Abstract

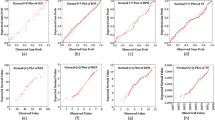

A reliable and accurate prediction of the tunnel boring machine (TBM) performance can assist in minimizing the relevant risks of high capital costs and in scheduling tunneling projects. This research aims to develop a novel hybrid intelligent system, i.e., adaptive neuro-fuzzy inference system (ANFIS)-polynomial neural network (PNN) optimized by the imperialism competitive algorithm (ICA), ANFIS-PNN-ICA for prediction of TBM performance. In fact, the role of ICA in this hybrid system is to optimize the membership functions obtained by ANFIS-PNN model for receiving a higher level of performance prediction. Based on previously published works, seven parameters including the rock quality designation, the rock mass rating, Brazilian tensile strength, rock mass weathering, the uniaxial compressive strength, revolution per minute and thrust force were set as inputs to predict TBM performance. Together with the ANFIS-PNN-ICA model, two single model of PNN and ANFIS were also constructed for comparison purposes. These models were designed conducting several parametric studies on their most important parameters and then, their performance capacities were assessed through the use of several performance indices, e.g., correlation coefficient (R). R values of (0.9642, 0.9654 and 1), (0.9482, 0.9671 and 0.9778) and (0.9652, 0.9642, 0.9898) were obtained for training, testing and all datasets of PNN, ANFIS and ANFIS-PNN-ICA models, respectively. These results revealed that the greater prediction capacity can be provided by the ANFIS-PNN-ICA predictive model compared to ANFIS and PNN models and this hybrid intelligent model can be introduced as an accurate, powerful and applicable technique in the field of TBM performance prediction.

Similar content being viewed by others

References

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22:808–814

Koopialipoor M, Fahimifar A, Ghaleini EN et al (2019) Development of a new hybrid ANN for solving a geotechnical problem related to tunnel boring machine performance. Eng Comput. https://doi.org/10.1007/s00366-019-00701-8

Yagiz S, Karahan H (2015) Application of various optimization techniques and comparison of their performances for predicting TBM penetration rate in rock mass. Int J Rock Mech Min Sci 80:308–315

Grima MA, Bruines PA, Verhoef PNW (2000) Modeling tunnel boring machine performance by neuro-fuzzy methods. Tunn Undergr Sp Technol 15:259–269

Bruines P (1998) Neuro-fuzzy modeling of TBM performance with emphasis on the penetration rate. Mem Cent Eng Geol Neth Delft 173:202

Ribacchi R, Fazio AL (2005) Influence of rock mass parameters on the performance of a TBM in a gneissic formation (Varzo Tunnel). Rock Mech Rock Eng 38:105–127

Innaurato N, Mancini A, Rondena E, Zaninetti A (1991) Forecasting and effective TBM performances in a rapid excavation of a tunnel in Italy. In: 7th ISRM Congress. International Society for Rock Mechanics and Rock Engineering

Bruland A (1998) Hard rock tunnel boring. Norwegian University of Science and Technology, Trondheim

Shijing W, Bo Q, Zhibo G (2006) The time and cost prediction of tunnel boring machine in tunnelling. Wuhan Univ J Nat Sci 11:385–388

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn Undergr Sp Technol 23:326–339

Yang HQ, Li Z, Jie TQ, Zhang ZQ (2018) Effects of joints on the cutting behavior of disc cutter running on the jointed rock mass. Tunn Undergr Sp Technol 81:112–120

Yang HQ, Zeng YY, Lan YF, Zhou XP (2014) Analysis of the excavation damaged zone around a tunnel accounting for geostress and unloading. Int J rock Mech Min Sci 69:59–66

Maidl B, Schmid L, Ritz W, Herrenknecht M (2008) Hardrock tunnel boring machines. Wiley, New Jersey

Farmer IW, Glossop NH (1980) Mechanics of disc cutter penetration. Tunnels Tunn 12:22–25

Rostami J (1997) Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure

Snowdon RA, Ryley MD, Temporal J (1982) A study of disc cutting in selected British rocks. Int J Rock Mech Min Sci Geomech Abst 19(3):107–121

Yagiz S (2002) Development of rock fracture and brittleness indices to quantify the effects of rock mass features and toughness in the CSM model basic penetration for hard rock tunneling machines

Gong Q-M, Zhao J (2009) Development of a rock mass characteristics model for TBM penetration rate prediction. Int J Rock Mech Min Sci 46:8–18

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunn Undergr Sp Technol 26:595–603

Mahdevari S, Shahriar K, Yagiz S, Shirazi MA (2014) A support vector regression model for predicting tunnel boring machine penetration rates. Int J Rock Mech Min Sci 72:214–229

