Abstract

This paper focuses on the effect of loading history on the ratcheting behavior and stress–strain hysteresis loops under uniaxial loading. A nonlinear constitutive model for cyclic elastoplastic behavior of metals is developed in the rate-independent framework of small deformation plasticity theory. The effect of applied loading history on plastic modulus under cyclic loading is analyzed and considered in the model, and a linear function describing the evolution of plastic modulus with the equivalent peak stress and stress amplitude under cyclic loading is introduced into a modified Chaboche kinematic hardening rule, to address yield surface translation under different historical stress levels. Furthermore, a maximum stress memory surface is defined to describe the ratcheting effect under multi-step loading conditions. Compared to experiments and the existing models, the quantitative results demonstrate that this proposed model can well capture the cyclic hardening, ratcheting strain and stress–strain hysteresis loops.

Similar content being viewed by others

References

Kang, G.: Ratchetting: recent progresses in phenomenon observation, constitutive modeling and application. Int. J. Fatigue 30(8), 1448–1472 (2008)

Halama, R., Fusek, M., Poruba, Z.: Influence of mean stress and stress amplitude on uniaxial and biaxial ratcheting of ST52 steel and its prediction by the AbdelKarim–Ohno model. Int. J. Fatigue 91, 313–321 (2016)

Bairstow, L.: The elastic limits of iron and steel under cyclical variations of stress. In: Proceedings of the Royal Society of London Series A, Containing Papers of a Mathematical and Physical Character, 82(557), 483–485 (1909)

Jiang, Y., Zhang, J.: Benchmark experiments and characteristic cyclic plasticity deformation. Int. J. Plast 24(9), 1481–1515 (2008)

Taleb, L., Cailletaud, G.: Cyclic accumulation of the inelastic strain in the 304L SS under stress control at room temperature: ratcheting or creep? Int. J. Plast 27(12), 1936–1958 (2011)

Lee, C.H., Van Do, V.N., Chang, K.H.: Analysis of uniaxial ratcheting behavior and cyclic mean stress relaxation of a duplex stainless steel. Int. J. Plast 62, 17–33 (2014)

Xu, L., Nie, X., Fan, J., et al.: Cyclic hardening and softening behavior of the low yield point steel BLY160: experimental response and constitutive modeling. Int. J. Plast 78, 44–63 (2016)

Xing, R., Yu, D., Shi, S., et al.: Cyclic deformation of 316L stainless steel and constitutive modeling under non-proportional variable loading path. Int. J. Plast 120, 127–146 (2019)

Dutta, K., Ray, K.K.: Ratcheting phenomenon and post-ratcheting tensile behaviour of an aluminum alloy. Mater. Sci. Eng., A 540, 30–37 (2012)

Sreenivasan, S., Mishra, S.K., Dutta, K.: Ratcheting strain and its effect on low cycle fatigue behavior of Al 7075–T6 alloy. Mater. Sci. Eng., A 698, 46–53 (2017)

Nath, A., Barai, S.V., Ray, K.K.: Prediction of asymmetric cyclic-plastic behaviour for cyclically stable non-ferrous materials. Fatigue Fract. Eng. Mater. Struct. 42(12), 2808–2822 (2019)

Paul, S.K., Sivaprasad, S., Dhar, S., et al.: Key issues in cyclic plastic deformation: experimentation. Mech. Mater. 43(11), 705–720 (2011)

Paul, S.K.: A critical review of experimental aspects in ratcheting fatigue: microstructure to specimen to component. J. Market. Res. 8(5), 4894–4914 (2019)

Chaboche, J.L.: A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast 24(10), 1642–1693 (2008)

Abdel-Karim, M.: Modified kinematic hardening rules for simulations of ratchetting. Int. J. Plast 25(8), 1560–1587 (2009)

Bari, S., Hassan, T.: Anatomy of coupled constitutive models for ratcheting simulation. Int. J. Plast 16(3–4), 381–409 (2000)

