Abstract

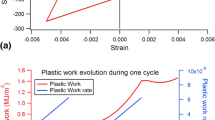

The classic unified viscoplasticity model has achieved great success in areas such as cyclic plasticity, time-dependent behavior, and creep–fatigue interaction. However, the unified viscoplasticity model may be inadequate to describe inelastic strain rate with static recovery term. Our previous study [Chen, Kitamura, Feng (Int J Fatigue 112:70–77, 2018)] of 316L stainless steel has shown that adding a static recovery term predicts an accelerating creep strain rate in the creep–relaxation interaction tests, which is inconsistent with the experimental test results. In this study, a modified non-unified viscoplasticity (NUV) model is proposed based on the mechanism of viscous glide. The parameter determination process and the role of different parts of the model are illustrated using experimental data drawn from Al 5083; then, the proposed model is verified by simulating the test of 316L stainless steel. The modeling results show that the proposed NUV model accurately predicts the strain rate evolution during the creep–relaxation interaction tests and other behaviors, i.e., cyclic plasticity and loading rate sensitivity. As with fewer parameters and more concise equations, the proposed NUV model is a good choice for engineering applications.

Similar content being viewed by others

References

Chaboche JL (2008) A review of some plasticity and viscoplasticity constitutive theories. Int J Plast 24:1642–1693

Kang G, Kan Q, Zhang J, Sun Y (2006) Time-dependent ratchetting experiments of SS304 stainless steel. Int J Plast 22:858–894

Kang G (2004) A visco-plastic constitutive model for ratcheting of cyclically stable materials and its finite element implementation. Mech Mater 36:299–312

Mayama T, Sasaki K (2006) Investigation of subsequent viscoplastic deformation of austenitic stainless steel subjected to cyclic preloading. Int J Plast 22:374–390

Mayama T, Sasaki K, Ishikawa H (2007) A constitutive model of cyclic viscoplasticity considering changes in subsequent viscoplastic deformation due to the evolution of dislocation structures. Int J Plast 23:915–930

Kaneko K, Oyamada T (2000) A viscoplastic constitutive model with effect of aging. Int J Plast 16:337–357

Chowdhury H, Naumenko K, Altenbach H, Krüger M (2018) Critical stresses estimation by crystal viscoplasticity modeling of rate-dependent anisotropy of Al-rich TiAl alloys at high temperature. Arch Appl Mech 88:65–81

Schindler S, Steinmann P, Aurich JC, Zimmermann M (2017) A thermo-viscoplastic constitutive law for isotropic hardening of metals. Arch Appl Mech 87:129–157

Taleb L, Cailletaud G (2011) Cyclic accumulation of the inelastic strain in the 304L SS under stress control at room temperature: ratcheting or creep? Int J Plast 27:1936–1958

Chen W, Wang F, Kitamura T, Feng M (2017) A modified unified viscoplasticity model considering time-dependent kinematic hardening for stress relaxation with effect of loading history. Int J Mech Sci 133:883–892

Meng L, Hallais S, Tanguy A, Chen W, Feng M (2019) The effect of stress rate on ratchetting behavior of rolled AZ31B magnesium alloy at 393 K and room temperature. Mater Res Express 6:086510

Zhang S, Xuan F (2017) Interaction of cyclic softening and stress relaxation of 9–12% Cr steel under strain-controlled fatigue-creep condition: experimental and modeling. Int J Plast 98:45–64

Xie X, Jiang W, Chen J, Zhang X, Tu S (2019) Cyclic hardening/softening behavior of 316L stainless steel at elevated temperature including strain-rate and strain-range dependence: experimental and damage-coupled constitutive modeling. Int J Plast 114:196–214

Kang G, Ohno N, Nebu A (2003) Constitutive modeling of strain range dependent cyclic hardening. Int J Plast 19:1801–1819

Yu D, Chen G, Yu W, Li D, Chen X (2012) Visco-plastic constitutive modeling on Ohno-Wang kinematic hardening rule for uniaxial ratcheting behavior of Z2CND18.12N steel. Int J Plast 28:88–101

Moosbrugger JC, McDowell DL (1990) A rate-dependent bounding surface model with a generalized image point for cyclic nonproportional viscoplasticity. J Mech Phys Solids 38:627–656

Benaarbia A, Rae Y, Sun W (2018) Unified viscoplasticity modelling and its application to fatigue-creep behaviour of gas turbine rotor. Int J Mech Sci 136:36–49

He X, Yao Y, Keer LM (2017) A rate and temperature dependent unified creep-plasticity model for high strength steel and solder alloys. Mech Mater 106:35–43

Chaboche JL (1989) Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int J Plast 5:247–302

Chaboche JL (1993) Cyclic viscoplastic constitutive equations, part I: a thermodynamically consistent formulation. J Appl Mech 60:813–821

Ma L, Luo Y, Wang Y, Du W, Zhang J (2017) Constitutive and damage modelling of H11 subjected to low-cycle fatigue at high temperature. Fatigue Fract Eng Mater Struct 40:2107–2117

