Abstract

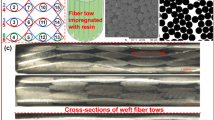

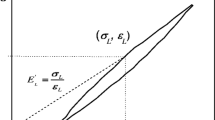

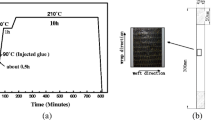

In this paper, the progressive damage of 2.5D layer-to-layer angle-interlock woven composites under quasi-static tension is investigated on a mesoscopic scale. A damage model is developed, considering the fiber damage, matrix crack and interfacial damage. The representative volume cell is established to predict the strength of the 2.5D woven composites. The damage initiation and propagation criteria are based on the Puck criterion for the fiber yarn, the paraboloidal yield criterion for the matrix and the quadratic stress criterion for the fiber yarn–matrix interface. The tensile stress–strain curve and damage evolution law of the woven composites are predicted. Some typical experiments are carried out to verify this numerical model. The damage behavior of the composites, where the variation of the interfacial fracture energy is taken into consideration, is simulated to study the influence of the interface properties on the strength. The results show that the fiber yarn–matrix interface damage characteristics play an important role in tensile strength.

Similar content being viewed by others

References

Dalmaz, A., Reynaud, P., Rouby, D., Fantozzi, G., Abbe, F.: Mechanical behavior and damage development during cyclic fatigue at high-temperature of a 2.5D carbon/SiC composite. Compos. Sci. Technol. 58, 693–699 (1998)

Boitier, G., Vicens, J., Chermant, J.L.: Understanding the creep behavior of a 2.5D Cf–SiC composite-I. Morphology and microstructure of the as-received material. Mater. Sci. Eng. A(279), 73–80 (2000)

Boitier, G., Vicens, J., Chermant, J.L.: Understanding the creep behavior of a 2.5D Cf–SiC composite. III. From mesoscale to nanoscale microstructural and morphological investigation towards creep mechanism. Mater. Sci. Eng. A(313), 53–63 (2001)

Ma, J., Xu, Y., Zhang, L., Cheng, L., Nie, J., Dong, N.: Microstructure characterization and tensile behavior of 2.5D C/SiC composites fabricated by chemical vapor infiltration. Scr. Mater. 54(11), 1967–1971 (2006). https://doi.org/10.1016/j.scriptamat.2006.01.047

Dong, W.F., Xiao, J., Li, Y.: Finite element analysis of the tensile properties of 2.5D braided composites. Mater. Sci. Eng. A 457(1–2), 199–204 (2007). https://doi.org/10.1016/j.msea.2006.12.032

Kong, C., Sun, Z., Niu, X., Song, Y.: Analytical model of elastic modulus and coefficient of thermal expansion for 2.5D C/SiC composite. J. Wuhan Univ. Technol. Mater. Sci. Ed. 28(3), 494–499 (2013). https://doi.org/10.1007/s11595-013-0719-0

Lu, Z., Zhou, Y., Yang, Z., Liu, Q.: Multi-scale finite element analysis of 2.5D woven fabric composites under on-axis and off-axis tension. Comput. Mater. Sci. 79, 485–494 (2013). https://doi.org/10.1016/j.commatsci.2013.07.003

Sun, B., Gu, B., Ding, X.: Compressive behavior of 3-D angle-interlock woven fabric composites at various strain rates. Polym. Test. 24(4), 447–454 (2005). https://doi.org/10.1016/j.polymertesting.2005.01.005

Dong, K., Liu, K., Pan, L.J., Gu, B.H., Sun, B.Z.: Experimental and numerical investigation on the thermal conduction properties of 2.5D angle-interlock woven composites. Compos. Struct. 154, 319–333 (2016). https://doi.org/10.1016/j.compstruct.2016.07.071

Guo-dong, F., Jun, L., Bao-lai, W.: Progressive damage and nonlinear analysis of 3D four-directional braided composites under unidirectional tension. Compos. Struct. 89(1), 126–133 (2009). https://doi.org/10.1016/j.compstruct.2008.07.016

Zhong, S., Guo, L., liu, G., Lu, H., Zeng, T.: A continuum damage model for three-dimensional woven composites and finite element implementation. Compos. Struct. 128, 1–9 (2015). https://doi.org/10.1016/j.compstruct.2015.03.030

Zhong, S., Guo, L., Liu, G., Zhang, L., Pan, S.: A random waveness model for the stiffness and strength evaluation of 3D woven composites. Compos. Struct. 152, 1024–1032 (2016). https://doi.org/10.1016/j.compstruct.2016.06.051

