Abstract

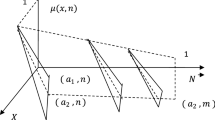

This paper focuses on a three-level distribution process in a supply chain (SC) modeling where the raw materials are received batchwise with imperfect quality. Defective batches are rejected instantly under “all or none” policy. Allowing partial backlogging and random disruption in supply, we develop an expected average cost function of the production inventory SC model first. Then, considering the several cost components of the model as linguistic triangular dense fuzzy lock set, the cost function itself has been fuzzified according to the needs of the problem defined at case study. Utilizing the proper application (growth) of key vectors, the objective function has been solved under crisp, general fuzzy, dense fuzzy, dense fuzzy lock of single and double keys environment, respectively. For managerial importance, numerical results and graphical illustrations are made to justify the novelty.

Similar content being viewed by others

References

Cabrerizo FJ, Al-Hmouz R, Morfeq A, Balamash AS, Martínez MA, Herrera-Viedma E (2017) Soft consensus measures in group decision making using unbalanced fuzzy linguistic information. Soft Comput 21(11):3037–3050

Cabrerizo FJ, Morente-Molinera JA, Pedrycz W, Taghavi A, Herrera-Viedma E (2018) Granulating linguistic information in decision making under consensus and consistency. Expert Syst Appl 99:83–92

Chakraborty D, Jana DK, Roy TK (2015) Multi-item integrated supply chain model for deteriorating items with stock dependent demand under fuzzy random and bifuzzy environments. Comput Ind Eng 88:166–180

Chang HC, Ho CH (2009) Exact closed-form solutions for optimal inventory model for items with imperfect quality and shortage backordering. Omega 38(3–4):233–237

Chiu YSP, Ting CK (2010) Determining the optimal run time for EPQ model with scrap, rework, and stochastic breakdowns. Eur J Oper Res 201(2):641–643

Chiu SW, Chou CL, Wu WK (2013) Optimizing replenishment policy in an EPQ-based inventory model with nonconforming items and breakdown. Econ Model 35:330–337

Das BC, Das B, Mondal SK (2015) An integrated production inventory model under interactive fuzzy credit period for deteriorating items with several markets. Appl Soft Comput 28:453–465

De SK (2017) Triangular dense fuzzy lock sets. Soft Comput 5:6–9. https://doi.org/10.1007/s00500-017-2726-0

De SK, Beg I (2016a) Triangular dense fuzzy sets and new defuzzification methods. Int J Intell Fuzzy Syst 31(1):469–477

De SK, Beg I (2016b) Triangular dense fuzzy neutrosophic sets. Neutrosophic Sets Syst 13:24–37

De SK, Mahata GC (2017) Decision of a fuzzy inventory with fuzzy backorder model under cloudy fuzzy demand rate. Int J Appl Comput Math 3(3):2593–2609

De SK, Mahata GC (2019) A comprehensive study of an economic order quantity Model under fuzzy monsoon demand. Sadhana. https://doi.org/10.1007/s12046-019-1059-3

De SK, Sana SS (2013a) Backlogging EOQ model for promotional effort and selling price sensitive demand—an intuitionistic fuzzy approach. Ann Oper Res 233(1):57–76

De SK, Sana SS (2013b) Fuzzy order quantity inventory model with fuzzy shortage quantity and fuzzy promotional index. Econ Model 31:351–358

De SK, Sana SS (2015) An EOQ model with backlogging. Int J Manag Sci Eng Manag. https://doi.org/10.1080/17509653.2014.995736

Ding J, Xu ZS, Zhao Z (2017) An interactive approach to probabilistic hesitant fuzzy multi-attribute group decision making with incomplete weight information. J Intell Fuzzy Syst 32:2523–2536

Dong Q, Zhou X, Martinez L (2019) A hybrid group decision making framework for achieving agreed solutions based on stable opinions. Inf Sci 490:227–243

Harris F (1913) How many parts to make at once factory. Mag Manag 10:135–136

Hsieh TP, Dye CY (2012) A note on the EPQ with partial backordering and phase-dependent backordering rate. Omega 40(1):131–133

Hu F, Lim CC, Lu Z (2014) Optimal production and procurement decisions in a supply chain with an option contract and partial backordering under uncertainties. Appl Math Comput 232(1):1225–1234

Karimi-Nasab M, Wee HM (2014) An inventory model with truncated exponential replenishment intervals and special sale offer. J Manuf Syst. https://doi.org/10.1016/j.jmsy.2014.09.003

Karmakar S, De SK, Goswami A (2015) A deteriorating EOQ model for natural idle time and imprecised demand: hesitant fuzzy approach. Int J Syst Sci Oper Logist. https://doi.org/10.1080/23302674.2015.1087070

Karmakar S, De SK, Goswami A (2017) A pollution sensitive dense fuzzy economic production quantity model with cycle time dependent production rate. J Clean Prod 154:139–150

Karmakar S, De SK, Goswami A (2018) A pollution sensitive re-manufacturing model with waste items: triangular dense fuzzy lock set approach. J Clean Prod 187:789–803

Kumar RS, Goswami A (2015a) A fuzzy random EPQ model for imperfect quality items with possibility and necessity constraints. Appl Soft Comput 34:838–850

Kumar RS, Goswami A (2015b) EPQ model with learning consideration, imperfect production and partial backlogging in fuzzy random environment. Int J Syst Sci 46:1486–1497

Li J, Wang S, Cheng TCE (2008) Analysis of postponement strategy by EPQ-based models with planned backorders. Omega 36:777–788

