Abstract

A promising solution to reduce energy usage and mitigate the wear of drilling and comminution tools during mining operations involves inducing vibrations within the piezoelectric phases dispersed in the structure of rocks using alternating current (AC). This paper presents experimental evidence of AC-induced weakening of Kuru granite, manifested as improvements in rock drillability and reductions of strength. Sievers’ J-miniature drill tests were used to assess surface drillability. The impact of AC treatment on the quasi-static strength of granite was assessed via three-point bending and indirect tension Brazilian disk tests. The influence of AC treatment on the dynamic tensile strength of the rock was determined using split Hopkinson bar tests, with the fragmentation process captured using in situ ultra-fast synchrotron X-ray phase contrast imaging. The quasi-static tests revealed no reduction in rock strength after the AC treatment. In contrast, reductions of 25% in hardness and 18% in dynamic tensile strength were observed. Fragmentation patterns differed between treated and non-treated rocks, with treated specimens exhibiting reduced macrocrack formation during loading.

Highlights

-

Diverse experiments confirm that alternating current excitations weaken Granite.

-

Sievers’ J-tests evidenced enhanced drillability of Granite after the alternating current treatment.

-

Exposure to alternating currents decreased the tensile strength of Granite in dynamic Brazilian disc experiments.

-

Treated Brazilian disc specimens showed lower energy absorption during dynamic loading.

-

Synchrotron X-ray phase contrast images revealed reduced crack branching of treated granite specimens during dynamic loading.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The high wear of drilling and comminution tools increases the costs related to mining operations. Considerable effort has been devoted to exploring alternative methods for weakening rock to increase the lifetime of tools and equipment. Adewuyi et al. (2020) and Somani et al. (2017) evaluated non-mechanical techniques to induce rock damage by pre-treatments before comminution. A family of such non-mechanical methods are based on using electricity to weaken rock. One example of these approaches consists of the rapid imposition of high-voltage electric pulses to rock immersed in a fluid to induce the formation of a plasma channel (Andres et al. 2001). Such a technique has been proven successful for drilling (Li et al. 2020) and comminution (Razavian et al. 2014). Nevertheless, the required voltages to achieve the electrical breakdown of the rocks are very high (100–150 kV/cm for granite), and the rate of voltage imposition must be higher than a threshold to create the plasma channel in the rock instead of in the immersion fluid.

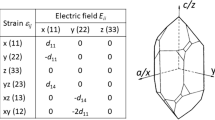

A promising alternative approach consists of the actuation of piezoelectric phases in rock to induce damage. The existence of piezoelectrically polarizable fabrics in quartz-rich rocks has been investigated in the past. Bishop (1981) and Ghomshei and Templeton (1989) measured piezoelectric effects in quartz-bearing rocks originating from piezoelectric fabrics. Sasaoka et al. (1998) measured pulsed electric potential variations that decayed exponentially over time after mechanically unloading granite specimens. They concluded that such variations in potential are caused by piezoelectric effects in the rock and obtained an apparent piezoelectric coefficient for granite that is three orders of magnitude smaller than that of pure Quartz. Matsuda et al. (2001, 2005) used atomic force microscopy to measure local piezoelectric effects near quartz grains in quartz-bearing rock. They reported a local piezoelectric coefficient of quartz in granite that is two orders of magnitude larger than the macroscopic value measured by Sasaoka et al. (1998). These results suggest that the piezoelectricity of quartz-bearing rocks could be exploited to induce local stresses and damage in the structure and thus facilitate rock breakage. The finite element study presented by Saksala et al. (2020) showed that the required electric field strength to exceed the tensile strength of a typical granite (10 MPa) by converse piezoelectric effect should be around 550 kV/cm when direct current (DC) is used. Thus, the weakening of granite due to piezoelectric excitation of dispersed quartz using DC excitation would be impossible since the electrical breakdown of the rock would happen with lower electric fields.

Moreover, the use of alternating current (AC) to excite piezoelectric phases dispersed in the structure to accumulate damage in the rock locally is a potential solution, and this is the object of study of the present paper. The potential application of high-voltage (HV) treatments with AC excitations on granite to facilitate the rock comminution was shown numerically in the work by Saksala (2021). His work showed that the rock weakening due to the HV-AC treatment is highly dependent on the AC frequency since excitations close to a natural frequency of the rock specimen can cause resonance phenomena. In such cases, the local stresses in granite can reach up to 50% of the tensile strength of the rock when the magnitude of the applied electric field reaches 25 kV/cm. Saksala et al. (2023b, c) numerically estimated a 12% reduction of the tensile strength and 10% of the compressive strength of cylindrical granite specimens due to an HV-AC pre-treatment. Saksala et al. (2023a) confirmed numerically a hypothesis of fatigue damage accumulation in a polycrystalline granitic structure due to AC excitation of quartz grains. They showed that a voltage amplitude of 15 kV (at 2.5 kHz of excitation frequency) is enough to accumulate considerable damage in the rock.