Benardos AG, Kaliampakos DC (2004) Modelling TBM performance with artificial neural networks. Tunn Undergr Sp Technol 19:597–605

Simoes MG, Kim T (2006) Fuzzy modeling approaches for the prediction of machine utilization in hard rock tunnel boring machines. In: Conference Record of the 2006 IEEE Industry Applications Conference 41st IAS Annual Meeting, pp 947–954

Javad G, NARGES T, (2010) Application of artificial neural networks to the prediction of tunnel boring machine penetration rate. Min Sci Technol 20:727–733

Shao C, Li X, Su H (2013) Performance prediction of hard rock TBM based on extreme learning machine. In: Lee J, Lee MC, Liu H, Ryu JH (eds) International conference on intelligent robotics and applications. Springer, Berlin, pp 409–416

Torabi SR, Shirazi H, Hajali H, Monjezi M (2013) Study of the influence of geotechnical parameters on the TBM performance in Tehran-Shomal highway project using ANN and SPSS. Arab J Geosci 6:1215–1227

Koopialipoor M, Nikouei SS, Marto A et al (2018) Predicting tunnel boring machine performance through a new model based on the group method of data handling. Bull Eng Geol Environ 78:3799–3813

Armaghani DJ, Koopialipoor M, Marto A, Yagiz S (2019) Application of several optimization techniques for estimating TBM advance rate in granitic rocks. J Rock Mech Geotech Eng. https://doi.org/10.1016/j.jrmge.2019.01.002

Yang H, Wang Z, Song K (2020) A new hybrid grey wolf optimizer-feature weighted-multiple kernel-support vector regression technique to predict TBM performance. Eng Comput. https://doi.org/10.1007/s00366-020-01217-2

Zhou J, Qiu Y, Zhu S et al (2020) Estimation of the TBM advance rate under hard rock conditions using XGBoost and Bayesian optimization. Undergr Sp. https://doi.org/10.1016/j.undsp.2020.05.008

Zhou J, Qiu Y, Armaghani DJ et al (2020) Predicting TBM penetration rate in hard rock condition: a comparative study among six XGB-based metaheuristic techniques. Geosci Front. https://doi.org/10.1016/j.gsf.2020.09.020

Grima MA, Verhoef PNW (1999) Forecasting rock trencher performance using fuzzy logic. Int J Rock Mech Min Sci 36:413–432

Yagiz S, Karahan H (2011) Prediction of hard rock TBM penetration rate using particle swarm optimization. Int J Rock Mech Min Sci 48:427–433

Salimi A, Esmaeili M (2013) Utilising of linear and non-linear prediction tools for evaluation of penetration rate of tunnel boring machine in hard rock condition. Int J Min Miner Eng 4:249–264

Salimi A, Faradonbeh RS, Monjezi M, Moormann C (2018) TBM performance estimation using a classification and regression tree (CART) technique. Bull Eng Geol Environ 77:429–440

Zhou J, Yazdani Bejarbaneh B, Jahed Armaghani D, Tahir MM (2020) Forecasting of TBM advance rate in hard rock condition based on artificial neural network and genetic programming techniques. Bull Eng Geol Environ 79:2069–2084. https://doi.org/10.1007/s10064-019-01626-8

Ghasemi E, Yagiz S, Ataei M (2014) Predicting penetration rate of hard rock tunnel boring machine using fuzzy logic. Bull Eng Geol Environ 73:23–35

Armaghani DJ, Mohamad ET, Narayanasamy MS et al (2017) Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition. Tunn Undergr Sp Technol 63:29–43. https://doi.org/10.1016/j.tust.2016.12.009

Salimi A, Rostami J, Moormann C, Delisio A (2016) Application of non-linear regression analysis and artificial intelligence algorithms for performance prediction of hard rock TBMs. Tunn Undergr Sp Technol 58:236–246

Fattahi H (2016) Adaptive neuro fuzzy inference system based on Fuzzy C-means clustering algorithm, a technique for estimation of Tbm penetration rate. Iran Univ Sci Technol 6:159–171

Minh VT, Katushin D, Antonov M, Veinthal R (2017) Regression models and fuzzy logic prediction of TBM penetration rate. Open Eng 7:60–68

Hajihassani M, Abdullah SS, Asteris PG, Armaghani DJ (2019) A gene expression programming model for predicting tunnel convergence. Appl Sci 9:4650

Asteris PG, Nozhati S, Nikoo M et al (2018) Krill herd algorithm-based neural network in structural seismic reliability evaluation. Mech Adv Mater Struct 26(13):1146–1153

