Abstract

It is well documented that temperatures higher than 400 ℃ can significantly lower rock strength due to thermally induced decomposition and microcracks. However, rock strength increase under temperatures 25–400 ℃ has also been reported. It remains elusive whether thermal strengthening does exist or it is just an illusion caused by rock heterogeneity. To uncover such a mystery, we carried out triaxial compression tests on Sichuan marble under 25–200 ℃. Rock heterogeneity was at a low level and data dispersion was limited in our experiment. We managed to observe a clear trend of strength increase with temperature, justifying the existence of thermal strengthening in Sichuan marble. To unveil the mechanism of thermal strengthening, five factors, as predominant and comprehensive as we could concern, were investigated. After careful examination and analysis, thermal expansion was inferred to be the main reason leading to the thermal strengthening in Sichuan marble. The mechanism may lie in tighter compaction between mineral grains due to thermal expansion. Since thermal expansion is a physical process that can occur in all crystalline rocks upon heating, thermal strengthening holds a high potential to be a general property of crystalline rocks in the moderate temperature range. To our best knowledge, this study is the first to explicitly confirm the existence of thermal strengthening and comprehensively investigate the underlying mechanisms. The findings provide a new understanding of the thermal effect on rock strength, which may aid rock engineering design under a thermo-mechanical coupling working condition.

Highlights

-

Triaxial compression tests were performed on Sichuan marble specimens in the temperature range 25–200 ℃.

-

Rock heterogeneity was at a low level and thermal strengthening in Sichuan marble was confirmed.

-

Thermal expansion is inferred to be the leading factor of thermal strengthening in Sichuan marble after a comprehensive investigation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Geologists have long sought the coupled thermo-mechanical effect on rock strength to better understand the crustal deformation and movement history. The earliest laboratory investigation of thermal effect on rock strength dates back to Griggs et al. (1951) on Yule marble, in which high confining pressures (0.5 and 1.0 GPa) and elevated temperature (150 ℃) were integrated into triaxial compression tests. The experimental results indicated that the rock deformation manifested a plastic-flow regime with a significant work-hardening stage, and the 150 ℃ temperature degraded the strength of all the specimens. Handin and Hager (1958) carried out extensive thermo-mechanical coupled experiments on 13 different rocks at 24 ℃, 150 ℃ and 300 ℃ under lower confining pressures (100 MPa and 200 MPa) than that in Griggs et al. (1951). Both brittle and ductile failure modes were reported, but not all the specimens were weakened by the high temperatures. Instead, the rock strength of some specimens increased along with the elevated temperatures. Later, Tullis and Yund (1977), Wong (1982), Covey-Crump (1998), Violay et al. (2012) and Castagna et al. (2018) performed thermo-mechanical coupled experiments up to 700 ℃ on different rocks. These studies demonstrated a general trend of thermal effect on rock strength: temperatures higher than 400 ℃ can significantly lower rock strength. By carrying out microscopic examinations, such as CT (Computed Tomography), thin-section, SEM (Scanning Electron Microscope) and EDX (Energy-dispersive X-ray Spectroscopy) (Gibert and Mainprice 2009; Kumari et al. 2017; Fan et al, 2018; Lei et al. 2019), the following two leading mechanisms were identified to be responsible for thermal weakening: (1) the corrosion caused by thermal decomposition, and (2) the development of thermal cracks due to the incompatible expansion among mineral grains.

As rock engineering goes deeper, the mechanical properties of rock material in the working environment of ~ 200 ℃ gradually became the focus of interest. To experimentally study the thermal effect on rock strength, two major thermal and mechanical loading schemes were adopted in previous studies as folows: (1) heat specimens to the designated temperatures and anneal before mechanical loading (thermal treatment), and (2) apply mechanical loading to specimens without annealing (real-time heating). In terms of rock strength, both uniaxial compressive strength (UCS) and triaxial compressive strength (TCS) were commonly measured. In the present literature review, we compiled previous experimental studies where thermal strengthening was reported (Table 1). We can conclude from Table 1 that (1) thermal strengthening takes place in a number of rock types, (2) thermal strengthening is more significant in real-time heating experiments than in thermal treatment experiments, and (3) thermal strengthening is more prominent in sedimentary rocks than in igneous rocks.

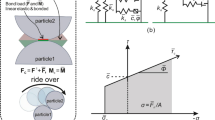

Of the 14 previous studies in Table 1, some manifested marked data dispersion in each test group, which was probably caused by rock heterogeneity. This reminds us that rock heterogeneity is a key factor that needs to be carefully assessed before concluding that thermal strengthening does take place (Wong et al. 2020). Fortunately, we did find some previous studies in which rock heterogeneity was well described, providing us with more definite clues. For example, Fig. 1a shows the raw data points of UCS under the real-time heating condition. Four granite specimens were tested at each temperature group. We are not able to explain the UCS decrease from 30 to 65 ℃. However, given the limited data dispersion in each temperature group, it is evident that the specimens in that study were fairly homogeneous. Above 65 ℃, rock strength continuously increased with temperature and this trend extrapolated beyond 160 ℃. It might be not persuasive to attribute the strength increase shown in Fig. 1a to rock heterogeneity. In addition, Fig. 1b shows the raw data points of TCS of granite specimens under different combinations of elevated temperatures and confining pressures. Although only one specimen was tested under each condition, a consistent trend is noticeable: At the same confining pressure, the magnitude sequence of TCS is always 200 ℃ > 300 ℃ > 100 ℃ > RT (room temperature). This again may not be reasonably explained by rock heterogeneity. Considering the evidence shown in Fig. 1, we tend to believe it was temperature, rather than rock heterogeneity, that resulted in the strength increase. Although the increase of rock strength with elevated temperatures has been frequently reported in the literature, studies that explicitly confirm the existence of thermal strengthening are very rare. In addition, if thermal strengthening does exist, an ensuing question arises: What is the mechanism of thermal strengthening?

In this study, we chose Sichuan marble, which is a typical metamorphic rock in southwest China, as the testing material. The reasons for choosing Sichuan marble are threefold. First, Table 1 indicates that granite and sandstone are the commonly investigated rocks. If a further experimental investigation is to be carried out, it is beneficial to expand the verification range to more rock types. Second, if rock material is clay-rich, complex chemical reactions may take place upon heating, and it is very difficult to isolate each reaction and analyze the respective effect on rock strength. Since Sichuan marble only consists of calcite and dolomite and it is clay-free, we confine chemical reactions, if occurring, to a very limited extent, which favors a relatively straightforward quantitative post-analysis. Finally, rock heterogeneity is a critical factor that can overshadow the thermal effect on rock strength. If rock specimens are overly heterogeneous and data in each test group show significant dispersion, it might be premature to conclude that rock strength increase/decrease results from the thermal effect. Sichuan marble is relatively homogeneous (see Fig. 3) and can suppress the adverse effect of rock heterogeneity to a large extent in our experiments. We first performed triaxial compression tests in the temperature range 25–200 ℃ to check if thermal strengthening took place in Sichuan marble (Sects. 2 and 3). We then studied five candidate factors, as predominant and comprehensive as we could concern, to assess their influence on rock strength and discover the mechanism(s) of thermal strengthening (Sect. 4). EDX, SEM and thin-section analysis were performed to assist the investigation. Based on the rock strength data and microscopic examinations, we reasonably generalize our findings and discuss the limitations of the present study (Sect. 5), which may enlighten future studies.