In the present paper, we study experimentally the weakening effect of the HV-AC pre-treatment on Kuru Gray granite. To this end, Kuru granite specimens were first exposed to the HV-AC treatment. Then, the mechanical performance of preconditioned and intact specimens was tested under abrasive drilling conditions, dynamic tension, and quasi-static loadings. Specifically, the weakening effect was assessed in the quasi-static three-point bending, dynamic and quasi-static Brazilian disk test, and the Sievers’ J-miniature drill test. The fragmentation patterns of the specimens under the dynamic Brazilian disk test were investigated using ultra-high-speed synchrotron X-ray phase contrast imaging (XPCI). The attained experimental results indicate that the weakening phenomena influence the mechanical behavior of the rock under dynamic loading. This is a significant finding since drilling operations might benefit from such rock weakening.

2 Materials and Methods

The granite studied in this paper is the Kuru Gray granite from the Niemenkylä quarry in Finland.

This rock is a small to medium-grained aggregate (average grain size 0.3–2 mm) with the nominal composition reported by Selonen et al. (2017). Kuru Gray granite texture (microstructure) is homogeneous and even grained, with the biotite sometimes showing foliation (Selonen et al. 2017). The mechanical properties of the material are those reported by Saksala et al. (2013).

2.1 High-Voltage Alternating Current Treatment

Cuboid rock specimens, measuring 11.5 mm in thickness, 52 mm in width, and 87 mm in length, were fabricated from a block of Kuru Gray granite. These specimens were subjected to an alternating current using parallel planar electrodes connected to an AC voltage source and a high-voltage transformer, as shown in Fig. 1a. This electrode arrangement produces a uniform field distribution within the specimen, with an electric field intensity determined by the ratio between the applied voltage and the separation distance between the electrodes. A 3D model of the specimen–electrodes array is shown in Fig. 1b. It is crucial to avoid any presence of trapped air at the point where the rock and electrodes meet. Thus, the contacting surfaces of the granite specimens were polished and semi-conductive elastic polymer sheets were used as interlayers to enhance the contact quality. The specimen–electrodes array was placed in a dielectric liquid (Midel 7131, M&I Materials Ltd, Manchester, UK) to prevent flashovers during the AC treatment. The electrical field strength imposed on the specimens was 2 kV/mm, with an alternating frequency of 50 Hz. A variable voltage source created by the EG Laboratory of SINTEF adjusted the voltage during the rock treatment. The voltage source ranges from 0 to 250 V AC and has an incorporated ammeter used to set the current flow limit to a desired value. However, it does not have an output for current monitoring. Thus, a current clamp was used for electric flow monitoring during the treatment. The voltage was set to the required levels by a 220V/100 kV MWB—Messwandler Bau AG transformer. The voltage profile was characterized using a polytetrafluoroethylene (PTFE) dummy specimen alongside high-voltage probe measurements. The effective voltage applied to the granite specimens was then determined from the established profile in conjunction with the measured specimen thickness.

Preliminary resistance measurements of some specimens, performed using a megohmmeter, yielded values exceeding 100 megohms, which led to low current flow during the initial stages of treatment. However, an increasing trend of current flow was observed after 2–3 h of continuous AC excitation. Therefore, as per safety protocol, the voltage supply was interrupted when the current reached 1 A, preventing internal discharge phenomena that could induce large heating and damage within the rock. Temperature monitoring was conducted during the treatment by placing a thermocouple in the oil surroundings of the rock. Furthermore, the surface temperature of the rock was measured right after the treatment. The highest temperature recorded at the surface of the specimens was 45 °C. Notably, these temperature levels are low for the rock specimens tested in this work, and no damage is expected to come from such heating.

2.2 Sievers’ J-Miniature Drill Tests

The Sievers’ J-miniature drill test assesses rock drillability by measuring the depth of a drill hole, in tenths of a millimeter, after a rock specimen is compressed against a drill bit rotating at 200 rpm under a 20 kg load (Sievers 1950; Dahl et al. 2012). This test was conducted on HV-AC-treated rocks and non-treated rocks, which were added as reference. Notice that Lu et al. (2022) reported that fluids like kerosene and hydraulic oil can reduce the bending strength of granite by up to 41%. Thus, non-treated specimens were also tested after oil immersion for the sake of comparability between treated and non-treated specimens. Specimens were classified as treated-wet (HV-AC treated), non-treated-wet (oil-immersed, non-treated), and non-treated-dry (neither treated nor immersed). 50 repetitions of the test were performed for each group.

