Abstract

In industrial applications, three-phase induction motors (IMs) are widely used, and they are subjected to many types of faults. One such fault is the loss of a motor phase caused by a blown fuse, a broken wire, mechanical damage, etc. When this fault occurs during motor operation, it continues to rotate but experiences rapid heating, which can ultimately lead to motor failure. Therefore, various protection devices are available to protect the motor against this fault, but most traditional protection devices do not offer a comprehensive classification of such a fault. So, in this paper, an efficient neural network model is presented for detecting and classifying 12 types of phase loss faults for a three-phase induction motor (IM) based on factors such as the unhealthy phase, fault location, and motor action modes (standstill, transient, and steady-state modes). Thus, the main goal of this work is to determine the motor mode during the fault, the defective phase, and its location to help the maintenance team repair the fault quickly. The system is simulated and tested using the “MATLAB/Simulink” software, employing a feed-forward neural network. The simulation results demonstrate that the proposed network achieves correct detection and classification of phase loss faults within a short time frame from the occurrence of the fault. Therefore, the proposed network model proves to be a simple and reliable solution for integration into the protection system of a three-phase IM, enabling the detection and classification of various phase loss faults.

Similar content being viewed by others

1 Introduction

Monitoring the condition and identifying faults of electric machines is extremely important in companies and industries due to several advantages, such as reducing downtime, improving the performance of equipment, reducing the costs of maintenance, increasing the accuracy of failure prediction, increasing machine dependability, and decreasing energy waste [1]. Among these electrical machines, the three-phase induction motor (IM) is most widely used in many different industrial processes because it has many advantages, such as reliability, low maintenance, durability in hostile environments, and quick adaptation to different loading conditions [2,3,4]. Despite the advantages of the three-phase IM, it is subjected to many different electrical and mechanical failures, as mentioned and briefly described in Table 1 [1, 5,6,7,8,9,10]. Electrical faults such as low voltage, over-voltage, unbalanced voltages, and phase loss cause changes in the current drawn, and short-circuit faults can cause the current to increase to levels that can damage the motor windings. Mechanical faults like locked rotor, bearing failure, and momentary or prolonged overloads also cause the motor to draw more current, which causes overheating [11].

Approximately 45% of three-phase motor faults are due to overload/overcurrent and single phasing [11, 12]. Single phasing, also known as open phase, phase failure, or phase loss, is one of the most common faults of industrial and commercial electrical drives [13]. There are many possible causes for this type of fault, including fuse blowing, damaged or broken wires, open switches, eroded or oxidized contacts, mechanical damage, melted conductors, etc. [14,15,16,17].

When a three-phase motor starts with only two phases, missing the third one, it cannot rotate because of the absence of starting torque, but it produces a humming sound [17]. If the motor loses one phase while rotating, it will continue rotation by drawing enough current from the other two healthy phases to drive the load if it is not tripped by the protection device against single phasing [14, 17, 18]. If phase loss occurs for a running 3-phase IM, it does not instantly cause any damage or failure, but if it is not recognized, it may force equipment to run under stress and cause overheating, which can burn the motor windings [16, 19].

When an IM loses one phase, it is subjected to the worst possible voltage imbalance, causing the motor to draw more current and suffer asymmetrical losses [11]. Some researchers studied the effect of voltage imbalances on motor drives and found that as small as 3% of voltage imbalances could increase motor temperature by up to 25% [20, 21]. For a fully loaded motor, phase current unbalance is 6–10 times the percentage of voltage unbalance at the motor’s terminals [15, 22]. However, single phasing causes a significant distortion of the voltage unbalance [14].

Also, the phase loss fault supplies motors with negative-sequence currents, which create parasitic magnetic fields, leading to a torque reduction [20]. The stator windings are also subjected to thermal overload, which leads to insulation damage [11, 17]. According to leading standard organizations, insulation failure accounts for 30% of IM failures, while overheating accounts for 60% [23]. Consequently, phase loss in a three-phase induction motor can have severe consequences and must be addressed promptly to ensure the motor’s proper operation [11, 24].

Most of the protection devices for motors that are commonly used, such as thermal overload relays or circuit breakers, are not designed to detect single-phasing faults [18]. Under single-phase conditions, the phase current of lightly loaded three-phase IM (70% of the full-load current) rises by the square root of three (√3). Because of this, the amount of current drawn will be roughly 20% higher than the value indicated on its nameplate for full-load current. If the overload protection is sized at 125% of the motor’s nameplate, the motor can still be damaged by circulating currents [16, 18]. Therefore, different protection devices are designed to protect the 3-ph motor from open-phase failure. The most widely used hardware to protect against single phasing in the low and intermediate power levels of electrical drives is the three-phase monitor relay, also known as a phase failure relay [13, 20]. This relay shuts down the protected equipment in the event of an error and could alert the monitoring system. Other devices to protect the motor against this type of fault have been discussed and studied in detail in [11, 13].

