Abstract

The paper presents a specific model used to assess and select the method of heavy metal leaching from waste materials. A recommendation for the rational selection of the leaching method was made, taking into account the crucial parameters affecting the leaching process derived from the authors' research experience. The assessment models were supplemented with characteristics relating to the cost and time required to perform the tests. An approach was developed that links the weights of the assessment criteria with the degree of environmental risk from a particular heavy metal and waste type. Using multiple-criteria decision analysis, four models were developed for the assessment and selection of a test method for the leaching of heavy metals from waste. The difference is in the way the weights of the assessment criteria depend on the potential threat of the waste to the environment. A key element of the proposed approach is assigning the weights of the criterion to the toxicity of the heavy metal, the type of waste, and their management method. The results obtained prove that the current practice of only employing the batch leaching test is inappropriate. The choice of method should be justified in terms of environmental safety as well as time- and cost-effectiveness. The results of the paper show that the proposed model can be used in practice and be a recommendation for choosing the method of leaching heavy metals from waste and their further treatment, following the principles of sustainable waste management.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the development of the economy, the volume of post-manufacturing waste is increasing. This involves the search for new ways to manage it. The priority in the activities of companies is now to apply the principles of circular economy. New technological solutions are constantly being sought to improve environmental protection while increasing the reuse of waste (Pawlita-Posmyk and Wzorek 2017). Unfortunately, it is not possible to utilize all waste economically. One reason for this is the degree of waste contamination and the threat of causing environmental pollution due to inadequate waste disposal. To improve environmental protection against the uncontrolled impact of waste, heavy metal leachability tests are performed. These tests are performed by all enterprises generating waste that may have a negative impact on the soil and water. Such an obligation follows directly from legislation. The discussion on selecting evaluation methods for heavy metal pollution in sediments is being taken up by various research communities (Böke and Arıman 2022; Shakil et. al. 2022). Environmental decisions usually involve multiple stakeholders with widely divergent goals. This is also the case with the selection of the test method for heavy metal leaching from waste. The development of a sustainable concept of waste management needs multi-criteria analysis to allow for the quality of the living environment and the socio-economic aspects at the same time.

In Poland, the document regulating how to perform leachability testing is the procedure introduced based on the standard EN 12457:2002, part 1–4 relating to the leaching of contaminants from granular waste materials and sludge. Meeting the relevant criteria for the leachability of contaminants is a prerequisite for allowing waste to be deposited in a landfill of a given type: inert waste, hazardous waste, and other than inert and hazardous waste. The basic indicators, deciding about the possibility of storing given waste types, are the permissible limits for the leaching of contaminants, including heavy metals. These indicators were introduced in the European Union by the Council Decision 2003/33/EC of 19 December 2002 establishing criteria and procedures for the acceptance of waste at landfills being the implementing document of the Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste (European Commission 2003). The EU Council left it up to the member states to decide on the choice of the test method and thus the application of appropriate leachability limit values. On this basis, criteria for landfilling of waste in Poland were established only at L/S = 10 dm3/kg (the so-called batch test) and L/S = 2 dm3/kg (auxiliary test). However, the auxiliary test is carried out in cases when the batch test cannot be performed. In the case of monolithic waste of large dimensions, the permissible leaching limits are determined according to the batch test after fragmenting the waste. The batch test is the least costly in economic terms. However, the results obtained in this test are incomplete and insufficient, as they do not allow determining the actual rate of heavy metal leaching, considering the influence of various external conditions and factors on the level of the release of contaminants. Based on the authors' previous studies (Bożym et al. 2021; Król and Mizerna 2015; Mizerna et al. 2017; Mizerna and Król 2018), it was found that even a small change in the conditions of the leaching process, such as a change in the pH of the leachant or the contact time of the material with the liquid, can cause the release of heavy metals into the aqueous phase at different levels. Therefore, efforts should be made to characterize the leachability of contaminants using a variety of comprehensive methods, as has been advocated since the 1990s (Hage and Mulder 2004). Previous studies (Bożym et al. 2021; Król and Mizerna 2015, 2016; Mizerna et al. 2017; Mizerna and Król 2018) and scientific reports on various materials, both construction and waste materials, show a variety of trends in the release of individual heavy metals, depending on changes in a given factor and the test method used (Engelsen et al. 2017; Loncnar et al. 2022; Sun et al. 2019; van der Sloot et al. 2018). Consequently, there are difficulties in unambiguous assessment of the leaching behavior of heavy metals. This creates a need to develop a tool for the rational selection of a method for testing the leachability of heavy metals from waste materials deposited in the environment.