2.3 Three-Point Bending Tests

The cuboid specimens were used to evaluate the impact of HV-AC treatment on the flexural strength of granite using a custom-built mini three-point bending device at the EG Laboratory of SINTEF. This apparatus contains two 8 mm diameter support rollers, spaced 51.25 mm apart, with a central load roller. Specimens underwent quasi-static loading at 0.3 MPa/s along the normal axis until failure. Each specimen category, as described in Sect. 2.2, was tested ten times.

2.4 Indirect Tension Brazilian Disc Tests

Brazilian disk (BD) indirect tensile tests were conducted to evaluate the effect of HV-AC treatment on the tensile strength of Kuru Gray granite under static and dynamic loads. Reference specimens, non-treated, were manufactured from a large granite block, drilling 12 mm diameter cylindrical cores. These cores were sliced into 4.5 mm thick BD specimens using a 0.5 mm thick diamond disk cutter. Treated BD specimens were similarly prepared from granite cuboids that underwent HV-AC excitation, as detailed in Sect. 2.1. Cylinders with 12 mm diameter were drilled from each treated cuboid and then cut into slices. This process produced two specimens from each cylinder: one with a side that was in direct contact with the dielectric fluid and another without any exposed sides. The non-exposed specimen was made by removing a 1.5 mm layer from the surface. The specimens were categorized as treated-wet (with direct fluid exposure), treated-dry (no direct fluid exposure), and non-treated-dry. This segmentation of the specimens facilitated the assessment of the impact of dielectric fluid immersion on the tensile strength of the treated rock.

The tensile stress at the center of the BD specimen is calculated based on the external force as follows,

with \(t\) and \(D\) the thickness and diameter of the disk. \(F\) stands for the force applied to the specimen.

The variable used to describe the global evolution of the experiments is a dimensionless displacement (\(\widetilde{D}\)) given by,

where \({D}_{{\text{in}}}\) and \({D}_{{\text{out}}}\) are the displacements of the input and output bars, respectively.

The mean density of mechanical work absorbed by the specimens during testing is calculated as,

where \(\delta\) is the relative displacement of the bars and \({V}_{{\text{samp}}}\) is the volume of the BD specimen.

2.4.1 Quasi-Static Tests

The three categories of BD specimens were loaded at a rate of 0.25 MPa/s using a servo-hydraulic universal testing machine (Instron 8800) with a 100 kN load cell at Tampere University. The compression, applied parallel to the diameter of the disk, induced tensile stresses transversely to the loading direction, leading to tensile failure. The non-treated-dry and treated-wet specimens underwent three tests each, while the treated-dry specimens were tested four times.

2.4.1.1 Dynamic Tests

The dynamic tests were carried out using a Split Hopkinson Pressure Bar (SHPB) device available at the ID-19 beamline of the European Synchrotron Radiation Facility (ESRF), France (Weitkamp et al. 2010). The SHPB set-up consists of a striker, incident and transmitted bars made of aluminum (T7 7075) with a diameter of 12.7 mm. The length of the striker bar was 150 mm, and the length of the incident and transmitted bars were 1300 and 1100 mm, respectively. Two maraging steel (Böhler W720, heat treated at 450 °C) discs with a thickness of 4 mm were used at the specimen–bar interfaces to avoid any damage at the faces of the bars, similarly as in the quasi-static tests. The granite specimens were placed between the incident bar and the transmitted bar, as schematically shown in Fig. 2. An air gun accelerates the striker bar to impact the incident bar, generating a longitudinal compressive wave. After the incident compressive pulse reaches the incident specimen–bar interface, a part of the pulse is reflected as a wave of tension and a part is transmitted through the specimen into the transmitted bar. During the experiment, the strain signals of the propagating waves were recorded by strain gauges attached to the incident and the transmitted bars. Based on the recorded strains in the bars, the force applied to the specimens can be obtained using one-dimensional wave-propagation theory (Chen and Song 2011). During the SHPB tests, the deformation and fragmentation of the granite specimens were recorded by X-ray phase contrast imaging (XPCI)(Olbinado et al. 2017; Cohen et al. 2019; Pournoori et al. 2023), as shown in Fig. 2. The storage ring operated in 16-bunch mode (4.68 mA/bunch) delivers an X-ray pulse train to the experimental hutch with a time separation of 176 ns (5.68 MHz) between each pulse. Two axially aligned long-period undulators (U32 λu = 32 mm, Nu = 50) set to a minimum gap (i.e., 11.5 mm) deliver a sufficiently high flux density with every X-ray pulse (Rack et al. 2014). The X-ray pulse train propagated 145 m from the source to the specimen, and the beam was conditioned with two sets of in-vacuum slits for heat load moderation and collimation onto the large field of view of 12.8 × 8 mm2. An indirect detector was located 9 m downstream from the specimen. The indirect detector assembly consists of an LYSO: Ce (Ce-dopped Lu1 − xYxSiO5, Hilger Crystals, UK) single-crystal scintillator equipped with a folding mirror and a Hasselblad lens tandem (100:100). This assembly yields a 1X magnification that conveys the transmitted X-ray radiograph into a visible light projection captured with an HPV-X2 camera (Shimadzu, Japan). The sensor of the ultra-high-speed camera has 400 × 250 pixels with a size of 32 μm/pixel, which allows the acquisition of 128 frames with a large field of view of 12.8 × 8 mm2. In this work, each frame was acquired by setting the camera exposure to 200 ns and 530 ns interframe temporal sampling. Given the fast decay and negligible afterglow of the scintillator, each radiograph consisted of a single-bunch interaction with the specimen, providing effective temporal resolution (over a part of acquired frames) down to 100 ps.