Bari, S., Hassan, T.: Kinematic hardening rules in uncoupled modeling for multiaxial ratcheting simulation. Int. J. Plast 17(7), 885–905 (2001)

Armstrong, P.J., Frederick, C.O.: A mathematical representation of the multiaxial Bauschinger effect. Berkeley: Central Electricity Generating Board [and] Berkeley Nuclear Laboratories, Research & Development Department (1966)

Chaboche, J.L.: Time-independent constitutive theories for cyclic plasticity. Int. J. Plast 2(2), 149–188 (1986)

Chaboche, J.L.: Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast 5(3), 247–302 (1989)

Ohno, N., Wang, J.D.: Kinematic hardening rules with critical state of dynamic recovery, part I: formulation and basic features for ratchetting behavior. Int. J. Plast 9(3), 375–390 (1993)

Abdel-Karim, M., Ohno, N.: Kinematic hardening model suitable for ratchetting with steady-state. Int. J. Plast 16(3–4), 225–240 (2000)

Kang, G., Gao, Q., Yang, X.: A visco–plastic constitutive model incorporated with cyclic hardening for uniaxial/multiaxial ratcheting of SS304 stainless steel at room temperature. Mech. Mater. 34(9), 521–531 (2002)

Dafalias, Y.F., Kourousis, K.I., Saridis, G.J.: Multiplicative AF kinematic hardening in plasticity. Int. J. Solids Struct. 45(10), 2861–2880 (2008)

Dafalias, Y.F., Feigenbaum, H.P.: Biaxial ratchetting with novel variations of kinematic hardening. Int. J. Plast 27(4), 479–491 (2011)

Kourousis, K.I., Agius, D., Wang, C., et al.: Constitutive modeling of additive manufactured Ti-6Al-4V cyclic elastoplastic behaviour. Technische Mechanik-European J. Eng. Mech. 36(1–2), 57–72 (2016)

Agius, D., Kourousis, K.I., Wallbrink, C.: A modification of the multicomponent Armstrong-Frederick model with multiplier for the enhanced simulation of aerospace aluminium elastoplasticity. Int. J. Mech. Sci. 144, 118–133 (2018)

Agius, D., Wallbrink, C., Kourousis, K.I.: Efficient modelling of the elastoplastic anisotropy of additively manufactured Ti-6Al-4V. Addit. Manuf. 38, 101826 (2021)

Zhang, S.L., Xuan, F.Z.: Interaction of cyclic softening and stress relaxation of 9–12% Cr steel under strain-controlled fatigue-creep condition: experimental and modeling. Int. J. Plast 98, 45–64 (2017)

Xie, X., Jiang, W., Chen, J., Zhang, X., et al.: Cyclic hardening/softening behavior of 316L stainless steel at elevated temperature including strain-rate and strain-range dependence: experimental and damage-coupled constitutive modeling. Int. J. Plast 114, 196–214 (2018)

Xu, L.Y., Fan, J.S., Yang, Y., et al.: Ratcheting assessment of low yield point steel BLY160: experimental analysis and constitutive modelling. Mech. Mater. 148, 103460 (2020)

Bemfica, C., Castro, F.: A cyclic plasticity model for secondary hardening due to strain-induced martensitic transformation. Int. J. Plast 140, 102969 (2021)

Song, K., Wang, K., Zhao, L., et al.: A combined elastic–plastic framework unifying the various cyclic softening/hardening behaviors for heat resistant steels: experiment and modeling. Int. J. Fatigue 158, 106736 (2022)

Mroz, Z.: On the description of anisotropic work hardening. J. Mech. Phys. Solids 15(3), 163–175 (1967)

Mroz, Z.: An attempt to describe the behavior of metals under cyclic loads using a more general work hardening model. Acta Mech. 7(2), 199–212 (1969)

Dafalias, Y.F., Popov, E.P.: Plastic internal variables formalism of cyclic plasticity. J. Appl. Mech. 43(4), 645 (1976)