Sun, Z., Kong, C., Niu, X., Song, Y., Wang, X.: Optimization and reliability analysis of 2.5D C/SiC composites turbine stator vane. Appl. Compos. Mater. 21(5), 789–803 (2014). https://doi.org/10.1007/s10443-013-9374-z

Song, J., Wen, W., Cui, H., Zhang, H., Xu, Y.: Finite element analysis of 2.5D woven composites, part II: damage behavior simulation and strength prediction. Appl. Compos. Mater. 23(1), 45–69 (2015). https://doi.org/10.1007/s10443-015-9449-0

Rahali, Y., Assidi, M., Goda, I., Zghal, A., Ganghoffer, J.F.: Computation of the effective mechanical properties including nonclassical moduli of 2.5D and 3D interlocks by micromechanical approaches. Compos. Part B Eng. 98, 194–212 (2016). https://doi.org/10.1016/j.compositesb.2016.04.066

Ismar, H., Schröter, F., Streicher, F.: Influence of the fiber volume fraction and the fiber Weibull modul on the behavior of 2D woven SiC_SiC—a finite element simulation. Acta Mech. 149, 41–54 (2001)

Shindo, Y., Narita, F., Sato, T.: Analysis of mode II interlaminar fracture and damage behavior in end notched flexure testing of GFRP woven laminates at cryogenic temperatures. Acta Mech. 187(1–4), 231–240 (2006). https://doi.org/10.1007/s00707-006-0357-0

Fish, J., Filonova, V., Kuznetsov, S.: Micro-inertia effects in nonlinear heterogeneous media. Int. J. Numer. Methods Eng. 91(13), 1406–1426 (2012). https://doi.org/10.1002/nme.4322

Hashin, Z.: Fatigue failure criteria for unidirectional fiber composites. J. Appl. Mech. 48, 846–852 (1981)

Puck, A., Schürmann, H.: Failure analysis of FRP laminates by means of physically based phenomenological models. Compos. Sci. Technol. 58, 1045–1067 (1998)

Puck, A., Kopp, J., Knops, M.: Guidelines for the determination of the parameters in Puck’s action plane strength criterion. Compos. Sci. Technol. 62, 371–378 (2002)

Chang, F.-K., Chang, K.-Y.: A progressive damage model for laminated composites containing stress. J. Compos. Mater. 21, 0834–0855 (1987)

Tsai, S.W., Wu, E.M.: A general theory of strength for anisotropic materials. J. Compos. Mater. 5, 58–80 (1971)

Hoffman, O.: The brittle strength of orthotropic materials. Journal of Composite Materials. J. Compos. Mater. 1, 200–206 (1967)

Hill, R.: A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 193, 281–297 (1948)

Tandon, G.P., Kim, R.Y., Bechel, V.T.: Fiber–matrix interfacial failure characterization using a cruciform-shaped specimen. J. Compos. Mater. 36(23), 2667–2691 (2002). https://doi.org/10.1177/002199802761675575

Zhandarov, S.: Characterization of fiber/matrix interface strength: applicability of different tests, approaches and parameters. Compos. Sci. Technol. 65(1), 149–160 (2005). https://doi.org/10.1016/j.compscitech.2004.07.003

Yang, L., Thomason, J.L.: Interface strength in glass fibre-polypropylene measured using the fibre pull-out and microbond methods. Compos. Part A Appl. Sci. Manuf. 41(9), 1077–1083 (2010). https://doi.org/10.1016/j.compositesa.2009.10.005

Ogihara, S., Koyanagi, J.: Investigation of combined stress state failure criterion for glass fiber/epoxy interface by the cruciform specimen method. Compos. Sci. Technol. 70(1), 143–150 (2010). https://doi.org/10.1016/j.compscitech.2009.10.002

Catalanotti, G., Camanho, P.P., Marques, A.T.: Three-dimensional failure criteria for fiber-reinforced laminates. Compos. Struct. 95, 63–79 (2013). https://doi.org/10.1016/j.compstruct.2012.07.016

Koyanagi, J., Hatta, H., Kotani, M., Kawada, H.: A comprehensive model for determining tensile strengths of various unidirectional composites. J. Compos. Mater. 43(18), 1901–1914 (2009). https://doi.org/10.1177/0021998309341847

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lu, H., Guo, L., Liu, G. et al. Progressive damage investigation of 2.5D woven composites under quasi-static tension. Acta Mech 230, 1323–1336 (2019). https://doi.org/10.1007/s00707-017-2024-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-017-2024-z