The experiments were started remotely with an instruction signal from the ID-19 control room with the synchronized XPCI system and SHPB using a coincidence logic unit, a radio frequency bunch clock, a series of delay units and a computer-triggered signal (Cohen et al. 2019; Lukić et al. 2022). A shot command of the logic unit simultaneously opens the X-ray fast shutter and fires the striker into the incident bar. A delay generator (SI DG535) was used to control the time between the incident trigger signals and acquisition. The delay value for the trigger of the camera was related to the time it takes for the incident wave to travel from the strain gauge to the specimen. Two separate oscilloscopes recorded the experiments. The first oscilloscope recorded the signals of the bar strain gauges, and the second oscilloscope monitored the radio frequency of the 16-bunch clock provided by the storage ring. Once coincidence between the stress wave arrival, arrival of the X-ray pulse, and fast shutter is achieved, a delay instruction signal is issued to the detector.

2.5 Microstructural Characterization

Extensive optical and electron microscopy, as well as EBSD measurements, were performed on both treated and non-treated specimens. However, no apparent microstructural changes, cracks, or voids were detected in the rock after undergoing the HV-AC treatment. Hence, this paper does not present comparative images of the rock microstructure before and after HV-AC treatment nor data from the EBSD measurements.

3 Results

3.1 Sievers’ J-Miniature Drill Tests

The influence of the HV-AC treatment on the surface hardness is assessed in terms of the Sievers’ J-value in Table 1. The mean Sievers’ J-value of the treated-wet specimens is about three times higher than that of the non-treated-dry material. Moreover, the non-treated-wet specimens also indicate an increased mean Sievers’ J-value, which is two times higher than that of the reference material.

3.2 Three-Point Bending Tests

Table 2 summarizes the assessment of HV-AC treatment effects on the quasi-static flexural strength of the rock. The strength measurements represent the average of ten test repetitions conducted for each of the three rock categories outlined in Sect. 2.2. The resulting strengths indicate that the HV-AC treatment did not induce any apparent weakening or mechanical deterioration in the mean strength values. Furthermore, the non-treated-wet and treated-wet specimens showed increased strength with respect to the non-treated-dry specimens. Figure 3 shows an example of a tested specimen.

3.3 Quasi-Static Indirect Tension Brazilian Disc Tests

The comparison between the mean BD tensile strengths (\({\sigma }_{{\text{BD}}}^{{\text{max}}}\)) with the corresponding standard error of the mean for each specimen category is shown in Table 3. The value of \({\sigma }_{{\text{BD}}}^{{\text{max}}}\) of the non-treated-dry specimens is slightly larger than that of the treated cases, but such a difference is smaller than the experimental dispersion. The treated-wet specimens have a slightly lower value of \({\sigma }_{{\text{BD}}}^{{\text{max}}}\) than the treated-dry specimens, but these differences are also within the range of experimental dispersion.

3.4 Dynamic Indirect Tension Brazilian Disc Tests

The temporal progression of \({\sigma }_{{\text{BD}}}\) in the performed dynamic tests is presented for the non-treated-dry, treated-wet, and treated-dry specimens in Fig. 4a–c. Notice that there may be slight variations in the loading pulse arrival time and the contact between the loading apparatus and the BD specimens in different tests. These variations can impact the alignment of the resulting curves. Thus, the initial time of all tests (t = 0) was defined as the moment when the specimens reached a stress level of 5 MPa. This enhances the alignment between the curves of different experiments, making it easier to compare the results. It should be noted that this alignment procedure affects only the origin of the time-axis but has no other effect on the stress–time curve. The attained curves were grouped and averaged for each specimen category using \(\widetilde{D}\) as a reference variable, and the attained mean curves are presented in Fig. 4d together with the standard errors.

