Abstract

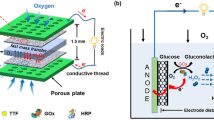

A micro-fluidic channel plate for self-pumping glucose oxidase enzymatic fuel cell is designed and fabricated. The fuel is driven into the fuel cell using capillary force without any extra pump. The fuel cell structure design includes both end plates and micro-fluidic flow channel plate. Three reservoirs are fabricated into the end plate. According to the experimental analysis the cathode and anode flow rate are less than ideal flow rate. The anode and cathode flow rate are 0.499 and 0.764 μl s−1, respectively. The capillary driven liquid efficiency of anode and cathode flow field are 36 and 53 %, respectively. The Tafel test result for self-pumping fluid enzymatic fuel cell achieves a power output 0.534 mW cm−2 (111.217 mW cm−3). Compared to the active pumping method, the passive (self-pumping) method shows lower output power. However, the current output performance from long term experiments at a constant voltage of 0.42 V indicated that the self-pumping fluid enzymatic fuel cell may work stably under a continuous fuel supply. It provides a bio-pumping power solution source different from current power generators.

Similar content being viewed by others

References

Barton SC, Gallaway J, Atanassov P (2004) Enzymatic biofuel cells for implantable and microscale devices. Chem Rev 104:4867–4886

Chen CH, Jung SP, Yen SC (2007) Flow distribution in the manifold of PEM fuel cell stack. J Power Sources 173:249–263

Choi J, Liu Y (2014) Power generation and oil sands process-affected water treatment in microbial fuel cells. Bioresour Technol 169:581–587

Fang W-T (2013) Circulatory system investigation of enzymatic bio-fuel cells. Master’s thesis of National Chung Hsing University

Ghayor R, Shakeri M, Sedighi K, Farhadi M (2010) Experimental and numerical investigation on passive and active μDMFC. Int J Hydrogen Energy 35:9329–9337

Hecht J, Kalisz HM, Hendle J, Schmid RD, Schomburg D (1993) Crystal-structure of glucose-oxidase from Aspergillus-niger refined at 2.3 angstrom resolution. J Mol Biol 229:153–172

Huang WF, Liu QS, Li Y (2006) Capillary filling flows inside patterned-surface microchannels. Chem Eng Technol 29:716–723

Karmali A, Oliveira P (1999) Glucose 1- and 2-oxidases from fungal strains: isolation and production of monoclonal antibodies. J Biotechnol 69:151–162

Kim KN, Jeon DH, Nam JH (2012) Numerical study of straight-parallel PEM fuel cells at automotive operation. Int Hydrogen Energy 37:9212–9227

Lai CC, Chung CK (2013) Numerical simulation of the capillary flow in the meander microchannel. Microsyst Technol 19:379–386

Nguyen NT, Chan SH (2006) Micromachined polymer electrolyte membrane and direct methanol fuel cells—a review. J Micromech Microeng 173:R1–R12

Qain F, He Z, Thelen MP, Li Y (2011) A microfluidic microbial fuel cell fabricated by soft lithography. Bioresour Technol 102:5836–5840

Ren H, Lee HS, Chae J (2012) Miniaturizing microbial fuel cells for potential portable power sources: promises and challenges. Microfluid Nanofluid 13:353–381

Yang H, Zhao TS (2005) Effect of anode flow field design on the performance of liquid feed direct methanol fuel cells. Electrochim Acta 50:3243–3252

Zhang G, Sun S, Yang D, Dodelet JP, Sacher E (2008) The surface analytical characterization of carbon fibers functionalized by H2SO4/HNO3 treatment. Carbon 46:196–205

Zhang W, Hu P, Lai X, Peng L (2009) Analysis and optimization of flow distribution in parallel-channel configurations for proton exchange membrane fuel cells. J Power Sources 194:931–940

Acknowledgments

This work was supported by by the Ministry of Science and Technology of Taiwan (Grant No. MOST 103-2221-E-005-087).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, YF., Shieh, CJ. & Yang, H. Capillary force pumping fluid for glucose oxidase enzymatic fuel cells. Microsyst Technol 23, 3927–3935 (2017). https://doi.org/10.1007/s00542-015-2728-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2728-8