Abstract

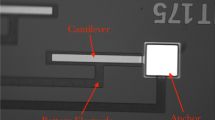

An electrostatic bifurcation-based microcantilever sensor equipped with a tip plate is investigated for sensitivity. A closed-form expression for sensitivity of this type of sensors is approximated using the frequency-response equation of the cantilever. The expression relates the sensor sensitivity due to the added mass with its geometric and material properties. The formula shows that the sensitivity of the sensor is quadratically proportional to the quality factor. Further, the sensitivity is inversely proportional to the third power of the beam stiffness and the ninth power of the gap distance. This formulation unveils the factors influencing the sensitivity of this sensor class configuration and could serve as a guideline in optimizing the design of this type of sensors for enhanced performance.

Similar content being viewed by others

References

Zribi, A., Knobloch, A., Tian, W., Goodwin, S.: Micromachined resonant multiple gas sensor. Sens. Actuators A 122, 31–38 (2005)

Favier, F., Walter, E., Zach, M., Benter, T., Penner, R.: Hydrogen sensors and switches from electrodeposited palladium mesowire arrays. Science 293, 2227–2231 (2001)

Johnson, J., Behnam, A., Pearton, S., Ural, A.: Hydrogen sensing using pd-functionalized multi-layer graphene nanoribbon networks. Adv. Mater. 22(43), 4877–4880 (2010)

Ilic, B., Yang, Y., Craighead, H.: Virus detection using nanoelectromechanical devices. Appl. Phys. Lett. 85, 2604–2606 (2004)

Hanay, M., Kelber, S., Naik, A., Chi, D., Hentz, S., Bullard, E., Colinet, E., Duraffourg, L., Roukes, M.: Single-protein nanomechanical mass spectrometry in real time nanomechanical mass spectrometry. Nat Nanotechnol 7, 602–608 (2012)

Zhu, W., Park, J., Sessler, J., Gaitas, A.: A colorimetric receptor combined with a microcantilever sensor for explosive vapor detection. Appl. Phys. Lett. 98(12), 123501 (2011)

Zhang, W., Turner, K.: Application of parametric resonance amplification in a single-crystal silicon micro-oscillator based mass sensor. Sens. Actuators A 122, 23–30 (2005)

Younis, M., Alsaleem, F.: Exploration of new concepts for mass detection in electrostatically-actuated structures based on nonlinear phenomena. J. Comput. Nonlinear Dyn. 4, 021010 (2009)

Waggoner, P., Craighead, H.: Micro- and nanomechanical sensors for environmental, chemical, and biological detection. Lab Chip 7, 1238–1255 (2007)

Dohn, S., Sandberg, R., Svendsen, W., Boisen, A.: Enhanced Functionality of Cantilever Based Mass Sensors Using Higher Modes and Functionalized Particles. In: The 13th International Conference on Solid-State Sensors, Actuators and Microsystems, Seoul, pp. 636–639, (2005)

Nayfeh, A., Ouakad, H., Najar, F., Choura, S., Abdel-Rahman, E.: Nonlinear dynamics of a resonant gas sensor. Nonlinear Dyn. 59, 607–618 (2010)

Kumar, V., Boley, J., Yang, Y., Ekowaluyo, H., Miller, J., Chiu, J., Rhoads, J.: Bifurcation-based mass sensing using piezoelectrically-actuated microcantilevers. Appl. Phys. Lett. 98(153510), 1–3 (2011)

Li, L., Holthoff, E., Shaw, L., Burgner, C., Turner, K.: Noise squeezing controlled parametric bifurcation tracking of MIP-coated microbeam MEMS sensor for TNT explosive gas sensing. J. Microelectromech. Syst. 23(5), 1228–1236 (2014)

Khater, M., Al-Ghamdi, M., Park, S., Stewart, K., Abdel-Rahman, E., Penlidis, A., Nayfeh, A., Abdel-Aziz, A., Basha, M.: Binary MEMS gas sensors. J. Micromech. Microeng. 24(6), 065007 (2014)

Al-Ghamdi, M., Khater, M., Stewart, K., Alneamy, A., Abdel-Rahman, E., Penlidis, A.: Dynamic bifurcation MEMS gas sensors. J. Micromech. Microeng. 29, 015005 (2019)

Khater, M., Abdel-Rahman, E., Nayfeh, A.: A Mass Sensing Technique for Electrostatically-Actuated MEMS. In: Proceeding of the ASME 2009 International Design Engineering Technical Conferences IDETC/CIE 2009. California, USA (2009)

Nayfeh, A., Mook, D.: Nonlinear Oscillations. Wiley (1979)

Acknowledgements

The author acknowledges KFUPM support under Project No. SR161007 and Dr. E. Abdel-Rahman at the University of Waterloo and Dr. M. Al-Ghamdi at KACST for their insightful comments and discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

In this appendix, the parameters given in the above analysis are introduced. For a sensor made of polysilicon as structural material with \(\rho =2300\) kg/m\(^3\) and \(E=160\) GPa, the following data are used: \(L=100\,\upmu \)m, \(b=10\,\upmu \)m, \(L_p=30\,\upmu \)m, \(b_p=60\,\upmu \)m, \(h=h_p=1.5\,\upmu \)m [14]. Implementing Eq. (7) using one mode shape for the system, the numerical form of the ordinary differential equation describing the motion of the beam-plate system can be obtained as

where the actuating electrostatic force is expanded in a Taylor series to the third order. It is worth noting that the electrostatic force causes softening in the beam stiffness which explains the negative signs of the coefficients of \(q(t)^2\) and \(q(t)^3\).

To have an estimate of the weight of each term of the equation of motion, a small bookkeeping parameter \(\epsilon \ll 1\) is used as a gauge parameter to signify how small the nondimensional system’s states and parameters are compared to 1. In this regard, q(t) is ordered at \(O(\epsilon )\), \(L_c\) at \(O(\epsilon )\), \(\alpha \) at \(O(\epsilon ^2)\), \(V_\mathrm{DC}\) at \(O(1/\epsilon )\), and \(V_\mathrm{AC}\) at \(O(\epsilon )\). Carrying out the scaling analysis and retaining terms up to order \(O(\epsilon ^4)\), a consistently expanded equation of motion is obtained in the form

Once the scaling analysis is carried out and very small terms are removed, the bookkeeping parameter \(\epsilon \) is removed and the expanded equation of motion reduces to

The modal coordinate q(t) is rewritten as summation of a static component \(q_s\) due to DC forcing and a dynamic component \(q_d(t)\) due to AC forcing:

The equation under static DC forcing is obtained by setting \(q(t)=q_s\), \(\dot{q}(t)=0\), \(\ddot{q}(t)=0\), \(V_\mathrm{{AC}}=0\) in Eq. (29), which yields

Substituting for q(t) with Eq. (30) and using Eq. (31) in Eq. (29), to eliminate the static deflection \(q_s\) terms, an equation representing the motion of the sense-plate around the equilibrium position \(q_s\) is obtained in the form

where

It is noted that for a sensor with geometric specifications similar to the present class of sensors, the first term in each of the above expressions is the dominant term of the expression leading to the approximations in Eqs. (17) and (22).

Rights and permissions

About this article

Cite this article

Khater, M.E. On the sensitivity of bifurcation-based electrostatic MEMS sensors: cantilever with tip plate. Acta Mech 232, 3033–3040 (2021). https://doi.org/10.1007/s00707-021-02984-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-02984-9