Results of the dynamic Brazilian disk tests: a σBD–time curves of the specimens in the non-treated-dry state, b σBD–time curves of the specimens in the treated-wet state, and c σBD–time curves of the specimens in treated-dry state. d Mean \({\upsigma }_{{\text{BD}}}\)–\(\widetilde{\text{D}}\) curves of each specimen state with the standard error bars

The mean \({\sigma }_{{\text{BD}}}^{{\text{max}}}\) and \(\omega\) values for each specimen category are shown in Table 4, together with their respective standard errors. The measured stresses in the treated specimens with and without exposure to the dielectric fluid are very close to each other, and the observed deviations are smaller than the standard error of the mean. The mean \({\upsigma }_{{\text{BD}}}\) of the non-treated-dry specimens is higher than those of the two types of treated materials, yielding a \({\upsigma }_{{\text{BD}}}^{{\text{max}}}\) value 18% larger for the non-treated-dry material than for the treated ones.

Figure 5a shows representative cases of \({\sigma }_{{\text{BD}}}\)–\(\widetilde{D}\) curves of each specimen category. Figure 5b, c shows X-ray images of the fragmentation process in the three chosen specimens at equivalent instants of the loading process. The instants at which the images were taken correspond to those indicated in Fig. 5a as instants one to four. The non-treated-dry specimen exhibited multiple macrocracks with different orientations with respect to the loading axis, including coaxial and radial cracks oriented perpendicularly and at various angles. In contrast, the two types of treated specimens showed only one macrocrack in the center of the disk, and no additional cracking perpendicular or in other angles to the loading axis was observed. It is worth noting that the non-treated-dry specimens had a larger area under the \({\sigma }_{{\text{BD}}}\)–\(\widetilde{D}\) curve than the two treated specimens (Table 4). Such observations suggest that the non-treated-dry specimen absorbed more energy during failure than the treated specimens.

Fragmentation process of BD tensile specimens with different initial states: a \({\upsigma }_{{\text{BD}}}\)–\(\widetilde{\text{D}}\) curves of representative cases of non-treated-dry, treated-wet, and treated-dry specimens. b Sequence of X-ray images showing the fragmentation process of the non-treated-dry specimen. c Sequence of X-ray images showing the fragmentation process of the treated-wet specimen. d Sequence of X-ray images showing the fragmentation process of the treated-dry specimen. The star markers in Fig.a align with the instances when each X-ray image was captured. The word wet in the name of the specimens indicates that the specimen has been exposed to the dielectric fluid used in the HV-AC treatment

4 Discussion

The observed Sievers’ J-values in Table 1 consistently demonstrate a decrease in the hardness of Kuru Gray granite under the influence of alternating current. Nevertheless, the immersion of the rock in the dielectric fluid leads to a hardness reduction comparable to 50% of that caused by the HV-AC treatment. Lu et al. (2022) showed that saturating the rock pores with fluids like kerosene and hydraulic oil reduces the flexural strength of granite by 23% and 41%, respectively. Thus, the measured Sievers’ J-values are expected to be affected by the infiltration of the dielectric fluid. Nevertheless, the comparison between the drillability of treated specimens and non-treated specimens immersed in dielectric fluid reveals an additional weakening effect associated with AC excitation.

It is noteworthy that the penetration of the dielectric fluid into the rock is expected to be small due to the lack of pressure gradients favoring the oil infiltration. This is supported by the results of the indirect tensile tests, which showed that the tensile strength of the rock was not affected by the exposure to the dielectric fluid. The three-point bending tests revealed an increase in strength for both treated and non-treated specimens which were exposed to the dielectric fluid, which contrasts with the reduced bending strength of fluid-immersed rock observed by Lu et al. (2022). Furthermore, the surface of the specimen is the place with the highest stresses and where crack propagation begins during three-point bending tests. Thus, in the context of the specimens examined in this paper, the effect of immersing the rock in the dielectric liquid is regarded as a localized phenomenon that affects surface mechanical properties in the three-point bending tests and the tribological conditions during Sievers’ J-minidrill tests without compromising the strength of the bulk material. Moreover, the detailed examination of such a phenomenon is considered beyond the scope of this paper.

The results from the quasi-static indirect tension tests indicated that the HV-AC treated specimens did not exhibit a significant reduction in strength compared to the non-treated material. However, the dynamic indirect tensile tests revealed that the strength of the HV-AC-treated specimens was 18% lower than that of the non-treated material. Furthermore, the obtained mean curves are statistically distinguishable from the beginning of the loading until failure. It is also worth noting that the rock is exposed to dynamic loading during the Sievers’ J-miniature drill. These observations suggest that the AV-induced weakening of the mechanical properties of the rock exhibits a rate-sensitive behavior.