Rationality in this case is understood as a combination, to the highest degree, of the requirements of the community, occupying the waste deposition areas (heaps, landfills), as well as the producers, who are obliged to dispose of the residues of their business activity. It is in the interest of the former to guarantee precise information about the risks of the landfill or the impact of waste. The producer, on the other hand, will aim at performing the cheapest tests. The redefined approach used in the model proposed here is a step toward eco-efficiency, which is described as economic and environmental efficiency achieved at the same time (Camarero et al. 2013). The objective of using different measurement methods as part of eco-efficiency approach is to provide decision-makers with indicators of the relationships between social, environmental, and economic goals (Czyżewski et al. 2020).

The application of an approach that simultaneously takes into account environmental and economic criteria requires MCDA. The key elements in solving this category of problems are the selection of criteria and the proper assignment of their weights. The authors discuss the adopted set of criteria and explain the concept of making the criterion weights dependent on the so-called “degree of hazard”, which links the toxicity of the identified metal and the type of waste (inert, hazardous, other than inert and hazardous) together with the method of its management (landfill, heap storage, non-agricultural land reclamation). The research question is concerned with how to represent the relevance of the criteria in the model, which will determine the choice of the test method used to assess the leachability of heavy metals.

The paper aims to develop a multi-criteria decision model for selecting the test method for leaching heavy metals from industrial waste, which would be rational in terms of environmental conditions of waste disposal and economic dimension.

2 Materials and methods

To achieve the purpose of the paper, it was proposed to use one of the most popular methods for solving multi-criteria decision-making (MCDM) issues, which is TOPSIS (Technique for Order Preference by Similarity to an Ideal Solution) (Hwang and Yoon 1981). TOPSIS takes into account a set of weights for the desired criteria, so the assessment depends on the weighting scheme that is given by the decision-maker. Thus, it allows criteria of different types to be related and allows the criterion weights to depend on the conditions under which the method is to be applied.

The basis for verifying the model assumptions was the authors’ own research on the leachability of heavy metals, such as Zn, Pb, Cu, Ni, Cd, and Cr from metallurgical slags and mineral-organic composite. The results were published in (Bożym et al. 2021; Król and Mizerna 2015; Mizerna et al. 2017; Mizerna and Król 2018).

2.1 Defining the problem and identifying alternatives

In order to develop a model for selecting a method to test the leaching of heavy metals from waste, the factors affecting that were carefully analyzed. The main factors affecting the leaching rate of heavy metals include the pH of the surrounding environment, the liquid to solid ratio (L/S), and the duration of the leaching process (the time the material is in contact with the leachant, such as rainwater) (Astrup et al. 2006; Saveyn et al. 2014; Sun et al. 2019; van der Sloot and Kosson 2010). Therefore, based on a review of the literature and authors’ previous research (Bożym et al. 2021; Król and Mizerna 2015; Mizerna et al. 2017; Mizerna and Król 2018) these parameters were identified and considered decisive in selecting the test method for the leaching of heavy metals from waste. They were introduced into the model as stimulant criteria, whose higher values mean greater benefits understood as the effectiveness of the method in detecting heavy metal content in aqueous extracts. Contacts with entrepreneurs proved that the cost and time of the test implementation are the most important factors for them when choosing a test method. In the developed model, they are destimulant criteria, since the higher their value, the worse such an option is from the waste producer's point of view.

The selection of methods for heavy metal leaching from waste was carried out among eight alternatives. These are represented by five different leaching tests used in Europe and three authors' modifications of the selected methods. Table 1 characterizes the main parameters of the leachability test methods used by the authors so far to evaluate heavy metal release from various waste materials. Descriptions of the procedures are presented based on the guidelines in the European standards (EN).