2 Experiment Setup

A true triaxial compression apparatus with real-time heating capability (Fig. 2), developed in-house by the Institute of Rock and Soil Mechanics, Chinese Academy of Science, was used in this study (Ma et al. 2019, 2020). The mechanical and thermal loadings are applied in three orthogonal directions. In each direction, one face of a specimen was placed against the rigid frame of the apparatus (Fig. 2a), while the opposite face was mechanically loaded by a servo-controlled piston pump. The specimen was surrounded by three layers of plates with different functions. The inner layer consisted of heating plates ((2) and (3) in Fig. 2b). Near the edge of each heating plate, three or four holes were pre-fabricated to accommodate electric heaters. The electric heaters were connected to a temperature control panel to display the real-time temperature and allow the operator to adjust the heating rate. The middle layer ((4) in Fig. 2b) served as a thermal insulator to reduce the heat exchange between the specimen and the ambient environment. The outer layer ((5) in Fig. 2b) comprised rigid steel plates to sustain mechanical loading. The three layers of plates were arranged in a staggered manner to wrap the specimen, and a gap of approximately 2 mm width ((7) in Fig. 2b) was reserved between the two adjacent layer sets to provide room for specimen deformation during mechanical loading. Similarly, the specimen was 7 mm higher than the three layers of plates to prevent the vertical incompatibility problem.

Cylindrical (\(\Phi\) 50 mm × 100 mm) and cubic (50 mm × 50 mm × 100 mm) specimens (Fig. 3) were cored and cut from a Sichuan marble block, aiming at the UCS test and thermo-mechanical coupled experiments, respectively. The density of Sichuan marble was roughly 2.97 × 103 kg/m3 and the UCS of three cylindrical specimens averaged 94.9 MPa. Under thin-section in polarized light, Sichuan marble is characterized by an interlocking crystalloblastic fabric, and the grains are generally equiaxed with sizes varying between 100 and 300 μm (Fig. 4). EDX analysis indicated an average mineral composition of 26% calcite and 74% dolomite (Fig. 5).

EDX (Energy-dispersive X-ray Spectroscopy) analysis of Sichuan marble at room temperature. The upper, middle and bottom rows indicate the elemental composition of the white patches, gray matrix, and the average value of the entire electron image window, respectively. The white patches are calcite and the gray matrix is dolomite. Sichuan marble contains around 26% calcite and 74% dolomite according to the data shown in the bottom row

The loading apparatus was capable of applying different intermediate and minor principal stresses (\(\sigma_{2}\) and \(\sigma_{3}\), respectively) to the specimen. In this study, the same intermediate and minor principal stresses (\(\sigma_{2} = \sigma_{3} = 20\) MPa) were adopted in all test groups, while the temperature ranged from 25 to 200 ℃. The reason for adopting equal intermediate and minor principal stresses lies in that we want to preclude the influence of deviatoric stress and thus highlight the thermal effect to favor a straightforward post-analysis. Such confining pressure and temperature settings are generally associated with the working environment of rock engineering at a depth of ~ 1000 m. The temperature increment was set to be 25 ℃, which would be sufficiently fine to reveal the dependence of rock strength on temperature. The specimen was jacketed by a copper sleeve of 0.01 mm thick to reduce the friction between the specimen faces and heating plates (Fig. 6). In total, eight real-time heating groups and one thermal treatment group at 175 ℃ were tested. In each group, three cubic specimens were loaded to assess the degree of data dispersion. The specimens were labelled as “S-T-N-x”: “S” for specimen, “T” for temperature, “N” for the sequence number of the test in each group and “x” was the marker of thermal treatment (absent for real-time heating groups). For example, “S-125-1” denoted the first specimen of the 125 ℃ real-time heating group, and “S-175-2-x” denoted the second specimen of the 175 ℃ thermal treatment group.

In terms of the test procedure, the confining pressure was first increased to \(\sigma_{2} = \sigma_{3} = 30\) MPa and then maintained for 5 more minutes before being reduced to \(\sigma_{2} = \sigma_{3} = 20\) MPa. In such a way, the three layers of plates could be compressed tightly against each other, stabilizing the measurement of the lateral deformation. The specimen was heated at a rate of 1.0 ℃/min to the designated temperature, which was then kept for two more hours to ensure a thermal equilibrium state within the specimen. Afterwards, the specimen was mechanically loaded in the vertical direction at a rate of 0.01 mm/s until the post-peak stage. Finally, the specimen was taken out from the apparatus and naturally cooled down to room temperature for post-loading analysis.

3 Test Results

Figure 7 shows two typical stress–strain curves (S-25-1 and S-150-2) of our experiment. In both Fig. 7a and b, the \(\sigma_{1} - \varepsilon_{1}\) curve was concave-up at the initial stage due to the compaction of the apparatus in the vertical direction, and a linear elastic stage then followed. Modulus decreased slightly prior to the peak stress and the plunge of \(\sigma_{1}\) thereafter indicated the loss of strength in a brittle failure regime. In terms of lateral deformation, the increase of \(\varepsilon_{2}\) and \(\varepsilon_{3}\) was very limited in the linear elastic stage but surged near the peak stress. A short period after the peak stress, both \(\varepsilon_{2}\) and \(\varepsilon_{3}\) manifested an abrupt drop (enclosed by the red dashed boxes in Fig. 7), implying the formation of a through-going shear fault. It is interesting that the peak stress well preceded the formation of the through-going fault. In the vicinity of the peak stress, both the \(\sigma_{1} - \varepsilon_{2}\) and \(\sigma_{1} - \varepsilon_{3}\) curves were concave-down but the emergence of the through-going fault marked the commencement of a concave-up stage, in which two different failure modes were observed (enclosed by the black solid boxes in Fig. 7). (1) The \(\varepsilon_{3}\) of specimen S-25-1 increased drastically, while the \(\varepsilon_{2}\) thereof remained almost constant. (2) The \(\varepsilon_{2}\) and \(\varepsilon_{3}\) of specimen S-150-2 increased simultaneously towards the end of the test. The former case probably stems from the formation of a through-going fault in a single lateral direction while the latter case might be caused by an equal dilation in both lateral directions.

