

- \({I}_{{G}_{\mathrm{P}}}\) :

-

Second moment of area about the centroid of a petalled sidewall

- K :

-

Bulk modulus

- K h :

-

Foam hardening coefficient

- K p :

-

Foam plateau strength coefficient

- K θ :

-

Extrusion membrane stretching coefficient

- L :

-

Extrusion length

- l b :

-

Blade wedge height

- l f :

-

Unconstrained/free radial position of petalled sidewall

- l r :

-

Distance between the outer edge of the extrusion and inner edge of the cutter

- l T :

-

Blade tip offset distance

- M :

-

Foam hardening exponent

- N :

-

Foam densification exponent

- n b :

-

Number of cutting blades

- R a :

-

Axial bend radius for cut petalled sidewalls

- r f :

-

Radius of in-plane foam expansion

- r i :

-

Inner radius of an extrusion

- r m :

-

Mean radius of an extrusion

- r o :

-

Outer radius of an extrusion

- R r :

-

Rolling radius of curled material at the wedge/blade interface

- r ring :

-

Radius of the exterior ring of the cutter

- SEA:

-

Specific energy absorption

- T :

-

Extrusion wall thickness

- T :

-

Blade tip width

- TEA:

-

Total energy absorption

- V M :

-

Validation metric

- X P :

-

Integrated petalled sidewall moment arm

- Δr ss :

-

Steady-state radial increment

- Δr t :

-

Transient radial increment

- Δv :

-

Axial displacement of the petalled sidewall

- Δ:

-

Crosshead position (displacement)

- δ P :

-

Onset displacement for hybrid cutting/clamping

- δ T :

-

Total axial displacement

- ε f :

-

Fracture strain

- ε V :

-

Volumetric strain

- ε Y :

-

Strain at onset of yielding

- Θ:

-

Wedge/blade semi angle

- μ B :

-

Coefficient of friction at the cutting (blade) interface

- μ f :

-

Coefficient of friction at the extrusion/foam interface

- ρ f :

-

Structural density of foam

- ρ s :

-

Structural density of solid, constitutive foam material

- σ o :

-

Flow stress

- σ p :

-

Plateau stress

- Ν :

-

Poisson’s ratio

- Ψ :

-

Energy absorbing effectiveness factor

- AA:

-

Aluminum alloy

- AC:

-

Axial cutting

- DM:

-

Deformation mode

- EAEF:

-

Energy absorbing effectiveness factor

- EM:

-

Extruded material

- FC:

-

Foam core

- HCC:

-

Hybrid cutting/clamping

- IPD:

-

In-plane direction

- OD:

-

Outer diameter

- PVC:

-

Polyvinyl chloride

- RD:

-

Rise direction

References

Pugsley, A.: The large-scale crumpling of thin cylindrical columns. Q. J. Mech. Appl. Math. 13(1), 1–9 (1960)

Wierzbicki, T., Bhatt, S.: A moving hinge solution for axisymmetric crushing of tubes. Int. J. Mech. Sci. 28(3), 135–151 (1986)

Abramowicz, W., Jones, N.: Dynamic axial crushing of circular tubes. Int. J. Impact Eng. 2(3), 263–281 (1984)

Alghamdi, A.: Collapsible impact energy absorbers: an overview. Thin Walled Struct. 39(2), 189–213 (2001)

Baroutaji, A., Sajjia, M., Olabi, A.: On the crashworthiness performance of thin-walled energy absorbers: recent advances and future developments. Thin Walled Struct. 118, 137–163 (2017)

Patel, V., Tiwari, G., Dumpala, R.: Review of the crushing response of collapsible tubular structures. Front. Mech. Eng. 15, 438–474 (2020)

Guan, W., Yu, Y., Gao, G.: Crashworthiness performance and multiobjective optimization of a combined splitting circular tube energy absorber under eccentric impact for subway vehicles. Int. J. Impact Eng. 158, 104006 (2021)

Azandariani, M., Rousta, A., Usefvand, E., Abdolmaleki, H., Azandariani, A.: Improved seismic behavior and performance of energy-absorbing systems constructed with steel rings. Structures 29, 534–548 (2021)