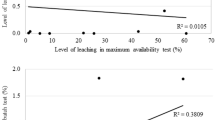

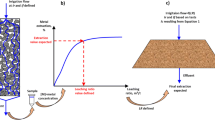

The batch test is used for the basic assessment of the leaching behavior of heavy metals released from granulated waste materials. The procedure was performed according to the standard EN 12457-2:2002. In order to determine the effect of pH changes on leachability, an own modification of the method was additionally used to decrease and increase the pH of the leaching liquid (Table 1). The evaluation of heavy metal leaching under percolation conditions was carried out using a column test according to EN 14405:2017. The column test was chosen because the waste may contain unstable substances that decompose due to exposure to weather conditions, causing the release of additional pollutants. This type of test simulates real conditions of contaminant leaching in the aeration zone of landfills. The percolation method made it possible to observe the effect of changing the liquid/solid (L/S) ratio on the resulting concentrations of individual elements. Another method used in the study on granular materials is the pHstat leaching test, which assesses the effect of a wide range of pH on the release of heavy metals. With this method, it is possible to observe the material's response to preset changes in pH and the acid or base reactions that occur (buffer capacity) during a variety of environmental scenarios (carbonization, infiltration, oxidation) (Tiwari et al. 2015; van der Sloot and Kosson 2010). The analysis of the leaching process in fine-grained waste materials under extreme conditions in an aerobic environment, reflecting the conditions in a landfill for example, after the decomposition of the material or in the case of loss of acid neutralizing capacity, was possible through the use of a maximum availability leaching test EA NEN 7371:2004. A leaching test in a tank test was also conducted for monolithic waste, based on the procedure in EA NEN 7374:2004. The purpose of the test was to simulate the leaching of heavy metals from materials as a function of time. Also in this case, a modification of the pH of the leachant was used to observe changes in the leaching level of heavy metals under the influence of a reduced liquid reaction (pH 4).

Explanation of the values in Table 1:

The effect of pH: 1—test is carried out with neutral reaction water with no change in pH; 2—there is a change in the pH of the leachant (decrease to pH 4 or increase to pH 12), which may result in a change in the rate of metal leaching; 3—the test is carried out first with a neutral reaction leachant, and then in the second stage, it is conducted at a reduced pH; 8—the test is carried out with neutral reaction water, the effect of pH solution on leachability is observed 8 times; 15—the test is conducted with a neutral reaction leachant and for seven environments with reduced or increased pH (leachant pH ranging from 3 to 12); 16—the test is conducted at reduced pH of leachant, with 8 leachates obtained for analysis.

Influence of L/S ratio: 1—test materials are subjected to leaching at a constant L/S ratio ≤ 10 dm3/kg throughout the procedure; there is no change in the value of the L/S ratio; 2—the effect of the L/S ratio on the leachability of metals in the long-term leaching process in the environment is analyzed (L/S > 10 dm3/kg); 7—the effect of the L/S ratio (L/S ≤ 10 dm3/kg) on the resulting heavy metal concentrations is analyzed seven times; 8—the effect of the L/S ratio (L/S ≤ 10 dm3/kg) on the resulting heavy metal concentrations is analyzed eight times.

It was recognized that cost is an important parameter for entrepreneurs, who are obliged to properly manage the post-production waste, and thus classify it in terms of the potential hazard it may pose to the environment. When estimating the cost of performing a given leachability test of a single sample and analysis for a single element, the following component costs were taken into account: the cost associated with preparing the sample for testing, conducting preliminary tests, preparing leachates for analysis, the cost of reagents and materials, water, wastewater, and the cost of laboratory equipment use. It was also based on the market price for performing the analysis of one element in one sample prepared by batch test.

The duration of the leaching process represents the period the materials were subjected to leaching, expressed in the number of days. For the column test, the duration varies depending on the physical and chemical properties of the test materials. Therefore, in the following analysis, one of three values was adopted depending on the type of waste (see Sect. 2.3).

2.2 Construction of a decision-making matrix in accordance with TOPSIS

TOPSIS is used in many decision problems, like in management (Shamsuzzoha et al. 2021; Wielki et al. 2019) or environmental issues (Li et al. 2021) because it is one of the most effective methods for ranking alternatives (Sałabun et al. 2020). The basic concept of TOPSIS method is that the selected alternative should have the shortest distance from the ideal solution and the farthest distance from the negative-ideal solution in a geometrical sense (Triantaphyllou 2000). TOPSIS takes into account a set of weights for the desired criteria so the assessment depends on the weighting scheme that is given by the decision-maker.

The TOPSIS method in the developed model evaluates the following decision matrix which refers to 8 alternatives (in columns) which are evaluated in terms of 4 criteria (in rows), where rij denotes the performance measure of the j-th method of the leaching of heavy metals from waste in terms of the i-th criterion. For example, r3,5 is the value of L/S for the tank test method.

2.3 Determining the significance of criteria and normalization of values

Generally, multi-criteria decision problems of this sort call for evaluating alternatives with respect to each criterion involved, the criteria being weighted by a vector that expresses the relative importance among them (Wang et al. 2009). The essence of the developed model is that it should be universal, i.e., it should be possible to indicate the recommended method of performing leachability tests for each heavy metal and waste management method. When considering the willingness to compromise between environmental and economic criteria, it depends on risk factors. The higher the risk of serious environmental contamination, the higher the importance of criteria related to the effectiveness of testing the rate of heavy metal leaching, and the lower the importance of the criteria related to the cost and time of conducting the test. This dependence was taken into account by introducing a parameter in the multi-criteria evaluation model called the degree of risk, which links three elements: the method of waste management (1), the type of waste (2), and the toxicity of the metal (3).