Armaghani DJ, Hatzigeorgiou GD, Karamani C et al (2019) Soft computing-based techniques for concrete beams shear strength. Procedia Struct Integr 17:924–933

Asteris PG, Apostolopoulou M, Skentou AD, Moropoulou A (2019) Application of artificial neural networks for the prediction of the compressive strength of cement-based mortars. Comput Concr 24:329–345

Yagiz S, Gokceoglu C (2010) Application of fuzzy inference system and nonlinear regression models for predicting rock brittleness. Expert Syst Appl 37:2265–2272

Khajeh A, Modarress H, Rezaee B (2009) Application of adaptive neuro-fuzzy inference system for solubility prediction of carbon dioxide in polymers. Expert Syst Appl 36:5728–5732

Yang HQ, Xing SG, Wang Q, Li Z (2018) Model test on the entrainment phenomenon and energy conversion mechanism of flow-like landslides. Eng Geol 239:119–125

Yang HQ, Lan YF, Lu L, Zhou XP (2015) A quasi-three-dimensional spring-deformable-block model for runout analysis of rapid landslide motion. Eng Geol 185:20–32

Huang J, Zhang J, Ren J, Chen H (2021) Anti-rutting performance of the damping asphalt mixtures (DAMs) made with a high content of asphalt rubber (AR). Constr Build Mater 271:121878

Huang J, Wang Q-A (2021) Influence of crumb rubber particle sizes on rutting, low temperature cracking, fracture, and bond strength properties of asphalt binder. Mater Struct 54:1–15

Huang J, Sun Y, Zhang J (2021) Reduction of computational error by optimizing SVR kernel coefficients to simulate concrete compressive strength through the use of a human learning optimization algorithm. Eng Comput. https://doi.org/10.1007/s00366-021-01305-x

Asteris PG, Armaghani DJ, Hatzigeorgiou GD et al (2019) Predicting the shear strength of reinforced concrete beams using artificial neural networks. Comput Concr 24:469–488

Sarir P, Chen J, Asteris PG et al (2019) Developing GEP tree-based, neuro-swarm, and whale optimization models for evaluation of bearing capacity of concrete-filled steel tube columns. Eng Comput. https://doi.org/10.1007/s00366-019-00808-y

Chen W, Sarir P, Bui X-N et al (2019) Neuro-genetic, neuro-imperialism and genetic programing models in predicting ultimate bearing capacity of pile. Eng Comput. https://doi.org/10.1007/s00366-019-00752-x

Asteris PG, Nikoo M (2019) Artificial bee colony-based neural network for the prediction of the fundamental period of infilled frame structures. Neural Comput Appl. https://doi.org/10.1007/s00521-018-03965-1

Najafzadeh M, Lim SY (2015) Application of improved neuro-fuzzy GMDH to predict scour depth at sluice gates. Earth Sci Inf 8:187–196

Najafzadeh M, Bonakdari H (2016) Application of a neuro-fuzzy GMDH model for predicting the velocity at limit of deposition in storm sewers. J Pipeline Syst Eng Pract 8:6016003

Asteris PG, Mokos VG (2019) Concrete compressive strength using artificial neural networks. Neural Comput Appl. https://doi.org/10.1007/s00521-019-04663-2

Apostolopoulou M, Armaghani DJ, Bakolas A et al (2019) Compressive strength of natural hydraulic lime mortars using soft computing techniques. Procedia Struct Integr 17:914–923

Jang J-SR (1992) Self-learning fuzzy controllers based on temporal backpropagation. IEEE Trans Neural Netw 3:714–723

Jang J-SR, Sun C-T, Mizutani E (1997) Neuro-fuzzy and soft computing-a computational approach to learning and machine intelligence [Book Review]. IEEE Trans Automat Contr 42:1482–1484

Brown M, Harris CJ (1994) Neurofuzzy adaptive modelling and control. Prentice Hall, New Jersey

Nuno AI, Arcay B, Cotos JM, Varela J (2005) Optimisation of fishing predictions by means of artificial neural networks, anfis, functional networks and remote sensing images. Expert Syst Appl 29:356–363

Chen W, Panahi M, Pourghasemi HR (2017) Performance evaluation of GIS-based new ensemble data mining techniques of adaptive neuro-fuzzy inference system (ANFIS) with genetic algorithm (GA), differential evolution (DE), and particle swarm optimization (PSO) for landslide spatial modelling. CATENA 157:310–324