In [25], the authors suggest using an additional neutral wire as a simple solution for operating the open-phase induction motor. They discovered that neutral conductors enhance motor torque and reduce motor temperature when there is a loss of phase. In addition, if a motor drive uses a neutral wire topology, it is preferable to use fault-tolerant control, as described in [26], which gives greater reliability and flexibility. However, while protecting this way is simple, it complicates the system, expands the space used, and increases the total cost of the drive. So, many engineers have developed software algorithms for the IM fault detection of phase loss that enable appropriate actions to be taken to prevent more serious failures [13].

The phase loss detection algorithms are crucial for all drives, not just conventional drives [27,28,29,30,31,32,33,34]. These drives are becoming increasingly common in applications, particularly where a drive failure could result in significant damage or have dramatic consequences [35]. These applications include drives used in military applications, electric vehicles, aircraft, and ship electrical equipment, especially propulsion systems, and the chemical and nuclear industries, to name a few [13]. All of these fault-tolerant drives use various approaches to improve reliability. Still, they all use the same fault processing algorithms, which include three steps: fault identification, separation of the faulty part, and implementation of the new control method [36, 37]. As can be seen, all drives must have the loss of phase detection method because it is one of the most important algorithms used to identify drive faults.

Modern trends in motor protection are indeed moving toward the use of microprocessor-based relays. These relays, commonly known as digital or numerical relays, offer several advantages over traditional electromechanical or static relays [38,39,40,41]. The best techniques used in motor protection schemes are artificial intelligence (AI)-based techniques due to their higher reliability and cost-effectiveness [42, 43]. Machine learning, neural networks, fuzzy logic, genetic algorithms, and hybrid algorithms are examples of AI-based fault classification techniques that can address issues that cannot be solved by the traditional methods of fault diagnosis [44, 45]. Several studies have been done on the topic of protection against single phasing [46,47,48,49,50,51,52,53,54,55,56].

All algorithms used in motor protection schemes against phase loss faults can be categorized into slow and fast methods according to the duration of fault detection from the time of its occurrence. It is well known that fast phase loss detection is the best method, but it is not easy in many systems due to several factors, such as high signal noise and distorted input voltage [13]. Artificial neural networks (ANNs) are one of the important techniques widely used in the protection algorithms of 3-ph IM due to their ability to learn complex patterns and adapt to diverse operating conditions [4, 45]. Therefore, the proposed system is designed based on a neural network to detect the types of phase loss faults for 3-ph IM.

The researchers were interested in presenting several techniques for detecting motor faults, but most do not give a detailed classification of single-phase faults. Therefore, the main objective of this work was to design an efficient neural network model to detect and provide a detailed classification of that type of fault. Thus, this detailed classification determines the motor mode during the fault occurrence and knows the unhealthy phase and its location to help the maintenance team repair the fault quickly after its occurrence. Consequently, the proposed method in this paper is designed to detect and classify 12 types of phase loss faults in a three-phase IM. These faults are classified according to the defective phase, fault location from the power source or after the relay point, and motor action modes (standstill mode, transient mode, and steady-state mode). When the motor is in standstill mode, detection of the loss of one of the phases from the power source is important to avoid starting the motor with only two phases, which causes high currents to pass through the other two healthy phases. Thus, the proposed scheme can be implemented using ANN as a simple and reliable solution for integration into the protection system of three-phase IM to detect and classify various phase loss faults in standstill, transient, and steady-state modes.

From an economic standpoint, the proposed system is considered more effective and acceptable compared to traditional protection systems in detecting and diagnosing this fault. It can be applied to most motors, whether large or small. However, the economic return on reducing downtime, predicting motor failures, and reducing maintenance costs will be more beneficial for larger motors.

2 System description

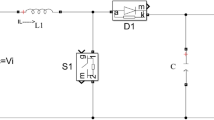

The studied system model is shown in Fig. 1. This system consists of seven main parts, which are the power source, motor, breaker, measurement unit, speed sensor, cables, and protective relay using ANN. The unit of measurement is used to step down the voltages and line currents of the 3-phase motor in order to be compatible with the protective relay based on ANN.

The phase loss fault and its types included in this research can be illustrated in Fig. 1. Phase loss fault means the loss of one of the phases of A, B, or C from the source (location 1 in Fig. 1) or after relay location (location 2 in Fig. 1). In all cases, phase loss problems can occur when the motor is running in steady-state mode or standstill mode. A loss of phase in the case of the motor running in a steady state should be detected and the motor disconnected by a breaker; otherwise, it will overheat. When the motor is in standstill mode, detection of the loss of one of the phases from the power source is important to avoid starting the motor with only two phases, which causes high currents to pass through the other two healthy phases. Also, when the motor is in standstill mode, the loss of one of the phases after the relay location must be detected in the transient mode as soon as the motor is running from standstill mode without rotation. So, the proposed method accurately identifies and categorizes 12 types of phase loss faults based on factors such as the unhealthy phase, fault location, and motor action modes (standstill, transient, and steady state) as follows:

-

Loss of phase “A” from the source side when the motor is running in steady-state mode.

-

Loss of phase “B” from the source side when the motor is running in steady-state mode.

-

Loss of phase “C” from the source side when the motor is running in steady-state mode.