Jiang, Y., Sehitoglu, H.: Comments on the Mroz multiple surface type plasticity models. Int. J. Solids Struct. 33(7), 1053–1068 (1996)

Montáns, F.J., Caminero, M.A.: On the consistency of nested surfaces models and their kinematic hardening rules. Int. J. Solids Struct. 44(14–15), 5027–5042 (2007)

Wolff, M., Taleb, L.: Consistency for two multi-mechanism models in isothermal plasticity. Int. J. Plast 24(11), 2059–2083 (2008)

Zhu, Y., Kang, G., Kan, Q.: A New Kinematic Hardening Rule Describing Different Plastic Moduli in Monotonic and Cyclic Deformations. From Creep Damage Mechanics to Homogenization Methods, pp. 587–601 Springer, Cham, (2015)

Wang, Z., Xu, X., Ding, L., et al.: A new damage-coupled cyclic plastic model for whole-life ratchetting of heat-treated U75V steel. Int. J. Damage Mech 29(9), 1397–1415 (2020)

Lukáš, P., Kunz, L., Weiss, B., et al.: Effect of mean stress on the low-amplitude cyclic stress-strain curve of polycrystalline copper. Mater. Sci. Eng., A 118, L1–L4 (1989)

Gaudin, C., Feaugas, X.: Cyclic creep process in AISI 316L stainless steel in terms of dislocation patterns and internal stresses. Acta Mater. 52(10), 3097–3110 (2004)

Feaugas, X., Gaudin, C.: Ratchetting process in the stainless steel AISI 316L at 300 K: an experimental investigation. Int. J. Plast 20(4–5), 643–662 (2004)

Chakrabarty, J.: Theory of Plasticity. Elsevier, (2012)

Zhu, Y., Kang, G., Yu, C.: A finite cyclic elasto-plastic constitutive model to improve the description of cyclic stress-strain hysteresis loops. Int. J. Plast 95, 191–215 (2017)

Xu, L.Y., Fan, J.S., Yang, Y., et al.: An improved elasto-plastic constitutive model for the exquisite description of stress-strain hysteresis loops with cyclic hardening and softening effects. Mech. Mater. 150, 103590 (2020)

Dong, Y., Kang, G., Yu, C.: A dislocation-based cyclic polycrystalline visco-plastic constitutive model for ratchetting of metals with face-centered cubic crystal structure. Comput. Mater. Sci. 91, 75–82 (2014)

Okorokov, V., Gorash, Y., Mackenzie, D., et al.: New formulation of nonlinear kinematic hardening model, part I: a dirac delta function approach. Int. J. Plast 122, 89–114 (2019)

Chung, K., Lee, W., Kim, D., et al.: Macro-performance evaluation of friction stir welded automotive tailor-welded blank sheets: part I-material properties. Int. J. Solids Struct. 47(7–8), 1048–1062 (2010)

Kang, G., Gao, Q.: Uniaxial and non-proportionally multiaxial ratcheting of U71Mn rail steel: experiments and simulations. Mech. Mater. 34(12), 809–820 (2002)

Benallal, A., Marquis, D.: Constitutive equations for nonproportional cyclic elasto-viscoplasticity. J. Eng. Mater. Technol. 109(4), 326–336 (1987)

Nath, A., Ray, K.K., Barai, S.V.: Evaluation of ratcheting behaviour in cyclically stable steels through use of a combined kinematic-isotropic hardening rule and a genetic algorithm optimization technique. Int. J. Mech. Sci. 152, 138–150 (2019)

Gaudin, C., Feaugas, X.: Cyclic creep process in AISI 316L stainless steel in terms of dislocation patterns and internal stresses. Acta Mater. 52(10), 3097–3110 (2004)

Zhu, Y., Kang, G., Kan, Q., et al.: Logarithmic stress rate based constitutive model for cyclic loading in finite plasticity. Int. J. Plast 54, 34–55 (2014)