Bui DT, Pradhan B, Lofman O et al (2012) Landslide susceptibility mapping at Hoa Binh province (Vietnam) using an adaptive neuro-fuzzy inference system and GIS. Comput Geosci 45:199–211

Dehnavi A, Aghdam IN, Pradhan B, Varzandeh MHM (2015) A new hybrid model using step-wise weight assessment ratio analysis (SWARA) technique and adaptive neuro-fuzzy inference system (ANFIS) for regional landslide hazard assessment in Iran. CATENA 135:122–148

Ivakhnenko AG (1968) The group method of data of handling; a rival of the method of stochastic approximation. Sov Autom Control 13:43–55

Darwin C (1987) Charles Darwin’s natural selection: being the second part of his big species book written from 1856 to 1858. Cambridge University Press, Cambridge

Farlow SJ (1984) Self-organizing methods in modeling: GMDH type algorithms. CRC Press, London

Jamali A, Nariman-Zadeh N, Darvizeh A et al (2009) Multi-objective evolutionary optimization of polynomial neural networks for modelling and prediction of explosive cutting process. Eng Appl Artif Intell 22:676–687

Nariman-Zadeh N, Darvizeh A, Ahmad-Zadeh GR (2003) Hybrid genetic design of GMDH-type neural networks using singular value decomposition for modelling and prediction of the explosive cutting process. Proc Inst Mech Eng Part B J Eng Manuf 217:779–790

Jolai F, Sangari MS, Babaie M (2010) Pareto simulated annealing and colonial competitive algorithm to solve an offline scheduling problem with rejection. Proc Inst Mech Eng Part B J Eng Manuf 224:1119–1131

Nicknam A, Hosseini MH (2012) Structural damage localization and evaluation based on modal data via a new evolutionary algorithm. Arch Appl Mech 82:191–203

Hajihassani M, Jahed Armaghani D, Marto A, Tonnizam Mohamad E (2014) Ground vibration prediction in quarry blasting through an artificial neural network optimized by imperialist competitive algorithm. Bull Eng Geol Environ 74:873–886. https://doi.org/10.1007/s10064-014-0657-x

Jahed Armaghani D, Mohd Amin MF, Yagiz S et al (2016) Prediction of the uniaxial compressive strength of sandstone using various modeling techniques. Int J Rock Mech Min Sci 85:174–186. https://doi.org/10.1016/j.ijrmms.2016.03.018

Atashpaz-Gargari E, Lucas C (2007) Imperialist competitive algorithm: an algorithm for optimization inspired by imperialistic competition. In: 2007 IEEE Congress on Evolutionary computation, CEC 2007, IEEE, pp 4661–4667

Khandelwal M, Mahdiyar A, Armaghani DJ et al (2017) An expert system based on hybrid ICA-ANN technique to estimate macerals contents of Indian coals. Environ Earth Sci 76:399. https://doi.org/10.1007/s12665-017-6726-2

Qin Y, Langari R, Gu L (2015) A new modeling algorithm based on ANFIS and GMDH. J Intell Fuzzy Syst 29:1321–1329

Sundaram M (2007) The effects of ground conditions on TBM performance in tunnel excavation–a case history. In: Proceedings of the 10th Australia New Zealand Conference on Geomechanics, Queensland, Australia pp. 21–24

Sundaram NM, Rafek AG, Komoo I (1998) The influence of rock mass properties in the assessment of TBM performance. In: Proceedings of the 8th IAEG Congress, Vancouver, British Columbia, Canada. pp. 3553–3559

Sapigni M, Berti M, Bethaz E et al (2002) TBM performance estimation using rock mass classifications. Int J Rock Mech Min Sci 39:771–788

Farrokh E, Rostami J, Laughton C (2012) Study of various models for estimation of penetration rate of hard rock TBMs. Tunn Undergr Sp Technol 30:110–123

Ulusay R, Hudson JA (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. Comm Test methods Int Soc Rock Mech Compil arranged by ISRM Turkish Natl Group, Ankara, Turkey 628

Tao H, Wang P, Chen Y et al (2020) An unsupervised fault diagnosis method for rolling bearing using STFT and generative neural networks. J Franklin Inst 357:7286–7307

Dong X, He S, Stojanovic V (2020) Robust fault detection filter design for a class of discrete-time conic-type non-linear Markov jump systems with jump fault signals. IET Control Theory Appl 14:1912–1919

Zhang X, Shuping H, Stojanovic V et al (2020) Finite-time asynchronous dissipative filtering of conic-type nonlinear markov jump systems. Sci CHINA Inf Sci. https://doi.org/10.1007/s11432-020-2913-x