-

Loss of phase “A” after the relay point when the motor is running in steady-state mode. (A phase loss fault occurs in the motor winding or in the cable between the relay and the motor).

-

Loss of phase “B” after the relay point when the motor is running in steady-state mode.

-

Loss of phase “C” after the relay point when the motor is running in steady-state mode.

-

Loss of phase “A” after the relay point when the motor starts in transient mode without rotation.

-

Loss of phase “B” after the relay point when the motor starts in transient mode without rotation.

-

Loss of phase “C” after the relay point when the motor starts in transient mode without rotation.

-

Loss of phase “A” from the source side when the motor is in standstill mode.

-

Loss of phase “B” from the source side when the motor is in standstill mode.

-

Loss of phase “C” from the source side when the motor is in standstill mode.

The inputs to the ANN in the proposed scheme are the RMS values of voltages, line currents, and motor speed. The ANN outputs are called A, B, C, and T. In the normal case, without any fault, all outputs of the NN are equal to zero. The first three outputs express the missing phase, each equal to the value one according to the faulty phase. The last output represents the fault type according to the motor mode.

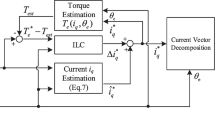

3 Methodology

The design stages of the proposed method for the detection and classification of phase loss faults for a three-phase IM using a feed-forward neural network consist of five main processes as follows:

-

Motor model development

-

Fault pattern generation and preprocessing

-

Selecting the structure of ANN

-

Training of ANN-based detector and classifier

-

The ANN performance assessment

Figure 2 shows the stages or processes of this research work for detecting and classifying the phase loss faults for a three-phase induction motor using a feed-forward neural network. These stages or processes are explained in detail in Subsect. 3.1, 3.2, 3.3, 3.4, and Sect. 4.

3.1 Model development

In this research, the studied system model, which includes a three-phase induction motor, has been built using MATLAB/Simulink software. The model is employed as a simulation platform to simulate the motor’s performance under various types of phase loss faults. The study is carried out on a model of the three-phase motor models found in the MATLAB Simulink environment. The research is based on a three-phase squirrel cage IM, 400 V, 15 kW (20 HP), 1460 rpm, 50 Hz, with star-connected windings. The data of a three-phase motor used in the simulation of MATLAB /Simulink, such as the values of stator and rotor resistances and stator and rotor inductances, are given in Table 2.

Figure 3 shows the diagram of the system under study in MATLAB/Simulink, which consists of many different types of blocks described as follows:

-

Block No. 1 is called a “three-phase programmable voltage source,” which is used to simulate the power supply of a three-phase motor and feed it at 400 volts and a frequency of 50 Hz.

-

Block No. 2 is called an “asynchronous machine,” which is used to simulate the 3-ph motor.

-

Block No. 3 is called a “three-phase breaker,” which is used to turn and stop the 3-ph motor.

-

Block No. 4 is called a “three-phase V–I measurement,” which is used to measure the voltages of the motor before the three-phase breaker of the motor.

-

Block No. 5 is called a “three-phase V–I measurement,” which is used to measure the motor line currents after the three-phase breaker of the motor.

-

Block No. 6 is called a “breaker,” which is used to simulate the phase loss fault from the power source in each phase by using one for each phase.

-

Block No. 7 is also called a “breaker,” and it is used to simulate the phase loss fault after the relay point for each phase by using one for each phase (i.e., the simulation of a phase loss fault occurs in the motor winding, or in the cable between the relay point and the motor, or if there is a problem with the connection box of motor, due to a misconnection one of the 3 phases).

-

Block No. 8 is called “subsystem 1,” which is designed for two reasons: the first is to run the motor with different loads as a percentage of the full load, and the other is to block the rotor of the motor when it starts under a phase loss failure.

-

Block No. 9 is called “subsystem 2,” which is designed to simulate a phase loss failure from the power source when the “three-phase breaker” is disconnected and the motor is not running. When one of the phases is lost from the source while the “three-phase breaker” is disconnected, there is a voltage in the simulation system on the end of the breaker even for the separated phase, unlike what happens in reality. The reason for this is that the loss of one of the phases in the simulation is considered a large resistance, and therefore, there will be a voltage on the end of the breaker. Therefore, block number 9 was designed to eliminate this problem when simulating this case.

-

Block No. 10 is called “subsystem 3,” which includes the blocks of the proposed method using the NN for detection and classification of phase loss faults for the three-phase motor.

-

Block No. 11 is known as “subsystem 4,” and it includes scopes for displaying all the results.

3.2 Fault patterns generation and preprocessing

This section includes the second process shown in Fig. 2. Preprocessing is a valuable technique that considerably reduces the size of the NN and increases the performance and speed of training process. After designing the proposed system in MATLAB/Simulink as previously described in Sect. 2, a simulation will be made to collect the data required to train the proposed NN. The input signals for NN were sampled at a sampling frequency of 1 kHz. The data collected during the simulation process are the RMS values of line-line voltages, line currents, and the motor speed in RPM. These measured values will be used as inputs to the NN. The simulation process will be done to collect data when the motor is operating normally and when it experiences a loss of one of the three phases while the motor is running in transient mode or steady-state mode. In addition, data are collected when one of the phases of the source is lost while the motor is stopped in order to prevent the motor from operating in this situation. For each simulated fault case, 20 samples were collected after one cycle from the fault’s inception in order to generate a training data set for the NN.