Mahata GC (2017) A production–inventory model with imperfect production process and partial backlogging under learning considerations in fuzzy random environments. J Intell Manuf 28(4):883–897

Mahata GC, Goswami A (2007) An EOQ model for deteriorating items under trade credit financing in the fuzzy sense. Prod Plan Control 18:681–692

Mahata GC, Goswami A (2013) Fuzzy inventory models for items with imperfect quality and shortage backordering under crisp and fuzzy decision variables. Comput Ind Eng 64:190–199

Mahata GC, Mahata P (2011) Analysis of a fuzzy economic order quantity model for deteriorating items under retailer partial trade credit financing in a supply chain. Math Comput Model 53:1621–1636

Mak KL (1987) Determining optimal production–inventory control policies for an inventory system with partial backlogging. Comput Oper Res 14(4):299–304

Montgomery DC, Bazaraa MS, Keswani AK (1973) Inventory models with a mixture of backorders and lost sales. Nav Res Logist Q 20(2):255–263

Morente-Molinera JA, Kou G, Pang C, Cabrerizo FJ, Herrera-Viedma E (2019) An automatic procedure to create fuzzy ontologies from users’ opinions using sentiment analysis procedures and multi-granular fuzzy linguistic modelling methods. Inf Sci 476:222–238

Parlar M, Berkin D (1991) Future supply uncertainty in EOQ models. Nav Res Logist 38:107–121

Paul SK, Sarker R, Essam D (2014) Managing disruption in an imperfect production–inventory system. Comput Ind Eng. https://doi.org/10.1016/j.cie.2014.09.013

Pentico DW, Drake MJ (2009) The deterministic EOQ with partial backordering: a new approach. Eur J Oper Res 194(1):102–113

Pentico DW, Drake MJ, Toews C (2011) The EPQ with partial backordering and phase-dependent backordering rate. Omega 39(5):574–577

Salehi H, Taleizadeh AA, Tavakkoli-Moghaddam R (2015) An EOQ model with random disruption and partial backordering. Int J Prod Res 54(9):1–10

San-José LA, Sicilia J, García-Laguna J (2009a) A general model for EOQ inventory systems with partial backlogging and linear shortage costs. Int J Syst Sci 40(1):59–71

San-José LA, García-Laguna J, Sicilia J (2009b) An economic order quantity model with partial backlogging under general backorder cost function. TOP 17:366–384

San-José LA, Sicilia J, García-Laguna J (2014) Optimal lot size for a production–inventory system with partial backlogging and mixture of dispatching policies. Int J Prod Econ 155:194–203

Shekarian E, Olugu EU, Abdul-Rashid SH, Kazemi N (2016) An economic order quantity model considering different holding costs for imperfect quality items subject to fuzziness and learning. J Intell Fuzzy Syst 30(5):2985–2997

Sicilia J, San-José LA, García-Laguna J (2012) An inventory model where backordered demand ratio is exponentially decreasing with the waiting time. Ann Oper Res 199:137–155

Skouri K, Konstantaras I, Lagodimos AG, Papachristos S (2014) An EOQ model with backorders and rejection of defective supply batches. Int J Prod Econ 155:148–154

Taft EW (1918) The most economical production lot. Iron Age 101:1410–1412

Taleizadeh AA, Pentico DW, Aryanezhad M, Ghoreyshi SM (2012) An economic order quantity model with partial backordering and a special sale price. Eur J Oper Res 221(3):571–583

Ureña R, Kou G, Dong Y, Chiclana F, Herrera-Viedma E (2019) A review on trust propagation and opinion dynamics in social networks and group decision making frameworks. Inf Sci 478:461–475

Wang H, Xu ZS (2016) Multi groups decision making using intuitionistic-valued hesitant fuzzy information. Int J Comput Intell Syst 9:468–482

Wee HM, Yu J, Chen MC (2007) Optimal inventory model for items with imperfect quality and shortage backordering. Omega 35:7–11

Wu J, Li X, Chiclana F, Rager RR (2015) An attitudinal trust recommendation mechanism to balance consensus and harmony in group decision making. IEEE Trans Fuzzy Syst. https://doi.org/10.1109/tfuzz.2019.2895564

Wu J, Sun Q, Fujita H, Chiclana F (2018) An attitudinal consensus degree to control feedback mechanism in group decision making with different adjustment cost. Knowl Based Syst 164:265–273

Wu J, Chang J, Cao Q, Liang C (2019) A trust propagation and collaborative fifiltering based method for incomplete information in social network group decision making with type-2 linguistic trust. Comput Ind Eng 127:853–864

Xu ZS, Zhou W (2016) Consensus building with a group of decision makers under the hesitant probabilistic fuzzy environment. Fuzzy Optim Decis Mak. https://doi.org/10.1007/s10700-016-9257-5

Zhang RQ (2009) A note on the deterministic EPQ with partial backordering. Omega 37(5):1036–1038

Zhang RQ, Kaku I, Xiao YY (2011) Deterministic EOQ with partial backordering and correlated demand caused by cross-selling. Eur J Oper Res 210(3):537–551

Acknowledgements

The authors are thankful to the anonymous reviewers for their valuable comments and suggestions to improve the quality and the presentation of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Communicated by V. Loia.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

De, S.K., Mahata, G.C. A production inventory supply chain model with partial backordering and disruption under triangular linguistic dense fuzzy lock set approach. Soft Comput 24, 5053–5069 (2020). https://doi.org/10.1007/s00500-019-04254-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-019-04254-2