Abstract

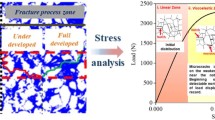

Understanding the inconsistent rock fracture toughness (KIc) measurement results from different test specimen geometries helps provide suitable fracture parameters for engineering applications, predict rock fracture load, and assess the safety of flawed rock engineering structures. In this study, fracture experiments using full- or half-disc specimens with chevron notches or straight-through notches were conducted. Experimental results show that the notch types and loading methods (Brazilian-type diametric compression and three-point bending) significantly affect the KIc measurements. It is indicated that only considering the T-stress or fracture process zone (FPZ) alone cannot explain the test results well, while a good agreement is found between the experimental results and the interpretation based on the combined effects of T-stress and FPZ. Moreover, Brazilian-type compression and three-point bending under a short support span can make the full- or half-disc specimens have higher negative T-stress and larger FPZ, thus producing lower KIc values than three-point bending under a relatively long support span. Compared with KIc measurements using the straight-through notch specimens, those utilizing the chevron-notched ones are less affected by FPZ and yield higher KIc results, providing that the loading method is the same. The notch types have little impact on the T-stresses of the specimens. This study sheds light on the combined influence of T-stress and FPZ on rock fracturing.

Similar content being viewed by others

Abbreviations

- a 0 :

-

Initial notch/crack length

- a c :

-

Critical crack length

- a e :

-

Effective crack length

- B :

-

Specimen thickness

- C :

-

Ratio of T-stress to stress intensity factor

- CCNBD:

-

Cracked chevron-notched Brazilian disc

- CNSCB:

-

Chevron-notched semi-circular bend

- D :

-

Specimen diameter

- E :

-

Young’s modulus

- FEM:

-

Finite element modeling

- FPZ:

-

Fracture process zone

- GMTSN:

-

Generalized maximum tangential strain

- H.O.T.:

-

Higher order terms

- ISRM:

-

International Society for Rock Mechanics

- K 0 :

-

Reference toughness (= 1 MPa·m0.5)

- K a :

-

Apparent fracture toughness

- K e :

-

Effective fracture toughness

- K I :

-

Mode I stress intensity factor

- K Ic :

-

Mode I fracture toughness

- \(K_{{{\text{Ic}}}}^{0}\) :

-

Fracture toughness corresponding to T = 0

- L CRL :

-

Critical residual ligament length

- L FPZ :

-

Fracture process zone length

- LEFM:

-

Linear elastic fracture mechanics

- NBD:

-

(Straight-through) notched Brazilian disc

- p, q :

-

Parameters related to Poisson's ratio and Young’s modulus

- P :

-

Load on specimen

- P max :

-

Maximum loading force

- r :

-

Distance to crack tip

- r c :

-

Critical distance to crack tip

- R :

-

Specimen radius

- \(R_{1}^{2}\) :

-

Coefficient of determination

- S :

-

Half of the support span in three-point bending tests

- SCB:

-

Semi-circular bend

- SIF:

-

Stress intensity factor

- T :

-

T-Stress

- T c :

-

T-stress at the onset of fracture

- ν :

-

Poisson’s ratio

- Y :

-

Non-dimensional stress intensity factors

- Y * :

-

Normalized non-dimensional stress intensity factors

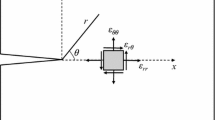

- \(\varepsilon _{{\varphi \varphi }}\) :

-

Tangential strain

- η :

-

Ratio of tensile strength to apparent fracture toughness

- α:

-

Normalized crack length

- α0 :

-

Normalized initial notch length

- α1 :

-

Normalized final notch length

- αB :

-

Normalized specimen thickness

- αc :

-

Normalized critical crack length

- αS :

-

Normalized saw radius

- κ:

-

Ratio between apparent and effective fracture toughness

- ρ:

-

Ratio of tensile strength to effective fracture toughness

- σ 0 :

-

Reference strength (= 1 MPa)

- σ t :

-

Tensile strength

References

Akbardoost J, Ayatollahi MR (2014) Experimental analysis of mixed mode crack propagation in brittle rocks: the effect of non-singular terms. Eng Fract Mech 129:77–89

Akbardoost J, Ayatollahi MR, Aliha MRM, Pavier MJ, Smith DJ (2014) Size-dependent fracture behavior of Guiting limestone under mixed mode loading. Int J Rock Mech Min Sci 71:369–380