Jones, N.: Several phenomena in structural impact and structural crashworthiness. Eur. J. Mech. A. Solids 22(5), 693–707 (2003)

Wang, Y., Zhai, X., Liu, S., Lu, J., Zhou, H.: Energy absorption performance of a new circular–triangular nested tube and its application as sacrificial cladding. Thin Walled Struct. 157, 106992 (2021)

Kalubadanage, D., Remennikov, A., Ngo, T., Qi, C.: Close-in blast resistance of large-scale auxetic re-entrant honeycomb sandwich panels. J. Sandw. Struct. Mater. 23(8), 4016–4053 (2021)

Blanc, L., Schunck, T., Eckenfels, D.: Sacrificial cladding with brittle materials for blast protection. Materials 14(14), 3980 (2021)

Njim, E., Al-Waily, M., Bakhy, S.: A review of the recent research on the experimental tests of functionally graded sandwich panels. J. Mech. Eng. Res. Dev. 44(3), 420–441 (2021)

Leng, B., Ruan, D., Tse, K.: Recent bicycle helmet designs and directions for future research: a comprehensive review from material and structural mechanics aspects. Int. J. Impact Eng. 168, 104317 (2022)

Op’t Eynde, J., Yu, A., Eckersley, C., Bass, C.: Primary blast wave protection in combat helmet design: a historical comparison between present day and World War I. PLoS ONE 15(2), e0228802 (2020)

Stopforth, R., Adali, S.: Experimental study of bullet-proofing capabilities of Kevlar, of different weights and number of layers, with 9 mm projectiles. Def. Technol. 15(2), 186–192 (2019)

Qiu, N., Gao, Y., Fang, J., Feng, Z., Sun, G., Li, Q.: Theoretical prediction and optimization of multi-cell hexagonal tubes under axial crushing. Thin-Walled Struct. 102, 111–121 (2016)

Zhang, X., Zhang, H., Yang, C., Leng, K.: Static and dynamic axial crushing of self-locking multi-cell tubes. Int. J. Impact Eng. 127, 17–30 (2019)

Ahmadi, A., Asgari, M.: Efficient crushable corrugated conical tubes for energy absorption considering axial and oblique loading. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 233(11), 3917–3935 (2019)

Ha, N., Lu, G.: Thin-walled corrugated structures: a review of crashworthiness designs and energy absorption characteristics. Thin Walled Struct. 157, 106995 (2020)

Sadighi, A., Mahbod, M., Asgari, M.: Bi-tubular corrugated composite conical-cylindrical tube for energy absorption in axial and oblique loading: analysis and optimization. J. Compos. Mater. 54(18), 2399–2432 (2020)

Keskin, S., Acar, E., Güler, M., Altin, M.: Exploring various options for improving crashworthiness performance of rail vehicle crash absorbers with diaphragms. Struct. Multidiscip. Optim. 64, 3193–3208 (2021)

Xu, F., Zhang, X., Zhang, H.: A review on functionally graded structures and materials for energy absorption. Eng. Struct. 171, 309–325 (2018)

Ajdari, A., Jahromi, B., Papadopoulos, J., Nayeb-Hashemi, H., Vaziri, A.: Hierarchical honeycombs with tailorable properties. Int. J. Solids Struct. 49, 1413–1419 (2021)

Yin, H., Fang, H., Xiao, Y., Wen, G., Qing, Q.: Multi-objective robust optimization of foam-filled tapered multi-cell thin-walled structures. Struct. Multidiscip. Optim. 52, 1051–1067 (2015)

Gupta, N., Abbas, H.: Axisymmetric crushing of thin frusta. Thin-Walled Struct. 36(3), 169–179 (2000)

Shiravand, A., Asgari, M.: Hybrid metal-composite conical tubes for energy absorption; theoretical development and numerical simulation. Thin Walled Struct. 145, 106442 (2019)

Xiang, J., Du, Y., Mousanezhad, D., Eydani Asl, M., Norato, J., Vaziri, A.: Sandwich structures with prismatic and foam cores: a review. Adv. Eng. Mater. 21, 1800036 (2018)

Lu, N.H.G.: A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. B Eng. 181, 107496 (2020)