Stress–strain curves of (a) specimen S-25-1 and (b) specimen S-150-2. The abrupt drop enclosed by the red dashed boxes implies the formation of a through-going shear fault. The portions enclosed by the black solid boxes in (a) and (b) indicate dilations in a single lateral direction and both lateral directions, respectively; the observed (for (a)) and inferred (for (b)) through-going faults are illustrated by the dark faces in the insets. (Color figure online)

Figures 8 and 9 show the surface fractures of specimen S-25-1 and specimen S-150-2, respectively. In both figures, the number at the end of each specimen ID (e.g. the “x” appended to “S-25-1-x”) indicated the sequence number of the specimen faces that had been photographed anticlockwise. On face S-25-1-1 (Fig. 8), a straight shear fault stretched along the upper part of the diagonal line and terminated at around the midpoint of the diagonal line. It was then connected by a shear band consisting of en-echelon fractures distributed along the lower part of the diagonal line region. On face S-25-1-3, a companion straight shear fault also developed, with a vertical branch initiating at the middle of the shear fault and extending to the upper boundary. In contrast, although a diagonal shear fracture was also present on face S-25-1-2, a companion fracture was absent on face S-25-1-4. Therefore, the through-going fault of specimen S-25-1 was unique, and its strike was roughly perpendicular to the face pair S-25-1-1 and S-25-1-3. On face S-150-2-1 (Fig. 9), the distribution of the fractures was similar to that on face S-25-1-1, but the shear fault did not terminate. Instead, it turned in the vertical direction and continued to extend until reaching the lower boundary. On face S-150-2-2, a number of conjugate fractures in alignment with both diagonal directions formed a shear band, but the fracture aperture was unobservable with naked eyes. On both faces S-150-2-3 and S-150-2-4, only one spalling fracture was present near the vertical boundary. For specimen S-150-2, no through-going fault splits the specimen until the end of the test, but we infer a potential fault as illustrated in Fig. 7b. We examined the traces of the surface fractures of all the specimens after loading. Overall, a through-going shear fault striking in one lateral direction (Fig. 7a) was more prevalent than equal dilation in two lateral directions (Fig. 7b), and the pattern of the surface fractures did not show a clear correlation with temperature.

Surface fractures of specimen S-25-1. The number at the end of the specimen ID in each photo indicates the sequence number of the specimen faces that had been photographed anticlockwise. A single through-going shear fault perpendicular to face pair S-25-1-1 and S-25-1-3 developed along the diagonal line. Connected en-echelon fractures developed in the bottom-left part of face S-25-1-1, which are enclosed by the red dashed box. (Color figure online)

Surface fractures of specimen S-150-2. En-echelon fractures were also present in the bottomleft part of face S-150-2-1 (enclosed by the red dashed box). On face S-150-2-2, a shear band developed, which consisted of many conjugate fractures (traced by the yellow dashed lines) in alignment with both the diagonal directions. No through-going fault splits the specimen until the end of the test, but we infer a potential fault as illustrated in Fig. 7b. (Color figure online)

The stress–strain curves and the ratios of \(- \varepsilon_{2}\) to \(\varepsilon_{1}\) at different elevated temperatures are shown in Fig. 10a and b, respectively; the former can be used to analyze the thermal effect on the modulus, while the latter can reflect the lateral deformation in response to temperature. In Fig. 10a, all the stress–strain curves were remarkably parallel to each other in the linear elastic stage. Since the slope of the stress–strain curves represents modulus, it is evident that elevated temperatures have a very limited effect on modulus in this stage. Figure 11 further supports this conclusion. Raw data points of modulus and the average values of modulus of each test group are provided in Fig. 11. Based on the stress–strain curves, the modulus in Fig. 11 was obtained by fitting a straight line and retrieving its slope in the axial stress range \(\sigma_{1}\) = (30 MPa, 240 MPa). The modulus of Sichuan marble is ~ 32 GPa under the confining pressure of 20 MPa, and the thermal effect on modulus in the real-time heating groups is less than 2.5% with the room temperature case as a benchmark. The thermal treatment group shows the lowest average modulus, but given rock heterogeneity, it is inconclusive if this phenomenon is associated with thermal treatment.

Modulus variation on the macroscale is closely related to changes in microstructure. In this sense, the limited thermal effect on modulus can provide at least two implications. (1) Rock heterogeneity is indeed at a low level in our study. The specimen-to-specimen difference is minor, which leads to less than 5% modulus variation in our tests. (2) Thermal damage (such as thermal cracks and thermal decomposition) in the elastic stage is insignificant. Thermal damage is irreversible and it may influence the deformation capability of specimens on the macroscale. If thermal damage builds up in the linear elastic stage, the modulus would soften and the stress–strain curves would deviate from each other. This implication is very helpful for us to explore the mechanism(s) of thermal strengthening subsequently stated in Sect. 4. Prior to the peak stresses in Fig. 10, noticeable modulus softening occurs, implying the accumulation of mechanically induced micro-damage (see Figs. 21, 22 and 23) begins to play a dominant role. A brittle failure stage then followed, as evidenced by the abrupt stress drop present in all the curves in Fig. 10a (e.g. the portion of S-200-1 enclosed by the red dashed box, see also Fig. 7). The ensuing frictional sliding stage is also closely related to the through-going fault.

In terms of the lateral deformation, in Fig. 7, the curves of \(\varepsilon_{2}\) and \(\varepsilon_{3}\) overlap in the linear elastic stage, thus thermal expansions in both lateral directions are roughly equal within this range. Therefore, we only present \(- (\varepsilon_{2} /\varepsilon_{1} )\) in Fig. 10b to explore the thermal effect on lateral deformation. Note that the ratio \(- (\varepsilon_{2} /\varepsilon_{1} )\) is influenced by at least three factors in this study: (1) deformation of the three layers of plates (Fig. 2b), (2) friction between the specimen face and the steel plate type B (Fig. 2b), and the lateral deformation of the rock specimen. It is very difficult to isolate the third factor from the total \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves, thus we are not able to provide accurate values of lateral deformation of the specimens. Nevertheless, the trend of \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves still facilitates the analysis of the thermal effect on the lateral deformation of the rock specimen. In contrast, since the axial loading was directly applied to the specimen, the stress–strain curves in Fig. 10a are accurate. In Fig. 10b, we can identify three stages regarding lateral deformation, as roughly divided by the two vertical dashed lines.

In the first stage (\(\varepsilon_{1}\) < 0.004), \(- (\varepsilon_{2} /\varepsilon_{1} )\) reduces gradually along with the increase of axial loading. We have three layers of plates surrounding the specimen in the lateral directions, and gaps exist in between these plates. In addition, the insulator is softer than the rock specimen. Therefore, a compaction stage is bound to take place when mechanical loading is applied. Although we prestressed the specimen and the three layers of plates by increasing the confining pressure to 30 MPa, maintaining for 5 min and then reducing it to 20 MPa. This process can alleviate, but cannot eradicate, the influence of plate compaction. In addition, gaps in between the three layers of plates varied from test to test. Therefore, \(- (\varepsilon_{2} /\varepsilon_{1} )\) shows differences across tests, which leads to the deviation of \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves in the first stage.

The second stage (0.004 \(\le \varepsilon_{1}\) < 0.0085) represents the linear elastic stage, and two phenomena are noticeable. (1) Data points fluctuate, as shown in the inset of Fig. 10b. (2) The \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves deviate from, but are parallel to, each other. The deviation stems from the plate compaction in the first stage. In the second stage, the \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves level out, indicating that the plate compaction effect is minor. In terms of the fluctuation of data points, it is very likely caused by the slight stick–slip sliding between the rock specimen face and the steel plate type B. Figure 12a shows a typical stick–slip sliding between rock faces under the direct shear test. The pattern of data oscillation is very similar to that in the inset of Fig. 10b. Note we did not use line segments to connect the data points in Fig. 10b. Figure 12b displays the potential relative sliding between the specimen face and the steel plate type B. Although we used a copper sleeve to reduce the friction therein, as with the prestressing process, the copper sleeve can alleviate, but cannot eradicate, the friction. Since the plate compaction effect is minor and the friction effect is largely featured by the data oscillation, the overall parallel trend of \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves is indicative of a limited thermal effect on the lateral deformation of the rock specimen. Otherwise, the parallel trend of the \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves would not manifest.