Aliha MRM, Ayatollahi MR (2013) Two-parameter fracture analysis of SCB rock specimen under mixed mode loading. Eng Fract Mech 103:115–123

Aliha MRM, Bahmani A (2017) Rock fracture toughness study under mixed mode I/III loading. Rock Mech Rock Eng 50(7):1739–1751

Aliha MRM, Mousavi SS (2020) Sub-sized short bend beam configuration for the study of mixed-mode fracture. Eng Fract Mech 225:106830

Aliha MRM, Ayatollahi MR, Akbardoost J (2012) Typical upper bound-lower bound mixed mode fracture resistance envelopes for rock material. Rock Mech Rock Eng 45(1):65–74

Aliha MRM, Hosseinpour GR, Ayatollahi MR (2013) Application of cracked triangular specimen subjected to three-point bending for investigating fracture behavior of rock materials. Rock Mech Rock Eng 46(5):1023–1034

Aliha MRM, Mahdavi E, Ayatollahi MR (2016) The influence of specimen type on tensile fracture toughness of rock materials. Pure Appl Geophys 3(174):1237–1253

Aliha MRM, Berto F, Mousavi A, Razavi SMJ (2017) On the applicability of ASED criterion for predicting mixed mode I+II fracture toughness results of a rock material. Theor Appl Fract Mech 92:198–204

Aliha MRM, Mahdavi E, Ayatollahi MR (2018) Statistical analysis of rock fracture toughness data obtained from different chevron notched and straight cracked mode I specimens. Rock Mech Rock Eng 51:2095–2114

Aliha MRM, Mousavi SS, Ghoreishi SMN (2019) Fracture load prediction under mixed mode I+II using a stress based method for brittle materials tested with the asymmetric four-point bend specimen. Theor Appl Fract Mech 103:102249

Al-Shayea NA (2005) Crack propagation trajectories for rocks under mixed mode I-II fracture. Eng Geol 81:84–97

Amrollahi H, Baghbanan A, Hashemolhosseini H (2011) Measuring fracture toughness of crystalline marbles under modes I and II and mixed mode I-II loading conditions using CCNBD and HCCD specimens. Int J Rock Mech Min Sci 48:1123–1134

ASTM E561 (1987) Annual book of ASTM standards. Metal test methods and analytical procedure. ASTM Publication, Philadephia

Atkinson BK (1987) Fracture mechanics of rock. Academic Press, Elsevier

Ayatollahi MR, Abbasi H (2001) Prediction of fracture using a strain based mechanism of crack growth. Build Res J 49(3):167–180

Ayatollahi MR, Akbardoost J (2014) Size and geometry effects on rock fracture toughness: mode I fracture. Rock Mech Rock Eng 47:677–687

Ayatollahi MR, Aliha MRM (2005) Cracked Brazilian disc specimen subjected to mode II deformation. Eng Fract Mech 72(4):493–503

Ayatollahi MR, Sedighiani K (2012) Mode I fracture initiation in limestone by strain energy density criterion. Theor Appl Fract Mech 57(1):14–18

Ayatollahi MR, Mahdavi E, Alborzi MJ, Obara Y (2016a) Stress intensity factors of semi-circular bend specimens with straight-through and chevron notches. Rock Mech Rock Eng 49(4):1161–1172

Ayatollahi MR, Moghaddam MR, Razavi SMJ, Berto F (2016b) Geometry effects on fracture trajectory of PMMA samples under pure mode-I loading. Eng Fract Mech 163:449–461

Ayatollahi MR, Bahrami B, Mirzaeil AM, Yazid Yahyab M (2019) Effects of support friction on mode I stress intensity factor and fracture toughness in SENB testing. Theor Appl Fract Mech 103(10):102288

Bahmani A, Nemati S (2021) Fracture resistance of railway ballast rock under tensile and tear loads. Eng Solid Mech 9(3):271–280

Bahmani A, Farahmand F, Janbaz MR, Darbandi AH, Ghesmati-Kucheki H, Aliha MRM (2021) On the comparison of two mixed-mode I + III fracture test specimens. Eng Fract Mech 241:107434

Barsoum RS (1977) Triangular quarter-point elements as elastic and perfectly-plastic crack tip elements. Int J Numer Meth Eng 11(1):85–98

Bažant ZP, Kazemi MT (1990) Determination of fracture energy, process zone length and brittleness number from size effect, with application to rock and concrete. Int J Fract 44(2):111–131