The fragmentation pattern of rock depends on how quickly the stress is applied (Hokka et al. 2016; Isakov 2024). When stress is applied rapidly, the relaxed area around an opened crack (known as obscuration zone) becomes smaller (Hild et al. 2003). This means that at high-stress rates, multiple flaws in the rock can be loaded simultaneously, causing multiple cracks to initiate, grow, and eventually coalesce. In contrast, when stress is applied slowly, the obscuration zones are large, and after a crack opens, the flaws in the obscuration zone do not experience any stresses, and a single fragmentation process is obtained. This means that, at slow loading conditions, the rock will typically fail at its weakest point, which is determined by the statistical distribution of flaws. The appreciation of weakening induced by the AC treatment exclusively at high loading rates suggests that the weakened spots during the treatment are still stronger than the critical flaws of the virgin rock. Thus, the failure process at low loading speeds is defined by the statistical dispersion of flaws, and the reduction of strength caused by the AC treatment is smaller than the variability in the local strength of the rock. In contrast, at high loading rates, the smaller obscuration zones enable crack nucleation in the weakened spots during the AC treatment and consequently lead to crack coalescence and final failure at lower strengths than that shown by the virgin rock.

It is noteworthy that the performed optical and electron microscopy exploration did not reveal any visible formation of cracks or voids in the material after the HV-AC treatment. Thus, the weakening caused by the HV-AC excitations is interpreted in this work as the introduction of localized reductions of strength throughout the rock, without the formation of new surfaces in the microstructure. Moreover, one possible physical micro mechanism driving the weakening is the converse piezoelectric effect which leads to vibrations of the structure under AC excitation.

Notice that the specimen sizes in the BD indirect tension tests are smaller than those recommended by the ISRM. This is because the XPCI system needs thin specimens for the X-ray beam to penetrate the rock. Generally, larger rock specimens are thought to be weaker due to a higher chance of having micro-defects that facilitate failure. However, in this study, the dynamic BD tensile strength of non-treated specimens is lower than what Saksala et al. (2013) reported for larger specimens. Here, the stress rate measured is about 1800 GPa/s, and the strength of the non-treated-dry specimens is 34.6 MPa. In contrast, the findings reported by Saksala et al. (2013) indicate a strength of 51.6 MPa for such loading rate. Thus, this study does not show the expected increase in strength for smaller specimens if the comparison is made with respect to the work by Saksala et al. (2013). However, Mardoukhi (2017) reported that large BD specimens of undamaged Kuru granite had a slightly lower dynamic indirect tensile strength than the results of the present paper. Furthermore, a recent publication by Pérez-Rey et al. (2023) showed the opposite trend of the size effect in granite, e.g., increased strength and fracture toughness in larger specimens of Blanco Mera granite. Based on these observations, a direct comparison between the results of this study with those using larger specimens is not straightforward. However, the main goal of this research is to evaluate how the HV-AC treatment weakens the rock. Since all specimens in this study are the same size, their comparison is considered valid.

The fragmentation pattern of HV-AC treated specimens showed differences when compared to the non-treated specimens. The non-treated-dry specimen showed multiple macrocracks propagating coaxially and transversally with respect to the loading direction. In contrast, the treated specimens showed one main macrocrack coaxial with the loading direction and no transverse cracking. A potential explanation for these differences is that, in the non-treated specimen, cracks deflect and branch out following randomly oriented, statistically dispersed flaws in the rock. Consequently, the stress levels escalated across the entire non-treated specimen, triggering multiple crack propagation mechanisms throughout the test. Conversely, in the treated specimens, crack propagation along the plane of maximum macroscopic tensile stress is facilitated by the weakened spots formed during the HV-AC treatment, which act as nucleation sites for new cracks during mechanical loading. As a result, the central regions of the treated specimens experienced tension-induced failure at lower stress levels and dissipated less energy than the non-treated specimen. This explanation can be extended to the observed results of the Sievers’ J-minidrill tests, in which the weakened spots during the HV-AC treatment facilitated crack nucleation and growth, leading to enhanced rock breakage and material removal.

5 Conclusions

This study investigated how the exposure of Kuru Gray granite to high-voltage alternating currents affects the mechanical properties of the rock. The key findings include:

-

The HV-AC treatment notably reduces the surface hardness of granite, doubling the penetration in Sievers’ J-minidrill tests. Half of this effect is due to the dielectric fluid used in the treatment, which weakens the rock surface and modifies the tribological conditions at the contact with the rotating bit.

-

Although the HV-AC treatment did not affect the strength of the rock measured in indirect tension BD tests under quasi-static conditions, it led to an 18% reduction in tensile strength under dynamic conditions.

-

The HV-AC treatment also alters the fragmentation pattern of the rock loaded at high speeds. Treated specimens typically showed one main crack aligned with the loading direction, in contrast to the multiple cracks propagating in different directions observed in non-treated specimens. Additionally, treated rocks absorbed less energy during failure than the virgin material.

In summary, while HV-AC treatment impacts the surface hardness, the dynamic tensile strength of granite and the fragmentation pattern of BD specimens, no consistent influence on the quasi-static mechanical properties was observed. These insights highlight the strain rate-dependent response of granite to the HV-AC treatment.