Zhang, W., Yu, T., Xu, J.: Uncover the underlying mechanisms of topology and structural hierarchy in energy absorption performances of bamboo-inspired tubular honeycomb. Extreme Mech. Lett. 52, 101640 (2022)

Gao, Z., Zhang, H., Zhao, J., Ruan, D.: The axial crushing performance of bio-inspired hierarchical multi-cell hexagonal tubes. Int. J. Mech. Sci. 239, 107880 (2022)

Ha, N., Pham, T., Chen, W., Hao, H., Lu, G.: Crashworthiness analysis of bio-inspired fractal tree-like multi-cell circular tubes under axial loading. Thin-Walled Struct. 169, 108315 (2021)

Le, D., Novak, N., Arjunan, A., Baroutaji, A., Estrada, Q., Tran, T., Le, H.: Crashworthiness of bio-inspired multi-stage nested multi-cell structures with foam core. Thin-Walled Struct. 182(Part B), 110245 (2023)

Sun, G., Chen, D., Zhu, G., Li, Q.: Lightweight hybrid materials and structures for energy absorption: a state-of-the-art review and outlook. Thin Walled Struct. 172, 108760 (2022)

Magliaro, J., Altenhof, W., Alpas, A.: A review of advanced materials, structures and deformation modes for adaptive energy dissipation and structural crashworthiness. Thin Walled Struct. 180, 109808 (2022)

Dubey, R., Jayaganthan, R., Ruan, D., Gupta, N., Jones, N., Velmurugan, R.: Energy absorption and dynamic behaviour of 6xxx series aluminium alloys: a review. Int. J. Impact Eng. 104397 (2022)

Issac, C., Ezekwem, C.: A review of the crashworthiness performance of energy absorbing composite structure within the context of materials, manufacturing and maintenance for sustainability. Compos. Struct. 257, 113081 (2021)

Reid, S., Reddy, T., Gray, M.: Static and dynamic axial crushing of foam-filled sheet metal tubes. Int. J. Mech. Sci. 28(5), 295–322 (1986)

Santosa, S., Wierzbicki, T., Hanssen, A., Langseth, M.: Experimental and numerical studies of foam-filled sections. Int. J. Impact Eng. 43(1), 153–176 (2001)

Hanssen, A., Langseth, M., Hopperstadd, O.: Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler. Int. J. Impact Eng. 24, 475–507 (2000)

Børvik, T., Hopperstad, O., Reyes, A., Langseth, M., Solomos, G., Dyngeland,: Empty and foam-filled circular aluminium tubes subjected to axial and oblique quasi-static loading. Int. J. Crashworthiness 8(5), 481–494 (2003)

Goel, M.: Deformation, energy absorption and crushing behavior of single-, double-and multi-wall foam filled square and circular tubes. Thin-Walled Struct. 90, 1–11 (2015)

Altin, M., Güler, M., Mert, S.: The effect of percent foam fill ratio on the energy absorption capacity of axially compressed thin-walled multi-cell square and circular tubes. Int. J. Mech. Sci. 131–132, 368–379 (2017)

Ha, N., Hao, H., Lu, G.: Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing. Int. J. Mech. Sci. 201, 106464 (2021)

Yang, C., Chen, Z., Yao, S., Xu, P., Li, S., Alqahtani, M.: Quasi-static and low-velocity axial crushing of polyurethane foam-filled aluminium/CFRP composite tubes: an experimental study. Compos. Struct. 299, 116083 (2022)

Yao, R., Pang, T., He, S., Li, Q., Zhang, B., Sun, G.: A bio-inspired foam-filled multi-cell structural configuration for energy absorption. Compos. B: Eng. 238, 109801 (2022)

Xiang, X., Zou, S., Ha, N., Lu, G., Kong, I.: Energy absorption of bio-inspired multi-layered graded foam-filled structures under axial crushing. Compos. B: Eng. 198, 108216 (2020)

Sun, G., Li, S., Liu, Q., Li, G., Li, Q.: Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes. Compos. Struct. 152, 969–993 (2016)

