Abstract

The following contribution focuses on the secondary cooling zone of a slab caster, analyzing the effects of nozzle parameters on cooling conditions. The research group employs experimental measurements, including the Nozzle Measuring Stand (NMS), to determine local heat transfer coefficients (HTC) and water distribution. These measurements are crucial for accurately setting the boundary conditions in the simulation. The implementation of these boundary conditions is realized by an Exponential Gaussian Process Regression (EGPR) to predict HTC values. The results highlight the importance of an accurate HTC assessment in regions with overlapping sprays. The developed methodology aids in enhancing the precision of simulations for continuous casting processes, contributing to a better product quality and process efficiency using the non-commercial software platform “m2CAST”.

Zusammenfassung

Dieser Beitrag konzentriert sich auf die sekundäre Kühlzone einer Brammengießmaschine und analysiert die Auswirkungen der Düsenparameter auf die Kühlbedingungen. Die Forschungsgruppe setzt experimentelle Messungen ein, einschließlich des Düsenmessstands (NMS), um die lokalen Wärmeübergangskoeffizienten (HTC) und die Wasserverteilung zu bestimmen. Diese Messungen sind entscheidend für die genaue Festlegung von Randbedingungen in der Simulation. Die Implementierung dieser Randbedingungen wird durch eine Exponential Gaussian Process Regression (EGPR) zur Vorhersage der HTC-Werte realisiert. Die Ergebnisse der Simulation verdeutlichen die Bedeutung einer lokalen HTC-Messung in Bereichen mit überlappenden Sprühkegel. Die entwickelte Methodik trägt dazu bei, die Genauigkeit von Simulationen für Stranggussverfahren zu erhöhen und damit zu einer besseren Produktqualität und Prozesseffizienz unter Verwendung der nicht-kommerziellen Softwareplattform „m2CAST“ beizutragen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The numerical simulation of continuous casting is state-of-the-art. It has become an essential tool for developing and improving the casting process concerning quality and productivity. By simulating the process, researchers can optimize the casting conditions to improve the quality of the final product, reduce waste and energy consumption, and increase the productivity of the process. The simulation can also be used to troubleshoot problems that may occur during the process, allowing for faster and more efficient solutions to be implemented. At Montanuniversität Leoben, the developed numerical models, databases, measurement techniques, and laboratory experiments are interconnected within the non-commercial offline platform “m2CAST”. The implementation of heat transfer coefficients (HTC) as thermal boundary conditions in a local resolution is a key factor for precise simulation results. The so-called Nozzle Measuring Stand (NMS) as well as different regression models, are a proper way to solve this challenge [1,2,3].

2 m2Cast—Continuous Casting Development Platform

The non-commercial offline software m2CAST is designed to connect physical experiments and numerical simulations to predict quality-relevant factors. M2Cast is divided into three main parts, namely preprocessing, solver, and postprocessing. A schematic illustration is given in Fig. 1.

In the first step, all data necessary for solving the 2d FV solver are collected and provided in the preprocessing. This includes thermodynamic data from the material module m2MAT, which are determined with the help of DSC measurements and calculations using FactSage 8.0. Within the caster configurator, the dimensions and geometry of the casting slab-comprising factors, like local strand thickness, strand width as well as the mesh size, must be defined. The thermal boundary conditions of the mold and the secondary cooling conditions are specified as temperature-dependent local Heat Transfer Coefficients (HTC). The chosen parameters of the nozzles in the secondary cooling zone of the casting machine are characterized experimentally using the NMS, which provides information about water impact density (WID) and the resulting HTC within the spray zone.

As mentioned before, a 2D Finite-Volume (FV) model computes the temperature distribution along the entire length of the strand. The computation assumes geometric symmetry and applies to only half of the slab’s width. Nonetheless, this approach allows the consideration of differing HTC and cooling strategies on the fixed and loose sides of the strand. The computed thermal history then serves as the foundation for experimental simulations, which are represented in the area of post-processing [1].

3 Nozzle Measuring Stand

A significant influencing parameter of the solidification calculation can be found in the selected cooling conditions of the secondary cooling zone. The Chair of Ferrous Metallurgy at Montanuniversität Leoben (MUL) has engineered a device called the Nozzle Measuring Stand (NMS) for generating local heat transfer coefficients (HTC) in spray cooling. The operational parameters encompass the water flow rate, air pressure, the spacing between nozzles, and the distance between the nozzle and the test sample. The experimental arrangement is divided into three zones (depicted in Fig. 2). Zone 1 features a cylindrical steel sample, an inductive heating unit, and a movable sample carrier controlled by linear axes. Zone 2 constitutes the “wet zone”, where spray nozzles are securely positioned to replicate the precise distance from the nozzle tip to the sample according to the dimension of the caster. These nozzles direct their spray upwards to measure HTC and downwards to quantify water distribution (WD). Lastly, Zone 3 accommodates the essential technical components, including the air and water supply, as well as the cooling mechanism for the induction device. [4, 5].