(a) Typical stick–slip sliding between rock faces under direct shear test (after Meng et al. (2019)), and (b) potential relative sliding (see the paired pink arrows) between the specimen surface and steel plate type B in this study. The fluctuation of data points shown in the inset of Fig. 10b implies that slight stick–slip sliding may occur in (b). (Color figure online)

In the third stage (\(\varepsilon_{1} \ge\) 0.0085), \(- (\varepsilon_{2} /\varepsilon_{1} )\) surges. In this stage, mechanically induced microcracks develop significantly and the through-going fault nucleates. The lateral deformation is strongly correlated with the development of the through-going fault, and the \(- (\varepsilon_{2} /\varepsilon_{1} )\) curves do not show a perceivable pattern related to elevated temperatures.

Overall, in the linear elastic stage, the thermal effect on modulus and lateral deformation is insignificant; the near-peak and frictional sliding stages are strongly influenced by the through-going fault, leaving the thermal effect overshadowed and difficult to analyze.

Table 2 exhibits the peak stresses (σl,max) of all the tests and Fig. 13 plots the raw data points normalized with respect to the average (σl,max) at room temperature. Figure 13 shows that the extent of (σl,max) increase was gentle below 125 ℃ but accelerated thereafter. (σl,max) increased by 12.1% at 200 ℃ as compared with that at room temperature, and the strengthening trend well extrapolated beyond 200 ℃. As shown in Fig. 13, data dispersion due to rock heterogeneity is limited; thus we can confirm that thermal strengthening did take place in Sichuan marble in the real-time heating groups. However, the thermal treatment group at 175 ℃ somehow showed almost no strengthening.

Normalized peak stresses (σ1,max) at different elevated temperatures relative to room temperature. The degree of (σ1,max) increase was gentle below 125 ℃ but accelerated thereafter. The increasing trend well extrapolated beyond 200 ℃. Since the data dispersion is limited, thermal strengthening in Sichuan marble can be confirmed. However, for the thermal treatment group at 175 ℃, thermal strengthening was absent

4 In Quest of the Mechanism(s) of Thermal Strengthening

Above we have confirmed that thermal strengthening does exist in Sichuan marble. In this section, we will try to uncover the underlying mechanism(s). Rock strength increase is a macroscopic manifestation with a collection of factors at play on the microscale. As far as we can consider, five factors that can impact rock strength, namely water content, thermal decomposition, thermal cracks, twin lamella and thermal expansion, were investigated and will be elaborated in turn in this section. These factors can either increase or decrease rock strength under elevated temperatures, and the strengthening effect is a net result of the interplay among them. In our experiment, the yet-to-be-discovered mechanism should take place to an extent that was adequate to influence rock strength. Meanwhile, the potential mechanism should also be able to reconcile the unusual phenomenon in our experiment that the thermal treatment group at 175 ℃ did not show measurable thermal strengthening. Note that we tried to investigate as comprehensive as possible factors associated with the thermal strengthening in Sichuan marble. However, it is no guarantee that the above five factors are sufficiently thorough; they are predominant and comprehensive only to our best knowledge. We quantitatively examined the five factors to assess the extent to which they took place and analyzed in detail if they had made a major contribution to the thermal strengthening, which will be presented in the remainder of this section.

4.1 Water Content

Water content was reported as a prominent factor that could significantly reduce rock strength, and such an effect can be compounded by elevated temperatures (Wong 1982; Vásárhelyi and Ván 2006; Wong et al. 2016; Castagna et al. 2018). Wong (1982) predried Westerly granite specimens overnight in vacuo at 80 ℃ before the mechanical loading. Fredrich et al. (1989) carried out a similar predrying process for Carrara marble specimens but the temperature used was 40 ℃. In our study, to measure the water content of Sichuan marble, three cylindrical specimens (Fig. 5a) were first weighed and then dried at 50 ℃ in an air-ventilated furnace for 24 h. They were weighed again immediately after being taken out of the furnace to prevent the influence of the water vapour in the ambient environment. Table 3 shows the mass of the specimens before and after drying, and the mass loss therein can be used to evaluate the water content. Two of the three specimens did not show any mass loss, and the remaining one only had a mass loss of 0.05%. Therefore, the water content of Sichuan marble is extremely low, and its influence on rock strength should be very limited. Such a conclusion can be further underpinned by the rock strength of the specimens at room temperature and those annealed from 175 ℃ (Fig. 13). If water content had a significant role to play during the heating process, the rock strength of the thermal treatment group at 175 ℃ should have manifested a measurable decrease as compared with that at room temperature. However, the two groups showed almost identical average rock strength, proving that the influence of water content was indeed fairly limited.

4.2 Thermal Decomposition

When the specimens of the thermal treatment group at 175 ℃ were taken out from the furnace, we immediately noticed that the specimens became whiter as compared with those at room temperature. Such a phenomenon was reminiscent of the potential chemical reactions (very likely thermal decomposition) that might have occurred during the heating process. It is well documented that significant thermal decomposition of calcite and dolomite takes place above 600 ℃ (Engler et al. 1989; Ewing et al. 1979; Rodriguez-Navarro et al. 2009; Samtani et al. 2002). Nevertheless, the color change during calcination was rarely reported, leaving our speculation of thermal decomposition fairly uncertain. Thermal decomposition is a critical factor that can degrade rock, thus it is necessary to quantitatively specify the degree of thermal decomposition in our experiments and clarify the above speculation. To this end, we used EDX to analyze the mineral composition of Sichuan marble. When heated, calcite and dolomite decompose following the reactions CaCO3(s)\(\to\) CaO(s) + CO2(g) and MgCa(CO3)2(s)\(\to\) CaO(s) + MgO(s) + CO2(g), respectively. If the two chemical reactions occur, the emission of gaseous CO2 must result in a reduction of the carbon element in EDX analysis. Therefore, the weight percentage of carbon (WPC) in EDX analysis can serve as an indicator to quantitatively evaluate the degree of mineral decomposition. To reduce the specimen-to-specimen variability in the test of WPC, one cubic specimen was equally cut into four small specimens with dimensions of 50 mm × 50 mm × 25 mm (Fig. 14). Three of the four small specimens were heated in an electric furnace at a rate of 1.0 ℃/min to 100 ℃, 175 ℃ and 200 ℃, respectively. They were then maintained at the designated temperature for two more hours before naturally cooling down to room temperature. The remaining one small specimen was left untreated as a benchmark.