Normal operation data sets (patterns) for an induction motor are collected at the rated load torque and some other normal variant loading conditions. Also, the fault patterns for phase loss failure while the motor is running are obtained at different load conditions from (0–100)% of full load. The phase loss fault simulation in MATLAB/Simulink is done for the following fault cases:

-

Loss of phase “A” from the source using breaker 1 when the motor is running in steady-state mode.

-

Loss of phase “B” from the source using breaker 2 when the motor is running in steady-state mode.

-

Loss of phase “C” from the source using breaker 3 when the motor is running in steady-state mode.

-

Loss of phase “A” after relay point using breaker 4 when the motor is running in steady-state mode.

(A phase loss fault occurs in the motor winding or in the cable between the relay and the motor).

-

Loss of phase “B” after relay point using breaker 5 when the motor is running in steady-state mode.

-

Loss of phase “C” after relay point using breaker 6 when the motor is running in steady-state mode.

-

Loss of phase “A” after the relay point using breaker 4 when the motor is starting without rotation.

-

Loss of phase “B” after the relay point using breaker 5 when the motor is starting without rotation.

-

Loss of phase “C” after the relay point using breaker 6 when the motor is starting without rotation.

-

Loss of phase “A” from the source using breaker 1 when the motor is in standstill mode.

-

Loss of phase “B” from the source using breaker 2 when the motor is in standstill mode.

-

Loss of phase “C” from the source using breaker 3 when the motor is in standstill mode.

3.3 The structure of the ANN for fault detection and classification task

Following the process of selecting the inputs to the NN, the next stage is to form the structure of the NN-based fault detector and classifier for the phase loss fault of the three-phase motor. A multilayer feed-forward NN is chosen for this research. It is necessary, in the design stage of the NN, to take into account the determination of the size and the ideal structure of the NN. The structure selection of the NN depends on the classification problem involving fault patterns, which ultimately relate to the number of input and output neurons. In this study, the RMS values of voltages, line currents, and motor speed were chosen as inputs to the NN, so the total number of neurons in the input layer for ANN is 7. The number of neurons in the output layer is 4. The target values of the outputs of NN are selected according to the fault type given in Table 3.

The NN outputs are called A, B, C, and T. In the normal case, without any fault, all outputs of the NN are equal to zero. The first three outputs express the missing phase, and each of them is equal to the value of 1 according to the faulty phase. The last output represents the fault type in one of the following four cases:

-

In the first case, the phase loss fault occurs from the power source while the motor is running in steady-state mode, and in this case, the output will be equal to 0.5.

-

In the second case, the phase loss fault occurs after the relay point while the motor is running in steady-state mode, and in this case, the output will be equal to 0.75.

-

In the third case, the phase loss fault occurs after the relay point while the motor is starting without rotation, and in this case, the output will be equal to 1.

-

In the fourth case, the phase loss fault occurs from the power source when the motor is in standstill mode, and in this case, the output will be equal to 0.

3.4 Training of ANN-based fault detector and classifier

After determining the number of neurons in the input and output layers of the proposed NN, the next step is to train the NN with the previously prepared fault patterns. Then, the number of hidden layers and the number of neurons in each hidden layer are determined. A set of trials is used to determine how many neurons are present in the hidden layer. After a series of experiments with different networks by changing the number of hidden neurons in the hidden layer, it was shown that the highest performance could be achieved by employing a single hidden layer that had 10 neurons. Thus, the final structure of the NN is a feed-forward neural network with 7 input neurons, 10 hidden neurons, and 4 output neurons. Both the hidden layer and the output layer have utilized the “tangent sigmoid” transfer function. The ANN was trained using the Levenberg–Marquardt training algorithm. As demonstrated in Fig. 4, the learning strategy converges rapidly, and the mean squared error (MSE) drops to 4.0779 e-6 in 109 epochs. The neural network training regression (plotregression) is shown in Fig. 5. The error histogram diagram of the NN training is shown in Fig. 6. It is clear from the error histogram that most of the network outputs after training have an error value of 7.99 e-5. Therefore, for a completely accurate classification, the NN outputs are made the same as the targets in a range ± 0.03. The NN outputs are delayed by 10 ms to avoid spurious errors during normal motor starting.

Following the training of the ANN, it is required to test the NN to check its performance. Therefore, the following section shows the results and the performance evaluation of the selected NN under normal conditions and in case of phase loss of the three-phase IM.

4 Results and discussion

After the NN has been trained, it is necessary to test it through a series of tests that simulate errors in conditions that were not presented during training. Testing of the selected NN is required to validate its performance in detecting the phase failure of an IM under different operating conditions. So, the network is tested when the motor is running normally and when any of the faults given in Table 2 happen under different loads and at different failure times, as explained below. In all simulations, the outputs of the presented method using a NN are represented through time with voltage signals, current signals, RMS line voltages, RMS currents, and motor speed. Also, in all cases of the simulation results, a distinction is made between the different faults according to the different indexes and codes, as mentioned previously in Table 3.