Data availability

The data associated with this paper are openly available in a Zenodo publication with DOI https://doi.org/10.5281/zenodo.8376267. In addition, the original data of the dynamic BD tests is available at this DOI https://data.esrf.fr/doi/10.15151/ESRF-ES-962080191.

References

Adewuyi SO, Ahmed HAM, Ahmed HMA (2020) Methods of ore pretreatment for comminution energy reduction. Minerals. https://doi.org/10.3390/min10050423

Andres U, Timoshkin I, Jirestig J, Stallknecht H (2001) Liberation of valuable inclusions in ores and slags by electrical pulses. Powder Technol 114:40–50. https://doi.org/10.1016/S0032-5910(00)00260-6

Bishop JR (1981) Piezoelectric effects in quartz-rich rocks. Tectonophysics 77:297–321. https://doi.org/10.1016/0040-1951(81)90268-7

Chen W, Song B (2011) Split hopkinson (Kolsky) bar: design, testing and applications. Springer US, Boston, MA

Cohen A, Levi-Hevroni D, Fridman P et al (2019) In-situ radiography of a split-Hopkinson bar dynamically loaded materials. J Inst 14:T06008–T06008. https://doi.org/10.1088/1748-0221/14/06/T06008

Dahl F, Bruland A, Jakobsen PD et al (2012) Classifications of properties influencing the drillability of rocks, based on the NTNU/SINTEF test method. Tunn Undergr Space Technol 28:150–158. https://doi.org/10.1016/j.tust.2011.10.006

Ghomshei MM, Templeton TL (1989) Piezoelectric and a-axes fabric along a quartz vein. Phys Earth Planet Inter 55:374–386. https://doi.org/10.1016/0031-9201(89)90084-8

Hild F, Denoual C, Forquin P, Brajer X (2003) On the probabilistic–deterministic transition involved in a fragmentation process of brittle materials. Comput Struct 81:1241–1253. https://doi.org/10.1016/S0045-7949(03)00039-7

Hokka M, Black J, Tkalich D et al (2016) Effects of strain rate and confining pressure on the compressive behavior of Kuru granite. Int J Impact Eng 91:183–193. https://doi.org/10.1016/j.ijimpeng.2016.01.010

Isakov M (2024) Cyclic impact test with the hopkinson bar: application to granite. J Dyn Behav Mater 10:75–91. https://doi.org/10.1007/s40870-023-00401-x

Li C, Duan L, Wu L et al (2020) Experimental and numerical analyses of electro-pulse rock-breaking drilling. J Nat Gas Sci Eng 77:103263. https://doi.org/10.1016/j.jngse.2020.103263

Lu G, Zhao W, Zheng J, Bunger AP (2022) Weakening effect of various pore fluids on the tensile strength of granite. Geomech Geophys Geo-Energ Geo-Resour 8:144. https://doi.org/10.1007/s40948-022-00452-9

Lukić B, Saletti D, Forquin P et al (2022) Single bunch X-ray phase-contrast imaging of dynamic tensile failure in geomaterials. J Dynamic Behavior Mater. https://doi.org/10.1007/s40870-022-00350-x

Mardoukhi A (2017) Effects of microstructural features, thermal shocks and strain rate on the mechanical response of granitic rocks. PhD Thesis, Tampereen teknillinen yliopisto

Matsuda T, Yamanaka C, Ikeya M (2001) Behavior of stress-induced charges in cement containing quartz crystals. Phys Stat Sol (a) 184:359–365

Matsuda T, Yamanaka C, Ikeya M (2005) Piezoelectric measurements of granite as composite material using atomic force microscope. Jpn J Appl Phys 44:968. https://doi.org/10.1143/JJAP.44.968

Olbinado MP, Just X, Gelet J-L et al (2017) MHz frame rate hard X-ray phase-contrast imaging using synchrotron radiation. Opt Express 25:13857. https://doi.org/10.1364/OE.25.013857

Pérez-Rey I, Muñoz-Ibáñez A, González-Fernández MA et al (2023) Size effects on the tensile strength and fracture toughness of granitic rock in different tests. J Rock Mech Geotech Eng 15:2179–2192. https://doi.org/10.1016/j.jrmge.2022.11.005

Pournoori N, Corrêa Soares G, Lukić B et al (2023) In situ damage characterization of CFRP under compression using high-speed optical, infrared and synchrotron X-ray phase-contrast imaging. Compos A Appl Sci Manuf 175:107766. https://doi.org/10.1016/j.compositesa.2023.107766

Rack A, Scheel M, Hardy L et al (2014) Exploiting coherence for real-time studies by single-bunch imaging. J Synchrotron Rad 21:815–818. https://doi.org/10.1107/S1600577514005852