A cubic specimen was cut into four equal small specimens (1 – 4) to perform the thermal treatment. The right subfigure shows the appearance of the four small specimens after thermal treatment, which was photographed simultaneously to preclude the influence of non-uniform illumination. The larger the grayscale, the closer the color approaches pure white. The specimens became increasingly whiter as temperature rises, implying the potential occurrence of thermal decomposition

The appearance of the four small specimens in the natural state ((1)) and after thermal treatment ((2)–(4)) is shown in Fig. 14. To quantitatively assess the color change of the specimens upon heating, the average grayscales of the four images were analyzed. Grayscale ranging from 0 to 255 denotes the gradual transition from black to white. The larger the grayscale, the closer the color approaches pure white. As shown in Fig. 14, grayscale increases by 20 from 25 ℃ to 200 ℃, therefore the specimens indeed became whiter as a result of thermal treatment. To quantitatively measure the WPC of the specimens being annealed from different temperatures, the specimen faces shown in Fig. 14 were used to carry out EDX analysis. As exhibited in Fig. 5, EDX analysis can be carried out either at a specific point or over a regular electron image window. For the latter case, the weight percentage of an element is the average value over the entire window. In this study, a square window of dimensions 3.3 mm × 3.3 mm was set to analyze the elemental composition at a candidate position. For each specimen face, EDX analysis was carried out in 50 randomly chosen windows. Figure 15 shows the raw data points of WPC varying with locations and temperatures. On the same specimen face, WPC fluctuates with locations, while across different sub-specimens, the overall WPC distribution shows a clear downward trend as temperature increases. However, the average value of the 50 WPCs at 200 ℃ reduces only by 1.46% as compared with that at 25 ℃. Therefore, thermal decomposition occurred to a very small extent and its influence on the strength of Sichuan marble should be insignificant. Again, such a conclusion may be further supported by the fact that the rock strength at room temperature and after 175 ℃ thermal treatment did not show a measurable variation, which would not be the case if thermal decomposition had impacted rock strength.

On each face shown in Fig. 14, 50 randomly chosen electron image windows were analyzed to obtain the weight percentage of carbon (WPC). Despite the WPC fluctuation with positions, the overall downward trend of WPC with temperature increase is clear

4.3 Thermal Cracks

Rock strength is closely related to microcracks because the propagation and coalescence of microcracks nucleate fractures on the macroscale. Thermal cracks due to the incompatible thermal expansion of mineral grains under high temperatures can enlarge the population of microcracks (Wong et al. 2021; Guo et al. 2021), which potentially reduces rock strength. To assess the thermal cracks in our experiment, SEM images were captured on the faces of the four specimens shown in Fig. 14, and thin-sections were also fabricated from the same faces.

The left and right columns of SEM images (Fig. 16) compare the micro-structures of Sichuan marble at 25 ℃ and 200 ℃. The white ((1)), gray ((2)) and dark ((3)) patches represent calcite, dolomite and voids, respectively. Under 50 × magnification, many calcite clusters and voids are scattered in the dolomite matrix. Part of the voids might be inherent but others were generated by polishing. Under 200 × magnification, micro-cracks along mineral boundaries ((4)) are observable in both 25 ℃ and 200 ℃ scenarios. Figure 17 shows the images of thin-sections at 25 ℃ and 200 ℃. Grain boundaries can be easily recognized because they appear much darker than the interior of the grains. We can find some potential inter-granular cracks in both 25 ℃ and 200 ℃ cases, but in the latter, it is difficult to conclude whether they were thermally induced or not. Overall, the SEM images and thin-sections in 25 ℃ and 200 ℃ scenarios show a limited difference between each other, and the thermal cracks therein are hard to perceive if considering the inherent defects of rock material on the microscale. Consequently, the influence of the thermal cracks on the strength of Sichuan marble, if any, tended to be minor.

4.4 Twin Lamella

Twin lamella (hereafter termed as twin(s)) is a common feature in calcites and it has been well documented to be the main reason for plastic deformation of carbonate rocks below 400 ℃ (Fredrich et al. 1989; Ferrill et al. 2004). Twins manifest as parallel black lines in thin-sections thus they are visually striking (Fig. 18). In addition, twinning in calcites features the density and thickness of twins, and the two attributes are closely related to the pressure and temperature history that calcites have experienced (Burkhard 1993; Ferrill et al. 2004). Therefore, the population and morphology of twins are viewed by geologists as handy paleo- piezometer and geothermometer. Twins nucleate new microcracks and interact with existing microcracks, affecting rock strength on the macroscale (Fredrich et al. 1989). The plastic deformation resulting from twins may blunt the tips of microcracks (Fredrich et al. 1989), which potentially stabilizes crack propagation and increases rock strength. Considering that Sichuan marble comprises ~ 26% calcite, which is remarkable, it is necessary to assess the effect of twins in our experiment.

Schematic classification of twins according to their appearance in thin-sections. Twin thickness is closely related to the temperature of deformation (after Burkhard 1993)

Burkhard (1993) classified twins into four categories according to their thickness in thin-section and correlated the four categories with the temperature of deformation (Fig. 18). Increasing the temperature of deformation generally leads to thicker twins. Ferrill et al. (2004) further reported that below 170 ℃ calcites accumulate plastic deformation by the formation of new thin twins rather than by twin enlargement or the formation of thick twins. In contrast, above 200 ℃ the strain of calcites is mainly attributed to the formation of thick twins and the enlargement of existing twins, rather than by the formation of thin twins. Therefore, the density and thickness of twins are typical indicators of the temperature of deformation. In previous studies (Fredrich et al. 1989; Rybacki et al. 2013), Carrara marble was commonly selected as the testing material which consists of ~ 99% calcite. Significant changes to the density and thickness of twins could be immediately observed in Carrara marble after deformation (Fig. 19).

However, twins are very rare in Sichuan marble both before and after deformation. We first examined the thin sections fabricated from two undeformed specimens at 25 ℃ and after thermal treatment at 200 ℃, respectively. When we searched the thin-sections throughout for twins under the microscope, usually there was no twin at all in a complete view window. Nevertheless, we did find a few twins, which are typically shown in Fig. 20a and b and pointed by the red arrows. Figure 20a and b each displays more than 300 grains in total and we could only capture 3–4 grains in which twins are present. Twins are visually striking, so they are easy to be recognized if there are any. It is less likely that we failed to capture a lot of twins. Therefore, the density of twins in Sichuan marble is indeed very low (less than 1%), and the thermal treatment process did not seem to increase twin density to a measurable extent. In terms of the thickness of the twin, we did find that the twins in Fig. 20b were thicker than that in Fig. 20a. However, considering the sparsity of twins, it is inconclusive if temperature led to such a phenomenon.

As mentioned above, in Sichuan marble, temperature up to 200 ℃ alone tends to be inadequate to result in a perceivable increase in twin density. Previous studies on the temperature effect on twin density and thickness were commonly accompanied by considerable strain levels (Fredrich et al. 1989; Ferrill et al. 2004). Rybacki et al. (2013) further suggested that twin microstructure is affected by at least three parameters, namely strain, temperature and peak load. A high level of stress/strain can activate the twinning system(s) within grains, which is very likely to be a prerequisite to underpin the temperature effect on twin microstructure. Therefore, examing the thin-sections fabricated from deformed specimens to search for twins and the potential interaction between microcracks and twins, is necessary to further clarify the twin effect on rock strength in our experiment.