Veerababu J, Goyal S, Sandhya R (2018) Cyclic viscoplastic analysis for steam generator material of Indian fast breeder reactor. Fatigue Fract Eng Mater Struct 41:2362–2375

Contesti E, Cailletaud G (1989) Description of creep-plasticity interaction with non-unified constitutive equations: application to an austenitic stainless steel. Nucl Eng Des 116:265–280

Cailletaud G, Saï K (1995) Study of plastic/viscoplastic models with various inelastic mechanisms. Int J Plast 11:991–1005

Panteghini A, Genna F (2010) Effects of the strain-hardening law in the numerical simulation of wire drawing processes. Comput Mater Sci 49:236–242

Ohguchi K, Sasaki K, Aso S (2009) Evaluation of time-independent and time-dependent strains of lead-free solder by stepped ramp loading test. J Electr Packag 131:021003–021003–021007

Kobayashi M, Mukai M, Takahashi H, Ohno N, Kawakami T, Ishikawa T (2003) Implicit integration and consistent tangent modulus of a time-dependent non-unified constitutive model. Int J Numer Meth Eng 58:1523–1543

Chen W, Wang F, Feng M (2017) Study of a modified non-unified model for time-dependent behavior of metal materials. Mech Mater 113:69–76

Chen W, Kitamura T, Feng M (2018) Creep and fatigue behavior of 316L stainless steel at room temperature: experiments and a revisit of a unified viscoplasticity model. Int J Fatigue 112:70–77

Meng L, Chen W, Yan Y, Kitamura T, Feng M (2019) Modelling of creep and plasticity deformation considering creep damage and kinematic hardening. Eng Fract Mech 218:106582

Goyal A (2018) Mechanical Behaviour of Ultra fine grain aluminium alloy. Analysis and modelling of the enhanced role of grain boundaries, in, Université Paris-Saclay

Perzyna P (1971) Thermodynamic theory of viscoplasticity. In: Yih CS (ed) Advances in Applied Mechanics. Elsevier, Netherlands, pp 313–354

Meng L, Chen W, Wang X, Yan Y (2020) Thermodynamic analysis on two plasticity models considering the time-dependency of metal materials. Mater Today Commun 25:101690

Kassner ME (2015) Fundamentals of creep in metals and alloys, Butterworth-Heinemann

Orowan E (1940) Problems of plastic gliding. Proc Phys Soc 52:8–22

Wang S, Zhang Y, Chen W (2001) Room temperature creep and strain-rate-dependent stress-strain behavior of pipeline steels. J Mater Sci 36:1931–1938

Kuhlmann-Wilsdorf D (1979) Dislocation behavior in fatigue IV Quantitative interpretation of friction stress and back stress derived from hysteresis loops. Mater Sci Eng 39:231–245

Xu H, Ye D, Mei L (2017) A study of the back stress and the friction stress behaviors of Ti-6Al-4V alloy during low cycle fatigue at room temperature. Mater Sci Eng, A 700:530–539

Kang G, Gao Q, Yang X (2002) A visco–plastic constitutive model incorporated with cyclic hardening for uniaxial/multiaxial ratcheting of SS304 stainless steel at room temperature. Mech Mater 34:521–531

Chen W, Feng M (2015) A study of a cyclic viscoplasticity model based on hyperbolic sine form for the inelastic strain rate. Int J Mech Sci 101–102:155–160

Nouailhas D (1989) Unified modelling of cyclic viscoplasticity: application to austenitic stainless steels. Int J Plast 5:501–520

Ahmed R, Barrett PR, Hassan T (2016) Unified viscoplasticity modeling for isothermal low-cycle fatigue and fatigue-creep stress–strain responses of Haynes 230. Int J Solids Struct 88–89:131–145

Zhan ZL, Tong J (2007) A study of cyclic plasticity and viscoplasticity in a new nickel-based superalloy using unified constitutive equations Part I: evaluation and determination of material parameters. Mech Mater 39:64–72

Jiang Y, Zhang J (2008) Benchmark experiments and characteristic cyclic plasticity deformation. Int J Plast 24:1481–1515

Chen W, Zhou H, Yang W (2021) Physically based modeling of cyclic plasticity for highly oriented nanotwinned metals. J Appl Mech 88:1–28

da Costa Mattos HS, de Abreu MS (2013) Plastic behaviour of an epoxy polymer under cyclic tension. Polym Test 32:1–8

Acknowledgment

The authors would like to deeply appreciate the support from the China Postdoctoral Science Foundation (2020M671705) and National Natural Science Foundation of China (12002205).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meng, L., Chen, W. Modeling for cyclic plasticity and rate dependence of metal materials with a new non-unified viscoplasticity model. J Braz. Soc. Mech. Sci. Eng. 43, 205 (2021). https://doi.org/10.1007/s40430-021-02927-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02927-4