Sun, G., Wang, Z., Yu, H., Gong, Z., Li, Q.: Experimental and numerical investigation into the crashworthiness of metal-foam-composite hybrid structures. Compos. Struct. 209, 535–547 (2019)

Gan, N., Feng, Y., Yin, H., Wen, G., Wang, D., Huang, X.: Quasi-static axial crushing experiment study of foam-filled CFRP and aluminum alloy thin-walled structures. Compos. Struct. 157, 303–319 (2016)

Fu, J., Liu, Q., Ma, Y., Zhang, Z.: A comparative study on energy absorption of flat sides and corner elements in CFRP square tube under axial compression. Thin-Walled Struct. 166, 108080 (2021)

Sun, G., Li, G., Hou, S., Li, W., Li, Q.: Crashworthiness design for functionally graded foam-filled thin-walled structures. Mater. Sci. Eng. A 527(78), 1911–1919 (2010)

Sun, G., Xu, F., Li, G., Li, Q.: Crashing analysis and multiobjective optimization for thin-walled structures with functionally graded thickness. Int. J. Impact Eng. 64, 62–74 (2014)

Salehi, M., Mirbagheri, S., Jafari Ramiani, A.: Deformation behavior and crashworthiness of functionally graded metallic foam-filled tubes under drop-weight impact testing. Metall. Mater. Trans. A 51, 5120–5138 (2020)

Najibi, A., Ghazifard, P., Alizadeh, P.: Numerical crashworthiness analysis of a novel functionally graded foam-filled tube. J. Sandw. Struct. Mater. 23(5), 1635–1661 (2021)

Mohsenizadeh, S., Ahmad, Z.: Auxeticity effect on crushing characteristics of auxetic foam-filled square tubes under axial loading. Thin-Walled Struct. 145, 106378 (2019)

Mohsenizadeh, S., Ahmad, Z., Alias, A.: Numerical prediction on the crashworthiness of circular and square thin-walled tubes with polymeric auxetic foam core. J. Mater. Eng. Perform. 29, 3092–3106 (2020)

Gao, Q., Yin, G., Wang, C., Liao, W.: Crushing and theoretical analysis of multi-cell tube filled with auxetic structure under axial impact loading. Mech. Adv. Mater. Struct. 1–13 (2022)

Gao, Q., Liao, W.: Energy absorption of thin walled tube filled with gradient auxetic structures-theory and simulation. Int. J. Mech. Sci. 201, 106475 (2021)

Gao, Q., Liao, W., Huang, C.: Theoretical predictions of dynamic responses of cylindrical sandwich filled with auxetic structures under impact loading. Aerosp. Sci. Technol. 107, 106270 (2020)

Huang, X., Lu, G., Yu, T.: On the axial splitting and curling of circular metal tubes. Int. J. Mech. Sci. 44(11), 2369–2391 (2002)

Jin, S., Altenhof, W., Li, Z.: A parametric study on extrusion geometry and blade quantity during axial cutting deformation of circular AA6061-T6 extrusions under impact and quasi-static loading. Int. J. Impact Eng. 49, 165–178 (2012)

Jin, S., Majumder, A., Altenhof, W., Green, D.: Axial cutting of AA6061-T6 circular extrusions under impact using single- and dual-cutter configurations. Int. J. Impact Eng. 37(6), 735–753 (2010)

Wang, J., Lu, Z., Zhong, M., Wang, T., Sun, C., Li, H.: Coupled thermal–structural analysis and multi-objective optimization of a cutting-type energy-absorbing structure for subway vehicles. Thin-Walled Struct. 141, 360–373 (2019)

Peng, Y., Zhou, J., Hou, L., Wang, K., Chen, C., Zhang, H.: A hybrid MCDM-based optimization method for cutting-type energy-absorbing structures of subway vehicles. Struct. Multidiscip. Optim. 65, 228 (2022)

Luo, M., Yang, J., Liu, H., Lu, G., Yu, J.: Energy absorption of expansion tubes using a conical-cylindrical die: theoretical model. Int. J. Mech. Sci. 157–158, 207–220 (2019)