Figures 21 and 22 show the thin-sections of some typical positions on specimen faces S-25-1-1 and S-200-3-2, respectively, which have undergone thermo-mechanical loading. On face S-25-1-1 (Fig. 21), position A is situated adjacent to the main fault. In this area, thin vertical microcracks are prevalent within a band offsetting around 7 grain sizes from the main fault. Some of the vertical cracks terminate at grain boundaries, but others pierce through 3 to 5 gains. Compared with Fig. 17, the aperture of the dark gain boundaries becomes wider without particularly preferred orientations. Position B is traversed by a thin macroscopic vertical fracture. A limited number of vertical microcracks can also be found in this region, but most of them are confined in the interior of the respective grains. Position C is situated in a fracture-free area and a few intra-granular vertical microcracks are also present. Position D is traversed by one branch of the en-echelon fractures. More crushed grains are present in this area and vertical inter- and intra-grain microcracks are prevalent at both sides of the macro fracture in the middle. In position D we could capture one grain carrying one set of twins, which is enclosed by the red circle. The distribution of vertical microcracks in Fig. 22 shows the same trend as in Fig. 21, i.e., they are dense adjacent to the shear fractures (positions A, C and D in Fig. 22), but sparse at the fracture-free region (position B in Fig. 22). Figures 21 and 22 indicate that microcracks in line with the major principal stress are prevalent in the thin-sections of deformed specimens, but twins are still very rare and far fewer than those in Carrara marble (cf. Fig. 19). The interaction between twins and microcracks can be found but is very weak due to the sparsity of twins. Figure 23 shows two of a few locations where the interaction between twins and microcracks was observed. Figure 23a depicts a possible thick twin overlapping a microcrack, but they were trapped within the grain. Figure 23b exhibits that a thin inter-granular microcrack terminated at one set of twins and the twins stopped the microcrack from propagating.

Thin-sections of face S-25-1-1 after thermo-mechanical loading. (Position A) Adjacent to the main shear fault; (position B) traversed by a tensile fracture; (position C) fracture-free area, and (position D) one branch of the en-echelon fractures. The red arrows point at some of the prevalent vertical cracks and the red circle encloses a grain with one set of twins. (Color figure online)

As illustrated above, we still could not find a significant increase in twin density in Sichuan marble even with the concurrent presence of pressure and temperature. The reasons might be twofold. Firstly, dolomite does not easily twin at low temperatures as calcite (Barber and Wenk 1979). Sichuan marble consists of ~ 26% calcite and ~ 73% dolomite as compared with ~ 99% calcite in Carrara marble. It is inherent that twins in Sichuan marble are fewer than those in Carrara marble. Secondly, in previous studies, the strains leading to a surge of twin density were usually large enough to reach at least the semi-ductile failure field. The confining pressure in our study was 20 MPa and all the stress–strain curves in Fig. 10 indicate a brittle failure mode. It is very likely that the stress level in our experiment was insufficient to activate the potential twins. Note that twins facilitate microcracks, but this does not mean that twins are indispensable for the formation of microcracks. The experiment of Fredrich et al. (1989) on Carrara marble indicated that deformation in the brittle field was related to both microcracking and twinning, and microcracks did not show any clear association with twinning. Our experiment on Sichuan marble suggested that deformation in the brittle field was predominantly caused by microcracks; twinning has a very limited role to play. In view of the evidence and analysis above, twins are unlikely to be the leading factor that causes the thermal strengthening in Sichuan marble.

4.5 Thermal Expansion

Up to now we still have not identified the mechanisms of thermal strengthening in Sichuan marble. Reflecting on the present experimental results, the most unexpected phenomenon lies in that thermal strengthening occurred in the real-time heating group at 175 ℃, but did not in the thermal treatment group at the same temperature. Thermal strengthening seems to be reversible with respect to the variation of temperature. Therefore, identifying the process that varies reversibly with temperature is a key clue to trace the source of thermal strengthening. We hereby consider thermal expansion due to the following two points. (1) When the specimens were heated in the temperature range 25–200 ℃, thermally induced cracks were very limited, as proved by Sect. 4.3. In contrast, thermal expansion was bound to take place. According to Robertson (1988), the volumetric thermal expansion coefficient of marble is around 2.1 × 10–5/℃; at 200 ℃, the thermal expansion in the lateral and vertical directions are expected to be around 0.06125 mm and 0.12250 mm, respectively. Thermal cracks and twins are irreversible once formed, and they are the main source of plastic deformation during the heating if any. Since we could not observe significant thermal cracks, and twins are very rare in the designated temperature range, it is reasonable to infer that the thermal expansion in our experiment was elastic, which could vary reversibly with temperature. The remarkable parallel stress–strain curves in Fig. 10 and the limited thermal effect on modulus quantitatively indicated by Fig. 11 can further support this inference. (2) Thermal expansion was capable of resulting in tighter compaction between grains. As a result, the normal stresses applied on the faces of microcracks may be enhanced. For shear microcracks, larger normal stress increases the frictional resistance and can stabilize the crack propagation. For tensile microcracks, the increased normal stress compresses them and directly reduces the stress intensity factor at the crack tip (cf. Fig. 23). Therefore, thermal expansion is competent to strengthen rock. On the macroscale, Barton (2007) compiled a number of experiments associated with different rock types where heating reduced the aperture of rock joints; the closure of rock joints included both the elastic and residual parts, and the latter was termed joint over-closure. On the microscale, although we do not have strong evidence to justify whether crack over-closure took place in Sichuan marble, the elastic closure alone can reduce the aperture of preexisting cracks, inhibiting the development of macrocracks and increasing rock strength. Therefore, in terms of the elastic closure only, the mechanism we analysed above is more or less akin to a microscopic replica of the closure of rock joints upon heating, which has been well documented.

The first point above can plausibly explain why thermal strengthening did not occur in the thermal treatment group. That is because the compaction caused by thermal expansion disappeared after the quench. The second point indicates that tighter compaction caused by thermal expansion was able to strengthen rock, which led to the strengthing phenomena in the real-time heating groups. Considering thermal expansion can reconcile all our experimental results, we tend to believe that thermal expansion was the dominant reason leading to the thermal strengthening in Sichuan marble.

5 Discussion

In Sect. 4 we attributed the thermal strengthening in Sichuan marble to thermal expansion. Thermal expansion is a physical phenomenon that can appear in all crystalline rocks upon heating, such as granite. Consequently, it is natural to speculate that thermal strengthening is a general property of crystalline rocks. Such speculation echos back the strengthening phenomena in granite shown in Fig. 1. In addition, Fig. 24 shows a previous study (Gautam et al. 2018) where thermal treatment was performed on granite but strengthening did not occur, which might be comparable to our thermal treatment tests on Sichuan marble; the data dispersion in Fig. 24 is limited and the rock strength was barely strengthened by temperature below 300 ℃. Another example that can support our generalization is a numerical simulation study carried out by Wong and Zhang (2019) where the GBM was utilized to investigate the influence of high temperature on rock strength. In GBM, circular particles are assembled to simulate mineral grains, and the breakage of particle bonds represents the formation of microcracks. Particle expansion was considered in that GBM study, therefore the influence of thermal expansion on rock strength, if any, can be reflected. Figure 25 shows the simulation results of two GBMs with the same strength parameters of particle bonds but different microstructural heterogeneities. UCS and TCS (confining pressure 5 MPa) at different temperatures were obtained by performing both the GBMs. We can see a slight downward trend of rock strength below 75 ℃, but an accelerating rate of thermal strengthening thereafter in all the simulated scenarios. Although the two GBM models are not ad hoc for the present experimental study, the thermal strengthening reproduced by them can still add some confidence to the present generalization.

Thermal strengthening barely took place in granite after thermal treatment as reported by Gautam et al. (2018)

Compressive strength subject to high temperatures simulated by grain-based model (GBM) (after Wong and Zhang (2019)). Two GBMs were modelled under both uniaxial and biaxial compressive conditions

In Table 1, although the thermal strengthening phenomenon also occurred in sedimentary rocks (sandstone and mudstone), apart from the twin lamella which is unique to carbonate rocks, the rest of the factors analyzed in Sect. 4 may take place to an extent markedly different from those in crystalline rocks. For example, upon heating in the moderate temperature range, it is possible that water evaporation and chemical reactions result in tighter cemented grain boundaries, leading to irreversible thermal strengthening. This effect should be more prominent in those sedimentary rocks with a higher component of clay minerals. To sum up, the findings of the present study may not be readily extended to the realm of sedimentary rocks.