Waste materials from various industries differ in their physical and chemical composition and consequently differ in their content and mobility of toxic elements. Therefore, due to the authors' research experience in the leachability of heavy metals from waste such as inert and hazardous metallurgical slags, stabilized hazardous waste in mineral matrices, as well as mineral-organic composites (Bożym et al. 2021; Król and Mizerna 2015; Mizerna et al. 2017; Mizerna and Król 2018), the model for the rational choice of the leaching method focused on three different types of waste (ways of classification) (Regulation 2015) and three selected viable scenarios of their management (Table 2). Six heavy metals were analyzed: copper (Cu), zinc (Zn), lead (Pb), cadmium (Cd), nickel (Ni), and chromium (Cr). Heavy metals are characterized by varying toxicity, understood as the metal's harmfulness to human and animal health and life, as well as harm to plant growth and development. In the literature (Monged et al. 2020; Radomirović et al. 2020; Orupõld et al. 2022) the following toxicity coefficient values are given for individual metals: Zn: 1; Cr: 2; Ni, Pb, Cu: 5; Cd: 30, with 1 being the least toxic and 30 being the most toxic. These values were adopted in the analysis, while the association of waste type and waste management is represented by the product of the values in the interval [0,1]. In the computational experiment carried out, the values of the elements that make up the degrees of hazard were adopted as shown in Table 2.

The value (wk) of 0.4 for inert waste indicates that such waste does not pose a major threat to the surrounding environment and human health and life. The value (wk) of 0.75 for other than inert and hazardous waste was adopted because these types of waste have higher levels of contaminant leaching than inert waste, hence their impact on the environment may be significant. The highest value for the type of waste, equal to 1.0, was assigned to hazardous waste. This waste has a high content of mobile forms of toxic elements. It is problematic for industrial reuse and potentially the greatest threat to the environment.

The assigning of the value we = 0.4 to the landfilling of hazardous waste results from the fact that landfilling is carried out in a properly prepared, secured, and monitored landfill. Therefore, this method of waste disposal should not potentially pose a threat to the environment. However, it should be kept in mind that, in the event of uncontrolled point emissions, pollution may occur. The value we = 0.75 was assumed for heap storage, as this method of management may involve the blowing away of material particles over long distances. The leaching of waste components into the soil and water environment may also occur. The method of management for reclamation purposes was assigned the highest value we = 1.0, since waste going into the soil is most exposed to a number of soil factors and processes that can contribute to the mobility of heavy metals.

The introduction of a parameter such as the degree of hazard into the multi-criteria evaluation model reflects a pragmatic point of view, in which the higher the degree of hazard, the lower the acceptance of ecological risk. Then, the criteria determining the effectiveness of the method (environmentally-wise) become more important, while the importance of economic criteria decreases. For the waste producer, a high degree of hazard also justifies incurring higher expenses for tests that give a picture of the level of metal leaching from waste. In contrast, with a low degree of hazard, the producer's acceptance of incurring economic expenditures decreases. In other words, entrepreneurs can accept higher testing costs if the degree of hazard is high.

The values of the hazard degree parameter were made conditional on the parameters in Table 2 according to Eq. (1).

where:d(m,w) —the degree of hazard of a given metal with a specific method of waste management,wk—type of waste,we—waste management,tm—metal toxicity.

The maximum value of the hazard degree parameter will be 1, while the minimum value in the conducted research according to the data in Table 2 is 0.17. For example, for non-hazardous waste that can be used for land reclamation, the hazard degree is 0.79.

The weights of the criteria depend on the degree of hazard parameter described by correlation 3.

where:wi—weight of i-th criterion.

For example, for d(Pb,KMO) the pH and L/S criteria will assume the weight of 0.395 \(\left( {\frac{0.79}{2}} \right)\), and the cost and time criteria will take the weight of 0.105 \(\left( {\frac{1 - 0.79}{2}} \right)\).

The values describing the different alternatives for conducting the tests are of different types, so they must be normalized in order to perform the calculations.

In general, data normalization and data standardization mean mapping the data values to a common scale, usually within the unity interval [0, 1]. Among many normalization techniques (Vafaei et al. 2018) vector normalization was chosen, which is symmetric and computationally efficient (Jahan & Edwards 2015), where normalization takes the following form:

where:nij is the normalized value of rij,rij is the rating of alternative j with respect to the criterion i.