4.1 Test results for normal conditions

The presented method using ANN is tested by running the motor normally under various loads without losing one of the phases. It was found that the proposed method works efficiently, and all its outputs are zero during the period of starting the motor and during its normal rotation without any failure of the loss of one of the phases. Figures 7 and 8 show two such cases, the first being the motor running normally under full load (100%) at 10.4 s and the second being the motor operating at 70% of full load at 20.7 s. It is clear from the two figures that all outputs of the proposed method using the NN are equal to zero. As a result, it is unaffected by the motor’s starting currents and operates without error during its normal rotation.

4.2 Test results for phase loss from the source while the motor is running in steady-state mode

The ANN-based fault detector is tested for many cases at one phase loss from the source, while the motor is running in steady-state mode. It was found that the proposed method worked efficiently under various load conditions. Figure 9 shows one of these cases (case no. 22 in Table 4), which is the loss of phase “A” from the source at a time of 20.6 s when the motor is running in steady-state mode under full load. It is clear from the figure that this fault was detected and classified at 20.618 s. Thus, the operation time for detecting and classifying the fault is 18 ms from the fault’s inception. Table 4 gives 22 cases of this type of fault, which is known as codes PL1-A, PL1-B, and PL1-C, as previously mentioned in Table 3.

4.3 Test results for phase loss after relay location while the motor is running in steady-state mode

The ANN-based fault detector is tested for many cases at one phase loss after the relay point, while the motor is running in steady-state mode. It was found that the proposed method worked efficiently under various load conditions. Figure 10 shows one of these cases (case no. 22 in Table 5), which is the loss of phase “B” after the relay at a time of 10.5 s when the motor is running in steady-state mode under full load. It is clear from this figure that this fault was detected and classified correctly at 10.526 s. Thus, the operation time for detecting and classifying the fault is 26 ms from the fault inception time. Table 5 gives 22 cases of this type of fault, which is known as codes PL2-A, PL2-B, and PL2-C, as mentioned in Table 3.

4.4 Test results for phase loss after relay location while the motor is starting without rotation

The ANN-based fault detector is tested for many cases at different times of the phase loss after the relay point, while the motor is starting without rotation. It was found that the proposed method worked efficiently in those cases. Figure 11 shows one of these cases (fault index: F7, code: FL3-A as in Table 3), which is the motor starting at 10.5 s without rotation due to the loss of phase “A” after the relay point. It is clear from the figure that the fault was detected and classified correctly at 10.514 s. Thus, the operation time for detecting and classifying this fault is 14 ms from the fault inception time.

Figure 12 shows another case (fault index: F8, code: FL3-B as in Table 3), which is the motor starting at 20.8 s without rotation due to the loss of phase “B” after the relay point. It is clear from this figure that the fault was detected and classified correctly at 20.828 s. Thus, the operation time in this case is 28 ms from the fault inception time.

Figure 13 shows the third case (fault index: F9, code: FL3-C as in Table 3), which is the motor starting at 5.3 s without rotation due to the loss of phase “C” after the relay point. It is clear from this figure that the fault was detected and classified correctly at 5.314 s. Thus, the operation time for detecting and classifying the fault is 14 ms from the fault inception.

4.5 Test results for phase loss from the source when the motor is standstill

The ANN-based fault detector is tested for many cases at different times of phase loss from the source when the motor is in standstill mode. It was found that the proposed method worked efficiently in those cases. Figure 14 shows one of these cases (fault index: F10, code: FL4-A as in Table 3), which is the loss of phase “A” of the power supply at a time of 12.7 s when the motor is in standstill mode. It is clear from the figure that this fault was detected and classified correctly at 12.727 s. Thus, the operation time of the proposed scheme is 27 ms from fault inception.

Figure 15 shows another case (fault index: F11, code: FL4-B as in Table 3), which is the phase loss “B” of the power supply at a time of 10.405 s when the motor is in standstill mode. It is clear from the figure that this fault was detected and classified correctly at 10.434 s. Thus, the operation time for detecting and classifying the fault is 29 ms from the fault inception.

Figure 16 shows the third case (fault index: F12, code: FL4-C as in Table 3), which is the phase loss “C” of the power supply at a time of 15.25 s when the motor is in standstill mode. It is clear from this figure that the fault was detected and classified correctly at 15.276 s. Thus, the operation time of the proposed scheme is 26 ms from the fault inception time.

5 Advantages of the proposed system

According to the simulation results that were discussed in the previous section for more than 50 different cases, it shows that the proposed system is characterized by several features, which are as follows:

-

It can detect and classify 12 types of phase loss faults of 3-phase IM based on factors such as the unhealthy phase, fault location, and motor action modes (standstill, transient, and steady state) as follows:

-

Loss of phase “A” from the source side when the motor is running in steady-state mode.

-

Loss of phase “B” from the source side when the motor is running in steady-state mode.

-

Loss of phase “C” from the source side when the motor is running in steady-state mode.