6 Conclusions

Ample previous experimental studies have documented that temperatures higher than 400 ℃ can significantly lower rock strength due to the corrosion by thermal decomposition and the disintegration by the development of thermal cracks. However, for most rock engineering projects at depth, rock temperature rarely exceeds 200 ℃. The trend of strength increase with temperature in the range 25–200 ℃ has been reported in some previous studies, but it remains elusive whether thermal strengthening does exist or it is just an illusion caused by rock heterogeneity. To uncover such a mystery, we performed thermo-mechanical experiments on Sichuan marble, which is relatively homogeneous to limit the influence of rock heterogeneity. Some pre- and post- analyses were carried out to reveal the mechanism of thermal strengthening. As predominant and comprehensive as we could consider, five factors, namely water content, thermal decomposition, thermal cracks, twin lamella and thermal expansion, were investigated in detail. Based on the test results and microscopic analysis, we draw the following conclusions.

-

1)

Thermal strengthening does exist in Sichuan marble in the moderate temperature range. The rock heterogeneity was at a low level and the data dispersion was limited in our experiment. Under such a condition, we still observed a clear strength increase with elevated temperatures.

-

2)

Thermal strengthening was not observed in the thermal treatment group, real-time heating tends to be a prerequisite for thermal strengthening to take place in Sichuan marble.

-

3)

Water content, thermal decomposition and thermal cracks have a very limited role to play in the thermal strengthening in Sichuan marble. Although previous studies on Carrara marble indicated that the concurrence of temperature and pressure could significantly increase twin density, such a phenomenon did not occur in Sichuan marble. The reasons might be a low percentage of calcite in Sichuan marble and a brittle failure mode in our experiment.

-

4)

Thermal expansion can reconcile all our experiment results, thus we infer that thermal expansion is the underlying mechanism leading to the thermal strengthening in Sichuan marble. The mechanism may lie in tighter compaction between mineral grains due to thermal expansion, which potentially increases the frictional resistance of shear microcracks and suppresses the development of tensile microcracks.

-

5)

Generally speaking, the influence of chemical reactions is limited for crystalline rocks in the moderate temperature range, while thermal expansion is bound to occur upon heating. If rock heterogeneity does not play a dominant role, thermal strengthening holds a high potential to take place in all crystalline rocks. However, although thermal strengthening in sedimentary rocks was also reported in the literature, the findings of the present study may not be readily extended to sedimentary rocks considering the possible chemical effect of clay minerals.

Rock engineering in recent years features great depth, multiphysics and a prolonged lifetime, such as nuclear waste disposal and Enhanced Geothermal Systems (EGS). Heating and cooling are critical processes associated with these engineering activities, and the working temperature thereof typically falls in the range investigated in this study. Our research outcome implies that temperature tends to be a favorable factor to enhance the integrity of rock material during the heating process (e.g. early stage of nuclear waste disposal), but may generate adverse effects during the cooling process (e.g. EGS).

References

Barber DJ, Wenk HR (1979) Deformation twinning in calcite, dolomite, and other rhombohedral carbonates. Phys Chem Miner 5(2):141–165. https://doi.org/10.1007/BF00307550

Barton N (2007) Thermal over-closure of joints and rock masses and implications for HLWrepositories. In: 11th ISRM congress. OnePetro

Burkhard M (1993) Calcite twins, their geometry, appearance and significance as stress-strain markers and indicators of tectonic regime: a review. J Struct Geol 15(3–5):351–368. https://doi.org/10.1016/0191-8141(93)90132-T

Castagna A, Ougier-Simonin A, Benson PM, Browning J, Walker RJ, Fazio M, Vinciguerra S (2018) Thermal damage and pore pressure effects of the brittle-ductile transition in comiso limestone. J Geophys Res Solid Earth 123(9):7644–7660. https://doi.org/10.1029/2017JB015105

Chen YL, Wang SR, Ni J, Azzam R, Fernandez-Steeger TM (2017) An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics. Eng Geol 220:234–242. https://doi.org/10.1016/j.enggeo.2017.02.010

Covey-Crump SJ (1998) Evolution of mechanical state in Carrara marble during deformation at 400 to 700 °C. J Geophys Res Solid Earth 103(B12):29781–29794. https://doi.org/10.1029/1998JB900005

Ding QL, Ju F, Song SB, Yu BY, Ma D (2016a) An experimental study of fractured sandstone permeability after high-temperature treatment under different confining pressures. J Nat Gas Sci Eng 34:55–63. https://doi.org/10.1016/j.jngse.2016.06.034

Ding QL, Ju F, Mao XB, Ma D, Yu BY, Song SB (2016b) Experimental investigation of the mechanical behavior in unloading conditions of sandstone after high-temperature treatment. Rock Mech Rock Eng 49(7):2641–2653. https://doi.org/10.1007/s00603-016-0944-x

Duclos R, Paquet J (1991) High-temperature behaviour of basalts—role of temperature and strain rate on compressive strength and Kic toughness of partially glassy basalts at atmospheric pressure. Int J Rock Mech Mining Sci Geomech Abstr 28(1):71–76

Dwivedi RD, Goel RK, Prasad VVR, Sinha A (2008) Thermo-mechanical properties of Indian and other granites. Int J Rock Mech Min Sci 45(3):303–315. https://doi.org/10.1016/j.ijrmms.2007.05.008

Engler P, Santana MW, Mittleman ML, Balazs D (1989) Non-isothermal, in situ XRD analysis of dolomite decomposition. Thermochim Acta 140:67–76. https://doi.org/10.1016/0040-6031(89)87285-5

Ersoy H, Karahan M, Kolaylı H, Sünnetci MO (2021) Influence of mineralogical and micro-structural changes on the physical and strength properties of post-thermal-treatment clayey rocks. Rock Mech Rock Eng 54(2):679–694. https://doi.org/10.1007/s00603-020-02282-1

Ewing JAY, Beruto D, Searcy AW (1979) The nature of CaO produced by calcite powder decomposition in vacuum and in CO2. J Am Ceram Soc 62(11–12):580–584. https://doi.org/10.1111/j.1151-2916.1979.tb12736.x

Fan LF, Gao JW, Wu ZJ, Yang SQ, Ma GW (2018) An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Appl Therm Eng 140:505–519. https://doi.org/10.1016/j.applthermaleng.2018.05.074

Ferrero AM, Marini P (2001) Experimental studies on the mechanical behaviour of two thermal cracked marbles. Rock Mech Rock Eng 34(1):57–66. https://doi.org/10.1007/s006030170026

Ferrill DA, Morris AP, Evans MA, Burkhard M, Groshong RH Jr, Onasch CM (2004) Calcite twin morphology: a low-temperature deformation geothermometer. J Struct Geol 26(8):1521–1529. https://doi.org/10.1016/j.jsg.2003.11.028