Razavian SM, Rezai B, Irannajad M (2014) Investigation on pre-weakening and crushing of phosphate ore using high voltage electric pulses. Adv Powder Technol 25:1672–1678. https://doi.org/10.1016/j.apt.2014.06.010

Saksala T (2021) Cracking of granitic rock by high frequency-high voltage-alternating current actuation of piezoelectric properties of quartz mineral: 3D numerical study. Int J Rock Mech Min Sci 147:104891. https://doi.org/10.1016/j.ijrmms.2021.104891

Saksala T, Hokka M, Kuokkala V-T, Mäkinen J (2013) Numerical modeling and experimentation of dynamic Brazilian disc test on Kuru granite. Int J Rock Mech Min Sci 59:128–138. https://doi.org/10.1016/j.ijrmms.2012.12.018

Saksala T, Rubio Ruiz A, Kouhia R et al (2023a) Modelling of fatigue damage in granitic rock by piezoelectric effect in quartz phase due to alternating current excitation. Geomech Geophys Geo-Energ Geo-Resour 9:83. https://doi.org/10.1007/s40948-023-00624-1

Saksala T, Rubio Ruiz RA, Kane A, Hokka M (2023b) Weakening of tensile strength of granitic rock by HV-HF-AC actuation of piezoelectric properties of Quartz: a 3D numerical study. IOP Conf Ser: Earth Environ Sci 1124:012116. https://doi.org/10.1088/1755-1315/1124/1/012116

Saksala T, Rubio Ruiz RA, Kane P-A, Hokka M (2023c) Weakening of compressive strength of granite by piezoelectric actuation of quartz using high-frequency and high-voltage alternating current: a 3D numerical study. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-023-03451-8

Saksala T, Moreno-Navarro P, Ibrahimbegovic A, Kane P-A (2020) Cracking of Granite Rock Through Actuation of Piezoelectric Properties of Quartz by High Voltage. In Proceedings of EUROCK2020. http://www.eurock2020.com

Sasaoka H, Yamanaka C, Ikeya M (1998) Measurements of electric potential variation by piezoelectricity of granite. Geophys Res Lett 25:2225–2228. https://doi.org/10.1029/98GL51179

Selonen O, Härmä P, Ehlers C (2017) Natural stones of the Kuru granite batholith in south-central Finland. The Finnish natural stone association. Geotechnical report 6. https://kivi.info/wp-content/uploads/2019/10/Natural-stones-of-the-Kuru-granite-batholith-in-southcentral-Finland.pdf

Sievers H (1950) Die Bestimmung des Bohrwiderstandes von Gesteinen. Glückauf 86: 37/38. Glückauf G.M.B.H, Essen, pp 776–784

Somani A, Nandi TK, Pal SK, Majumder AK (2017) Pre-treatment of rocks prior to comminution—a critical review of present practices. Int J Min Sci Technol 27:339–348. https://doi.org/10.1016/j.ijmst.2017.01.013

Weitkamp T, Tafforeau P, Boller E et al (2010) Status and evolution of the ESRF beamline ID19. AIP Conf. Proc. 1221, 33–3. https://doi.org/10.1063/1.3399253

Acknowledgements

The authors acknowledge the European Synchrotron Radiation Facility (ESRF) for providing beamtime access at ID 19 beamline (Proposal MI-1397, within the Shock BAG project supported by the European Union’s Horizon 2020 research and innovation program under Grant Agreement No. 870313, Streamline). In addition, we would like to thank Dr. Jari Rämö for his assistance and support during the quasi-static indirect tension Brazilian disk tests.

Funding

Open access funding provided by Tampere University (including Tampere University Hospital). This research was funded by the Academy of Finland (grant number 340192) and the Research Council of Norway (grant number 280755).

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception and design of this work. Rafael Arturo Rubio Ruiz wrote the original draft of the manuscript; he performed data collection and analysis for all sections of the paper and participated in the dynamic and quasi-static Brazilian disk tests and the analysis of their results. Nazanin Pournoori contributed to dynamic Brazilian disk tests, the analysis of their results, as well as writing the original manuscript. Matti Isakov and Mikko Hokka contributed to dynamic Brazilian disk tests and the analysis of their results. Ruben Bjørge and Alexandre Kane conducted HV-AC treatments, the Sievers’ J-miniature drill tests and the three-point bending tests. Alexander Rack, Bratislav Lukic, Amitay Cohen, and David Levi-Hevroni contributed to the design of the experiments at ESRF and the data collection during the experiments. All authors contributed to the finalization of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rubio Ruiz, R.A., Pournoori, N., Isakov, M. et al. Progressive Weakening of Granite by Piezoelectric Excitation of Quartz with Alternating Current. Rock Mech Rock Eng (2024). https://doi.org/10.1007/s00603-024-03948-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00603-024-03948-w