Guan, W., Gao, G., Yu, Y., Zhuo, T.: Crashworthiness analysis and multi-objective optimization of expanding circular tube energy absorbers with cylindrical anti-clamber under eccentric loading for subway vehicles. Struct. Multidiscip. Optim. 61, 1711–1729 (2020)

Moreno, C., Winnett, J., Williams, T.: On the effect of anisotropy on the performance and simulation of shrinking tubes used as energy absorbers for railway vehicles. Thin-Walled Struct. 161, 107513 (2021)

Magliaro, J., Altenhof, W.: Mechanical performance and crashworthiness of plates and extrusions subjected to cutting: an overview. Thin-Walled Struct. 148, 106612 (2020)

Simonsen, B., Wierzbicki, T.: Plasticity, fracture and friction in steady-state plate cutting. Int. J. Impact Eng. 21(5), 387–411 (1998)

Lu, G., Calladine, C.: On the cutting of a plate by a wedge. Int. J. Mech. Sci. 32(4), 293–313 (1990)

Moreno, C., Williams, T., Beaumont, R., Hughes, D., Dashwood, R.: Testing, simulation and evaluation of a novel hybrid energy absorber. Int. J. Impact Eng. 93, 11–27 (2016)

Moreno, C., Beaumont, R., Hughes, D., Williams, T., Dashwood, R.: Quasi-static and dynamic testing of splitting, expansion and expansion-splitting hybrid tubes under oblique loading. Int. J. Impact Eng. 100, 117–130 (2017)

Magliaro, J., Shakib, A., Gudisey, A., Altenhof, W.: Evolution of energy dissipation mechanisms over a comprehensive range of cutting modes and enhanced capabilities via hybrid cutting/clamping in AA6061 extrusions. Thin-Walled Struct. 159, 107238 (2021)

Magliaro, J., Altenhof, W., Gudisey, A., Shakib, A.: Energy dissipation characteristics for AA6061 extrusions subjected to hybrid cutting/clamping at impact velocities up to 32 m/s. Int. J. Mech. Sci. 208, 106678 (2021)

Atkins, A.: On the number of cracks in the axial splitting of ductile metal tubes. Int. J. Mech. Sci. 29(2), 115–121 (1987)

Rezaei, B., Niknejad, A., Assaee, H., Liaghat, G.: Axial splitting of empty and foam-filled circular composite tubes—an experimental study. Arch. Civ. Mech. Eng. 15, 650–662 (2015)

Zhang, J., Guo, H., Du, J., Yuan, H., Zhu, Y., Qin, Q.: Splitting and curling collapse of metal foam core square sandwich metal tubes: experimental and theoretical investigations. Thin-Walled Struct. 169, 108346 (2021)

Zhang, J., Ye, Y., Li, J., Zhu, Y., Yuan, H., Qin, Q., Zhao, M.: Dynamic collapse of circular metal foam core sandwich tubes in splitting and curling mode. Thin-Walled Struct. 161, 107464 (2021)

Zhang, J., Du, J., Guo, H., Yuan, H., Qin, Q.: Splitting and curling performance of metal foam-filled. Acta Mech. 233, 535–559 (2022)

Zhang, J., Ye, Y., Zhu, Y., Yuan, H., Qin, Q., Wang, T.: On axial splitting and curling behaviour of circular sandwich metal tubes with metal foam core. Int. J. Solids Struct. 202, 111–125 (2020)

Magliaro, J., Altenhof, W.: Analytical predictions of the complete mechanical response of AA6061 energy absorbers subjected to axial cutting. Thin-Walled Struct. 139, 151–168 (2019)

Liu, Y., Rahimidehgolan, F., Altenhof, W.: Anisotropic compressive behavior of rigid PVC foam at strain rates up to 200 s−1. Polym. Test. 91, 106836 (2020)

Avalle, M., Belingardi, G., Ibba, A.: Mechanical models of cellular solids: Parameters identification from experimental tests. Int. J. Impact Eng. 34, 3–27 (2007)

Cronin, D., Ouellet, S.: Low density polyethylene, expanded polystyrene and expanded polypropylene: strain rate and size effects on mechanical properties. Polym. Test. 53, 40–50 (2016)