-

Loss of phase “A” after the relay point when the motor is running in steady-state mode.

-

Loss of phase “B” after the relay point when the motor is running in steady-state mode.

-

Loss of phase “C” after the relay point when the motor is running in steady-state mode.

-

Loss of phase “A” after the relay point when IM is starting from standstill mode (in transient mode).

-

Loss of phase “B” after the relay point when IM is starting from standstill mode (in transient mode).

-

Loss of phase “C” after the relay point when IM is starting from standstill mode (in transient mode).

-

Loss of phase “A” from the source side when the motor is in standstill mode.

-

Loss of phase “B” from the source side when the motor is in standstill mode.

-

Loss of phase “C” from the source side when the motor is in standstill mode.

-

It can detect and classify phase loss faults correctly within 30 ms of the fault inception time.

-

It can determine the motor mode during the occurrence of a phase loss.

-

It can detect the unhealthy phase and its location, either from the power source or after the relay point, to help the maintenance team repair the fault within a short period of time from its occurrence.

-

It proves to be a simple and reliable solution for integration into the protection system of a three-phase IM, enabling the detection and classification of various phase loss faults.

Economically speaking, the proposed method is considered more efficient and acceptable for identifying and treating this kind of fault than existing protective systems. This system can be applied to most motors, regardless of their size, big or small. However, in the case of larger motors, the economic return on minimizing downtime, forecasting motor failure, and reducing maintenance costs will be more advantageous.

The actual cost savings from the adoption of the system for phase loss detection in motors will vary depending on factors such as the size of the motors, the industry, the specific application, and the operational parameters. Here are a few ways in which cost savings can be achieved:

-

Preventing Motor Damage: Rapid detection and response to phase loss can prevent motor damage and reduce the need for costly repairs or motor replacements. By minimizing downtime and avoiding extensive repairs, organizations can save significant costs associated with equipment maintenance and replacement.

-

Avoiding Production Losses: Unplanned downtime resulting from motor failure can have a substantial financial impact on industries that rely on continuous operation. By detecting phase loss early and implementing preventive measures, organizations can avoid production stoppages, maintain productivity, and prevent potential losses in revenue.

-

Energy Efficiency: Phase loss in motors can result in inefficient operation and increased energy consumption. By promptly identifying and addressing phase loss, energy waste can be minimized, leading to cost savings in electricity bills. Energy management systems that monitor phase loss events can provide insights into energy usage patterns and help optimize motor operations for improved efficiency.

-

Predictive Maintenance: Implementing a system for phase loss detection as part of a broader condition monitoring and predictive maintenance strategy can lead to cost savings. By analyzing historical data and identifying patterns related to phase loss, maintenance activities can be planned proactively and scheduled during planned downtime, reducing the need for emergency repairs and minimizing associated costs.

-

Extended Motor Lifespan: Early detection and mitigation of phase loss can help extend the lifespan of motors. By minimizing stress on motor components and preventing overheating, organizations can avoid premature motor failures and the associated costs of replacement or rewinding.

Thus, the actual cost savings will depend on the specific circumstances and operational characteristics of the industry. Conducting a detailed cost–benefit analysis based on industry-specific data, such as motor sizes, energy costs, production schedules, and maintenance expenses, will provide a more accurate assessment of the potential cost savings resulting from the adoption of a phase loss detection system in a particular industry.

6 Conclusion

An efficient NN model is introduced in this paper to detect and classify 12 types of phase loss faults for a three-phase IM. These faults are classified according to the defective phase, fault location, either from the power source or after the relay point, and motor action modes (standstill, transient, and steady-state modes). The RMS values of line-line voltages, line currents, and motor speed (RPM) are used as inputs to the NN. Several tests have been performed in MATLAB/Simulink under different conditions to evaluate the proposed ANN’s performance. The proposed NN model is tested for more than 50 different cases under normal conditions and various phase loss faults at different times and under different motor loads. Among these cases, 22 different cases of phase loss faults from the source and another 22 cases after the relay point are tested, while the motor is running in steady-state mode. The remaining cases are tested for both normal conditions and phase loss faults from the source or beyond the relay point when the motor is in standstill mode. The simulation results of all test cases show that the proposed network can correctly detect and classify phase loss faults within 30 ms from the fault inception time. Therefore, the proposed network model proves to be a simple and reliable solution for integration into the protection system of three-phase IM to detect and classify various phase loss faults in standstill, transient, and steady-state modes. Thus, the proposed system is considered more effective and acceptable compared to traditional protection systems.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Sheikh MA, Bakhsh ST, Irfan M, Nor N, Nowakowski G (2022) A review to diagnose faults related to three-phase industrial induction motors. J Fail Anal Prev 22(4):1546–1557

Senthil Kumar R, Rajesh Kumar B, Lincy Luciana M (2018) Fault detection for three-phase induction motor drives using fuzzy logic. Int J Pure Appl Math 118(20)

Sengamalai U, Anbazhagan G, Thamizh Thentral T, Vishnuram P, Khurshaid T, Kamel S (2022) Three phase induction motor drive: a systematic review on dynamic modelling, parameter estimation, and control schemes. Energies 15:8260