Bidadi J, Akbardoost J, Aliha MRM (2020) Thickness effect on the mode III fracture resistance and fracture path of rock using ENDB specimens. Fatigue Fract Eng Mater Struct 43:277–291

Chang SH, Lee CI, Jeon S (2002) Measurement of rock fracture toughness under modes I and II and mixed-mode conditions by using disc-type specimens. Eng Geol 66(1):79–97

Chen CH, Chen CS, Wu JH (2008) Fracture toughness analysis on cracked ring disks of anisotropic rock. Rock Mech Rock Eng 41(4):539–562

Chong KP, Kuruppu MD (1984) New specimen for fracture toughness determination for rock and other materials. Int J Fract 26(2):59–62

Chong KP, Kuruppu MD, Kuszmaul JS (1987) Fracture toughness determination of layered materials. Eng Fract Mech 28:43–54

Cui ZD, Liu DA, An GM, Sun B, Zhou M, Cao FQ (2010) A comparison of two ISRM suggested chevron notched specimens for testing mode-I rock fracture toughness. Int J Rock Mech Min Sci 47:871–876

Dwivedi RD, Soni AK, Goel RK, Dube AK (2000) Fracture toughness of rocks under sub-zero temperature conditions. Int J Rock Mech Min Sci 37:1267–1275

Erarslan N (2013) A study on the evaluation of the fracture process zone in CCNBD rock samples. Exp Mech 53:1475–1489

Fan H, Zhang S, Wang Q (2010) Determination of dynamic initiate toughness of concrete using cracked straight-through flattened Brazilian disc. Shuili Xuebao 41(10):1234–1240

Fayed AS (2018) Numerical evaluation of mode I/II SIF of quasi-brittle materials using cracked semi-circular bend specimen. Eng Solid Mech 6(2):175–186

Fowell RJ (1995) ISRM commission on testing methods. Suggested method for determining mode I fracture toughness using cracked chevron notched Brazilian disc (CCNBD) specimens. Int J Rock Mech Min Sci Geomech Abstr 32(1):57–64

Funatsu T, Kuruppu MD, Matsui K (2014) Effects of temperature and confining pressure on mixed-mode (I–II) and mode II fracture toughness of Kimachi sandstone. Int J Rock Mech Min Sci 67:1–8

Funatsu T, Shimizu N, Kuruppu M, Matsui K (2015) Evaluation of mode I fracture toughness assisted by the numerical determination of K-resistance. Rock Mech Rock Eng 48:143–157

Ghouli S, Ayatollahi MR, Bushroa AR (2018) Fracture characterization of ceria partially stabilized zirconia using the GMTSN criterion. Eng Fract Mech 199:647–657

Haeri H, Sarfarazi V, Yazdani M, Shemirani AB, Hedayat A (2018) Experimental and numerical investigation of the center-cracked horseshoe disk method for determining the mode I fracture toughness of rock-like material. Rock Mech Rock Eng 51(1):173–185

Hu X, Duan K (2008) Size effect and quasi-brittle fracture: the role of FPZ. Int J Fract 154(1):3–14

Huang RQ, Wu LZ, He Q, Li JH (2017) Stress intensity factor analysis and the stability of overhanging rock. Rock Mech Rock Eng 50:2135–2142

Iqbal MJ, Mohanty B (2006) Experimental calibration of stress intensity factors of the ISRM suggested cracked chevron-notched Brazilian disc specimen used for determination of mode-I fracture toughness. Int J Rock Mech Min Sci 43:1270–1276

Irwin GR (1948) Fracture dynamics. Fracturing of metals. American Society of Metals, Cleveland, pp 147–166

Jenkins MG, Kobayashi AS, White KW, Bradt RC (1987) A 3-D finite element analysis of a chevron-notched, three-point bend fracture specimen for ceramic materials. Int J Fract 34:281–295

Keles C, Tutluoglu L (2011) Investigation of proper specimen geometry for mode I fracture toughness testing with flattened Brazilian disc method. Int J Fract 169(1):61–75

Khan K, Al-Shayea NA (2000) Effect of specimen geometry and testing method on mixed mode I-II fracture toughness of a limestone rock from Saudi Arabia. Rock Mech Rock Eng 33(3):179–206

Kuruppu MD (1997) Fracture toughness measurement using chevron notched semi-circular bend specimen. Int J Fract 86(4):33–38