Zhou L, Tao H, Paszke W et al (2020) PD-type iterative learning control for uncertain spatially interconnected systems. Mathematics 8:1528

Chen Z, Zhang B, Stojanovic V et al (2020) Event-based fuzzy control for TS fuzzy networked systems with various data missing. Neurocomputing 417:322–332

Tahmassebi A, Gandomi AH, Meyer-Baese A (2018) A Pareto front based evolutionary model for airfoil self-noise prediction. In: 2018 IEEE Congress on Evolutionary Computation (CEC). IEEE, pp. 1–8

Huang J, Asteris PG, Pasha SMK et al (2020) A new auto-tuning model for predicting the rock fragmentation: a cat swarm optimization algorithm. Eng Comput. https://doi.org/10.1007/s00366-020-01207-4

Rahimi I, Gandomi AH, Chen F (2021) Analysis and Prediction of COVID-19 using SIR, SEIR, and Machine Learning Models: Australia, Italy, and UK Cases. Information 12:109. https://doi.org/10.3390/info12030109

Ly H, Pham BT, Le LM et al (2020) Estimation of axial load-carrying capacity of concrete-filled steel tubes using surrogate models. Neural Comput Appl. https://doi.org/10.1007/s00521-020-05214-w

Asteris PG, Cavaleri L, Ly H-B, Pham BT (2021) Surrogate models for the compressive strength mapping of cement mortar materials. Soft Comput. https://doi.org/10.1007/s00500-021-05626-3

Zeng J, Asteris PG, Mamou AP et al (2021) The effectiveness of ensemble-neural network techniques to predict peak uplift resistance of buried pipes in reinforced sand. Appl Sci 11:908

Zhang H, Nguyen H, Bui X-N et al (2021) A generalized artificial intelligence model for estimating the friction angle of clays in evaluating slope stability using a deep neural network and Harris Hawks optimization algorithm. Eng Comput. https://doi.org/10.1007/s00366-020-01272-9

Bai C, Nguyen H, Asteris PG et al (2020) A refreshing view of soft computing models for predicting the deflection of reinforced concrete beams. Appl Soft Comput 97:106831

Wang S, Zhou J, Li C et al (2021) Rockburst prediction in hard rock mines developing bagging and boosting tree-based ensemble techniques. J Cent South Univ 28:527–542

Yu C, Koopialipoor M, Murlidhar BR et al (2021) Optimal ELM–Harris Hawks optimization and ELM–Grasshopper optimization models to forecast peak particle velocity resulting from mine blasting. Nat Resour Res. https://doi.org/10.1007/s11053-021-09826-4

Armaghani DJ, Asteris PG, Fatemi SA et al (2020) On the Use of Neuro-Swarm System to Forecast the Pile Settlement. Appl Sci 10:1904

Armaghani DJ, Mirzaei F, Shariati M et al (2020) Hybrid ANN-based techniques in predicting cohesion of sandy-soil combined with fiber. Geomech Eng 20:191–205

Armaghani DJ, Kumar D, Samui P et al (2020) A novel approach for forecasting of ground vibrations resulting from blasting: modified particle swarm optimization coupled extreme learning machine. Eng Comput. https://doi.org/10.1007/s00366-020-00997-x

Xu H, Zhou J, Asteris PG et al (2019) Supervised machine learning techniques to the prediction of tunnel boring machine penetration rate. Appl Sci 9:3715

Ahmadi MA, Ebadi M, Shokrollahi A, Majidi SMJ (2013) Evolving artificial neural network and imperialist competitive algorithm for prediction oil flow rate of the reservoir. Appl Soft Comput 13:1085–1098

Taghavifar H, Mardani A, Taghavifar L (2013) A hybridized artificial neural network and imperialist competitive algorithm optimization approach for prediction of soil compaction in soil bin facility. Measurement 46(8):2288–2299

Armaghani DJ, Hasanipanah M, Mohamad ET (2016) A combination of the ICA-ANN model to predict air-overpressure resulting from blasting. Eng Comput 32:155–171. https://doi.org/10.1007/s00366-015-0408-z

Acknowledgements

The authors wish to express their appreciations to the project team of the Pahang–Selangor Raw Water Transfer tunnel and also Universiti Teknologi Malaysia for supporting this research, especially during data collection stage.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that this article content has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

About this article

Cite this article

Harandizadeh, H., Armaghani, D.J., Asteris, P.G. et al. TBM performance prediction developing a hybrid ANFIS-PNN predictive model optimized by imperialism competitive algorithm. Neural Comput & Applic 33, 16149–16179 (2021). https://doi.org/10.1007/s00521-021-06217-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-021-06217-x