2.4 Calculation in the proposed model

This paper proposes a multi-criteria decision model for the selection of suitable alternatives among methods for the leaching of heavy metal from waste. In the previous sections, the criteria and alternatives for the computational experiment were defined. To illustrate the application of the model, its implementation is presented in the problem of selecting a method for testing six metals against three different methods of waste management. The calculations were carried out in a specially prepared application in MS Excel, in which the user makes a selection from a list of the following input data: the name of the metal, the type of waste and the waste management method (as given in Table 3). The focus was on calculations for selected waste management scenarios consistent with the methods of recovery and disposal indicated in the Act on Waste of 14 December 2012 (Act 2022). Example calculations will be presented for lead Pb with toxicity factor tm = 5 in hazardous waste (H) stored in a hazardous waste landfill (L). Table 3 shows the input data for the calculations and the calculated criterion weights according to Eq. 3.

Table 4 shows the values normalized according to Eqs. 4 and 5 with the weighting values determined according to Eq. 6.

where:vi,j—weighted value of ni,j,wi—weight of criterion i.

In addition, Table 4 introduces positive ideal solution (PIS) and negative ideal solution (NIS) values, which are defined in terms of the weighted normalized values according to Eqs. 7 and 8.

The positive ideal solution (PIS) is defined as the sum of all the best values that can be achieved for each attribute, while the negative-ideal solution (NIS) consists of all the worst values achieved for each attribute.

The next step is to calculate the distance (DPIS) measures for each solution. The distance of each solution from the positive ideal alternative PIS is:

Similarly, the distance (DNIS) of each solution from the negative ideal alternative (NIS) is:

The last step of the model is to calculate the similarity of each alternative to the worst alternative according to the Eq. 11 i.e. relative closeness coefficients.

Table 5 presents the separation of each alternative from the positive ideal solution \(D_{j}^{PIS}\), the separation of each alternative from the negative ideal solution \(D_{j}^{NIS}\) and the relative closeness for each alternative with respect to the positive ideal solution \(R_{j}\).

A set of alternatives now can be ranked by the descending order of relative closeness coefficients given in Table 5. In the analyzed case, the authors should recommend the maximum availability content test for studying the leachability of heavy metals from hazardous waste stored in a landfill.

3 Results and discussion

This Section presents the study results of four models for selecting the method for the leaching of heavy metals from waste. They show the values of Rj (the relative closeness of each alternative with respect to the positive ideal solution), the highest of which indicates a recommendation for the use of a particular method of heavy metal leaching from waste in the situation indicated in the description of rows (type of metal and method of waste management). The differences between the studied models are summarized in Table 6.

3.1 Results of evaluating the methods for the leaching of heavy metals from waste according to Model 1

Correlating the weights of the criteria with the degree of risk, different recommendations of methods for the leaching of heavy metals from waste were obtained, as shown in Table 7. Cells with maximum values of the Rj parameter, indicating a recommendation for a particular method, are bold.

Model 1 shows the recommendation for the maximum availability leaching test although similar results were also obtained for the modified pH 12 batch test. In several cases, Rj values equal to zero were obtained for the batch test. Such a situation occurred for Cd in 3 scenarios, as the highest hazard level of 1.00 was obtained here. According to the model assumptions, “cost of test” and “leaching time” are not relevant in such cases and the weights of these criteria take the value of 0. Then the method that has the lowest possible values for the criteria “effect of pH” and “effect of L/S” becomes the negative ideal solution (NIS). The tank test and the modified tank test for all O/R scenarios were not included in the calculations. In such a leaching procedure, monolithic/integrated waste in the form of a lump/chunk is required for testing. Hence, the tank test is not recommended by the authors for testing the leachability of heavy metals from waste used for reclamation. If monolithic waste was used, land reclamation would be difficult and inappropriate, and any fragmentation of such waste would be uneconomic. Therefore, such a scenario applies only to fragmented waste.

Heavy metals react strongly to changes in the pH of the environment, so the purpose of creating such a model was to show changes in the choice of the leaching method when the pH factor has a greater influence on leaching.

3.2 Results of evaluating the methods for the leaching of heavy metals from waste according to Model 2

In Model 2, whose results are shown in Table 8, the pHstat leaching test achieved the highest Rj value for all elements in the O/R scenario and for Cd, Pb, Ni and Cu for the H/L scenario. In most other cases, the recommended method is the batch test with the modification of the leachant to pH 4 or 12.

The recommendations of Model 2 are very similar to Model 1. The main difference is that in Model 2 the pHstat test is recommended not only for the scenario in which the waste is used for reclamation purposes I but also for final landfilling (L). For the other scenarios, in addition to the maximum availability test, modified batch tests pH 4 and pH 12 are indicated with the same values of Rj. In both Model 1 and Model 2, the modified tank test was recommended twice for the metal with the highest toxicity.