Kuruppu MD, Chong KP (2012) Fracture toughness testing of brittle materials using semi-circular bend (SCB) specimen. Eng Fract Mech 91:133–150

Kuruppu MD, Obara Y, Ayatollahi MR, Chong KP, Funatsu T (2014) ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen. Rock Mech Rock Eng 47:267–274

Labuz JF, Shah SP, Dowding CH (1985a) Fracture analysis of subsize, charcoal granite specimens. Int J Rock Mech Min Sci Geomech Abstr 22(6):192–193

Labuz JF, Shah SP, Dowding CH (1985b) Experimental analysis of crack propagation in granite. Int J Rock Mech Min Sci Geomech Abstr 22(2):85–98

Labuz JF, Shah SP, Dowding CH (1987) The fracture process zone in granite: evidence and effect. Int J Rock Mech Min Sci Geomech Abstr 24(4):235–246

Labuz JF, Shah SP, Dowding CH (1989) Measurement and description of tensile fracture in granite. J Eng Mech 115(9):1935–1949

Labuz JF, Chen CN, Berger DJ (1991) Microcrack-dependent fracture of damaged rock. Int J Fract 51(3):231–240

Mahdavi E, Obara Y, Ayatollahi M (2015) Numerical investigation of stress intensity factor for semi-circular bend specimen with chevron notch. Eng Solid Mech 3(4):235–244

Mahdavi E, Aliha MRM, Bahrami B, Ayatollahi MR (2020) Comprehensive data for stress intensity factor and critical crack length in chevron notched semi-circular bend specimen subjected to tensile type fracture mode. Theor Appl Fract Mech 106:102466

Mirsayar MM (2014) A new mixed mode fracture test specimen covering positive and negative values of T-stress. Eng Solid Mech 2(2):67–72

Mirsayar MM (2015) Mixed mode fracture analysis using extended maximum tangential strain criterion. Mater Des 86:941–947

Mirsayar MM (2017) On the low temperature mixed mode fracture analysis of asphalt binder—theories and experiments. Eng Fract Mech 186:181–194

Mirsayar MM (2018) On fracture analysis of dental restorative materials under combined tensile-shear. Theor Appl Fract Mech 93:170–176

Mirsayar MM, Razmi A, Aliha MRM, Berto F (2018a) EMTSN criterion for evaluating mixed mode I/II crack propagation in rock materials. Eng Fract Mech 190:186–197

Mirsayar MM, Razmi A, Berto F (2018b) Tangential strain-based criteria for mixed-mode I/II fracture toughness of cement concrete. Fatigue Fract Eng Mater Struct 41:129–137

Ouchterlony F (1982) A review of fracture toughness testing of rocks. Solid Mech Arch 7:131–211

Ouchterlony F (1988) ISRM commission on testing methods. Suggested methods for determining fracture toughness of rock. Int J Rock Mech Min Sci Geomech Abstr 25:71–96

Razavi SMJ, Aliha MRM, Berto F (2018) Application of an average strain energy density criterion to obtain the mixed mode fracture load of granite rock tested with the cracked asymmetric four-point bend specimens. Theor Appl Fract Mech 97:419–425

Rossmanith HP (1983) Rock fracture mechanics. Springer, Berlin

Schmidt RA (1980) A microcrack model and its significance to hydraulic fracturing and fracture toughness testing. In: Proceedings of the 21st U.S. symposium on rock mechanics (USRMS), Rolla, MO, USA, May, pp 581–590

Shannon JL, Bubsey RT, Pierce WS, Munz D (1982) Extended range stress intensity factor expressions for chevron-notched short bar and short rod fracture toughness specimens. Int J Fract 19(3):55–58

Sheity DK, Rosenfield AR, Duckworth WH (1985) Fracture toughness of ceramics measured by a chevron-notch diametral-compression test. J Am Ceram Soc 68(12):325–327

Tutluoglu L, Keles C (2011) Mode I fracture toughness determination with straight notched disk bending method. Int J Rock Mech Min Sci 48(8):1248–1261

Tutluoglu L, Keles C (2012) Effects of geometric factors on mode I fracture toughness for modified ring tests. Int J Rock Mech Min Sci 51:149–161

Wang QZ, Fan H, Gou XP, Zhang S (2013) Recalibration and clarification of the formula applied to the ISRM-suggested CCNBD specimens for testing rock fracture toughness. Rock Mech Rock Eng 46(2):303–313