To enhance the understanding of the overlapping spray cone zone (Fig. 3), a configuration involving two nozzles with distinct water-air circuits has been implemented. This setup facilitates the creation of two separate and manageable water circuits for spray cooling.

The equipment installed and the sensors employed, within specified ranges and tolerances, are detailed in Table 1.

3.1 Local Spray Water Distribution

For assessing local water distribution (WD) in spray cooling, one or two nozzles are strategically positioned in an inverted manner at a defined distance from a patternator. This distance corresponds to the separation between the nozzle tip and the strand in the industrial setting (Nz). In situations involving two nozzles, the spacing between the nozzles must be adjusted accordingly (Nx). The patternator comprises 7 × 100 cells, each with a 10 mm x 10 mm inlet area. These cells collect the water, while the nozzles operate at specific flow rates, pressures, and distances. Following a predetermined period of time, the patternator is removed, and digital image processing software computes the WD, culminating in the so-called water impact density (WID) for the given nozzle parameters. The fundamental concept of this measurement method is illustrated in Fig. 4. This test setup provides the measurement of a local water impingement density [4, 5].

3.2 Local Heat Transfer Coefficient

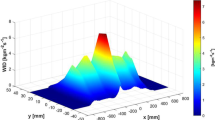

To conduct unsteady measurements of HTC, a test sample is exposed to controlled heating using an inductive heating unit, as illustrated in Fig. 3. The austenitic steel sample material’s temperature is restricted to 1200 °C. Three thermocouples are strategically positioned at varying distances from the surface to capture the internal temperature variations within the specimen. The linear motion unit moves the test sample across the spray cone. To calculate the HTC, an inverse heat conduction model called maximum a posteriori (MAP) is employed. The cylindrical sample body is thermally insulated, enabling the simplification of the heat conduction to a one-dimensional problem. Repeating such a measurement at different positions across the spray width leads to a 3-dimensional distribution of heat transfer coefficients for the specified spray parameters, which is shown exemplarily in Fig. 5. [4,5,6].

4 Implementation of NMS Measurements

The precision of numerical simulations relies on factors like grid size and boundary conditions. To achieve the highest possible resolution, the offline model m2Cast focuses on fine grid resolution. Ensuring localized HTC resolution and knowing the HTC values for nearly all positions corresponding to predetermined surface temperatures is crucial. Employing regression models emerges as a clear solution. Multiple regression models are explored for this purpose. The input characteristics comprise data triplets involving HTC, water impact density (WID), and surface temperature (Tsurf) from WID and HTC measurements across different positions. A single measurement can generate seven datasets according to the seven measuring grids used in the patternator. The basic allocation of these triplets, along with additional features such as initial temperature, nozzle distances, spray parameters, and more, is depicted in Fig. 6, starting with several measurements at different positions across the spray cone (a) and assembling measured WID and surface temperature Tsurf with calculated HTC values at the same position (b). Table 2 exemplifies the information and data behind the measurements. These supplementary features stem from specific test conditions. The dataset employed for constructing the models encompassed approximately 3000 records, while a set of 600 unknown data records was used to evaluate the regression models. The creation of the regression models was carried out using Matlab.

4.1 Exponential Gaussian Process Regression

Exponential Gaussian Process Regression (EGPR) is a variant of Gaussian Process Regression (GPR), a popular probabilistic approach for regression tasks. GPR models the relationship between input variables and output variables as a Gaussian process, which is a collection of random variables that have a joint Gaussian distribution. In GPR, the prediction of the output variable is made based on a mean function and a covariance function, which describes the correlation between input variables. The covariance function is modified to include an exponential term that captures the effect of the distance between input variables on their correlation. The exponential term is added to the standard squared exponential covariance function used in GPR. This modification allows the EGPR model to better capture long-range correlations between input variables, which may be missed by standard GPR. However, as with any machine learning technique, the performance of EGPR depends on the quality and quantity of data, the choice of hyperparameters, and the appropriateness of the model assumptions for the specific application. The result for the developed model between predicted and measured values is shown in Fig. 7. The root mean square error (RMSE) amounts to around 60 [Wm−2K−1] [7].

For a deeper understanding of the applicability of the regression model, a dataset, unknown for the model, with two different casting speeds were investigated. In Fig. 8a, the measured surface temperatures with the corresponding (calculated) HTC course are given. In Fig. 8b, there are the HTC values gained by the EPGR regression model embedded in the results of the testset (transparent grey).

According to the explanation in Section 4 (seven datapoints gained from one measurement), Fig. 8b shows seven marks for each casting speed. The root mean square error (RMSE) for these datapoints is under 35 [Wm−2K−1].

5 Simulation Results

Studying nozzles experimentally is essential for establishing precise boundary conditions in continuous casting machines. Nonetheless, gauging the complete water dispersion poses challenges, often leading to the practice of assessing a fraction of sprayed water and adjusting the dispersion accordingly. This approach can lead to notable disparities between computed and measured distributions, particularly in regions with overlapping sprays (Fig. 9). Thus, it becomes imperative to experimentally determine the actual spray water distribution.