Mohar N, Mid EC, Suboh S, Baharudin N, Ahamad N, Rahman N et al (2021) Fault detection analysis for three-phase induction motor drive system using neural network. J Phys: Conf Ser 1878:012039

IEEE Recommended Practice for motor protection in industrial and Commercial Power Systems (2016) IEEE, IEEE Std 3004.8-2016. https://ieeexplore.ieee.org/document/7930540

Sudha M, Anbalagan P (2008) A protection scheme for three-phase induction motor from incipient faults using an embedded controller. Asian J Sci Res 2(1):28–50

Bayindir R, Sefa I, Colak I, Bektas A (2008) Fault detection and protection of induction motors using sensors. IEEE Trans Energy Convers 23(3):734–741

Shetgaonkar SS (2018) Fault diagnosis in induction motor using Fuzzy Logic. In: International conference on computing methodologies and communication (ICCMC), Vol 05

Kokare M (2018) Fuzzy logic based fault diagnosis of induction motor using MATLAB. Int J Res Sci Innov (IJRSI) 5:149–152

Dudhat NM, Pandya AA (2017) Induction motor protection system using fuzzy logic. Int J Sci Eng Technol 6(2):134–136

Ferreira FJ, Silva AM, de Almeida AT (2017) Single-phasing protection of line-operated motors of different efficiency classes. In: IEEE/IAS industrial and commercial power systems technical conference (I&CPS), pp 1–13

Bussman C (2005) Motor protection – voltage unbalance & single-phasing

Dianov A, Anuchin A (2021) Phase loss detection using current signals: a review. IEEE Access 9:114727–114740

Sinha A, Grover S (2021) Modified circuit design of VFD for critical loads under single phasing condition. Int J Eng Trends Technol 6:233–238

Alsayid B (2020) Experimental investigation and analysis of induction motors operation under single-phasing condition. Palestine Technical University Research Journal

Motor protection: voltage unbalance and single-phasing. Bussmann Company. https://tinyurl.com/23k79t8y

Ogbuka CU, Bassey O (2014) Protection method against induction motor single-phasing fault. Int. J. of innovative technology and exploring engineering (IJITEE), vol 4

Open-phase protection issues for motors, Pacific Gas and Electric company. https://tinyurl.com/6psh5m8e

Aree P (2018) Effects of neutral conductor on induction motor steady-state performance under loss of one phase of supply voltages.In: IEEE international conference on power electronics, intelligent control, and energy systems (ICPEICES), pp 837–840

Smith T, Graves B (2013) Detection of loss of voltage phase, In: Conference record of the 2013 annual IEEE pulp and paper industry technical conference (PPIC), pp 165–169

Mollet Y et al. (2018) Multi-physical signature analysis of induction machines under unbalanced supply voltage. In: IEEE international conference on electrical machines, pp 2378–238

Rajashree U, Chaudhari H (2015) Behaviour of induction motor at voltage unbalance. Int J Eng Res Technol (IJERT) 4(5):17–25

Wiedenbrug E (2013) Overheating electric motors: a major cause of failure. https://tinyurl.com/2p8v9jk4

Hang J, Ren X, Tang C, Tong M, Ding S (2020) Fault-tolerant control strategy for five-phase PMSM drive system with high-resistance connection. IEEE Trans Transp Electr 7(3):1390–1400

Aree P (2018) Effects of neutral conductor on induction motor steadystate performance under loss of one phase of supply voltages. In: Proceeding 2nd IEEE international conference power electronics, intelligent control energy systems (ICPEICES), pp 837–840

Kiselev A, Catuogno GR, Kuznietsov A, Leidhold R (2020) Finitecontrol-set MPC for open-phase fault-tolerant control of PM synchronous motor drives. IEEE Trans Ind Electron 67(6):4444–4452

Bethoux O, Laboure E, Remy G, Berthelot E (2017) Real-time optimal control of a 3-phase PMSM in 2-phase degraded mode. IEEE Trans Veh Technol 66(3):2044–2052

Odnokopylov GI, Bragin AD (2015) Algorithms of fault tolerant control of induction motor electric drive in phase loss operate mode. In: Proceedings international Siberian conference on control and communications, pp 1–5

Toliyat HA (1998) Analysis and simulation of five-phase variable-speed induction motor drives under asymmetrical connections. IEEE Trans Power Electron 13(4):748–756

Chikondra B, Muduli UR, Behera RK (2021) An improved open-phase fault-tolerant DTC technique for five-phase induction motor drive based on virtual vectors assessment. IEEE Trans Ind Electron 68(6):4598–4609

Son DK, Kwon SH, Kim DO, Song HS, Lee GH (2021) Control comparison for the coordinate transformation of an asymmetric dual three-phase synchronous motor in healthy and single-phase open fault states. Energies 14:17–35

Wang B, Wang J, Griffo A, Sen B (2019) Experimental assessments of a triple redundant nine-phase fault-tolerant PMA SynRM drive. IEEE Trans Ind Electron 66(1):772–783

Liu Z, Xu Z, Zhang X (2021) A novel real-time fast fault-tolerance diagnosis and fault adjustment strategy for m-phase interleaved boost converter. IEEE Access 9:11776–11786