Ahmadzadeh, G.R., Varvani-Farahani, A.: Ratcheting assessment of materials based on the modified Armstrong-Frederick hardening rule at various uniaxial stress levels. Fatigue Fract. Eng. Mater. Struct. 36(12), 1232–1245 (2013)

Varvani-Farahani, A.: A comparative study in descriptions of coupled kinematic hardening rules and ratcheting assessment over asymmetric stress cycles. Fatigue Fract. Eng. Mater. Struct. 40(6), 882–893 (2017)

Hamidinejad, S.M., Varvani-Farahani, A.: Ratcheting assessment of steel samples under various non-proportional loading paths by means of kinematic hardening rules. Mater. Des. 85(1), 367–376 (2015)

Hamidinejad, S.M., Noban, M.R., Varvani-Farahani, A.: Ratcheting of 304 stainless steel alloys subjected to stress-controlled and mixed stress- and strain-controlled conditions evaluated by kinematic hardening rules. Fatigue Fract. Eng. Mater. Struct. 39(2), 238–250 (2016)

Shen, F., Zhao, B., Li, L., et al.: Fatigue damage evolution and lifetime prediction of welded joints with the consideration of residual stresses and porosity. Int. J. Fatigue 103, 272–279 (2017)

Ohno, N., Nakamoto, H., Morimatsu, Y., et al.: Modeling of cyclic hardening and evaluation of plastic strain range in the presence of pre-loading and ratcheting. Int. J. Plast 145, 103074 (2021)

Kobayashi, M., Ohno, N.: Implementation of cyclic plasticity models based on a general form of kinematic hardening. Int. J. Numer. Meth. Eng. 53(9), 2217–2238 (2002)

Yu, L., Liu, W., Sui, H., et al.: A dislocation-based model for cyclic plastic response of lath martensitic steels. Acta Mech. Sin. 38(2), 1–9 (2022)

Acknowledgements

This work is supported by National Natural Science Foundation of China (Nos. 12072246, 11872286 and 11972272) and National Numerical Wind tunnel project (NNW2020ZT3-A23). The authors gratefully acknowledge these supports.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A. Finite element implementation of equivalent maximum stress

Let us consider the interval of the state [n, n + 1], assuming that \({\text{s}}_{n + 1}\) has been obtained using the method given by reference [62]. We are given \(\left( {s_{{{\text{MAX}}}} } \right)_{n}\), \(\left( {s_{{{\text{MAX}}}}^{e} } \right)_{n}\) and \(s_{n + 1}^{e}\), then the maximum stress \(\left( {s_{{{\text{MAX}}}}^{e} } \right)_{n + 1}\) can be obtained by the following equation:

Appendix B. Discussion on limitation of material parameter \(r_{c}^{\left( i \right)}\)

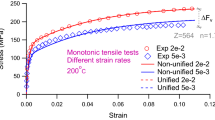

The cyclic activation function \(\left[ {1 - H\left( {\varepsilon^{p} - p} \right)} \right]\) in Eq. (8) is removed in order to illustrate the limitation of \(r_{c}^{\left( i \right)}\) describing the variation of plastic modulus, so that \(r_{c}^{\left( i \right)}\) also comes into play in the monotonic loading stage. As shown in Fig.

17, it has been observed that the plastic modulus can be reduced in a small strain range by changing \(r_{c}^{\left( 1 \right)}\). If the limitations of \(r_{c}^{\left( 2 \right)} = 0\) and \(r_{c}^{\left( 3 \right)} = 0\) given in Sect. 2.4 are removed, the model may be able to describe the change of plastic modulus over a larger strain range, but this will make it difficult to determine material parameters. Therefore, if there is a material whose plastic modulus varies in a large strain range, it will be difficult to adopt the model in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bai, J., Jin, K. & Kou, Y. An improved kinematic hardening rule describing the effect of loading history on plastic modulus and ratcheting strain. Acta Mech 234, 1757–1776 (2023). https://doi.org/10.1007/s00707-022-03469-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-022-03469-z