3.3 Results of evaluating the methods for the leaching of heavy metals from waste according to Model 3

Model 3 (Table 9) shows that when the criterion weights are independent of the degree of hazard posed by the given elements and the waste type and its management, considerable differences in the Rj results in comparison to the previous two models can be seen.

The differences between the Rj values have decreased. The highest recommendation values for the H/L and I/S scenarios were obtained by the modified tank test (with the leachant pH of 4), and the lowest, for all the scenarios, were obtained by the column test, although it should be noted that the difference between them is about 40%. For other than inert and hazardous waste used for reclamation (O/R), the pHstat leaching test would be recommended.

The results of Model 3 show that it does not seem right to use a model in which the weights of the criteria do not depend on the degree of hazard posed by the elements and the various types of waste.

3.4 Results of evaluating the methods for the leaching of heavy metals from waste according to Model 4

In the last of the models considered, it was decided to make the criterion weights dependent on the degree of hazard, tying it exclusively to the method of waste management and not to metal toxicity. The results of the evaluation of metal leaching methods in this model are presented in Table 10.

Guided by the values of the relative closeness (Rj), in Model 4, the use of the batch test for I/S scenarios, the maximum availability test for H/L scenarios and the pHstat for O/R scenarios can be recommended. By not considering the toxicity of the metal in Model 4, the environmental aspects of the choice of leaching method cease to matter, and only the cost- and time-consuming nature of the methods become relevant. The authors of the article believe that adopting such a model is not acceptable from the point of view of protecting the soil and water environment.

To summarize the previous considerations, the batch test is relatively easy to perform, low in labor and requiring the least expense. However, it does not provide an opportunity to observe the leaching process under the influence of changes in various factors, such as pH and L/S ratio. On the other hand, by using only a slight modification involving passing acidic or alkaline liquid through waste samples, the method still requires little investment in economic terms and already offers the possibility of changing the processes involved in the leaching of heavy metals. With the maximum availability leaching test, we can observe the influence of a wide range of factors on the level of heavy metal leaching. However, the method is labor-intensive in the case of a non-automated test stand. The advantage, on the other hand, is that the test is short and relatively inexpensive. It also provides an opportunity to determine the maximum available leaching concentrations from a given type of waste. It is worth noting that the column test was not chosen in any of the models presented in the article. In addition to being time-consuming, this test is also labor-intensive. It only provides an opportunity to observe changes in heavy metal concentrations over a wide L/S range and allows the comparison of results with other methods for the same L/S ratio. The pHstat leaching test requires predetermining the concentration and volume of the acid or base to be added in order to obtain a specific pH of the liquid in which the waste is leached. It is also a time-consuming test. In contrast, it provides opportunities to assess the leachability over a wide range of pH and to identify potential processes that control leaching.

The tank test is an easy test to perform but the whole process is long. Moreover, this test can only be performed for monolithic/integrated waste. On the other hand, it provides opportunities to estimate leaching mechanisms. Based on the presented limitations and advantages of the analyzed leachability tests, it can be seen that the model that should be used for the choice of the rational leaching method is Model 1, in which the weights of stimulants and destimulants depend on the degree of hazard, taking into account the toxicity of the element as well as the waste management method.

4 Conclusion

When considering the issue of selecting an appropriate method for the leaching of heavy metals from waste, the relationship between the waste producer and the environment in which the waste will be deposited comes to the forefront. In order to rationally recommend an adequate test method, for example, for legislation or regulations, it is necessary to evaluate them from both perspectives. Making such an assumption in this article, the authors proposed using an approach based on multi-criteria evaluation. The developed evaluation models are based on TOPSIS, which allows capturing differences in method evaluation by relating it to the distance between the potentially best and worst solution. The results show that in terms of environmental and economic aspects it is not appropriate to recommend only the batch test according to EN 12457:2002, as is currently the case in Poland. Four different models were proposed based on the evaluation criteria indicated in the literature as the most relevant for environmental and economic reasons. The difference between the models lies in the way the weights for these criteria are selected.