Afsharian J, Xu DD, Wu B, Gong B, Yang Z, Itoh JI (2018) Analysis of one-phase loss operation of a three-phase isolated buck matrix-type rectifier with an eight-segment PWM scheme. In: Proceeding international power electronics conference (IPEC-Niigata-ECCE Asia), pp 30–36

Ashoush A, Gadoue SM, Abdel-Khalik AS, Mohamadein AL (2011) Current optimization for an eleven-phase induction machine under fault conditions using genetic algorithm. In: Proceeding 8th IEEE symposium on diagnostics for electrical machines, power electronics & drives, pp 529–534

Huang C, Zhou L, Cao Z, Yao G (2021) Fault-tolerant control strategy with asymmetric phase currents for single to four-phase open-circuit faults of six-phase PMSM. Energies 14:3164

de la Guerra A, Jimenez-Mondragon VM, Torres L, Haes HA, Escarela-Perez R, Olivares-Galvan JC (2020) On-line open-phase fault detection method for switched reluctance motors with bus current measurement. Actuators 9(4):117

Talaat H, Ezzat M, Saleh A (2014) Fuzzy logic based induction motor condition monitoring. In: The international conference on electrical engineering, pp 1–6

Premerlani W et al. (2005) Fundamental of motor thermal model and its application in motor protection. In: 58th annual conference for protective relay engineers, pp 127–142

Baurand G, Moliton V (2007) Protection of LV Motors, Cahier Technique No. 211, Schneider Electric

Gaucheron E (2004) Electric motors...and how to improve their control and protection, Cahier Technique No. 207, Schneider Electric, pp 17-21

Sharma S, Malik H, Khatri A (2015) External fault classification experienced by three-phase induction motor based on multi-class ELM. In: International Conference on Eco-friendly Computing Systems, pp 814–820

Rama H (2014) Fault identification in three-phase induction motors using support vector machines. Master of Technology Management Plan II Graduate Projects, BGS University

Lang W, Hu Y, Gong C, Zhang X, Xu H, Deng J (2022) Artificial intelligence-based technique for fault detection and diagnosis of EV motors: a review. IEEE Trans Transp Electr 8(1):384–406

Kaminski M, Kowalski CT, Orlowska-Kowalska T (2011) Application of radial basis neural networks for the rotor fault detection of the induction motor. In: IEEE EUROCON: international conference on computer as a tool, pp 1–4

Giceva IZ, Sarac VJ, Gelev SA, Cingoski VT (2018) Single phasing of three-phase induction motors under various load conditions. In: 23rd international scientific-professional conference on information technology (IT), pp 1–4

Obed AA (2018) Detection, protection from, classification, and monitoring of electrical faults in 3-phase induction motors based on discrete S-transform. Int J Appl Eng Res 13(9):6690–6699

Kumar D, Verma PK, Singh BK, Singh R, Singh V (2014) Single phasing phase reversal overvoltage under voltage and overheating protection of three phase induction motor. Int J Sci Res Manag Stud (IJSRMS) 1(1):7–10

Chudasama K, Shah V, Shah S (2016) Induction motor relaying scheme for external fault detection and classification using subtractive clustering-based sugeno fuzzy inference system. Electric Power Compon Syst 44(10):1149–1162

Prabakaran S, Venkatesan S (2018) Analysis of 3-phase induction motor protection using numerical relay. Int J Eng Tech 4:513–519

Boum A, Maurice NJ, Nneme LN, Mbumda LM (2018) Fault diagnosis of an induction motor based on fuzzy logic, artificial neural network, and hybrid systems. Int J Control 8(2):42–51

Mulindwa R (2019) Protecting 3-phase motors from single phasing. Makerere Universty

Boopathi C, Chowdhary S, Karn S (2020) Three phase induction motor protection using embedded technology. Int J Electr Eng Technol 11(3):265–272

Singh P, Dash RN, Panigrahi CK (2021) Open phase fault analysis of a three-phase induction motor. In: Advances in power systems and energy management: select proceedings of ETAEERE 2020, Springer, pp 81–89

Dianov A (2022) A novel phase loss detection method for low-cost motor drives. IEEE Trans Power Electron 37(6):6660–6668

Dianov A, Anuchin A (2021) Phase loss detection using voltage signals and motor models: a review. IEEE Sens J 21(23):26488–26502

Acknowledgements

The authors thank the Associate Editor and two anonymous Reviewers for their constructive comments and suggestions, which helped us substantially improve the manuscript.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

AD contributed to conceptualization, methodology, simulation, data curation, writing–original draft, and visualization. BMH was involved in data curation, writing–review and editing, and supervision. AMAA contributed to conceptualization, methodology, simulation, validation, writing–review and editing, and supervision.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dawood, A., Hasaneen, B.M. & Abdel-Aziz, A.M. Design of an efficient neural network model for detection and classification of phase loss faults for three-phase induction motor. Neural Comput & Applic 36, 5827–5845 (2024). https://doi.org/10.1007/s00521-023-09387-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-023-09387-y