Wei MD, Dai F, Xu NW, Xu Y, Xia K (2015) Three-dimensional numerical evaluation of the progressive fracture mechanism of cracked chevron notched semi-circular bend rock specimens. Eng Fract Mech 134:286–303

Wei MD, Dai F, Xu NW, Liu JF, Xu Y (2016a) Experimental and numerical study on the cracked chevron notched semi-circular bend method for characterizing the mode I fracture toughness of rocks. Rock Mech Rock Eng 49:1595–1609

Wei MD, Dai F, Xu NW, Zhao T (2016b) Stress intensity factors and fracture process zones of ISRM-suggested chevron notched specimens for mode I fracture toughness testing of rocks. Eng Fract Mech 168:174–189

Wei MD, Dai F, Xu NW, Liu Y, Zhao T (2017) Fracture prediction of rocks under mode I and mode II loading using the generalized maximum tangential strain criterion. Eng Fract Mech 186:21–38

Wei MD, Dai F, Xu NW, Zhao T (2018a) Experimental and numerical investigation of cracked chevron notched Brazilian disc specimen for fracture toughness testing of rock. Fatigue Fract Eng Mater Struct 41(1):197–211

Wei MD, Dai F, Xu NW, Liu Y, Zhao T (2018b) A novel chevron notched short rod bend method for measuring the mode I fracture toughness of rocks. Eng Fract Mech 190:1–15

Wei MD, Dai F, Zhou JW, Liu Y, Luo J (2018c) A further improved maximum tangential stress criterion for assessing mode I fracture of rocks considering non-singular stress terms of the Williams expansion. Rock Mech Rock Eng 51:3471–3488

Wong LNY, Guo TY (2019) Microcracking behavior of two semi-circular bend specimens in mode I fracture toughness test of granite. Eng Fract Mech 221:106565

Wu LZ, Wang QZ, Jia XM (2004) Determination of mode-i rock fracture toughness with cracked chevron notched Brazilian disc (CCNBD) and application of size effect law. Chin J Rock Mechan Eng 23(3):383–390

Xu Y, Dai F, Xu N, Zhao T (2016a) Numerical investigation of dynamic rock fracture toughness determination using a semi-circular bend specimen in split Hopkinson pressure bar testing. Rock Mech Rock Eng 49:731–745

Xu Y, Dai F, Zhao T, Xu N, Liu Y (2016b) Fracture toughness determination of cracked chevron notched Brazilian disc rock specimen via Griffith energy criterion incorporating realistic fracture profiles. Rock Mech Rock Eng 49(8):3083–3093

Xu S, Malik MA, Li Q, Wu Y (2016c) Determination of double-K fracture parameters using semi-circular bend test specimens. Eng Fract Mech 152:58–71

Yin X, Yan Y, Li H, Liao Y, Wu J, Shi Y (1990) Experimental investigation on the measurement of fracture toughness KIc of rocks using different methods. Chin J Rock Mechan Eng 4:328–333

Zhang ZX (2002) An empirical relation between mode I fracture toughness and the tensile strength of rock. Int J Rock Mech Min Sci 39:401–406

Zhang S, Wang QZ (2009) Determination of rock fracture toughness by split test using five types of disc specimens. Rock Soil Mech 30(1):12–18

Zhang CG, Zhou Y, Yang JR, Wang QZ (2014) A series of edge cracked flattened ring(disc) specimens for determining fracture toughness: numerical analysis and calibration results. Chin J Rock Mechan Eng 33(8):1546–1555

Zhou YX, Xia K, Li XB, Li HB, Ma GW, Zhao J, Zhou ZL, Dai F (2012) Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials. Int J Rock Mech Min Sci 49:105–112

Acknowledgements

The authors thank the financial support from the National Natural Science Foundation of China (Nos. 52039007, 52009086, and 52009002), the Youth Science and Technology Innovation Research Team Fund of Sichuan Province (2020JDTD0001) and the State Key Laboratory of Hydraulics and Mountain River Engineering, China (No. SKHL2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, M., Dai, F., Liu, Y. et al. Influences of Loading Method and Notch Type on Rock Fracture Toughness Measurements: From the Perspectives of T-Stress and Fracture Process Zone. Rock Mech Rock Eng 54, 4965–4986 (2021). https://doi.org/10.1007/s00603-021-02541-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-021-02541-9