The research presented in the article on models for the multi-criteria evaluation of methods for the leaching of heavy metals from waste shows that even with a low degree of hazard, as is the case with zinc or nickel in waste stored on a heap, it is worth using at least a modified batch test (changing the pH of the leachant) to influence the degree of metal leaching from the waste. Introducing the parameter of the degree of hazard, the results of the evaluation of test methods for a given type of waste and metal differ significantly from each other, contrary to the case when the weights are fixed. By making the weights of the criteria dependent on the parameter of hazard degree, the clearest recommendations were obtained. The differences in cost and time between the available methods lose their importance with increasing environmental risk. This is already indicated by a preliminary qualitative analysis of the problem of selecting a method for the leaching of heavy metals from waste. Heavy metal toxicity coefficients are widely used in the literature, so the authors advocate taking this parameter into account for describing the degree of hazard. This is in line with the direction of Eco-efficiency and should not raise objections from waste producers. Doubts could arise, however, if twice as much weight should be given to the pH criterion as to L/S. For this reason, the authors recommend Model 1, in which environmental and economic criteria are given weight depending on the degree of hazard taking into account toxicity, while the environmental and cost criteria are given equal weight. To evaluate the leachability of heavy metals from waste materials, in Model 1 the authors recommend using the maximum availability leaching test or the pHstat leaching test, depending on the degree of hazard the waste poses to the environment and the way it is managed. Evaluating the leachability of heavy metals using these two methods makes it possible to take into account changes in environmental factors affecting the level of contaminant release. This is important in order to correctly classify the waste in terms of the hazard it may pose to the environment (inert, hazardous, or other than inert and hazardous waste), and then select an appropriate waste management method. The new approach presented by the authors, which goes beyond the use of only legally sanctioned leaching methods, allows a broader analysis of the issue of heavy metals’ impact on the environment.

References

Act on Waste of 14 December 2012 (2012) Poland’s Journal of Laws dated March 29, 2022, item 699, 2022

Astrup T, Mosbæk H, Christensen TH (2006) Assessment of long-term leaching from waste incineration air-pollution-control residues. Waste Manag 26(8):803–814. https://doi.org/10.1016/J.WASMAN.2005.12.008

Böke Özkoç H, Arıman S (2022) Contamination and risk assessment of heavy metals in coastal sediments from the Mid-Black Sea, Turkey. Stoch Environ Res Risk Assess 37(1):375–394. https://doi.org/10.1007/s00477-022-02300-4

Bożym M, Król A, Mizerna K (2021) Leachate and contact test with Lepidium sativum L. to assess the phytotoxicity of waste. Int J Environ Sci Technol 18:1975–1990. https://doi.org/10.1007/s13762-020-02980-x

Camarero M, Castillo J, Picazo-Tadeo AJ, Tamarit C (2013) Eco-efficiency and convergence in OECD countries. Environ Resour Econ 55(1):87–106. https://doi.org/10.1007/S10640-012-9616-9/TABLES/6

Czyżewski B, Smędzik-Ambroży K, Mrówczyńska-Kamińska A (2020) Impact of environmental policy on eco-efficiency in country districts in Poland: How does the decreasing return to scale change perspectives? Environ Impact Assess Rev 84:106431. https://doi.org/10.1016/J.EIAR.2020.106431

Engelsen CJ, van der Sloot HA, Petkovic G (2017) Long-term leaching from recycled concrete aggregates applied as sub-base material in road construction. Sci Total Environ 587–588:94–101. https://doi.org/10.1016/J.SCITOTENV.2017.02.052

Hage JLT, Mulder E (2004) Preliminary assessment of three new European leaching tests. Waste Manag 24(2):165–172. https://doi.org/10.1016/S0956-053X(03)00129-6

Hwang CL, Yoon K (1981) Multiple attribute decision making. vol 186, Springer, Berlin Heidelberg. https://doi.org/10.1007/978-3-642-48318-9

Jahan A, Edwards KL (2015) A state-of-the-art survey on the influence of normalization techniques in ranking: improving the materials selection process in engineering design. Mater Des 65:335–342. https://doi.org/10.1016/J.MATDES.2014.09.022

Król A, Mizerna K (2015) The effect of particle size reduction of waste material on heavy metals release. Chemik 69(10):670–673

Król A, Mizerna K (2016) Directions of development of research methods in the assessment of leaching of heavy metals from mineral waste. E3S Web Conf 10:00050. https://doi.org/10.1051/e3sconf/20161000050

Li J, Xu K, Ge J, Fan B (2021) Development of a quantitative risk assessment method for a biomass gasification unit by combining DEMATEL-ISM and CM-TOPSIS. Stoch Environ Res Risk Assess 36(7):1975–1991. https://doi.org/10.1007/s00477-021-02084-z

Loncnar M, Mladenovič A, Zalar Serjun V, Zupančič M, van der Sloot HA (2022) Leaching and geochemical modelling of an electric arc furnace (EAF) and ladle slag heap. Toxics 10(1):10. https://doi.org/10.3390/toxics10010010

Mizerna K, Król A (2018) Leaching of heavy metals from monolithic waste. Environ Prot Eng 44(4):143–158. https://doi.org/10.5277/epel80410

Mizerna K, Król A, Mróz A (2017) Environmental assessment of applicability of mineral-organic composite for landfill area rehabilitation. E3S Web Conf 19:02020. https://doi.org/10.1051/e3sconf/20171902020