In the software m2CAST, comparative computations underscore the significance of empirically determining the heat transfer coefficient (HTC), particularly in regions where sprays overlap. When the water impact is more intense, the surface temperature in Fig. 10b is lower than what the calculated water impact distribution (WID) suggests. These cold spots elevate the potential for crack formation, underscoring the importance of accurate HTC assessment.

m2Cast simulation for corresponding WID. (a calculated and (b) measured given in Fig. 10)

Another simulation result is given in Fig. 11. The underlying water distributions are shown in Fig. 11. In Fig. 11a, the ground condition for a conventional continuous casting machine close under the mold is given. This setting leads to a high maximum in the area of overlapping. By optimizing the nozzle to nozzle distance (Nx) from 190 mm up to 260 mm, the maximum of the WID can be minimized to about 15 kgm−2s−1.

The effects of this optimization were also investigated with our simulation software m2CAST. Figure 12a shows the position of the cutout, which is shown in detail on the right. Case (a) represents the general setting, and the optimization is shown in case (b). Due to the higher water impingement density in the overlap zone, the surface temperature in case (a) is significantly lower (dark area). Such low surface temperatures are avoided by optimizing the nozzle to nozzle spacing (Nx). The possibility of cracks is reduced.

6 Conclusion

The non-commercial casting development platform m2CAST is a powerful tool for the prediction of factors relevant for quality. With the help of the so-called Nozzle Measuring Stand the Chair of Steel Metallurgy at the Montanuniversität Leoben has the ability to measure and investigate the cooling conditions in the secondary cooling zone with a high local resolution. The implementation of these measurements as boundary conditions through regression models offers low errors in the prediction of required heat transfer coefficients for precise simulation results [1].

References

Bernhard, M., Santos, G., Preuler, L., Taferner, M., Wieser, G., Laschinger, J., Ilie, S., Bernhard, C.: A near-process 2D heat transfer model for continuous slab casting of steel. Steel Res. Int. 93, 12 (2022). https://doi.org/10.1002/srin.202200089

Bernhard, M., Presoly, P., Fuchs, N., Bernhard, C., Kang, Y.-B.: Experimental Study of High Temperature Phase Equilibria in the Iron-Rich Part of the Fe‑P and Fe-C‑P Systems. Metall. Mater. Trans. A 51, 5351–5364 (2020). https://doi.org/10.1007/s11661-020-05912-z

Presoly, P., Pierer, R., Bernhard, C.: Identification of Defect Prone Peritectic Steel Grades by Analyzing High-Temperature Phase Transformations. Metall. Mater. Trans. A 44(12), 5377–5388 (2013). https://doi.org/10.1007/s11661-013-1671-5

Preuler, L., Bernhard, C., Ilie, S., Six, J.: Experimental investigations on spray characteristics of water-air nozzles. Berg- Hüttenmännische Monatshefte 163(1), 29–36 (2017). https://doi.org/10.1007/s00501-017-0693-5

Arth, G., Taferner, M., Bernhard, C.: Experimental und numerical investigations on cooling efficiency in the secondary cooling zone during continuous casting of steel. 2nd ESTAD—European Steel Technology and Application Days. Steel Institute VDEh, Düsseldorf, Germany, pp. 1–7 (2015)

Rappaz, M., Drezet, J., Gandin, C., Jacot, A.: Application of inverse methods to the extimation of boundary conditions and properties. Modelling of Casting, Welding and Advanced Solidification Processes VII London, pp. 1–9 (1995)

Rasmussen, C.E., Christopher, K.I.: Williams, Gaussian Processes for Machine Learning (2005)

Funding

The authors gratefully acknowledge the funding support of K1-MET GmbH, metallurgical competence center. The research programme of the K1-MET competence center is supported by COMET (Competence Center for Excellent Technologies), the Austrian programme for competence centers. COMET is funded by the Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology, the Federal Ministry for Labour and Economy, the Federal States of Upper Austria, Tyrol and Styria as well as the Styrian Business Promotion Agency (SFG) and the Standortagentur Tyrol. Furthermore, Upper Austrian Research GmbH continuously supports K1-MET. Beside the public funding from COMET, this research project is partially financed by the scientific partner Montanuniversität Leoben and the industrial partner voestalpine Stahl GmbH.

Funding

Open access funding provided by Montanuniversität Leoben.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Taferner, M., Laschinger, J., Bernhard, C. et al. Effect of Nozzle Parameters on the Cooling Conditions in the Secondary Cooling Zone of a Slab Caster. Berg Huettenmaenn Monatsh 168, 536–542 (2023). https://doi.org/10.1007/s00501-023-01402-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-023-01402-y

Keywords

- Secondary cooling

- Water distribution

- Spray parameters

- Heat transfer coefficients

- Regression

- Continuous casting

- Numerical simulation