Fredrich JT, Evans B, Wong TF (1989) Micromechanics of the brittle to plastic transition in Carrara marble. J Geophys Res Solid Earth 94(B4):4129–4145. https://doi.org/10.1029/JB094iB04p04129

Gautam PK, Verma AK, Jha MK, Sharma P, Singh TN (2018) Effect of high temperature on physical and mechanical properties of Jalore granite. J Appl Geophys 159:460–474. https://doi.org/10.1016/j.jappgeo.2018.07.018

Gibert B, Mainprice D (2009) Effect of crystal preferred orientations on the thermal diffusivity of quartz polycrystalline aggregates at high temperature. Tectonophysics 465(1–4):150–163. https://doi.org/10.1016/j.tecto.2008.11.006

Griggs D, TuRNER FJ, Borg I, Sosoka J (1951) Deformation of Yule marble: Part IV—effects at 150° C. Geol Soc Am Bull 62(12):1385–1406. https://doi.org/10.1130/0016-7606(1951)62[1385:DOYMPI]2.0.CO;2

Guo TY, Wong LNY, Wu Z (2021) Microcracking behavior transition in thermally treated granite under mode I loading. Eng Geol 282:105992. https://doi.org/10.1016/j.enggeo.2021.105992

Handin J, Hager RV Jr (1958) Experimental deformation of sedimentary rocks under confining pressure: tests at high temperature. AAPG Bull 42(12):2892–2934. https://doi.org/10.1306/5CEAE5FB-16BB-11D7-8645000102C1865D

Kumari WGP, Ranjith PG, Perera MSA, Shao S, Chen BK, Lashin A et al (2017) Mechanical behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: an application to geothermal energy extraction. Geothermics 65:44–59. https://doi.org/10.1016/j.geothermics.2016.07.002

Lei R, Wang Y, Zhang L, Liu B, Long K, Luo P, Wang Y (2019) The evolution of sandstone microstructure and mechanical properties with thermal damage. Energy Sci Eng 7(6):3058–3075. https://doi.org/10.1002/ese3.480

Ma X, Ma D, Hu D, Zhou H, Chen S, Yu Z, Tian X (2019) High-temperature of real-time true triaxial test system and its application. Chin J Rock Mech Eng 38(8):1605–1614 (In Chinese)

Ma X, Wang G, Hu D, Liu Y, Zhou H, Liu F (2020) Mechanical properties of granite under real-time high temperature and three-dimensional stress. Int J Rock Mech Min Sci 136:104521. https://doi.org/10.1016/j.ijrmms.2020.104521

Meng F, Wong LNY, Zhou H, Yu J, Cheng G (2019) Shear rate effects on the post-peak shear behaviour and acoustic emission characteristics of artificially split granite joints. Rock Mech Rock Eng 52(7):2155–2174. https://doi.org/10.1007/s00603-018-1722-8

Ozguven A, Ozcelik Y (2014) Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng Geol 183:127–136. https://doi.org/10.1016/j.enggeo.2014.10.006

Ranjith PG, Viete DR, Chen BJ, Perera MSA (2012) Transformation plasticity and the effect of temperature on the mechanical behaviour of Hawkesbury sandstone at atmospheric pressure. Eng Geol 151:120–127. https://doi.org/10.1016/j.enggeo.2012.09.007

Robertson EC (1988) Thermal properties of rocks. US Geological Survey

Rodriguez-Navarro C, Ruiz-Agudo E, Luque A, Rodriguez-Navarro AB, Ortega-Huertas M (2009) Thermal decomposition of calcite: Mechanisms of formation and textural evolution of CaO nanocrystals. Am Miner 94(4):578–593. https://doi.org/10.2138/am.2009.3021

Rybacki E, Evans B, Janssen C, Wirth R, Dresen G (2013) Influence of stress, temperature, and strain on calcite twins constrained by deformation experiments. Tectonophysics 601:20–36. https://doi.org/10.1016/j.tecto.2013.04.021

Samtani M, Dollimore D, Alexander KS (2002) Comparison of dolomite decomposition kinetics with related carbonates and the effect of procedural variables on its kinetic parameters. Thermochim Acta 392:135–145. https://doi.org/10.1016/S0040-6031(02)00094-1

Tullis J, Yund RA (1977) Experimental deformation of dry Westerly granite. J Geophys Res 82(36):5705–5718. https://doi.org/10.1029/JB082i036p05705

Vásárhelyi B, Ván P (2006) Influence of water content on the strength of rock. Eng Geol 84(1–2):70–74. https://doi.org/10.1016/j.enggeo.2005.11.011

Violay M, Gibert B, Mainprice D, Evans B, Dautria JM, Azais P, Pezard P (2012) An experimental study of the brittle-ductile transition of basalt at oceanic crust pressure and temperature conditions. J Geophys Res Solid Earth. https://doi.org/10.1029/2011JB008884

Wei S, Yang Y, Su C, Cardosh SR, Wang H (2019) Experimental study of the effect of high temperature on the mechanical properties of coarse sandstone. Appl Sci 9(12):2424. https://doi.org/10.3390/app9122424

Wong TF (1982) Effects of temperature and pressure on failure and post-failure behavior of Westerly granite. Mech Mater 1(1):3–17. https://doi.org/10.1016/0167-6636(82)90020-5

Wong LNY, Maruvanchery V, Liu G (2016) Water effects on rock strength and stiffness degradation. Acta Geotech 11(4):713–737. https://doi.org/10.1007/s11440-015-0407-7

Wong LNY, Zhang Y, Wu Z (2020) Rock strengthening or weakening upon heating in the mild temperature range? Eng Geol. https://doi.org/10.1016/j.enggeo.2020.105619

Wong LNY, Guo TY, Wu Z, Xiao X (2021) How do thermally induced microcracks alter microcracking mechanisms in Hong Kong granite? Eng Geol 292:106268. https://doi.org/10.1016/j.enggeo.2021.106268

Wong LNY, Zhang YH (2019) Numerical investigation of micromechanisms of thermal strengthening in rock. In: 53rd US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

Wu G, Wang Y, Swift G, Chen J (2013) Laboratory investigation of the effects of temperature on the mechanical properties of sandstone. Geotech Geol Eng 31(2):809–816. https://doi.org/10.1007/s10706-013-9614-x

Zhang L, Mao X, Li M, Li B, Liu R, Lu A (2020) Brittle-ductile transition of mudstone in coal measure rock strata under high temperature. Int J Geomech 20(1):04019149. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001549

Acknowledgements

We thank Professor Dawei Hu for providing us with access to the true triaxial compression apparatus. We thank Dr Xiao Ma and Mr Zhiwei Yu for the assistance in performing the triaxial compression tests, and Mr Tanzhuo Cheng for helping carry out the thermal treatment process. We acknowledge the support from National Natural Science Foundation of China under grant No. 41877217, General Research Fund of the Research Grants Council (Hong Kong) under grant No. 17200721 and Natural Science Foundation of Guangdong Province under grant No. 2019A1515010999. The Open Access charge of this paper is supported by the first grant mentioned above (No. 41877217). The second and third authors acknowledge the Postgraduate Scholarship from the University of Hong Kong.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wong, L.N.Y., Cui, X., Zhang, Y. et al. Experimental Investigation of Thermal Strengthening in Sichuan Marble. Rock Mech Rock Eng 55, 6683–6702 (2022). https://doi.org/10.1007/s00603-022-02995-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02995-5