Monged MHE, Hassan HB, El-Sayed SA (2020) Spatial distribution and ecological risk assessment of natural radionuclides and trace elements in agricultural soil of Northeastern Nile valley Egypt. Water Air Soil Pollut 231(7):1–24. https://doi.org/10.1007/S11270-020-04678-9/FIGURES/10

Orupõld K, Somani M, Kaczala F, Hogland M, Bhatnagar A, Hogland W, Saaremäe E, Kriipsalu M (2022) Ecotoxicity assessment of fine fractions obtained from landfill mining. J Hazard Toxic Radioact Waste 26(4):04022030. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000715

Pawlita-Posmyk M, Wzorek M (2017) Assessment of application of selected waste for production of biogas. E3S Web Conf 19:02017. https://doi.org/10.1051/E3SCONF/20171902017

Radomirović M, Ćirović Ž, Maksin D, Bakić T, Lukić J, Stanković S, Onjia A (2020) Ecological risk assessment of heavy metals in the soil at a former painting industry facility. Front Environ Sci 8:560415. https://doi.org/10.3389/FENVS.2020.560415/FULL

Sałabun W, Watróbski J, Shekhovtsov A (2020) Are MCDA methods benchmarkable? A comparative study of TOPSIS, VIKOR, COPRAS, and PROMETHEE II methods. Symmetry 12(9):1549. https://doi.org/10.3390/SYM12091549

Saveyn H, Eder P, Garbarino E, Muchova L, Hjelmar O, van Der SH, Comans R, Van ZA, Hyks J, Oberender A (2014) Study on methodological aspects regarding limit values for pollutants in aggregates in the context of the possible development of end-of-waste criteria under the EU waste framework directive: final report. Publ off. https://doi.org/10.2791/1125

Shakil S, Nawaz K, Sadef Y (2022) Evaluation and environmental risk assessment of heavy metals in the soil released from e-waste management activities in Lahore Pakistan. Environ Monit Assess. https://doi.org/10.1007/s10661-022-10701-9

Shamsuzzoha A, Piya S, Shamsuzzaman M (2021) Application of fuzzy TOPSIS framework for selecting complex project in a case company. J Glob Oper Strateg 14(3):528–566. https://doi.org/10.1108/JGOSS-07-2020-0040/FULL/PDF

Sun Z, Vollpracht A, van der Sloot HA (2019) pH dependent leaching characterization of major and trace elements from fly ash and metakaolin geopolymers. Cem Concr Res 125:105889. https://doi.org/10.1016/J.CEMCONRES.2019.105889

Tiwari MK, Bajpai S, Dewangan UK, Tamrakar RK (2015) Suitability of leaching test methods for fly ash and slag: a review. J Radiat Res Appl Sci 8(4):523–537. https://doi.org/10.1016/J.JRRAS.2015.06.003

Triantaphyllou E (2000) Multi-criteria decision making methods: a comparative study. Kluwer Academic Publishers

van der Sloot HA, Kosson DS (2010) Leaching assessment methodologies for disposal and use of bauxite residues. https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.738.5347&rep=rep1&type=pdf. Accessed Apr 2023

van der Sloot HA, Kosson DS, van Zomeren A (2018) Landfilling of different kinds of waste: leaching behavior. Solid Waste Landfill. https://doi.org/10.1016/B978-0-12-407721-8.00052-8

Vafaei N, Ribeiro RA, Camarinha-Matos LM (2018) Data normalisation techniques in decision making: case study with TOPSIS method. Int J Inf Decis Sci 10(1):19–38. https://doi.org/10.1504/IJIDS.2018.090667

Wang JJ, Jing YY, Zhang CF, Zhao JH (2009) Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew Sustain Energy Rev 13(9):2263–2278. https://doi.org/10.1016/J.RSER.2009.06.021

Wielki J, Jurczyk-Bunkowska M, Madera D (2019) Application of TOPSIS Method for Evaluation of IT Application in the Hospital. In: Proceedings of the European Conference on Knowledge Management, ECKM, pp 1096–1104

Acknowledgements

The authors are grateful to the Opole University of Technology for the financial support toward this work.

Funding

The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

The experimental data were prepared by KM. The first draft of the manuscript was written by MJ-B and KM. The methodology was developed by AK and MJ-B. AK also analyzed the results and reviewed the manuscript. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Król, A., Jurczyk-Bunkowska, M. & Mizerna, K. Evaluation and selection of a rational test method for heavy metal leaching in terms of environmental and economic factors. Stoch Environ Res Risk Assess 37, 4323–4336 (2023). https://doi.org/10.1007/s00477-023-02510-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00477-023-02510-4