Li, J., Gao, G., Dong, H., Xie, S., Guan, W.: Study on the energy absorption of the expanding-splitting circular tube by experimental investigations and numerical simulations. Thin-Walled Struct. 103, 105–114 (2016)

Shakib, A., Magliaro, J., Altenhof, W.: Maximum energy absorbing capacity and structural stability for energy dissipation devices exploiting a hybrid cutting/clamping deformation mode. Thin-Walled Struct. 182(Part B), 110304 (2023)

Boldyrev, I., Shchurov, I., Nikonov, A.: Numerical simulation of the aluminum 6061–T6 cutting and the effect of the constitutive material model and failure criteria on cutting forces’ prediction. Procedia Eng. 150, 866–870 (2016)

Rajaneesh, A., Sridhar, I., Rajendran, S.: Relative performance of metal and polymeric foam sandwich plates. Int. J. Impact Eng. 65, 126–136 (2014)

Atkins, A.: Toughness and cutting: a new way of simultaneously determining ductile fracture toughness and strength. Eng. Fract. Mech. 72, 849–860 (2005)

Jones, N.: Some comments on the energy-absorbing effectiveness factor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 232(8), 1433–1445 (2018)

Oberkampf, W., Trucano, T.: Verification and validation in computational fluid dynamics. Prog. Aerosp. Sci. 39(3), 209–272 (2002)

Magliaro, J., Rahimidehgolan, F., Altenhof, W., Alpas, A.: Superior energy dissipation mechanisms compounded within composite AA6061/H130 foam structures. Int. J. Mech. Sci. 238, 107843 (2023)

Magliaro, J., Altenhof, W., Gudisey, A.: Analytical and experimental investigations of the enhanced mechanical response of cutting deformation compared to progressive folding in AA6061 energy dissipation devices. Int. J. Mech. Sci. 151, 808–827 (2019)

Acknowledgements

The authors would like to acknowledge the financial support of this research from the Natural Sciences and Engineering Research Council (NSERC) of Canada. The authors also sincerely thank Mr. Martin Heiskell and the team at Diab Americas LP for generously supplying the H-series PVC foam material, Mr. Tim Bolger, Mr. Dave Tremblay, Mr. Bruce Durfy and the Engineering Technical Support staff at the University of Windsor for manufacturing the specimens and test fixtures.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The following geometric expressions represent necessary terms for the expressions presented and derived in Sect. 4.3 to obtain the predictions contained in Sect. 5. Only the most essential details were replicated for brevity. A simplified schematic of the axial cutting and radial petal clamping deformation modes is also included in Fig.

32 to provide a convenient visualization of these secondary variables. Readers are encouraged to seek out the following sources [74, 75] for comprehensive discussions on the underlying theory, assumptions and step-by-step derivations.

First and foremost, the plastic deformation force which develops at the cutting interface, Fp, and the corresponding rolling radius, Rr, which minimizes the cutting resistance force in this strain field are defined in Eqs. (41) and (42), respectively.

The following terms represent critical dimensions which develop and are maintained in the steady-state axial cutting field (i.e., at the extrusion/blade interfaces) and are named as follows: the steady-state radial increment, Δrss, axial bend radius, Ra, membrane stretching coefficient, Kθ, and deformed shoulder length, Dss, respectively. These parameters are defined in Eqs. (43) through (46), respectively.

The remaining terms are arise for radial petal clamping and the hybrid cutting/clamping mode, which generally occurs for cutting tools with 8 or more evenly spaced blades and a solid exterior ring [74, 75]. The onset displacement of petal clamping, δP, unconstrained (free) horizontal, hf, and radial (lateral), lf, positions of the petalled sidewall, blade tip offset distance, lT, axial deflection of the petal tip, \({\Delta }_{v}\), second moment of area for a petalled sidewall, \({{I}_{G}}_{P}\), and bending moment arm, XP, are provided in Eqs. (47) through (53), respectively.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Magliaro, J., Rahimidehgolan, F., Mohammadkhani, P. et al. Modular energy absorbing capabilities achieved with compounded deformation mechanisms in composite AA6061-T6/PVC foam structures. Acta Mech 234, 4217–4258 (2023). https://doi.org/10.1007/s00707-023-03607-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03607-1